Escolar Documentos

Profissional Documentos

Cultura Documentos

Polyurea Resistance Chart

Enviado por

Tanmay Gor0 notas0% acharam este documento útil (0 voto)

114 visualizações1 páginaChemical resistance of polyurea

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoChemical resistance of polyurea

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

114 visualizações1 páginaPolyurea Resistance Chart

Enviado por

Tanmay GorChemical resistance of polyurea

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 1

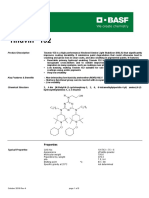

Product Data Sheet

Polyurea Elastomer Chemical Resistance Chart

Test Procedure: ASTM D1308 at 720°F

R: Recommended (little or no visible damage)

C: Recommended Conditionally (some swelling, discoloration, cracking ‑ wash down within 1 hour of spillage)

N: Not Recommended

1 : Some discoloration only

This data represents 7 days spot test exposure for the Polyurea Elastomer System. The noted chemical; was placed on the

surface area of the polyurea and exposed for the prescribed time period. This test represents industry‑recognized conditions.

Test Media Results Test Media Results

Acetic Acid 10% R Methanol R

Acetone C Methanol (5%) Gasoline C

Ammonium Hydroxide 10%/20% R Methylene Chloride C H 2C12 C

Ammonium Nitrate R Mineral spirits R

Ammonium Phosphate R Motor Oil R‑1

Antifreeze (50% Ethylene Glycol) C Nitric Acid 20% N

Battery Acid (Sulfuric Acid) C Phosphoric Acid 10% R

Benzene C Phosphoric Acid 50% N

Brine ‑ saturated (>I 30,000 ppm) R Potassium Hydroxide 10% R

Brake Fluid R Potassium Hydroxide 20% R‑1

Chlorine (2,000 ppm in water) R Propylene Carbonate C

Chlorox, 10% C‑1 Sodium Chloride R

Citric Acid R Sodium Hydroxide 5%/10%/25% R

Copper Chromate Arsenic R Sodium Hydroxide 50% R‑1

4% working solution R Sodium Hypochlorite (household bleach)

C‑1

Dimethyl Formamide N Stearic Acid R

Gasoline R Sulfuric Acid 5%/10%/20% R

Hexane R Sulfuric Acid 50%/98% N

Hydraulic Oil R‑1 Toluene C

Hydrochloric Acid R 1, 1, 1 Trichloroethylene C

Polyurea Elastomer Chemical Resistance Chart

Isopropyl Alcohol R Trisodium Phosphate R

Lactic Acid 10% R Vinegar R

Liquid Notrogne Fertilizer (25‑0‑0) R Water R

Liquid Urea Fertilizer R Xylene R

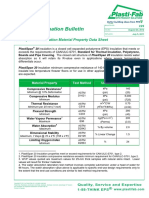

Test Procedure: ASTM D‑3912 Immersion at 75°F

This data represents 12 month immersion exposure for the Polyurea Elastomer The elas system was applied to a steel panel,

having a 2 mil blast profile. The coated panels were then immersed half way into the following chemicals/solution for a period

of 12 months, except where noted.

Test Media Results Test Media Results

Acetic Acid 10% R Motor Oil R‑1

Acetone 7 days N MTBE R, C

Ammonium Hydroxide 10%/20% R MTBE/Gasoline 2% R, C

Chromic Acid, 10% N Nitric Acid 5% R

Diesel Fuel R Phosphoric Acid 10% R

Ethylene Glycol R Sodium Chloride 10% (75°F) R

Gasoline R Sodium Chloride 10% (125°F) R

Hydraulic Fluid C Potassium Hydroxide 10% / 20% R

Hydrochloric Acid 5%, 10% R Sodium Hydroxide 50% C

Hydrogen Peroxide 5% R‑1 Sodium Hydroxide 1% 50*C 14 days C

Hydrogen Peroxide 30% N Sodium Hypochlorite 10% R

lsopropyl Alcohol N 10% Sugar/Water R

Methanol N Sulfuric Acid 5%/10%/3% 50* 14 days

Methylethyl Ketone N Toluene N

Water75*F, 180°F, 14 days R

SealBoss®

Revised 201705

SealBoss Corp. USA info@sealboss.com ph. 877-932-2293 intl. 1+ 714-662-4445

Você também pode gostar

- CHEMICAL RESISTANCEDocumento1 páginaCHEMICAL RESISTANCEAllahbaksh ShaikhAinda não há avaliações

- Application Fields Polyurea CoatingsDocumento47 páginasApplication Fields Polyurea CoatingsNabored SiakoAinda não há avaliações

- JPCL Pipeline Ebook1 PDFDocumento27 páginasJPCL Pipeline Ebook1 PDFDorje Phagmo100% (1)

- 5.2.2 MIO Coatings - What Types Are ThereDocumento2 páginas5.2.2 MIO Coatings - What Types Are ThereRama HidayatAinda não há avaliações

- Paint Over Galvanized Steel Duplex SystemsDocumento12 páginasPaint Over Galvanized Steel Duplex Systemselectrosysro8560Ainda não há avaliações

- Inspection Report Insulation Check: Inspectors Ceri Name: Signature: Date: Gama Consortium Consortium StegDocumento1 páginaInspection Report Insulation Check: Inspectors Ceri Name: Signature: Date: Gama Consortium Consortium StegRamzi Zoghlami100% (1)

- Steps to PVDF Coating on AluminumDocumento4 páginasSteps to PVDF Coating on AluminumnarmathaAinda não há avaliações

- Salt TestDocumento16 páginasSalt Testم.ذكى فضل ذكى100% (1)

- Industrial Coatings Market Shows Optimism After DownturnDocumento5 páginasIndustrial Coatings Market Shows Optimism After DownturnjagrititanuAinda não há avaliações

- FBE Testleri - DeFelskoDocumento54 páginasFBE Testleri - DeFelskoÖzgür TuştaşAinda não há avaliações

- How Thermal Cutting Affects Galvanized CoatingsDocumento5 páginasHow Thermal Cutting Affects Galvanized Coatingsnarmatha100% (1)

- BS 2015 Glossary of Paint and Related TermsDocumento56 páginasBS 2015 Glossary of Paint and Related TermsMarcelo Rodriguez FujimotoAinda não há avaliações

- MarketLineIC AsiaPacificPaintsCoatings 060920 PDFDocumento47 páginasMarketLineIC AsiaPacificPaintsCoatings 060920 PDFSahil GargAinda não há avaliações

- 1.2.4 HDG - Painting Issues PDFDocumento2 páginas1.2.4 HDG - Painting Issues PDFAnonymous 1AAjd0Ainda não há avaliações

- Paint Guide For GI SteelDocumento12 páginasPaint Guide For GI SteelDiLungBanAinda não há avaliações

- ISO 4628engDocumento4 páginasISO 4628engLuisArmandoFranyuttiArciaAinda não há avaliações

- Anticorrosion Paint & CoatingDocumento4 páginasAnticorrosion Paint & CoatingGoutam GiriAinda não há avaliações

- Inspection Thermal Spray WebinarDocumento29 páginasInspection Thermal Spray WebinarShriya Soni100% (1)

- Industry Binder FOAMGLAS Products, Insulation Systems, Accessories Products.Documento188 páginasIndustry Binder FOAMGLAS Products, Insulation Systems, Accessories Products.Christian DoriaAinda não há avaliações

- Table of Contents for Painting SpecificationDocumento33 páginasTable of Contents for Painting SpecificationGautam100% (1)

- Surface Preparation Standards - ComparasionDocumento4 páginasSurface Preparation Standards - ComparasiontaiAinda não há avaliações

- Cathodic Disbondment TestingDocumento2 páginasCathodic Disbondment Testingravi00098Ainda não há avaliações

- Norsok Surface Preparation M-501Documento28 páginasNorsok Surface Preparation M-501Ricky WCK100% (2)

- Working Procedure For Coating Repair C4Documento7 páginasWorking Procedure For Coating Repair C4tuyen nguyenAinda não há avaliações

- Blastline Institute of Surface Preparation & PaintingDocumento12 páginasBlastline Institute of Surface Preparation & PaintingKawish TamourAinda não há avaliações

- Paint Types - Important NotesDocumento3 páginasPaint Types - Important Notesmushroom0320Ainda não há avaliações

- Application Guide Jotun Super Durable Tcm180 142472Documento8 páginasApplication Guide Jotun Super Durable Tcm180 142472Mrk KhanAinda não há avaliações

- General: Insulated Aluminium CladdingDocumento5 páginasGeneral: Insulated Aluminium Claddingeccos3338Ainda não há avaliações

- Data Sheet Proguard CN 200 A.SDocumento3 páginasData Sheet Proguard CN 200 A.SAlexir Thatayaone NdovieAinda não há avaliações

- What Is Paint? Composition of Paint Binder Pigment Extenders Solvents Application of PaintDocumento13 páginasWhat Is Paint? Composition of Paint Binder Pigment Extenders Solvents Application of PaintmhnmndrkAinda não há avaliações

- Chapter 1 Oil Seal IntroductionDocumento0 páginaChapter 1 Oil Seal IntroductionZMCONTROLAinda não há avaliações

- Polyurea Waterproofingitp-1 PDFDocumento3 páginasPolyurea Waterproofingitp-1 PDFgops1963Ainda não há avaliações

- AI Hempel's Galvosil 15700 EnglishDocumento7 páginasAI Hempel's Galvosil 15700 EnglishvitharvanAinda não há avaliações

- Long Question/ Narrative Question.: Define Pigment?Documento3 páginasLong Question/ Narrative Question.: Define Pigment?Hau LeAinda não há avaliações

- Date Sheet For PaintingDocumento5 páginasDate Sheet For PaintingAws MohamedAinda não há avaliações

- FRP Joining and Repair Guide PDFDocumento12 páginasFRP Joining and Repair Guide PDFArjed Ali ShaikhAinda não há avaliações

- Touch Up and Repair of Galvanized SteelDocumento5 páginasTouch Up and Repair of Galvanized SteelkhuzafaAinda não há avaliações

- ICorr Insulation InspectorDocumento31 páginasICorr Insulation Inspector22238.spoAinda não há avaliações

- eBroc-FRP Custom Cooling Towers, YWCTDocumento28 páginaseBroc-FRP Custom Cooling Towers, YWCTJurizal Julian Luthan100% (1)

- 04-200-R1 Silicon Iron AnodesDocumento2 páginas04-200-R1 Silicon Iron Anodessams1101Ainda não há avaliações

- MetallizingDocumento26 páginasMetallizingShubham KumarAinda não há avaliações

- 521 Mio Coatings-What Are TheyDocumento3 páginas521 Mio Coatings-What Are TheypardissAinda não há avaliações

- International Paint - Corrossion Knowledge Sharing - RizalDocumento87 páginasInternational Paint - Corrossion Knowledge Sharing - RizalMikiRoniWijaya100% (1)

- Power PlantDocumento34 páginasPower Plantmiguel0581Ainda não há avaliações

- Ballast TK HempelsDocumento15 páginasBallast TK HempelsGeorgios PapakostasAinda não há avaliações

- Paints & Coatings Guide: Constituents, Types & ManufacturingDocumento5 páginasPaints & Coatings Guide: Constituents, Types & ManufacturingSheena GagarinAinda não há avaliações

- Painting FailureDocumento21 páginasPainting FailureNnamdi Celestine NnamdiAinda não há avaliações

- Factors Affecting The Friction Between SurfacesDocumento12 páginasFactors Affecting The Friction Between Surfacesmatealoredana8015Ainda não há avaliações

- PPG - Pull-Off Test Report For PUB ProjectDocumento1 páginaPPG - Pull-Off Test Report For PUB ProjectErin Williams100% (1)

- Corrosion Protection of SteelDocumento9 páginasCorrosion Protection of SteelChristian D. OrbeAinda não há avaliações

- Types of Sealants Used For Joints in Buildings - Properties, Uses, WorkingDocumento6 páginasTypes of Sealants Used For Joints in Buildings - Properties, Uses, WorkingJustin MusopoleAinda não há avaliações

- JOTUN Survey ReportDocumento2 páginasJOTUN Survey ReportMosstafa Faisal100% (2)

- SCILOGEX DispensMate Chemical CompatibilityDocumento3 páginasSCILOGEX DispensMate Chemical CompatibilitynasmineAinda não há avaliações

- Tekncoat - Technical - Data (1) - 017Documento1 páginaTekncoat - Technical - Data (1) - 017aboali8686Ainda não há avaliações

- TEKNPLUS Technical Data Sheet - Adhesive and Protective Coating PropertiesDocumento1 páginaTEKNPLUS Technical Data Sheet - Adhesive and Protective Coating Propertiesaboali8686Ainda não há avaliações

- Chemical Compatibility Chart For Nylon Membrane: R N T LDocumento1 páginaChemical Compatibility Chart For Nylon Membrane: R N T LLiea Vhelievha DjuanAinda não há avaliações

- Data Sheet Item 4 Sampe 12Documento4 páginasData Sheet Item 4 Sampe 12sitaAinda não há avaliações

- Chemset 101 M16Documento12 páginasChemset 101 M16Zilong ZhangAinda não há avaliações

- SW Estimating ManualDocumento141 páginasSW Estimating ManualTanmay GorAinda não há avaliações

- Hempafire Optima 500 Test Certficate BS 476Documento97 páginasHempafire Optima 500 Test Certficate BS 476Tanmay GorAinda não há avaliações

- 100919-SW-C Application Manual - Field (December 2020)Documento40 páginas100919-SW-C Application Manual - Field (December 2020)Tanmay GorAinda não há avaliações

- Southwest Type 5Gp™: Simplified Yield Chart - InjectedDocumento2 páginasSouthwest Type 5Gp™: Simplified Yield Chart - InjectedTanmay GorAinda não há avaliações

- ICC Updates Require Higher Bond Strength FireproofingDocumento2 páginasICC Updates Require Higher Bond Strength FireproofingTanmay GorAinda não há avaliações

- Hempafire Optima 500 Test Certficate BS 476Documento97 páginasHempafire Optima 500 Test Certficate BS 476Tanmay GorAinda não há avaliações

- Steemaster 1200 CF5276 Jotun - 413464Documento50 páginasSteemaster 1200 CF5276 Jotun - 413464Tanmay GorAinda não há avaliações

- PDS Hempafire Optima 500Documento3 páginasPDS Hempafire Optima 500Tanmay GorAinda não há avaliações

- AD Type TC-55 SealerDocumento2 páginasAD Type TC-55 SealerTanmay GorAinda não há avaliações

- ENGINEERS CONTRACTORS & TRADERS SECURE FIREPROOFING ORDERDocumento5 páginasENGINEERS CONTRACTORS & TRADERS SECURE FIREPROOFING ORDERTanmay GorAinda não há avaliações

- INT SFRM A Spray TechniquesDocumento4 páginasINT SFRM A Spray TechniquesTanmay GorAinda não há avaliações

- Hempafire Optima 500 120-Minute Fire Protection CoatingDocumento3 páginasHempafire Optima 500 120-Minute Fire Protection CoatingTanmay GorAinda não há avaliações

- Alsiflex®-1260 Blankets - Technical Data Sheet - English PDFDocumento2 páginasAlsiflex®-1260 Blankets - Technical Data Sheet - English PDFTanmay GorAinda não há avaliações

- OSHA Exposure To Respirable Crystalline Silica Technical Bulletin 080717Documento2 páginasOSHA Exposure To Respirable Crystalline Silica Technical Bulletin 080717Tanmay GorAinda não há avaliações

- Southwest Type 5GP Technical Specification GuideDocumento2 páginasSouthwest Type 5GP Technical Specification GuideTanmay GorAinda não há avaliações

- Surface Preparation and Coating Failures PDFDocumento39 páginasSurface Preparation and Coating Failures PDFTanmay GorAinda não há avaliações

- Porosil XR PDSDocumento3 páginasPorosil XR PDSTanmay GorAinda não há avaliações

- Steemaster 1200 CF5276 Jotun - 413464Documento50 páginasSteemaster 1200 CF5276 Jotun - 413464Tanmay GorAinda não há avaliações

- INT SFRM A Spray TechniquesDocumento4 páginasINT SFRM A Spray TechniquesTanmay GorAinda não há avaliações

- AD Type TC-55 SealerDocumento2 páginasAD Type TC-55 SealerTanmay GorAinda não há avaliações

- Pyrolite 15 Technical Specification Guide PDFDocumento3 páginasPyrolite 15 Technical Specification Guide PDFTanmay Gor100% (1)

- Brochure - Saita Screens & Filters PDFDocumento1 páginaBrochure - Saita Screens & Filters PDFTanmay GorAinda não há avaliações

- Product Flier - HICOTE ETDocumento1 páginaProduct Flier - HICOTE ETTanmay GorAinda não há avaliações

- Pyrolite 15 Technical Specification Guide PDFDocumento3 páginasPyrolite 15 Technical Specification Guide PDFTanmay Gor100% (1)

- Alsiflex®-1260 Blankets - Technical Data Sheet - English PDFDocumento2 páginasAlsiflex®-1260 Blankets - Technical Data Sheet - English PDFTanmay GorAinda não há avaliações

- Non-Reactive Fire Protective Coating: PROMASPRAY®-P300 Product Data SheetDocumento3 páginasNon-Reactive Fire Protective Coating: PROMASPRAY®-P300 Product Data SheetTanmay GorAinda não há avaliações

- Cafco 300 UL N800 - BeamDocumento3 páginasCafco 300 UL N800 - BeamTanmay GorAinda não há avaliações

- Product Flier - HICOTE SPDocumento1 páginaProduct Flier - HICOTE SPTanmay GorAinda não há avaliações

- Arrival Air Side: Refer Separate Roof Detail Refer Separate Roof DetailDocumento1 páginaArrival Air Side: Refer Separate Roof Detail Refer Separate Roof DetailTanmay GorAinda não há avaliações

- 04 Roof Section - ArrivalDocumento1 página04 Roof Section - ArrivalTanmay GorAinda não há avaliações

- US6509503Documento4 páginasUS6509503ahmed hargaAinda não há avaliações

- The Effect O-Phenyl Phenol On The Dyeing An Acrylic Fiber With Basic DyesDocumento6 páginasThe Effect O-Phenyl Phenol On The Dyeing An Acrylic Fiber With Basic Dyesapi-3733260Ainda não há avaliações

- Zinc Hydroxystannate & Stannate Flame RetardantsDocumento1 páginaZinc Hydroxystannate & Stannate Flame RetardantsJimmy WongAinda não há avaliações

- Fish Bone - Skip Plating Ishikawa Poly PuneDocumento3 páginasFish Bone - Skip Plating Ishikawa Poly Puneshivakumar ctAinda não há avaliações

- Gas Law WorksheetDocumento3 páginasGas Law WorksheetRonaldo Manaoat50% (2)

- Experiment No. 5 Types of Chemical Reactions: I. ObjectivesDocumento5 páginasExperiment No. 5 Types of Chemical Reactions: I. ObjectivesASDSADDSADSAAinda não há avaliações

- Pipe Wall Thickness Calculations and Allowable StressesDocumento21 páginasPipe Wall Thickness Calculations and Allowable StressesYehia HassanAinda não há avaliações

- Tubular Formwork Precast Foundation Wall Twin WallDocumento13 páginasTubular Formwork Precast Foundation Wall Twin WallAnmol KillamsettyAinda não há avaliações

- Kiln Heat Up Optimun Kiln Operation ÖNEMLİ PDFDocumento42 páginasKiln Heat Up Optimun Kiln Operation ÖNEMLİ PDFAli HüthütAinda não há avaliações

- Reflo Brochure LUB2377EDocumento8 páginasReflo Brochure LUB2377EEber.CVAinda não há avaliações

- ASTM B 446 - 03 (Reapproved 2008)Documento5 páginasASTM B 446 - 03 (Reapproved 2008)singaravelan narayanasamyAinda não há avaliações

- Shell Turbo Oil T32: Performance, Features & BenefitsDocumento2 páginasShell Turbo Oil T32: Performance, Features & BenefitsCertified Rabbits LoverAinda não há avaliações

- Specifications: Project: Owner:: LocationDocumento6 páginasSpecifications: Project: Owner:: LocationMaria Theresa AlarconAinda não há avaliações

- Chemistry - Ionic Equilibrium DPPDocumento6 páginasChemistry - Ionic Equilibrium DPPmy missionAinda não há avaliações

- Eco Water Solutions - RO PlantDocumento19 páginasEco Water Solutions - RO PlantRabindra SinghAinda não há avaliações

- Astm A 217 - 04Documento4 páginasAstm A 217 - 04Raul Humberto Mora VillamizarAinda não há avaliações

- Pvi PDFDocumento3 páginasPvi PDFBharat ChatrathAinda não há avaliações

- Ks Series Vertical Cad Details KSMR KSMMR Ksaz KSMW KSSL NaDocumento72 páginasKs Series Vertical Cad Details KSMR KSMMR Ksaz KSMW KSSL NaTaurai ChiwanzaAinda não há avaliações

- Klübersynth PEG 46: Special Greases For The Lubrication of Enclosed Gear DrivesDocumento2 páginasKlübersynth PEG 46: Special Greases For The Lubrication of Enclosed Gear DrivesShubham JainAinda não há avaliações

- Tinuvin 152 October 2019 R4 ICDocumento3 páginasTinuvin 152 October 2019 R4 ICEmilio HipolaAinda não há avaliações

- Building Construction-V: Types of Metal CladdingDocumento6 páginasBuilding Construction-V: Types of Metal CladdingShrish BaglaAinda não há avaliações

- Bubble Leak Testing Level I - Questionaire: Southern Inspection ServicesDocumento8 páginasBubble Leak Testing Level I - Questionaire: Southern Inspection Servicesprabhakaran.SAinda não há avaliações

- PIB 229 - PlastiSpan 20 Insulation Material Property Data Sheet-1Documento1 páginaPIB 229 - PlastiSpan 20 Insulation Material Property Data Sheet-1Bojan BjelajacAinda não há avaliações

- 2 2002 Barkaukas Concrete Contruction ManualDocumento294 páginas2 2002 Barkaukas Concrete Contruction ManualpelinAinda não há avaliações

- The Feasibility Study of Using Oyster Shells As Substitute in Manufacturing BricksDocumento27 páginasThe Feasibility Study of Using Oyster Shells As Substitute in Manufacturing BricksDarla MamuyacAinda não há avaliações

- Surface Vehicle Standard: Rev. SEP81Documento48 páginasSurface Vehicle Standard: Rev. SEP81anupthattaAinda não há avaliações

- Damp ProofingDocumento15 páginasDamp ProofingKhushboo PriyaAinda não há avaliações

- Revision of IS 456 & IS 1343 - SummaryDocumento3 páginasRevision of IS 456 & IS 1343 - Summaryshiv paa0% (1)

- Study The Correlation of Clinker Quality, Reside, PSD On The Performance of Portland CementDocumento12 páginasStudy The Correlation of Clinker Quality, Reside, PSD On The Performance of Portland CementIAEME PublicationAinda não há avaliações

- Chemical Resistance Guide For Valves: Val-Matic Valve and Manufacturing CorpDocumento13 páginasChemical Resistance Guide For Valves: Val-Matic Valve and Manufacturing CorpEdinsonAinda não há avaliações