Escolar Documentos

Profissional Documentos

Cultura Documentos

Astm Sa 192

Enviado por

arifin rizalTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Astm Sa 192

Enviado por

arifin rizalDireitos autorais:

Formatos disponíveis

SPECIFICATION FOR SEAMLESS CARBON STEEL

BOILER TUBES FOR HIGH-PRESSURE SERVICE

SA-192/SA-192M

(Identical with ASTM Specification A 192/A 192M-91)

1. Scope 2. Referenced Documents

1.1 This specification covers minimum-wall thickness, 2.1 ASTM Standards:

seamless carbon steel boiler and superheater tubes for A 450/A 450M Specification for General Requirements

high-pressure service. for Carbon, Ferritic Alloy, and Austenitic Alloy Steel

Tubes

A 520 Specification for Supplementary Requirements for

1.2 The tubing sizes and thicknesses usually furnished Seamless and Electric-Resistance-Welded Carbon

to this specification are 1⁄2 in. to 7 in. [12.7 to 177.8 Steel Tubular Products for High-Temperature Service

mm] outside diameter and 0.085 to 1.000 in. [2.2 to Conforming to ISO Recommendations for Boiler Con-

25.4 mm], inclusive, in minimum wall thickness. Tubing struction

having other dimensions may be furnished, provided

such tubes comply with all other requirements of this

specification. 3. General Requirements

3.1 Material furnished under this specification shall

conform to the applicable requirements of the current

1.3 Mechanical property requirements do not apply edition of Specification A 450/A 450M, unless otherwise

to tubing smaller than 1⁄8 in [3.2 mm] inside diameter provided herein.

or 0.015 in. [0.4 mm] thickness.

4. Ordering Information

1.4 When these products are to be used in applications

conforming to ISO Recommendations for Boiler Con- 4.1 Orders for material under this specification should

struction, the requirements of Specification A 520 shall include the following, as required, to described the

supplement and supersede the requirements of this desired material adequately:

specification. 4.1.1 Quantity (feet, metres, or number of lengths),

4.1.2 Name of material (seamless tubes),

1.5 The values stated in either inch-pound units or 4.1.3 Manufacture (hot-finished or cold-drawn),

SI units are to be regarded separately as standard.

Within the text, the SI units are shown in brackets. The 4.1.4 Size (outside diameter and minimum wall

thickness),

values stated in each system are not exact equivalents;

therefore, each system must be used independently of 4.1.5 Length (specific or random),

the other. Combining values from the two systems may

4.1.6 Optional Requirements (Section 8),

result in nonconformance with the specification. The

inch-pound units shall apply unless the “M” designation 4.1.7 Test report required (see section on Certifica-

of this specification is specified in the order. tion of Specification A 450/A 450M),

274

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

PART A — FERROUS MATERIAL SPECIFICATIONS SA-192/SA-192M

4.1.8 Specification designation, and NOTE — A lot consists of 250 tubes for sizes 3 in. [76.2 mm]

and under and of 100 tubes for sizes over 3 in. [76.2 mm], prior

4.1.9 Special requirements. to cutting to length.

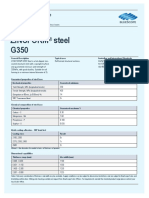

5. Manufacture 9. Hardness Requirements

5.1 Tubes shall be made by the seamless process 9.1 The tubes shall have a hardness number not

and shall be either hot-finished or cold-finished, as exceeding the following:

specified. Brinell Hardness Number Rockwell Hardness

(Tubes 0.200 in. [5.1 Number (Tubes less than

mm] and over in wall 0.200 in. [5.1 mm] in

thickness) wall thickness)

6. Heat Treatment 137 HB 77 HRB

6.1 Hot-finished tubes need not be heat treated. Cold-

finished tubes shall be heat treated after the final cold-

finished at a temperature of 1200°F [650°C] or higher. 10. Mechanical Tests Required

10.1 Flattening Test — One flattening test shall be

made on specimens from each of two tubes selected

7. Chemical Composition

from each lot (see Note) or fraction thereof.

7.1 The steel shall conform to the following require-

ments as to chemical composition: 10.2 Flaring Test — One flaring test shall be made

on specimens from each end of two tubes selected

from each lot (see Note) or fraction thereof. These

Carbon, % 0.06–0.18

Manganese, % 0.27–0.63 tubes shall be selected apart from those used for the

Phosphorus, max 0.035 flattening test.

Sulfur, max, % 0.035

Silicon, max, % 0.25 10.3 Hardness Test — Brinell or Rockwell hardness

tests shall be made on specimens from two tubes from

7.2 Supplying an alloy grade of steel that specifically each lot. The term lot applies to all tubes prior to

requires the addition of any element other than those cutting, of the same nominal diameter and wall thickness

listed in 7.1 is not permitted. which are produced from the same heat of steel. When

final heat treatment is in a batch-type furnace, a lot

shall include only those tubes of the same size and

the same heat which are heat treated in the same

8. Product Analysis furnace charge. When the final heat treatment is in a

8.1 When requested on the purchase order, a product continuous furnace, a lot shall include all tubes of the

analysis shall be made by the supplier from one tube same size and heat, heat treated in the same furnace

per 100 pieces for sizes over 3 in. [76.2 mm] and one at the same temperature, time at heat, and furnace

tube per 250 pieces for sizes 3 in. [76.2 mm] and speed.

under; or when tubes are identified by heat, one tube

10.4 Hydrostatic Test — Each tube shall be subjected

per heat shall be analyzed. The chemical composition

to the hydrostatic pressure test, or instead of this test,

thus determined shall conform to the requirements

a nondestructive test may be used when specified by

specified.

the purchaser.

8.2 If the original test for product analysis fails,

retests of two additional billets or tubes shall be made.

Both retests, for the elements in question shall meet

11. Forming Operations

the requirements of the specification; otherwise all

remaining material in the heat or lot (see Note) shall 11.1 Tubes when inserted in the boiler shall stand

be rejected or, at the option of the producer, each billet expanding and beading without showing cracks or flaws.

or tube may be individually tested for acceptance. Superheater tubes when properly manipulated shall stand

Billets or tubes which do not meet the requirements all forging, welding, and bending operations necessary

of the specification shall be rejected. for application without developing defects.

275

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

SA-192/SA-192M 2001 SECTION II

12. Product Marking

12.1 In addition to the marking prescribed in Specifi-

cation A 450/A 450M, the marking shall indicate

whether the tube is hot finished or cold finished.

EXPLANATORY NOTE

NOTE — For purposes of design, the following tensile properties may be assumed:

Tensile strength, min, ksi [MPa] 47 [325]

Yield strength, min, ksi [MPa] 26 [180]

Elongation in 2 in. or 50 mm, min, % 35

276

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

Você também pode gostar

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Flow Computer Printer: To EhkDocumento1 páginaFlow Computer Printer: To Ehkarifin rizalAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Astm Sa 234 PDFDocumento11 páginasAstm Sa 234 PDFarifin rizalAinda não há avaliações

- HDD Kalimas RiverDocumento14 páginasHDD Kalimas Riverarifin rizalAinda não há avaliações

- Astm e 562 DSSDocumento7 páginasAstm e 562 DSSarifin rizal100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Astm Sa 516Documento4 páginasAstm Sa 516arifin rizalAinda não há avaliações

- Forged Carbon and Alloy Steel Flanges For Low-Temperature ServiceDocumento5 páginasForged Carbon and Alloy Steel Flanges For Low-Temperature Servicegaso99Ainda não há avaliações

- Daftar Sop Departemen O&M Operasi Checklist MaintenanceDocumento2 páginasDaftar Sop Departemen O&M Operasi Checklist Maintenancearifin rizalAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- ASTM B 251 Cu and Cu Alloy TubeDocumento8 páginasASTM B 251 Cu and Cu Alloy Tubearifin rizalAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Astm A 928 Dss Pipe EfwDocumento6 páginasAstm A 928 Dss Pipe Efwarifin rizalAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Astm B 865Documento6 páginasAstm B 865arifin rizalAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Astm Sa 193Documento18 páginasAstm Sa 193arifin rizalAinda não há avaliações

- Astm D 2846-D 2846M (CPVC)Documento11 páginasAstm D 2846-D 2846M (CPVC)arifin rizal100% (2)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Calculation of PumpDocumento19 páginasCalculation of Pumparifin rizal100% (1)

- Rubber Hose For Automotive Air and Vacuum Brake System: Standard Test Methods ForDocumento5 páginasRubber Hose For Automotive Air and Vacuum Brake System: Standard Test Methods Forarifin rizalAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Piping Fittings CalculatorDocumento12 páginasPiping Fittings Calculatorarifin rizalAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Jalur Pipa Gas Tambun - Tegal Gede 8 Inch X 35 KM Kurva S Pekerjaan Pemasangan Sistem Proteksi KatodikDocumento2 páginasJalur Pipa Gas Tambun - Tegal Gede 8 Inch X 35 KM Kurva S Pekerjaan Pemasangan Sistem Proteksi Katodikarifin rizalAinda não há avaliações

- Astm A6Documento63 páginasAstm A6arifin rizalAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Total Sisa PipaDocumento1 páginaTotal Sisa Pipaarifin rizalAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Pemanfaatan LNG Sebagai Sumber Energi Di IndonesiaDocumento7 páginasPemanfaatan LNG Sebagai Sumber Energi Di IndonesiaSyarif MuhammadAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Specification For Hot-Rolled Structural Steel Sections: Kenya StandardDocumento28 páginasSpecification For Hot-Rolled Structural Steel Sections: Kenya StandardKalpeshAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- محاضرات تحليل انشائي الخزاناتDocumento50 páginasمحاضرات تحليل انشائي الخزاناتdadhouAinda não há avaliações

- Ahi Evran Sunum enDocumento26 páginasAhi Evran Sunum endenizakbayAinda não há avaliações

- Design of Bearing Bolts Subjected To Eccentric Loading Causing Moment in The Plane Perpendicular To The Plane of Group of BoltsDocumento8 páginasDesign of Bearing Bolts Subjected To Eccentric Loading Causing Moment in The Plane Perpendicular To The Plane of Group of BoltsKathleen RossAinda não há avaliações

- Fiber Composites6Documento61 páginasFiber Composites6NounaAinda não há avaliações

- Sika PDS E Sika - 101aDocumento2 páginasSika PDS E Sika - 101alwin_oo2435Ainda não há avaliações

- Design BriefDocumento216 páginasDesign BriefGia Vinh Bui TranAinda não há avaliações

- Evaluate Stresses From Ansys Caesar II or Any Other Program For Fatigue - High TempDocumento4 páginasEvaluate Stresses From Ansys Caesar II or Any Other Program For Fatigue - High TempEsapermana RiyanAinda não há avaliações

- l10752 4000 Series Cement Plant Elevator Chain BrochureDocumento4 páginasl10752 4000 Series Cement Plant Elevator Chain BrochureUrip S. SetyadjiAinda não há avaliações

- Prestressed Concrete Analysis and Design Fundamentals 2nd Ed CAP 13Documento76 páginasPrestressed Concrete Analysis and Design Fundamentals 2nd Ed CAP 13Carlos Alberto Pacheco SierraAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Imperfection Analysis On The Patch Loading Resistance of Girders With OpenDocumento11 páginasImperfection Analysis On The Patch Loading Resistance of Girders With OpenKariim DiíbAinda não há avaliações

- Luran S 797se: Acrylonitrile Styrene Acrylate (ASA)Documento3 páginasLuran S 797se: Acrylonitrile Styrene Acrylate (ASA)bobAinda não há avaliações

- PLAXIS 2D CE V20.00 Tutorial Lesson 08Documento19 páginasPLAXIS 2D CE V20.00 Tutorial Lesson 08Safwat El RoubyAinda não há avaliações

- Lee Jun Hong FYP2 ReportDocumento65 páginasLee Jun Hong FYP2 Report伍家宏Ainda não há avaliações

- Boundary WallsDocumento39 páginasBoundary WallsvengadAinda não há avaliações

- ISIS EC Module 2Documento27 páginasISIS EC Module 2Ibrahim AdelAinda não há avaliações

- Mechanical Properties 301015Documento47 páginasMechanical Properties 301015Eugene Daga-angAinda não há avaliações

- Jubin MOTAMEDDocumento522 páginasJubin MOTAMEDMaurício Ferreira100% (1)

- Pushover Analysis Using ETABS and SAP2000Documento194 páginasPushover Analysis Using ETABS and SAP2000apirakq86% (22)

- Ac 133Documento7 páginasAc 133thirumalaichettiar100% (2)

- Machine Tool Structures PDFDocumento10 páginasMachine Tool Structures PDFMohan Nanjan S50% (2)

- EI ServicesDocumento2 páginasEI ServicesAnonymous P8Bt46mk5IAinda não há avaliações

- AWD D1.8 Seismic Supplement - 2Documento4 páginasAWD D1.8 Seismic Supplement - 2mrezaiAinda não há avaliações

- Ductile Iron ValvesDocumento44 páginasDuctile Iron ValvesCattleya MalaikaAinda não há avaliações

- Title: Properties of Steel Self Learning Assessment (Problem Set)Documento14 páginasTitle: Properties of Steel Self Learning Assessment (Problem Set)Migaea AndresAinda não há avaliações

- Fiberhome Technologies: Cfoa-Sm-As300-S-24 NRDocumento6 páginasFiberhome Technologies: Cfoa-Sm-As300-S-24 NRriltomaraquinoAinda não há avaliações

- Project On Partial Replacement of Cement With Marble PowderDocumento8 páginasProject On Partial Replacement of Cement With Marble PowderYu Paing HanAinda não há avaliações

- Steel Cable Creates Novel Structural Space SystemsDocumento11 páginasSteel Cable Creates Novel Structural Space Systemsuhu_plus6482Ainda não há avaliações

- Spring Dowel SpiralDocumento24 páginasSpring Dowel SpiraldineshkshirsagarAinda não há avaliações

- A Place of My Own: The Architecture of DaydreamsNo EverandA Place of My Own: The Architecture of DaydreamsNota: 4 de 5 estrelas4/5 (242)