Escolar Documentos

Profissional Documentos

Cultura Documentos

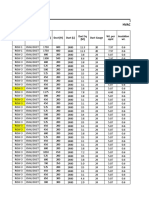

Fig. 4-1

Enviado por

vikas0 notas0% acharam este documento útil (0 voto)

12 visualizações1 páginaa

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoa

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

12 visualizações1 páginaFig. 4-1

Enviado por

vikasa

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 1

48 ‘API Stancano 650

FS cH

& ee

2 0 , ei

i

a ‘

a 4

a 7

§

' ‘co = “2

| Fos 18

| Boon 4

| i

: ae we i

a |

I

| a |

i| a “0

| a svi |

| a 1 |

= 8 ves rs 7 2 36

mes oan os in os al

/ Treinen ming eorein sownes

votes

| 1. The Group Il and Group V lines coincide at thicknesses less than 12.5 mm (1/z in.)

Feces ne nas nis maseeseseseran2 nh)

/ Brace pa ta a abet

| Tee tguctenrapleae cote ee pos ce 4274)

| FASS ae eigen tces bara 2 nase)

fl Figure 4-1—Minimum Permissible Design Metal Temperature for Materials Used in Tank Shells

1 without Impact Testing

4.2.9.4 ‘The requirements in 42.9.3 apply only to shell nozzles and manholes. Materials for roof nozzles and manholes 60

| require special toughness.

42.10 Toughness Procedure

perature to show Charpy V-notch longitudinal (or transverse) values that fulfil the minimum requirements of Table 4-4

4.2.8 forthe minimum values for one specimen and for subsize specimens). As used here, the term plate as rolled refers

‘unit plate rolled fom a slab or directly from an ingot in its relation to the location and number of specimens, not to the

tion ofthe plate.

i

i ‘ 4.2.40.4 When a material’s toughness must be determined, it shall be done by one of the procedures described in 4.2.

| through 4.2.10.4, as specified in 42.9.

[ 4.2.10.2 Each plate as rolled or heat treated shall be impact tested in accordance with 4.2.8 ator below the design metal’

Sreranon anes semis wt eae an otto Stee te 6 wT " '

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Technical Bid Evaluation (Attachment9) - 1178067845726Documento16 páginasTechnical Bid Evaluation (Attachment9) - 1178067845726vikas100% (1)

- AyurvedDocumento1 páginaAyurvedvikasAinda não há avaliações

- Evaluate Air Cooled Heat ExchangersDocumento1 páginaEvaluate Air Cooled Heat ExchangersvikasAinda não há avaliações

- Quot - First Floor (Mb2 - 1st Co-Ord Lay)Documento2 páginasQuot - First Floor (Mb2 - 1st Co-Ord Lay)vikasAinda não há avaliações

- 15th Floor R4Documento16 páginas15th Floor R4vikasAinda não há avaliações

- Fig 5-3ADocumento1 páginaFig 5-3AvikasAinda não há avaliações

- Jay & Co. ducting solutionDocumento3 páginasJay & Co. ducting solutionvikasAinda não há avaliações

- Us Meetings GSG 6.12 PDFDocumento4 páginasUs Meetings GSG 6.12 PDFvikasAinda não há avaliações

- AyurvedDocumento1 páginaAyurvedvikasAinda não há avaliações

- DC Pandey (M2)Documento77 páginasDC Pandey (M2)Adithya Sampath79% (24)

- 179 Sample ChapterDocumento7 páginas179 Sample ChaptervikasAinda não há avaliações

- Appendix RDocumento1 páginaAppendix RvikasAinda não há avaliações

- Ac LCH Ipd 08 Seventh Floor Sd02Documento10 páginasAc LCH Ipd 08 Seventh Floor Sd02vikasAinda não há avaliações

- MB2 - 1ST Co-Ord LayDocumento18 páginasMB2 - 1ST Co-Ord LayvikasAinda não há avaliações

- Technical Bid Evaluation (Attachment8) - 1178067845349Documento27 páginasTechnical Bid Evaluation (Attachment8) - 1178067845349vikas100% (1)

- Engineering DWG (Attachment 1 Process Data) (1) 1177904451196Documento2 páginasEngineering DWG (Attachment 1 Process Data) (1) 1177904451196vikasAinda não há avaliações

- PV Elite 2007 Licensee: Pvelite Demonstration Version Filename: Untitled-23 - Earthquake Load Calculation Step: 9 4:02P Nov 18,2008Documento7 páginasPV Elite 2007 Licensee: Pvelite Demonstration Version Filename: Untitled-23 - Earthquake Load Calculation Step: 9 4:02P Nov 18,2008vikasAinda não há avaliações

- CalculationDocumento3 páginasCalculationvikasAinda não há avaliações

- Group of Materials PDFDocumento1 páginaGroup of Materials PDFvikasAinda não há avaliações

- Equipment Design As Per Russian Norms - 20090218Documento45 páginasEquipment Design As Per Russian Norms - 20090218vikasAinda não há avaliações

- Evaluate Air Cooled Heat ExchangersDocumento1 páginaEvaluate Air Cooled Heat ExchangersvikasAinda não há avaliações

- Shell ThicknessDocumento1 páginaShell ThicknessvikasAinda não há avaliações

- Boe Thermal Paper PDFDocumento31 páginasBoe Thermal Paper PDFvikasAinda não há avaliações

- Reading Drawings BOE EXAMDocumento12 páginasReading Drawings BOE EXAMvikasAinda não há avaliações

- h103 - Hvac Service Layout For First FloorDocumento33 páginash103 - Hvac Service Layout For First FloorvikasAinda não há avaliações

- Mechanical Engineer LeadDocumento1 páginaMechanical Engineer LeadvikasAinda não há avaliações

- 179 Sample ChapterDocumento7 páginas179 Sample ChaptervikasAinda não há avaliações

- 11th Floor R3Documento17 páginas11th Floor R3vikasAinda não há avaliações

- 11th Floor-R3Documento17 páginas11th Floor-R3vikasAinda não há avaliações