Escolar Documentos

Profissional Documentos

Cultura Documentos

SOP For Dye Sealing Test For Anodized Aluminium

Enviado por

Suraj RawatTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

SOP For Dye Sealing Test For Anodized Aluminium

Enviado por

Suraj RawatDireitos autorais:

Formatos disponíveis

SOP FOR DYE SEALING TEST FOR ANODIZED ALUMINIUM

OBJECTIVE & SIGNIFICANCE OF TEST:- The purpose of sealing an Anodic coating is to

close the pore structure of the anodic film & render the film inert. This is accomplished by

chemically changing the surface oxide structure through hydration with hot water & metallic based

sealing compounds. This sealing process useful for Non staining, Non absorbing, Non reacting, Non

corroding properties. To check the effectiveness of sealing process, dye sealing test is

recommended. It is test of ability of Anodized coating to absorb dyestuffs under specified

conditions.

CHEMICAL REAGENTS:- 1:3 Nitric Acid, Mercuric Blue Dye

PROCEDURE:-

1. Clean the Aluminum Anodized surface with tap running water to remove any dirt, dust etc.

2. Put 2 – 3 drops of 1:3 Nitric Acid on anodized surface with the help of glass rod for Etching

purpose. Wait for 2 minutes.

3. After 2 minutes, clean the anodized surface with tap running water.

4. Then put 2 – 3 drops of Mercuric blue dye on Etched surface with the help of glass rod and

allow it for 2 – 3 minutes for better penetration of dye.

5. Then again clean the test area with tap running water & wipe it with dry cloth & then observe

for any stain marks of dye remains on the surface by visually.

6. Acceptance Criteria – More than 90 % dye stain marks should get invisible.

DO’S & DON’T:-

1. Before the test clean the test specimen properly to remove any surface contaminations.

2. Use separate Glass rods for Nitric Acid & dye respectively.

3. Handle the dye carefully otherwise the dye stain marks on cloths will not be easily get

removed.

SAFETY PRACUATIONS:-

1. Use Rubber hand gloves and safety goggles while handling the Nitric Acid.

2. Diluted Nitric acid should be kept in air tight glass bottle with proper identification.

Você também pode gostar

- Anodizing Ver 1Documento14 páginasAnodizing Ver 1aditya_welekarAinda não há avaliações

- Qualanod SpecDocumento62 páginasQualanod SpecwilliamAinda não há avaliações

- Hard Chrome 105 Plating ProcesDocumento3 páginasHard Chrome 105 Plating ProcesKishora BhatAinda não há avaliações

- Hard Chrome Plating PlantsDocumento5 páginasHard Chrome Plating Plants19bt01019Ainda não há avaliações

- Safecoat Hard AnodizingDocumento47 páginasSafecoat Hard AnodizingyahsooyAinda não há avaliações

- TALAT Lecture 2102.02: An Upper Casing For An Automobile Steering Column, Special Study: Impact ExtrusionDocumento15 páginasTALAT Lecture 2102.02: An Upper Casing For An Automobile Steering Column, Special Study: Impact ExtrusionCORE Materials100% (1)

- HR S 50 B (Bright Nickel Bath)Documento8 páginasHR S 50 B (Bright Nickel Bath)Sinar Cemaramas AbadiAinda não há avaliações

- Enprep - 220EC Steel Cu Brass MSDS.Documento5 páginasEnprep - 220EC Steel Cu Brass MSDS.LựuLiềuLìAinda não há avaliações

- Surface Preparation Of: Aluminum, Copper, BrassDocumento14 páginasSurface Preparation Of: Aluminum, Copper, BrassGaneshAinda não há avaliações

- TALAT Lecture 1100.01: Introduction: Aluminium, A Light MetalDocumento10 páginasTALAT Lecture 1100.01: Introduction: Aluminium, A Light MetalCORE MaterialsAinda não há avaliações

- Chrome Plating On ABSDocumento52 páginasChrome Plating On ABSmarkAinda não há avaliações

- Determination of Sulfate ConcentrationDocumento3 páginasDetermination of Sulfate Concentrationm daneshpourAinda não há avaliações

- CrO3 Alternatives in Decorative and Functional Plating PDFDocumento22 páginasCrO3 Alternatives in Decorative and Functional Plating PDFLukeAinda não há avaliações

- TALAT Lecture 2301: Design of Members Example 4.1: Bending Moment Resistance of Open Cross Section With Closed PartDocumento7 páginasTALAT Lecture 2301: Design of Members Example 4.1: Bending Moment Resistance of Open Cross Section With Closed PartCORE MaterialsAinda não há avaliações

- GMW14668Documento20 páginasGMW14668Carlos LanzillottoAinda não há avaliações

- Chromate Conversion Coatings and Their Current AppDocumento5 páginasChromate Conversion Coatings and Their Current AppDeni HermawanAinda não há avaliações

- 304 Chromic Acid AnodizingDocumento6 páginas304 Chromic Acid AnodizingPuguh Cahpordjo BaeAinda não há avaliações

- Black PassivationDocumento12 páginasBlack PassivationZineb100% (1)

- APU Aluminum 0411Documento8 páginasAPU Aluminum 0411roohollah13Ainda não há avaliações

- Croda NF-TDocumento3 páginasCroda NF-Tnirai101259Ainda não há avaliações

- Defects in Galvanised Coatings INGALSM3Documento14 páginasDefects in Galvanised Coatings INGALSM3khurshedlakhoAinda não há avaliações

- Plating - Interpharm PDFDocumento4 páginasPlating - Interpharm PDFvasudev_nAinda não há avaliações

- Sur Tec 650Documento17 páginasSur Tec 650donhan91Ainda não há avaliações

- NiSO4 MSDSDocumento7 páginasNiSO4 MSDSCoralie ShrosbreeAinda não há avaliações

- Zinc Nickel Electroplating Guide ZyliteDocumento9 páginasZinc Nickel Electroplating Guide ZyliteBryan DixAinda não há avaliações

- Decorative Chromium Plating BasicsDocumento8 páginasDecorative Chromium Plating Basicsm daneshpour100% (1)

- Techseal Silver SL GDocumento11 páginasTechseal Silver SL GAnh Quang NgoAinda não há avaliações

- ATOTECH - EcoTri - Bright Zinc Plating - Hexavalent Chrome FreeDocumento4 páginasATOTECH - EcoTri - Bright Zinc Plating - Hexavalent Chrome FreeWK Sinn100% (1)

- Chrom I TingDocumento11 páginasChrom I TingAshish RawatAinda não há avaliações

- Control of The Mat Gloss BalanceDocumento3 páginasControl of The Mat Gloss Balancejulio100% (1)

- Hydroclear Spec SheetDocumento4 páginasHydroclear Spec Sheetamitleck100% (1)

- Du-Zinc 019Documento7 páginasDu-Zinc 019KaRenthLuNaAinda não há avaliações

- Preparation of Zinc Alloy Die Castings For ElectroplatingDocumento4 páginasPreparation of Zinc Alloy Die Castings For ElectroplatingFrancisco BocanegraAinda não há avaliações

- ACED Murugadoss PPT TAFEDocumento91 páginasACED Murugadoss PPT TAFEMarikya GuptaAinda não há avaliações

- Zylite Stabilizer Ds v05Documento5 páginasZylite Stabilizer Ds v05Santiago TuestaAinda não há avaliações

- Modern Electroplating Fourth Edition Edited by M SDocumento2 páginasModern Electroplating Fourth Edition Edited by M Smiguelin91690% (1)

- Overview - Aerospace Anodize Finishes - Products FinishingDocumento20 páginasOverview - Aerospace Anodize Finishes - Products FinishingVu NguyenAinda não há avaliações

- Instructions Tifoo Anodization Starterkit enDocumento23 páginasInstructions Tifoo Anodization Starterkit enHoang TanAinda não há avaliações

- Bright Chrome HR 75Documento12 páginasBright Chrome HR 75Ringga sonifaAinda não há avaliações

- New Concepts Non Cyanide Alkaline ZincDocumento35 páginasNew Concepts Non Cyanide Alkaline ZincJOSE ANGEL CARRASCO100% (1)

- Corrosion Management Issue140 LowResDocumento32 páginasCorrosion Management Issue140 LowResReno100% (1)

- Chromic Acid Lanxess-MSDS PDFDocumento10 páginasChromic Acid Lanxess-MSDS PDFyuk ming wongAinda não há avaliações

- IndustrialDocumento462 páginasIndustrialTamagnsewNegnAinda não há avaliações

- Coatings 06 00024 PDFDocumento22 páginasCoatings 06 00024 PDFcvazquez999Ainda não há avaliações

- Review On Automotive Body Coating ProcessDocumento4 páginasReview On Automotive Body Coating ProcessIJEMR JournalAinda não há avaliações

- Hingley - PHD ThesisDocumento233 páginasHingley - PHD ThesisCicero Gomes de SouzaAinda não há avaliações

- Pamantasan NG Lungsod NG Maynila College of Engineering and Technology Department of Chemical EngineeringDocumento8 páginasPamantasan NG Lungsod NG Maynila College of Engineering and Technology Department of Chemical EngineeringMaria Cecille Sarmiento GarciaAinda não há avaliações

- Metal Ink and Can CoatingDocumento5 páginasMetal Ink and Can Coatingkimkimtan0% (1)

- Cleaning and Polishing CompoundDocumento9 páginasCleaning and Polishing CompoundcuibaprauAinda não há avaliações

- Review On Automotive Body Coating ProcessDocumento4 páginasReview On Automotive Body Coating ProcessIJEMR JournalAinda não há avaliações

- Technical Data Sheet: Trichrome HB 1700 TDocumento3 páginasTechnical Data Sheet: Trichrome HB 1700 TLuuThiThuyDuong100% (1)

- DM Adapt Laser Sys Prod Tech Data PDFDocumento28 páginasDM Adapt Laser Sys Prod Tech Data PDFInaamAinda não há avaliações

- Understanding Pre-Painted MetalDocumento69 páginasUnderstanding Pre-Painted MetalErick Quan LunaAinda não há avaliações

- TALAT Lecture 5105: Surface Treatment of AluminiumDocumento15 páginasTALAT Lecture 5105: Surface Treatment of AluminiumCORE MaterialsAinda não há avaliações

- Chromate Conversion Coatings On Aluminium - Influences of AlloyingDocumento16 páginasChromate Conversion Coatings On Aluminium - Influences of AlloyingDaniel Alfonso Moreno VerbelAinda não há avaliações

- Electroplating of PlasticsDocumento4 páginasElectroplating of PlasticsislammughalAinda não há avaliações

- Guidance Note - No.2 Guide To Correct Specification of Powder Coated AluminiumDocumento2 páginasGuidance Note - No.2 Guide To Correct Specification of Powder Coated AluminiumAnwar100% (1)

- Decorative Chromium PlatingDocumento8 páginasDecorative Chromium Platingcauthon82Ainda não há avaliações

- Overall Aspects of Non-Traditional Glasses: Synthesis, Properties and ApplicationsNo EverandOverall Aspects of Non-Traditional Glasses: Synthesis, Properties and ApplicationsAinda não há avaliações

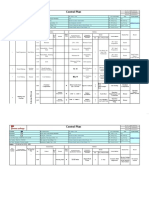

- Control Plan: FG 260 As Per IS 210: 2009Documento24 páginasControl Plan: FG 260 As Per IS 210: 2009Suraj RawatAinda não há avaliações

- FT 35 DC D10447340A Process SheetDocumento7 páginasFT 35 DC D10447340A Process SheetSuraj RawatAinda não há avaliações

- NT-EHS-SOP04 SOP For Communication - EMSDocumento3 páginasNT-EHS-SOP04 SOP For Communication - EMSSuraj RawatAinda não há avaliações

- Fuel Bill Template 3Documento1 páginaFuel Bill Template 3Suraj RawatAinda não há avaliações

- Cycle Count Process StepsDocumento3 páginasCycle Count Process StepsSuraj RawatAinda não há avaliações

- Time PlotDocumento1 páginaTime PlotSuraj RawatAinda não há avaliações

- FT 35 DC D10447340A Setup ApprovalDocumento7 páginasFT 35 DC D10447340A Setup ApprovalSuraj RawatAinda não há avaliações

- Push Pull Meter - Act - 1000n PDFDocumento7 páginasPush Pull Meter - Act - 1000n PDFSuraj RawatAinda não há avaliações

- Training Module and Training SheetDocumento6 páginasTraining Module and Training SheetSuraj RawatAinda não há avaliações

- In-Process Inspection Report: Date: - / - / - Rev. No.: 01 (11/05/2016)Documento4 páginasIn-Process Inspection Report: Date: - / - / - Rev. No.: 01 (11/05/2016)Suraj RawatAinda não há avaliações

- No. of EmployeesDocumento3 páginasNo. of EmployeesSuraj RawatAinda não há avaliações

- Process Sheet: Part No.: Hub 1500629 (Annexure 1 To PCP 1500629E CP-08)Documento5 páginasProcess Sheet: Part No.: Hub 1500629 (Annexure 1 To PCP 1500629E CP-08)Suraj RawatAinda não há avaliações

- Capacity ManagementDocumento2 páginasCapacity ManagementSuraj RawatAinda não há avaliações

- Testing FacilitiesDocumento5 páginasTesting FacilitiesSuraj RawatAinda não há avaliações

- Process Sheet: Rev. No. 01 (19/10/2015)Documento6 páginasProcess Sheet: Rev. No. 01 (19/10/2015)Suraj RawatAinda não há avaliações

- .Builds Relations: Awards & CitationsDocumento15 páginas.Builds Relations: Awards & CitationsSuraj RawatAinda não há avaliações

- Preventive Maintenance SystemDocumento3 páginasPreventive Maintenance SystemSuraj RawatAinda não há avaliações

- Rev 03Documento5 páginasRev 03Suraj RawatAinda não há avaliações

- Contingency Plan 2017-2018Documento1 páginaContingency Plan 2017-2018Suraj RawatAinda não há avaliações

- D10414410A CP Rev 00Documento21 páginasD10414410A CP Rev 00Suraj RawatAinda não há avaliações

- Process Sheet: 9 Inner Diameter Ø 95.21/ 95.31 MM 100% 20th PC 10 Inner Diameter Ø 89.934/ 89.957 MM 100% 10th PCDocumento5 páginasProcess Sheet: 9 Inner Diameter Ø 95.21/ 95.31 MM 100% 20th PC 10 Inner Diameter Ø 89.934/ 89.957 MM 100% 10th PCSuraj RawatAinda não há avaliações

- Rev 02Documento3 páginasRev 02Suraj RawatAinda não há avaliações

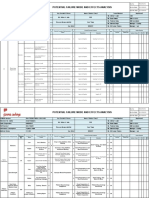

- D10414410a Fmea CastingDocumento7 páginasD10414410a Fmea CastingSuraj RawatAinda não há avaliações

- D10414410a Fmea MachiningDocumento13 páginasD10414410a Fmea MachiningSuraj RawatAinda não há avaliações

- Machining PFMEADocumento8 páginasMachining PFMEASuraj RawatAinda não há avaliações

- Fmea CastingDocumento4 páginasFmea CastingSuraj RawatAinda não há avaliações

- GM Machining CP REV 03Documento17 páginasGM Machining CP REV 03Suraj RawatAinda não há avaliações

- Fmea Machining Rev 01Documento12 páginasFmea Machining Rev 01Suraj RawatAinda não há avaliações

- GM Process SheetDocumento1 páginaGM Process SheetSuraj RawatAinda não há avaliações

- Fmea CastingDocumento8 páginasFmea CastingSuraj RawatAinda não há avaliações