Escolar Documentos

Profissional Documentos

Cultura Documentos

ASSAB Tool Steel Performance Comparison Chart PDF

Enviado por

Sophian Hakim WirajayaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

ASSAB Tool Steel Performance Comparison Chart PDF

Enviado por

Sophian Hakim WirajayaDireitos autorais:

Formatos disponíveis

ASSAB Tool Steel Performance Comparison Chart

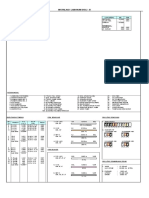

Reference Standard Hardness Chemical Composition % Austenising Range of

ASSAB Grade Uddeholm Grade Characteristics Applications

AISI WNr. JIS Supplied C Si Mn Cr Mo W V Others Temp. oC Hardness

Cold Work

Cutting : blanking, punching, shearing, trimming.

General purpose oil hardening tool steel with good surface hardness and

ASSAB DF-3 ARNE O1 1.2510 SKS 3 HB 190 0.95 0.3 1.1 0.5 - 0.5 0.1 - 790-850 56-62 wear resistance. Forming : bending, drawing, rim rolling, spinning, flow forming.

Gauges and measuring tools.

ASSAB XW-5 SVERKER 3 D6 (D3) (1.2436) (SKD 2) HB 240 2.05 0.3 0.8 12.7 - 1.1 - - 920-1000 56-62 A 12% Cr, high carbon tool steel with excellent abrasive wear resistance. Blanking, punching, cropping, shearing, trimming and clipping.

Good hardenability, wear resistance and excellent size stability for Blanking, punching, piercing, cropping, shearing, trimming and moulds for

ASSAB XW-10 RIGOR A2 1.2363 SKD 12 HB 215 1.0 0.3 0.6 5.3 1.1 - 0.2 - 925-970 56-62 medium runs. abrasive plastics.

ASSAB XW-42 SVERKER 21 D2 1.2379 SKD 11 HB 210 1.55 0.3 0.4 11.3 0.8 - 0.8 - 990-1080 58-63 A 12% Cr tool steel with high wear resistance and strength. Blanking, fine blanking, punching, cropping, shearing, trimming and clipping.

A general steel with high toughness, good wear resistance and polishability. Moulds for the production of electrical components. Typical for blanking

CALMAX CALMAX 1.2358 HB 200 0.6 0.35 0.8 4.5 0.5 - 0.2 - 950-970 52-59 dies with high demands on toughness.

HB 225 Versatile with an excellent combination of toughness and wear resistance Suitable for chipper-knives, heavy duty blanking, forming and also abrasive

VIKING VIKING / CHIPPER (max) 0.5 1.0 0.5 8.0 1.5 - 0.5 - 980-1050 52-59 required for chipper-knives, heavy duty blanking and forming. plastic parts.

HB 215 Very good chipping and cracking resistance with high compressive Cold forging, forming dies, fine blanking and heavy duty blanking, thread

CALDIE CALDIE (max) 0.7 0.2 0.5 5.0 2.3 - 0.5 - 1000-1050 56-61 strength. Suitable for PVD coating to maximise wear resistance. rolling dies and coining dies. Suitable for AHSS automotive parts.

Mixed-abrasive profile, good resistance to chipping, good machining and Blanking, fine blanking, shearing, forming, coining, cold forging, cold

ASSAB 88 SLEIPNER HB 235 0.9 0.9 0.5 7.8 2.5 - 0.5 - 950-1080 58-64 WEDM properties. extrusion, thread rolling, drawing, deep drawing and powder pressing.

Plastic Mould

Pre-hardened plastic mould steel with good polishability and machinability. Injection moulds and extrusion dies for thermoplastics, blow moulds,

ASSAB 618 HH (P20) 1.2738 HB 340-380 0.37 0.3 1.4 2.0 0.2 - - Ni 1.0 Pre-hardened, no hardening is needed. forming tools, machine components, structural components and shafts.

Pre-hardened mould steel with exceptional through hardening properties, Suitable for large and very large moulds where there is high demand on

ASSAB 618 T (P20) (1.2738) HB 310-355 0.26 0.1 1.45 1.25 0.6 - 0.12 Ni 1.05 Pre-hardened, no hardening is needed. good polishability and etching properties combined with good machinability. surface finish.

Injection moulds and extrusion dies for thermoplastics, blow moulds,

ASSAB 718 HH IMPAX HH (P20) 1.2738 HB 340-380 0.37 0.3 1.4 2.0 0.2 - - Ni 1.0 Pre-hardened, no hardening is needed. Pre-hardened plastic mould steel with very good polishability. forming tools, machine components, structural components and shafts.

Mould for plastic injection (e.g. packaging containers, automotive interior

Pre-hardened mould steel with best toughness, good machinability and parts, reflectors, panels and handles for appliances), holder material for

NIMAX NIMAX HB 360-400 0.1 0.3 2.5 3.0 0.3 - - Ni 1.0 Pre-hardened, no hardening is needed. very good polishability. forging, diecasting dies, cutting tools, hot runner manifolds and structural

components.

Injection moulds and blow moulding for corrosive plastics. Plastic

Ni 0.6 Pre-hardened corrosion-resistant mould steel. It has very good

MIRRAX 40 MIRRAX 40 (420) HB 360-400 0.21 0.9 0.45 13.5 0.2 - 0.25 +N Pre-hardened, no hardening is needed. machinability, toughness and polishing properties. moulding of high surface finish parts (e.g. Bezels and casings for LED/LCD).

PET bottles and construction parts.

Ni 1.3 Stainless mould steel with a unique combination of toughness, corrosion For all types of moulds, especially suited for larger tools where corrosion

MIRRAX ESR MIRRAX ESR (420) HB 250 0.25 0.3 0.5 13.3 0.3 - 0.3 +N 1000-1025 44-52 resistance and through-hardening properties. in production is unacceptable and where high surface finish is required.

Stainless plastic mould steel with excellent polishability and corrosion Injection moulds for highly polished parts and for moulding corrosive

STAVAX ESR STAVAX ESR (420) (1.2083) (SUS 420J2) HB 190 0.38 0.9 0.5 13.6 - - 0.3 - 1000-1050 44-52 resistance. plastics.

For general hot work and plastic moulds. Specifically used where high

Suitable for both hot work and plastic mould applications, especially large toughess and high surface requirements are needed in large plastic

VIDAR 1 ESR VIDAR 1 ESR H11 1.2343 SKD 6 HB 185 0.38 1.0 0.4 5.0 1.3 - 0.4 - 990-1010 44-52 plastic moulds that require good toughness in combination with high moulds, such as lens, extension and reflector moulds for Automotive

surface finish obtained by polishing or texturing. lighting systems.

High hardness and very good toughness. ESR for excellent polishability. Plastic moulds for abrasive plastics. Suitable for heavy blanking, powder

UNIMAX UNIMAX HB 185 0.5 0.2 0.5 5.0 2.3 - 0.5 - 1000-1025 52-58 Suitable for coating and nitriding. compacting as well as for warm forging.

S 0.12 Holders/bolsters for plastic moulds, plastic and rubber moulds with

Stainless steel for holder blocks with excellent machinability and

ROYALLOY ROYALLOY (420 F) HB 290-330 0.05 0.4 1.2 12.6 - - - +N Pre-hardened, no hardening is required. corrosion resistance. low requirements on polishability, dies for plastic extrusion and for

+Cu constructional parts.

Excellent polishability, good machinability and good resistance to Recommended where extreme surface finishes are required, such as lens

POLMAX POLMAX (420) (1.2083) (SUS 420J2) HB 200 0.38 0.9 0.5 13.6 - - 0.3 - 1000-1050 46-52 corrosion and wear. moulds and CD moulds.

Ni 9.2 Injection moulds for corrosive plastics, rubber, medical and food industry,

CORRAX CORRAX HRC 34 0.03 0.3 0.3 12.0 1.4 - - Al 1.6 Age hardening to HRC 40-51 Age hardening stainless steel with superior corrosion resistance. extrusion dies, and engineering parts.

Pre-hardened, do not have a solid solution High-strength beryllium copper mould alloy supplied at approx. 40 HRC, Blow moulds : pinch offs, neck rings and handle inserts.

ASSAB MM40 HRC 40 Be 1.9 (Co+Ni) 0.25 Cu Bal. and aging treatment suitable where a combination of high thermal conductivity, corrosion Injection moulds : moulds, cores and inserts.

resistance and polishablity is needed. Injection nozzles and manifolds for hot runner systems.

Hot Work

High performance hot work tool steel with very good resistance to heat Excellent choice for die casting of aluminium and magnesium, hot stamping,

DIEVAR DIEVAR HB 160 0.35 0.2 0.5 5.0 2.3 - 0.6 - 1000-1030 44-52 checking, gross cracking, hot wear and plastic deformation. forging, and aluminium extrusion.

ASSAB 8407 ORVAR H13 Meets and exceeds NADCA 207-2011 specification for premium die Suitable for high pressure die casting, hot extrusion, press forging tools

SUPREME SUPREME Premium 1.2344 SKD 61 HB 180 0.39 1.0 0.4 5.2 1.4 - 0.9 - 1020-1050 44-52 casting materials. and moulds for plastics.

Hot work tool steel with overall good ductility, toughness, wear

ASSAB 8407 2M ORVAR 2M H13 1.2344 SKD 61 HB 185 0.39 1.0 0.4 5.3 1.3 - 0.9 - 1020-1050 42-52 resistance, hardenability and machinability. Tools for extrusion, hot forging and pressing and moulds for plastics.

Die casting dies and associated tooling, extrusion dies and extrusion

QRO 90 SUPREME QRO 90 SUPREME HB 180 0.38 0.3 0.8 2.6 2.3 - 0.9 - 1020-1050 42-52 Highest temperature strength and very good thermal fatigue resistance. tooling, forging dies, esp. for copper and brass and hot stamping dies.

HB 230 Good temper resistance and higher temperature strength than H13 type

FORMVAR FORMVAR (max) 0.35 0.2 0.5 5.0 2.3 - 0.6 - 1000-1030 44-52 steel. Tools for hot forging and extrusion.

Powder Metallurgy

ASSAB PM 23 VANADIS 23 HB 260 Powder high speed steel with excellent wear resistance and toughness. Blanking of medium to high carbon steel, blanking of harder materials.

(M3:2) 1.3395 (SKH 53) (max) 1.28 - - 4.2 5.0 6.4 3.1 - 1050-1180 60-65 Suitable for very long runs. Moulds for very abrasive plastics and IC moulds.

SUPERCLEAN SUPERCLEAN

ASSAB PM 30 VANADIS 30 Suitable for chip forming multi-edge cutting tools, single-edge cutting

HB 300 Powder high speed steel for cutting tools with excellent wear resistance,

(M3:2 + Co) 1.3294 SKH 40 (max) 1.28 - - 4.2 5.0 6.4 3.1 Co 8.5 1050-1180 60-66 toughness and good hot hardness. tools, cold work applications with high demands on wear resistance and

SUPERCLEAN SUPERCLEAN IC moulds.

ASSAB PM 60 VANADIS 60 HB 340 Powder high speed steel for cutting tools with excellent wear resistance, Suitable for chip forming multi-edge cutting tools, single-edge cutting tools

(1.3292) (max) 2.3 - - 4.2 7.0 6.5 6..5 Co 10.5 1100-1180 60-68 toughness and excellent hot hardness. and cold work applications with high demands on wear resistance.

SUPERCLEAN SUPERCLEAN

VANADIS 4 EXTRA VANADIS 4 EXTRA HB 230 1.4 0.4 0.4 4.7 3.5 - 3.7 - 950-1150 58-64 Powder tool steel for long run tooling, where high demands on adhesive Blanking, fine blanking, forming of thicker work material, esp. austenitic

SUPERCLEAN SUPERCLEAN wear and chipping resistance is required. stainless steel. mild carbon steel, AHSS, copper and aluminium.

VANADIS 8 VANADIS 8 HB 270 2.3 0.4 0.4 4.8 3.6 - 8.0 - 1020-1080 58-64 Powder tool steel for very long run tooling ,where abrasive wear Blanking, forming, fine blanking, deep drawing, cold forging and powder

SUPERCLEAN SUPERCLEAN resistance and good toughness is required. compacting,

VANCRON 40 VANCRON 40 HB 300 1.1 0.5 0.4 4.5 3.2 3.7 8.5 N 1.8 950-1150 58-65 A nitrided powder tool steel for the very best resistance to galling and Blanking, fine blanking, deep drawing, bending powder compacting of soft

SUPERCLEAN SUPERCLEAN adhesive wear. Normally no coating is necessary. and adhesive metals.

ELMAX ELMAX HB 280 1.7 0.8 0.3 18.0 1.0 - 3.0 - 1050-1100 56-60 Powder tool steel and stainless plastic mould steel with high wear and Electronics industry: connectors, plugs, switches, resistors and integrated

SUPERCLEAN SUPERCLEAN corrosion resistance. circuits.

( ) - modified grade

www.assab.com This information is based on our present state of knowledge and is intended to provide general notes on our products and their uses. It should not therefore be construed as a warranty of specific properties of the products described or a warranty for fitness for a particular purpose. Edition 160921

Você também pode gostar

- ASSAB Tool Steel Performance Comparison ChartDocumento1 páginaASSAB Tool Steel Performance Comparison ChartNugroho Faris Sudrajat100% (2)

- Improving Die Casting Melt QualityDocumento12 páginasImproving Die Casting Melt QualityCsaba WalczerAinda não há avaliações

- Die Casting GuidelinesDocumento12 páginasDie Casting GuidelinesMichael Arvin GabineteAinda não há avaliações

- 111th Metalcasting Congress NadcaDocumento12 páginas111th Metalcasting Congress NadcaMehwishYasmenAinda não há avaliações

- Casting Processes: DR Ajay BatishDocumento46 páginasCasting Processes: DR Ajay BatishAlisha GuptaAinda não há avaliações

- Roll ForgingDocumento6 páginasRoll ForgingSaptarshi SinhaAinda não há avaliações

- Aluminio TestsDocumento14 páginasAluminio TestsPaco RotenAinda não há avaliações

- NADCA-High Temp DieDocumento12 páginasNADCA-High Temp DiejalilemadiAinda não há avaliações

- Foundry ProcessDocumento54 páginasFoundry ProcessgovindarajaluvAinda não há avaliações

- Sandvik Part - 1 PDFDocumento38 páginasSandvik Part - 1 PDFEliel AbadAinda não há avaliações

- VacuumDocumento6 páginasVacuum03sri03Ainda não há avaliações

- Fast Flow Channel SimulationDocumento4 páginasFast Flow Channel Simulationgrg_greAinda não há avaliações

- HPDC Thermal Die CyclingDocumento5 páginasHPDC Thermal Die CyclingSimon RisteskiAinda não há avaliações

- Semi Solid Metal CastingDocumento2 páginasSemi Solid Metal CastingSuresh KumarAinda não há avaliações

- Casting Technology: DC School Text BookDocumento23 páginasCasting Technology: DC School Text BookmikeAinda não há avaliações

- Computer Aided Manufacturability Analysis of Die-Cast Parts: Pvmrao@mech - Iitd.ac - in Tkkundra@mech - Iitd.ac - inDocumento12 páginasComputer Aided Manufacturability Analysis of Die-Cast Parts: Pvmrao@mech - Iitd.ac - in Tkkundra@mech - Iitd.ac - indamonlanglois100% (1)

- HPDC Runner and Gating System DesignDocumento18 páginasHPDC Runner and Gating System DesignMNAinda não há avaliações

- Gating SystemDocumento27 páginasGating SystemAnup Tigga75% (4)

- Casting IntroDocumento94 páginasCasting IntroJith ViswaAinda não há avaliações

- 2c-CASTING DESIGN ECONOMICSDocumento18 páginas2c-CASTING DESIGN ECONOMICSIzzat IkramAinda não há avaliações

- A Study of Casting Characteristics For Die Cast Aluminum Alloy-Anwar HussainDocumento23 páginasA Study of Casting Characteristics For Die Cast Aluminum Alloy-Anwar Hussainoquintero99100% (2)

- HPDCdesign Basic PrinciplesDocumento9 páginasHPDCdesign Basic PrinciplesGanesan ThangasamyAinda não há avaliações

- Metal Casting Design: Mold and Gating System Design, Directional Solidification, and TroubleshootingDocumento7 páginasMetal Casting Design: Mold and Gating System Design, Directional Solidification, and TroubleshootingzidaaanAinda não há avaliações

- Casting Simulation & Study CaseDocumento37 páginasCasting Simulation & Study CaseRosalina KeziaAinda não há avaliações

- 1.6.1 Die Casting (Pressure Die Casting) : Module-I of Manufacturing Science-IDocumento8 páginas1.6.1 Die Casting (Pressure Die Casting) : Module-I of Manufacturing Science-IChinmay Das100% (2)

- Forging and ForgeabilityDocumento3 páginasForging and ForgeabilityjestinAinda não há avaliações

- Operator TrainingDocumento38 páginasOperator TrainingluisA1923Ainda não há avaliações

- Beta Die Casting Buyers GuideDocumento19 páginasBeta Die Casting Buyers Guidekaniappan sakthivel100% (1)

- Sand Casting and Other Casting ProcessesDocumento74 páginasSand Casting and Other Casting ProcessesRashid KareemAinda não há avaliações

- Forging, Rolling, Extrusion and Drawing ProcessesDocumento45 páginasForging, Rolling, Extrusion and Drawing ProcessesHarshan Arumugam100% (1)

- Gating-Risering Sec2Documento35 páginasGating-Risering Sec2jagan_4u100% (1)

- Diecasting DefectsDocumento14 páginasDiecasting DefectsEdwardAinda não há avaliações

- Introduction in Alloys and Influence of Elements: Alloys and Melting 01 - Alloys - and - Melting - EN - Docx 1/13Documento13 páginasIntroduction in Alloys and Influence of Elements: Alloys and Melting 01 - Alloys - and - Melting - EN - Docx 1/13luisA1923Ainda não há avaliações

- Fundamentals of Metal CastingDocumento45 páginasFundamentals of Metal CastingsuntharAinda não há avaliações

- Pushed Ejector Pins: Chapter Twenty-OneDocumento2 páginasPushed Ejector Pins: Chapter Twenty-Onegowrianand2000Ainda não há avaliações

- Heat TreatmentDocumento56 páginasHeat TreatmentAakarsh RastogiAinda não há avaliações

- Mold Material: H13 P20 Mirror Polish Texture H13 P20Documento1 páginaMold Material: H13 P20 Mirror Polish Texture H13 P20Jyoti KaleAinda não há avaliações

- Product Design For Sand CastingDocumento10 páginasProduct Design For Sand CastingChinmay Das100% (7)

- Aluminium Die Casting Lubrication Technology and Trends en v1Documento6 páginasAluminium Die Casting Lubrication Technology and Trends en v1g_nazario100% (1)

- Die Casting Die Design - Runner, Gate, EtcDocumento45 páginasDie Casting Die Design - Runner, Gate, EtcVig PankajAinda não há avaliações

- Tolerances For Aluminium Die CastingsDocumento3 páginasTolerances For Aluminium Die CastingsPurushothama Nanje GowdaAinda não há avaliações

- Casting TolerancesDocumento1 páginaCasting TolerancesKumaraswamy ViswanathanAinda não há avaliações

- Metalurgi PengecoranDocumento49 páginasMetalurgi PengecoranAdinda Trianandari WAinda não há avaliações

- A Runner-Gate DesignDocumento9 páginasA Runner-Gate DesignKetan ChhedaAinda não há avaliações

- Jet Cooling English Presentationv2Documento21 páginasJet Cooling English Presentationv2susu22200050% (2)

- Wear Analysis of Hard Faced Agricultural Equipment - Doc FFDocumento15 páginasWear Analysis of Hard Faced Agricultural Equipment - Doc FFSunil BasavarajuAinda não há avaliações

- Compound Die PDFDocumento4 páginasCompound Die PDFNhan Le100% (1)

- Casting TheoryDocumento22 páginasCasting TheoryJairam Atluri100% (1)

- Die Casting ProcessDocumento35 páginasDie Casting ProcessgarciarodrigoAinda não há avaliações

- Electrogalvanized Steel SheetDocumento34 páginasElectrogalvanized Steel SheetEstuardoAAinda não há avaliações

- Aluminum Alloy Specification'Documento12 páginasAluminum Alloy Specification'ArjunAinda não há avaliações

- Squeeze Casting - An Overview PDFDocumento9 páginasSqueeze Casting - An Overview PDFDian Try SaputriAinda não há avaliações

- Procast - ESI - Casting SimulationsDocumento14 páginasProcast - ESI - Casting Simulationsvmgobinath100% (2)

- Brochure For HPDC ProcessDocumento4 páginasBrochure For HPDC Processramaswamykama786Ainda não há avaliações

- ASSAB Tool Steel Performance Chart A4 enDocumento2 páginasASSAB Tool Steel Performance Chart A4 en631052Ainda não há avaliações

- Viking: Tool Steel For Heavy Duty Blanking and FormingDocumento9 páginasViking: Tool Steel For Heavy Duty Blanking and Formingkbwoniu123Ainda não há avaliações

- CZ 120Documento1 páginaCZ 120Taner DemirelAinda não há avaliações

- CZ120 (CW612N) : Technical DatasheetDocumento1 páginaCZ120 (CW612N) : Technical DatasheetAmrut KanungoAinda não há avaliações

- Equip. No: E1-GT - 1A: Pt. Badak NGL "PM" Machinery & Heavy Equipment Lubricating Oil Analysis DataDocumento172 páginasEquip. No: E1-GT - 1A: Pt. Badak NGL "PM" Machinery & Heavy Equipment Lubricating Oil Analysis DataSophian Hakim WirajayaAinda não há avaliações

- Stean Turbin Building: Inlet Culvert SectionDocumento1 páginaStean Turbin Building: Inlet Culvert SectionSophian Hakim WirajayaAinda não há avaliações

- Dearator 1of2Documento1 páginaDearator 1of2Sophian Hakim WirajayaAinda não há avaliações

- Dearator 2of2Documento1 páginaDearator 2of2Sophian Hakim WirajayaAinda não há avaliações

- JKNHHDocumento1 páginaJKNHHSophian Hakim WirajayaAinda não há avaliações

- ID Perancangan Termal Heat Recovery Steam GDocumento5 páginasID Perancangan Termal Heat Recovery Steam GSophian Hakim WirajayaAinda não há avaliações

- Tanggal Number Maximo Parameter Satuan: Log Sheet Unit HRSG 1.1 TANGGAL 01-04-2018 S/D 26-04-2018Documento69 páginasTanggal Number Maximo Parameter Satuan: Log Sheet Unit HRSG 1.1 TANGGAL 01-04-2018 S/D 26-04-2018Sophian Hakim WirajayaAinda não há avaliações

- P&i D GT HSD Oil (Common System) (s1-61443)Documento1 páginaP&i D GT HSD Oil (Common System) (s1-61443)Sophian Hakim WirajayaAinda não há avaliações

- Report LokalDocumento18 páginasReport LokalSophian Hakim WirajayaAinda não há avaliações

- 10 5923 J Ijee 20120205 03 PDFDocumento8 páginas10 5923 J Ijee 20120205 03 PDFSophian Hakim WirajayaAinda não há avaliações

- 7649 14697 1 SM PDFDocumento7 páginas7649 14697 1 SM PDFSophian Hakim WirajayaAinda não há avaliações

- Seebeck and Peltier EffectsDocumento8 páginasSeebeck and Peltier EffectskiranpatruduAinda não há avaliações

- Basic Functions of Mold Base Parts - Injection Mold Design Tutorial, Technology and EngineeringDocumento5 páginasBasic Functions of Mold Base Parts - Injection Mold Design Tutorial, Technology and EngineeringSophian Hakim WirajayaAinda não há avaliações

- Csr2015e PDFDocumento197 páginasCsr2015e PDFSophian Hakim WirajayaAinda não há avaliações

- Datfas Inst - LDL BDocumento1 páginaDatfas Inst - LDL BSophian Hakim WirajayaAinda não há avaliações

- Derating FactorDocumento2 páginasDerating FactorSophian Hakim WirajayaAinda não há avaliações

- ReadmeDocumento3 páginasReadmescribd4edAinda não há avaliações

- NYA 450-750vDocumento1 páginaNYA 450-750vDanur QahariAinda não há avaliações

- ReadmeDocumento3 páginasReadmescribd4edAinda não há avaliações

- Spec Kabel NYYDocumento2 páginasSpec Kabel NYYburhansuciptoAinda não há avaliações

- Depot 30.FAF4D8ECDocumento94 páginasDepot 30.FAF4D8ECSophian Hakim WirajayaAinda não há avaliações

- Depot 30.FAF4D8ECDocumento94 páginasDepot 30.FAF4D8ECSophian Hakim WirajayaAinda não há avaliações

- Fanuc MacroDocumento3 páginasFanuc MacroGopi Nath0% (1)

- Hollow Lateral Extrusion Stuttgart Rudolf Ifu StuttgartDocumento7 páginasHollow Lateral Extrusion Stuttgart Rudolf Ifu StuttgartjoaopedrosousaAinda não há avaliações

- GB-T 232-2010 Metallic Materials-Bend TestDocumento14 páginasGB-T 232-2010 Metallic Materials-Bend TestH. Camer E.Ainda não há avaliações

- Titanium Heat ExchangersDocumento13 páginasTitanium Heat Exchangersxo123456789Ainda não há avaliações

- Forgingforging ProcessDocumento13 páginasForgingforging Processpatel ketanAinda não há avaliações

- 003Documento13 páginas003Rene CamposAinda não há avaliações

- The Forging of Compressor and Turbine Blades: WellsDocumento2 páginasThe Forging of Compressor and Turbine Blades: Wellsffazlali0% (1)

- Jfe SteelDocumento44 páginasJfe SteelTuấn Phạm AnhAinda não há avaliações

- Steel Forgings, General Requirements: Standard Specification ForDocumento9 páginasSteel Forgings, General Requirements: Standard Specification ForNilton Santillan OrtegaAinda não há avaliações

- Zahoor&JajjaDocumento22 páginasZahoor&JajjaMuhammad Farhan AshrafAinda não há avaliações

- ASTM A503 A503-2015 (R2020) 大型曲轴锻件超声波检测的标准规范 双语Documento6 páginasASTM A503 A503-2015 (R2020) 大型曲轴锻件超声波检测的标准规范 双语Jinliang LiuAinda não há avaliações

- The Benefits of Forged Steel Gears - HofmannEng - MarkupDocumento11 páginasThe Benefits of Forged Steel Gears - HofmannEng - MarkupJorge VillalobosAinda não há avaliações

- Classic Metallic Brochure 2010Documento24 páginasClassic Metallic Brochure 2010JayeshAinda não há avaliações

- ThyssenKrupp Drilling CatálogoDocumento16 páginasThyssenKrupp Drilling Catálogoflasher_for_nokiaAinda não há avaliações

- Hot Metal FormingDocumento12 páginasHot Metal FormingKiran DuggarajuAinda não há avaliações

- Plastic Deformation Tool Die Yield STR Ength Geometry of The Die. Stresses Applied Co Mpressive Stretch Bend Shear StressesDocumento102 páginasPlastic Deformation Tool Die Yield STR Ength Geometry of The Die. Stresses Applied Co Mpressive Stretch Bend Shear StressesEbrahim AliAinda não há avaliações

- Determining The Inclusion Content of Steel: Standard Test Methods ForDocumento15 páginasDetermining The Inclusion Content of Steel: Standard Test Methods ForKenny Andrea Calderon OrozcoAinda não há avaliações

- 10 FORGING TECHNOLOGY New 1Documento43 páginas10 FORGING TECHNOLOGY New 1Alfred KuwodzaAinda não há avaliações

- Forging PresentationDocumento17 páginasForging PresentationRakesh PuriAinda não há avaliações

- Ugima 4404 HMDocumento3 páginasUgima 4404 HMReginaldoAinda não há avaliações

- MSRR 6522Documento7 páginasMSRR 6522pradellesAinda não há avaliações

- Part L EQUIPMENT 430 - Erstl - L - Egstl - L-CV - 2013Documento63 páginasPart L EQUIPMENT 430 - Erstl - L - Egstl - L-CV - 2013Dave DumontAinda não há avaliações

- BTG ValvesDocumento20 páginasBTG ValvesShivakumarAinda não há avaliações

- 02 Samss 011Documento36 páginas02 Samss 011OMER ELFADILAinda não há avaliações

- Internship ReportDocumento16 páginasInternship ReportAshu DrwalAinda não há avaliações

- Steel Forgings, Carbon and Alloy, For Pinions, Gears and Shafts For Reduction GearsDocumento5 páginasSteel Forgings, Carbon and Alloy, For Pinions, Gears and Shafts For Reduction GearsDanZel DanAinda não há avaliações

- Ultrasonic Testing of Austenitic and Austenitic Ferritic Stainless Steel ForgingsDocumento17 páginasUltrasonic Testing of Austenitic and Austenitic Ferritic Stainless Steel ForgingsAlvice Max100% (1)

- Manufacturing Method of Cotter JointDocumento10 páginasManufacturing Method of Cotter JointAkshay Jadhav33% (6)

- 2012 ASCE Dynamic Effects of Impact Machine FoundationsDocumento17 páginas2012 ASCE Dynamic Effects of Impact Machine FoundationsBilal LoveAinda não há avaliações

- Operation Manual For MSMEDocumento61 páginasOperation Manual For MSMESaran RpAinda não há avaliações