Escolar Documentos

Profissional Documentos

Cultura Documentos

8.IWCF Worked Questions and Answers PDF

Enviado por

ElrohirPendragonTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

8.IWCF Worked Questions and Answers PDF

Enviado por

ElrohirPendragonDireitos autorais:

Formatos disponíveis

International Well Control Forum

Worked Questions and Answers

A Learning Document for prospective Candidates

For the Rotary Drilling Well Control Test Programme

Copyright, IWCF June 2000

Revision No.1, November 2000

© IWCF 2000 page 1 of 10

International Well Control Forum

Candidates sitting the IWCF written test papers for the first time are often rather anxious about the

structure of the test.

They will frequently ask:

• Are there any trick questions?

• How does the IWCF compose questions?

• Is there more than one answer and so on?

It is not easy to give straightforward answers to these questions. It is for this reason that this publication

has been prepared. It aims to assist the candidate by providing a collection of various questions and fully

worked-out answers.

IMPORTANT POINTS

.

• Read questions first, don't rush or skip words. Then read the question once again, highlighting with

a transparent marker (or underline with your pen) important words or phrases.

• If a question has multiple-choice answers you can note your correct answers first (in the right

margin) and then review the remaining answers before you finally make your selection in the check

boxes. Alternatively, you can strike out the incorrect answers first and then review the remaining

answers before you finally make your selection in the check boxes. Both methods are perfectly

valid.

• Some questions require more than one answer – the candidate must select the requested number of

answers. If a candidate does not select the requested number of answers – the answers that have

been selected will be ignored and the candidate will not receive any points for the question.

• Check your test paper one final time before handing it to the Invigilator.

The following pages contain some examples with detailed analysis.

© IWCF 2000 page 2 of 10

International Well Control Forum

Example Question 1

It is planned to perform a leak-off test. Which of the following actions have to be performed before the

test is conducted?

(TWO ANSWERS)

4 A. Circulate the mud to obtain a uniform weight and condition.

q

q B. Drill 3 ft (1 m) out of the casing shoe and test the BOP-stack against exposed formation

and cement.

q C. Spot a viscous LCM pill on bottom.

q

4 D. Drill 6 - 15 ft (2 - 5 m) of new formation.

q E. Run a calliper through casing and open hole.

Comments:

Each set of answers has a few distracters. These might be legitimate answers but in the wrong context or

they might be inappropriate answers altogether.

In this question we find the following important words. A candidate could highlight these as follows: -

'plan' It is planned to perform the test, the test has not yet been performed.

'actions' The first indication that more than one answer is required.

'before' Once again stressing that these are activities that happen prior to, not during,

the test.

‘two correct answers’ Below the question and in bold style the number of answers required is stated.

The above suggestions might seem insignificant, but candidates are literally distracted by answers and fail to

remember the intent of the question. Highlighting critical words not only improves the focus, it also shortens

the time to answer the question.

Detailed Analysis:

Answers ‘A’ and ‘D’ are correct. They are key activities preceding all leak-off tests performed in

accordance with good practice.

Answer ‘B’ is incorrect. Drilling a mere 3 ft (1 m) out of the casing shoe is usually not sufficient to get into

new formation. Testing the BOP stack against the exposed formation is totally out of bounds.

Nevertheless, it is important to properly read the answer before discounting any inappropriate activity.

Answer ‘C’ is incorrect. Spotting a viscous LCM pill might have an operational purpose, but it is not the

standard action to take before a leak-off test. Use the common sense approach and don't be led by

activities, which could be taken, instead of those which need to be taken.

Answer ‘E’ is incorrect. The volume of drilling fluid is fairly accurately known when the casing has just

been set and cemented. It also does not serve any immediate purpose for calculating the formation strength

following the leak-off test.

© IWCF 2000 page 3 of 10

International Well Control Forum

Example Question 2

Determine the leak-off pressure from the leak-off test graph shown above.

q

4 A. 875 psi.

q B. 975 psi.

q C. 1,050 psi.

q D. 1,125 psi.

q E. 1,175 psi.

Detailed Analysis:

The correct answer is 875 psi.

© IWCF 2000 page 4 of 10

International Well Control Forum

The incorrect answers are 975, 1050, 1125, and 1175 psi. The test should have been terminated at

975psi, the first visible deviation from the straight line. In some weak formations a breakdown could result

if the test continued beyond this pressure.

The leak-off pressure is here defined as the highest pressure point (875 psi) at which no leak-off has taken

place. The volume of mud pumped from surface (3.5 bbls) has only compressed the total fluid volume in

the hole and expanded the casing in the process. After another ½ bbl is pumped from surface we have

injected a small amount of fluid into a newly created fracture. It is quite conceivable and probably even

likely that the leak-off starts somewhere between 875 and 900 psi, but the graph does not allow us to be

more accurate than intervals of ¼ bbl volume being pumped. Furthermore, no details are given about the

leak-off method.

If the graph is difficult to read, ensure you use a ruler and there will be no doubt about the last pressure

point on the straight line.

What can we do with this leak-off pressure?

What other information is required to calculate the formation strength?

Where does MAASP fit in all of this?

The relationship between the leak-off pressure, MAASP and fracture pressure (not breakdown pressure)

relies on the fluid column between surface and casing shoe. The fluid column needs to be a uniform and

accurately measured density.

The true vertical depth of the casing shoe is information we also require. If the overall fluid density is

changed, or if we have two or more different densities between surface and casing shoe, the pressure at

surface will change. This is because the fracture pressure is - for practical purposes - considered to be an

absolute value and will remain the same as long as we do not initiate a breakdown.

In summary:

• The leak-off pressure is directly related to the fracture pressure with a fluid column of a known

density between surface and true vertical casing shoe depth.

• The MAASP allows the user to relate to the fracture pressure during a well control situation, as

long as the density of one (or more) fluid columns is accurately known.

© IWCF 2000 page 5 of 10

International Well Control Forum

Understanding the reasons for performing a leak-off test simplifies the following question.

Example Question 3

The leak-off test results are now recorded.

Which of the following information is essential to calculate the fracture pressure?

(TWO ANSWERS)

q A. The capacity of the drill string.

q

4 B. The true vertical depth of the casing shoe.

q C. The presence of a float sub in the drill string.

q D. The pore pressure of the formation being tested.

4

q E. The mud density.

Comments:

The candidate can highlight the following words: -

'results.....recorded' The information related to leak-off pressure.

'essential' It is the essential information that is required, not any other.

'fracture pressure' This is what we are after....!

Detailed Analysis:

Answers (B) and (E) are correct. Without this information no accurate calculation(s) can be made. You

could scribble the following formula on a piece of paper, or next to the question itself, to jog your memory.

Pfrac = (MW x TVDepthcsg.shoe) + LOP

Note that the abbreviations (Pfrac, MW, TVDepthcsg.shoe, LOP) are not universal and could be quite

different in your company or area!

Answer (A) is incorrect. The capacities or volumes of hole, casing and drill string have no impact on the

hydrostatic head calculation.

Answer (C) is incorrect. It is a distracter in relation to the leak-off test activity. A float sub in the drill

string might have an influence on the value of the leak-off pressure, if the test was performed through the

drill string instead of the annulus. However, the validity of the leak-off test result is not part of the question.

We want to calculate the fracture pressure from the information we already have. Note that this

(somewhat disputable) distracter has been chosen to illustrate the importance to carefully read the question!

Answer (D) is incorrect. The pore pressure value has no direct relationship with the fracture pressure

value. We do not need this information to calculate the fracture pressure.

© IWCF 2000 page 6 of 10

International Well Control Forum

By now you have probably come to terms with some aspects of the IWCF testing methodology. The

following three questions have fully worked answers.

Example Question 4

Which of the following are relevant considerations when selecting a slow circulation rate during a well kill

using a surface BOP system?

(THREE ANSWERS)

q4 A. Choke control management.

q4 B. Annular friction losses.

q C. Vacuum degasser handling capacity.

q D. Pressure rating of the Ram Preventer.

q4 E. Removal of gas influx in horizontal holes.

Detailed Analysis:

Answers (a), (b) and (e) are correct.

• A reduced or slow circulation rate will simplify choke control management. Pressure fluctuations at the

choke will be slower because any decompression of mud and influx will take place at a slower rate. If

choke control cannot be managed at any given rate, a further reduction will be beneficial, provided the

circulation pressure is adjusted accordingly.

• Annular friction losses will always be affected by the circulation rate, the amount is dependent on many

factors, such as annular capacity and mud rheology.

• In horizontal holes it might be more difficult to remove gas trapped in washouts when circulation rate is

vastly reduced. If circulation rates higher than normal cannot be applied, circulation time might be

substantially longer than is commonly experienced in deviated or vertical holes.

Answer (c) is incorrect. The vacuum degasser has no impact on the selection of the reduced circulation

rate pressure during the well kill.

Answer (d) is incorrect.

• The well pressure below the Ram Preventer is the same as that of the casing or choke pressure. Any

decrease or increase in slow circulation rate while maintaining bottom hole pressure will have an impact

on the choke pressure.

• However this choke pressure will always be lower than the shut in casing or well pressure below the

Ram Preventer, because with no pump running, no annular friction loss has to be taken into account

(static casing pressure = dynamic choke pressure plus dynamic friction loss when bottom hole pressure

is kept constant).

When in doubt, sketch a diagram with typical data.

© IWCF 2000 page 7 of 10

International Well Control Forum

Example Question 5

While running in the hole it is observed that the trip tank level is significantly higher than pre-calculated

values. There is a float valve in the drill string. What action should the Driller take?

q A. Flowcheck. If no flow, pump out of hole and check for plugged nozzles.

q B. Flowcheck. If no flow, close the well in and spot LCM around the bit to cure seepage

losses.

q C. Continue running in the hole. It is impossible to swab the well while running in. Ignore

trip tank levels.

q D. Shut the well in and reverse circulate to clean the hole.

q

4 E. Flowcheck. If no flow, continue running in the hole or consider stripping to bottom.

Detailed Analysis

Note the words significantly higher and float valve in the question.

Answer (E) is the only correct answer.

• Whatever procedure you would like to follow, utmost caution needs to be exercised. The string will

need to go back to the bottom before circulation can commence, preferably under controlled

conditions (consider closing the BOPs and diverting returns through the choke while continually

monitoring pit levels).

• If the trip tank level increase is genuine, it is probably caused by a swabbed influx during the trip out of

the hole. This influx is migrating and expanding in volume.

Answer (A) is incorrect.

• It is unlikely that any of the nozzles are plugged as we have a float in the string.

• Furthermore, we should not pull out of the hole before investigating the trip tank volume discrepancy.

• Pulling out of the hole will always place you in a disadvantageous situation when an (possible) influx

migrates and expands even further up the hole.

Answer (B) is incorrect.

• A significant increase in trip tank level is unlikely to be caused by losses.

• Spotting LCM at random depth would not be a solution in all situations.

Answer (C) is incorrect.

• The statement (it is impossible to swab the well in whilst running in) is probably correct in most

common well situations, but the proposed action (continue running in the hole - ignore trip tank levels)

is wrong practice.

Answer (D) is incorrect.

• It is assumed there is an influx in the well located above the bit.

• The Driller’s Method would be the first choice kill method.

• Reverse circulation is not possible as there is a float in the string.

• If it had been possible to reverse circulate it would have created higher annular pressures leading to

induced losses.

© IWCF 2000 page 8 of 10

International Well Control Forum

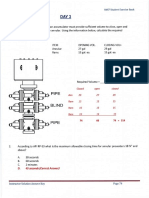

Example Question 6.

The figure below illustrates a BOP-stack and wellhead.

Indicate if the following activity can take place safely.

With the well shut in under pressure on 5 inch drill pipe, is it possible to repair a leaking flange on

the drilling spool?

q A. Yes.

q

4 B. No.

The correct answer is B. (No).

• If the well is shut in under pressure, it has been closed using either the Annular Preventer or the ‘5-inch’

Ram Type Preventer.

• Because the lower pipe ram is fitted with 3-1/2 inch pipe rams instead of 5 inch pipe or variable bore

rams the well cannot be secured below the drilling spool. Therefore, any attempt to repair the drilling

spool would expose it to well pressure.

© IWCF 2000 page 9 of 10

International Well Control Forum

• With this sort of questions it is important not to be led by situations you might have experienced at the

well site. The illustration has been chosen to portray a situation, which allows only one answer to the

question. Use your pen to mark the drawing when in doubt and/or to assist you with getting the correct

answer.

• Incorrect answers usually stem from hasty decision making or oversight. Be aware.

© IWCF 2000 page 10 of 10

Você também pode gostar

- Applied Drilling Circulation Systems: Hydraulics, Calculations and ModelsNo EverandApplied Drilling Circulation Systems: Hydraulics, Calculations and ModelsNota: 5 de 5 estrelas5/5 (4)

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsNo EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsNota: 5 de 5 estrelas5/5 (1)

- IWCF Well Control Practice Test (ENFORM)Documento12 páginasIWCF Well Control Practice Test (ENFORM)Houssam Adjina88% (8)

- IWCF Workbook Instructor Solution KeyDocumento32 páginasIWCF Workbook Instructor Solution KeyElrohirPendragon80% (5)

- IWCF Workbook - DB - (All Questions)Documento135 páginasIWCF Workbook - DB - (All Questions)ElrohirPendragon100% (2)

- 27 - Iwcf Ss Sample Questions - AnswersDocumento9 páginas27 - Iwcf Ss Sample Questions - Answersshoaib Khalil100% (1)

- 19 - IWCF Homework Answers Day 2 - 1blankDocumento53 páginas19 - IWCF Homework Answers Day 2 - 1blankAdolfo Angulo100% (2)

- P and P Quiz 1 at 2Documento30 páginasP and P Quiz 1 at 2Jeneesh ShanmughanAinda não há avaliações

- IWCF ProblemsDocumento21 páginasIWCF ProblemsTamlom100% (1)

- IWCF Principles & Procedures Test Paper (Answer)Documento5 páginasIWCF Principles & Procedures Test Paper (Answer)andrzema100% (3)

- Iwcf Q&aDocumento91 páginasIwcf Q&aKhaled AdelAinda não há avaliações

- Completion Equipment Wa (1) - IWCFDocumento12 páginasCompletion Equipment Wa (1) - IWCFWH Baloch100% (2)

- IWCF Practice QuestionsDocumento95 páginasIWCF Practice QuestionsYousafZaiCennian100% (10)

- Surface Driller Equipment Paper NO. 1.: All Questions Require Only ONE Answer Unless Otherwise StatedDocumento22 páginasSurface Driller Equipment Paper NO. 1.: All Questions Require Only ONE Answer Unless Otherwise StatedandrzemaAinda não há avaliações

- Wire Line Exercises: by Entering Numbers From The Drawing in The Boxes BelowDocumento4 páginasWire Line Exercises: by Entering Numbers From The Drawing in The Boxes BelowmissaouiAinda não há avaliações

- IWCF Practice 1 (With Answer)Documento22 páginasIWCF Practice 1 (With Answer)syazwan80% (5)

- Iwcf l3 4 PDFDocumento2 páginasIwcf l3 4 PDFBENMAAMER AZOUAOU100% (1)

- Well Control Exercises PDFDocumento69 páginasWell Control Exercises PDFal7assany88% (17)

- IWCF Formula Sheet - APIDocumento4 páginasIWCF Formula Sheet - APIAwani Kester100% (1)

- IWCF Well Control 4Documento13 páginasIWCF Well Control 4Abdur Rahman100% (1)

- 3 - Well Control ExercisesDocumento98 páginas3 - Well Control ExercisesJoão MayrinkAinda não há avaliações

- IWCF Equipment Sample Questions (Surface Stack)Documento6 páginasIWCF Equipment Sample Questions (Surface Stack)Ogbadibo100% (2)

- 03 - WellSharp WC Methods and Subsea - Day 2 Pre - CourseDocumento5 páginas03 - WellSharp WC Methods and Subsea - Day 2 Pre - CourseAdolfo AnguloAinda não há avaliações

- 18 - IWCF Homework Answers Day 1 - 1blank PDFDocumento61 páginas18 - IWCF Homework Answers Day 1 - 1blank PDFKenaouia BahaaAinda não há avaliações

- Well Control PrinciplesDocumento196 páginasWell Control PrinciplesAnonymous rey6aU3ZAinda não há avaliações

- 3 Well Control ExercisesDocumento98 páginas3 Well Control ExercisesLuisSossaAinda não há avaliações

- P&Pof Intervention Pressure ControlDocumento69 páginasP&Pof Intervention Pressure ControlRajat Khanna100% (4)

- IWCF Set 1 - 6Documento33 páginasIWCF Set 1 - 6Jeneesh Shanmughan100% (1)

- Iwcf Question and AnswerDocumento4 páginasIwcf Question and AnswerHendra Jurbon50% (14)

- Well Intervention QuizDocumento4 páginasWell Intervention QuizAkol Majook50% (2)

- Well ControlDocumento19 páginasWell ControlberrouiAinda não há avaliações

- IADC WellSHARP Drilling Driller Course OutlineDocumento2 páginasIADC WellSHARP Drilling Driller Course OutlineLuis Augusto Calizaya Castillo100% (1)

- IWCF Test 2 With Answers: Driller'S Technical HandbookDocumento25 páginasIWCF Test 2 With Answers: Driller'S Technical HandbookBeni N Solo67% (3)

- Equipment Questions.Documento137 páginasEquipment Questions.rajgogoi85% (20)

- IWCF Drilling Levels 3 and 4 SyllabusDocumento37 páginasIWCF Drilling Levels 3 and 4 SyllabusNacer Lagraa100% (1)

- 10 - WellSharp Study Guide - Pre - Course - Rev 1Documento6 páginas10 - WellSharp Study Guide - Pre - Course - Rev 1mjm_1365Ainda não há avaliações

- 18b - IWCF Homework Answers Day 1 - Answers HighlightedDocumento61 páginas18b - IWCF Homework Answers Day 1 - Answers HighlightedAhmed Ayad86% (7)

- IWCF Surf. Equip Supv. 01Documento23 páginasIWCF Surf. Equip Supv. 01andrzemaAinda não há avaliações

- Know Energy - P&P Test 2 With AnswersDocumento21 páginasKnow Energy - P&P Test 2 With AnswerssyazwanAinda não há avaliações

- IWCF Comb. Supv Equip. 01Documento25 páginasIWCF Comb. Supv Equip. 01andrzema100% (3)

- IWCF Well Control Training Level 2 SyllabusDocumento28 páginasIWCF Well Control Training Level 2 SyllabusEgisto Mannini100% (5)

- ICWF Study PackDocumento143 páginasICWF Study PackRaJa100% (4)

- Surface Well Control Exercise No. 11 - Equipment - GeneralDocumento27 páginasSurface Well Control Exercise No. 11 - Equipment - GeneralKaleem UllahAinda não há avaliações

- Interview QuestionsDocumento4 páginasInterview QuestionsAbdelkader Fattouche100% (1)

- Well Control Level 4 PDFDocumento1 páginaWell Control Level 4 PDFMassinissa MassinissaAinda não há avaliações

- AC-0018 Practical Assessor HandbookDocumento24 páginasAC-0018 Practical Assessor HandbookRichard ReiersenAinda não há avaliações

- Well Control Training & Assessment: Sample Supervisor-Level QuestionsDocumento27 páginasWell Control Training & Assessment: Sample Supervisor-Level QuestionsShe DoelsAinda não há avaliações

- Well Control OpenDocumento311 páginasWell Control OpenRobert Verret100% (1)

- Iwcf ManualDocumento214 páginasIwcf Manualجاسم100% (5)

- Drilling Supervisor: Passbooks Study GuideNo EverandDrilling Supervisor: Passbooks Study GuideAinda não há avaliações

- Drilling Engineering Problems and Solutions: A Field Guide for Engineers and StudentsNo EverandDrilling Engineering Problems and Solutions: A Field Guide for Engineers and StudentsNota: 5 de 5 estrelas5/5 (1)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsAinda não há avaliações

- Managed Pressure Drilling: Modeling, Strategy and PlanningNo EverandManaged Pressure Drilling: Modeling, Strategy and PlanningNota: 5 de 5 estrelas5/5 (3)

- Sand Control and Gravel Packing Techniques: It Never Rains in the Oil Field!No EverandSand Control and Gravel Packing Techniques: It Never Rains in the Oil Field!Nota: 5 de 5 estrelas5/5 (1)

- Common Well Control Hazards: Identification and CountermeasuresNo EverandCommon Well Control Hazards: Identification and CountermeasuresNota: 4.5 de 5 estrelas4.5/5 (4)

- Genesys Character Sheet (Form Fill Dice Pools)Documento5 páginasGenesys Character Sheet (Form Fill Dice Pools)ElrohirPendragonAinda não há avaliações

- IWCF Workbook - DB - (All Questions)Documento135 páginasIWCF Workbook - DB - (All Questions)ElrohirPendragon100% (2)

- IWCF Workbook Instructor Solution Key - Day 3 Part IIIDocumento20 páginasIWCF Workbook Instructor Solution Key - Day 3 Part IIIElrohirPendragon50% (2)

- IWCF Workbook Instructor Solution Key - Day 3 Part IIDocumento19 páginasIWCF Workbook Instructor Solution Key - Day 3 Part IIElrohirPendragonAinda não há avaliações

- Global Production Report 2018Documento36 páginasGlobal Production Report 2018ElrohirPendragonAinda não há avaliações

- IWCF Workbook Instructor Solution Part 2Documento24 páginasIWCF Workbook Instructor Solution Part 2ElrohirPendragon100% (1)

- 33 - IWCF Workbook Instructor Solution Key - Day 3 Part I - DB - 23 Dec 14 PDFDocumento23 páginas33 - IWCF Workbook Instructor Solution Key - Day 3 Part I - DB - 23 Dec 14 PDFElrohirPendragon100% (4)

- IWCF Workbook Instructor Solution KeyDocumento32 páginasIWCF Workbook Instructor Solution KeyElrohirPendragon80% (5)

- 105bbe7a 78a3f9Documento2 páginas105bbe7a 78a3f9ElrohirPendragonAinda não há avaliações

- Drilling Levels 3 and 4 Syllabus PDFDocumento35 páginasDrilling Levels 3 and 4 Syllabus PDFGOKUL PRASADAinda não há avaliações

- 31 - IWCF Workbook Instructor Solution KeyDocumento17 páginas31 - IWCF Workbook Instructor Solution KeyElrohirPendragon100% (3)

- EX-0035 Drilling - English API Formula Sheet THDocumento4 páginasEX-0035 Drilling - English API Formula Sheet THPavin PiromAinda não há avaliações

- Welltrain Subsea Vertical Kill Sheet - API Field Units - Revised July 2010Documento4 páginasWelltrain Subsea Vertical Kill Sheet - API Field Units - Revised July 2010ElrohirPendragonAinda não há avaliações

- Subsea BOP Stack Operations API - Vertical Well Kill SheetDocumento2 páginasSubsea BOP Stack Operations API - Vertical Well Kill Sheetittehad100% (1)

- The Fast, Easy To Use Assessment Tool: Bowtie Pro™Documento21 páginasThe Fast, Easy To Use Assessment Tool: Bowtie Pro™ElrohirPendragonAinda não há avaliações

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Subsea BOP Stack Operations API - Deviated Well Kill SheetDocumento3 páginasSubsea BOP Stack Operations API - Deviated Well Kill SheetMannattil Krishna KumarAinda não há avaliações

- Terminal Unit Performance and Control (Expansion Tank) : Dr. Samah E. HatabDocumento15 páginasTerminal Unit Performance and Control (Expansion Tank) : Dr. Samah E. HatabLulu PixAinda não há avaliações

- 16-9 Accuracy of Erected SteelworkDocumento8 páginas16-9 Accuracy of Erected SteelworkZuberYousufAinda não há avaliações

- Voorbeeld: Internatio N Al Standard 2186Documento10 páginasVoorbeeld: Internatio N Al Standard 2186Pansawut WanitwanakornAinda não há avaliações

- SAEP - 306 Evaluating The Safe Operating Pressure of Corroded PipeDocumento2 páginasSAEP - 306 Evaluating The Safe Operating Pressure of Corroded PipeSalik SiddiquiAinda não há avaliações

- 1 Building Const 1Documento38 páginas1 Building Const 1ashleyane garlanAinda não há avaliações

- EQ04Documento121 páginasEQ04chandan naiduAinda não há avaliações

- MSBTE Questions Bank With Answer: Maintenance and Repairs of Structures - 22602Documento13 páginasMSBTE Questions Bank With Answer: Maintenance and Repairs of Structures - 22602aniket100% (3)

- Vibrating Plate 2D Viscous Flow 53Documento7 páginasVibrating Plate 2D Viscous Flow 53Dr-Ateeq Ur RehmanAinda não há avaliações

- Waste Water Treatment ProcessDocumento15 páginasWaste Water Treatment ProcessDihadihaAinda não há avaliações

- Calculating ESAL1 PDFDocumento2 páginasCalculating ESAL1 PDFRobert Walusimbi50% (2)

- Column ReportDocumento24 páginasColumn Reportmsiddiq1Ainda não há avaliações

- Saidi Issa B-10-022. Civil Engineering: Zonal Irrigation & Technical Services Unit TaboraDocumento31 páginasSaidi Issa B-10-022. Civil Engineering: Zonal Irrigation & Technical Services Unit TaborachingtonyAinda não há avaliações

- 03 DILG Bridge HydraulicsDocumento31 páginas03 DILG Bridge HydraulicsHarry BasadaAinda não há avaliações

- ETABS 2016 Shear Wall Design: ETABS 2016 16.2.1 License # 1VT4JZ6NBETB3BFDocumento1 páginaETABS 2016 Shear Wall Design: ETABS 2016 16.2.1 License # 1VT4JZ6NBETB3BFArmando CasasAinda não há avaliações

- Theory 1Documento191 páginasTheory 1Joseph Arben Agus100% (1)

- Column JacketingDocumento3 páginasColumn Jacketinganonymousupldr666100% (1)

- PhDThesis - Bruno PedrosaDocumento298 páginasPhDThesis - Bruno Pedrosam.w.wintermansAinda não há avaliações

- SeepageDocumento3 páginasSeepageJed YasisAinda não há avaliações

- Experiment 1: Forces in A Roof Truss With A Central and Wind LoadDocumento5 páginasExperiment 1: Forces in A Roof Truss With A Central and Wind LoadAinur NasuhaAinda não há avaliações

- The National Academies Press: Manual On Subsurface Investigations (2019)Documento24 páginasThe National Academies Press: Manual On Subsurface Investigations (2019)Andres PuertaAinda não há avaliações

- Complete Report On HvacDocumento57 páginasComplete Report On HvacJunaid Khan100% (2)

- ASDSO Directory ofDocumento72 páginasASDSO Directory ofsasan bluelineAinda não há avaliações

- Casting DefectsDocumento5 páginasCasting DefectsGurjinder SinghAinda não há avaliações

- NRL2TRK2102 PDFDocumento123 páginasNRL2TRK2102 PDFREHAZ100% (1)

- Steel Members DesignDocumento195 páginasSteel Members DesignStephen JamesAinda não há avaliações

- BGS-AU-055 Rev B1Documento19 páginasBGS-AU-055 Rev B1Allwyn AbrahamAinda não há avaliações

- DSR Elec 2022 PDFDocumento155 páginasDSR Elec 2022 PDFShivam50% (2)

- Design & Detailing of Prestressed Building Floors in Singapore Using Eurocode May 2015 PDFDocumento151 páginasDesign & Detailing of Prestressed Building Floors in Singapore Using Eurocode May 2015 PDFjohnkoh99Ainda não há avaliações

- Uel Sugarcrete Slab Report - 7 Nov 2022Documento85 páginasUel Sugarcrete Slab Report - 7 Nov 2022Eng_RochaAinda não há avaliações

- CONSOLI Et Al. (2009) - Key Parameters For The Strength Control of Lime Stabilized SoilsDocumento7 páginasCONSOLI Et Al. (2009) - Key Parameters For The Strength Control of Lime Stabilized SoilsSaymonServiAinda não há avaliações