Escolar Documentos

Profissional Documentos

Cultura Documentos

Shell Thickness

Enviado por

vikas0 notas0% acharam este documento útil (0 voto)

15 visualizações1 páginat

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentot

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

15 visualizações1 páginaShell Thickness

Enviado por

vikast

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 1

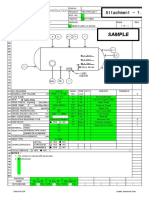

WELDED STEEL TANKS FOR Olt STORAGE

4 Thering of annular pats shall havea circular outside eicumference, but may havea regular polygonal shape inside the

shell, with the numberof sides equsl to the number of annular plates, These pieces shall be welded in accordance with

1.56and 5.1.5.7, Item b.

5455. Inliew of annular plates, the entire botfom may be burt-welded provided thatthe requirements for annular plate thickness

relding, materials, and inspection are met for the annular distance specified in 5.5.2.

56 SHELL DESIGN

56.1 General

36.1.1 The required shell thickness shall be the greater ofthe design shel thickness, including any corrosion allowance, or the

tyostatic test shell thickness, bu the shell thickness shall not be less than the following:

‘Nominal Tank Diameter ‘Nominal Plate Thickness lor

m=) @, am) )

<15 = 30 3 Ths Lor

1510 <36 s0t0< 120 Ng

3610 60 129 9 200 8 he

> > 200 10 4s

1 Utes otherwise specified by the Purchaser, the nominal tank diameter sal be the centerline diameter ofthe bottom shell-course plats,

2: Nominal plate thickness refers o the tank shell as constructed. The thicknesses specified sre based on erection requirements

3 When specified by the Purchaser, plate with a rinimam nominal thickness of 6 mm may be substituted for Varin. plate.

a er dioneters less than 15 m (50 f) but greater than 3.2 m (10.5 R), the minimum thickness of the lowest shell course only is increased to

6mm (Ms in).

5.6.1.2 Unless otherwise agreed to by the Purchaser, the shel plates shall have a minimum nominal width of 1800 mm (72 in)

Plates that are to be butt-welded shall be properly squared.

5.6.1.3 The calculated stress for each shell course shall not be greater than the stress permitted for the particular material used

for the course. No shell course shall be thinner than the course above i.

5.6.4.4 The tank shell shall be checked for stability sgainst buckling from the design wind speed in accordance with 5.9.7. If

requited for stability, intermediate girders, increased shell-plate thicknesses, or both shall be used.

§.6-1.5 Isolated radial loads on the tank shell, such as those caused by heavy loads on platforms and elevated walkways

‘between tanks, shall be distributed by rolled structural sections, plate ribs, or built-up members. 7

5.6.2 Allowable Stress

s s rable 5 —

‘thickesses les any corrosion allowange—shall be used.in the calculation, The design stress basis, Sz, shall be either two-thirds

the yield strength or two-fifths the tensile strength, whichever is less.

5.6.2.2 The maximum allowable hydrostatic test stress, 5, shall be as shown in Table 5-2. The gross plate thicknesses, includ-

ing any corrosion allowance, shall be used in the calculation. The hydrostatic test basis shall be either three-fourths the yield

strength or three-sevenths the tensile strength, whichever is less.

5.6.2.3 Appendix A permits an altemative shell design with a fixed allowable stress of 145 MPa (21,000 Ibfin2) and a joint effi-

ciency fator of 0.85 or 0.70. This design may only be used for tanks with shell thicknesses les than or equal to 12.5 mm (2 in}.

5.6.2.4 Structural design stresses shall conform to the allowable working stresses given in 5.10.3.

5.6.3 Calculation of Thickness by the 1-Foot Method

5.6.3.1. The 1-foot method calculates the thicknesses required at design points 0.3 m (I ft) above the bottom of each shell

Course. Appendix permits only this design method. This method shall not be used for tanks larger than 60 m (200-ft) in

liameter.

tron eae engreing cuncan coat} :

get esa Sonar

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Technical Bid Evaluation (Attachment9) - 1178067845726Documento16 páginasTechnical Bid Evaluation (Attachment9) - 1178067845726vikas100% (1)

- Quot - First Floor (Mb2 - 1st Co-Ord Lay)Documento2 páginasQuot - First Floor (Mb2 - 1st Co-Ord Lay)vikasAinda não há avaliações

- Us Meetings GSG 6.12 PDFDocumento4 páginasUs Meetings GSG 6.12 PDFvikasAinda não há avaliações

- AyurvedDocumento1 páginaAyurvedvikasAinda não há avaliações

- 15th Floor R4Documento16 páginas15th Floor R4vikasAinda não há avaliações

- AyurvedDocumento1 páginaAyurvedvikasAinda não há avaliações

- 179 Sample ChapterDocumento7 páginas179 Sample ChaptervikasAinda não há avaliações

- MB2 - 1ST Co-Ord LayDocumento18 páginasMB2 - 1ST Co-Ord LayvikasAinda não há avaliações

- Test PaperACHE - 20.08.10Documento1 páginaTest PaperACHE - 20.08.10vikasAinda não há avaliações

- MB2 - 1ST Co-Ord LayDocumento3 páginasMB2 - 1ST Co-Ord LayvikasAinda não há avaliações

- Engineering DWG (Attachment 1 Process Data) (1) 1177904451196Documento2 páginasEngineering DWG (Attachment 1 Process Data) (1) 1177904451196vikasAinda não há avaliações

- Test PaperACHE - 20.08.10Documento1 páginaTest PaperACHE - 20.08.10vikasAinda não há avaliações

- Technical Bid Evaluation (Attachment8) - 1178067845349Documento27 páginasTechnical Bid Evaluation (Attachment8) - 1178067845349vikas100% (1)

- Appendix RDocumento1 páginaAppendix RvikasAinda não há avaliações

- Group of Materials PDFDocumento1 páginaGroup of Materials PDFvikasAinda não há avaliações

- 179 Sample ChapterDocumento7 páginas179 Sample ChaptervikasAinda não há avaliações

- Equipment Design As Per Russian Norms - 20090218Documento45 páginasEquipment Design As Per Russian Norms - 20090218vikasAinda não há avaliações

- h103 - Hvac Service Layout For First FloorDocumento33 páginash103 - Hvac Service Layout For First FloorvikasAinda não há avaliações

- PV Elite 2007 Licensee: Pvelite Demonstration Version Filename: Untitled-23 - Earthquake Load Calculation Step: 9 4:02P Nov 18,2008Documento7 páginasPV Elite 2007 Licensee: Pvelite Demonstration Version Filename: Untitled-23 - Earthquake Load Calculation Step: 9 4:02P Nov 18,2008vikasAinda não há avaliações

- Reading Drawings BOE EXAMDocumento12 páginasReading Drawings BOE EXAMvikasAinda não há avaliações

- Boe Thermal Paper PDFDocumento31 páginasBoe Thermal Paper PDFvikasAinda não há avaliações

- Mechanical Engineer LeadDocumento1 páginaMechanical Engineer LeadvikasAinda não há avaliações

- Flange Excel NewDocumento26 páginasFlange Excel NewvikasAinda não há avaliações

- 11th Floor-R3Documento17 páginas11th Floor-R3vikasAinda não há avaliações

- 11th Floor R3Documento17 páginas11th Floor R3vikasAinda não há avaliações

- TanksDocumento3 páginasTanksvikasAinda não há avaliações

- Chillers PPT in Doe WorkshopDocumento40 páginasChillers PPT in Doe WorkshopchummafileAinda não há avaliações

- Viii-1 - App S PDFDocumento3 páginasViii-1 - App S PDFvikasAinda não há avaliações

- Pipe SheetDocumento1 páginaPipe SheetvikasAinda não há avaliações