Escolar Documentos

Profissional Documentos

Cultura Documentos

Rolls Royce Gas Engine of 5.255 MW

Enviado por

Rashid MahmoodTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Rolls Royce Gas Engine of 5.255 MW

Enviado por

Rashid MahmoodDireitos autorais:

Formatos disponíveis

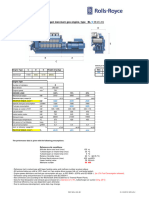

ANNEX 2.

Project: Stallion Power, Pakistan

Bergen lean-burn gas engine, type B36:45 L 9 AG1

PERFORMANCE DATA

Engine Type A B C Weight (dry) [kg] Bore/stroke [mm] Engine speed [rpm]

B36:45 L9AG1 12850 3310 4560 135300 360 / 450 750

Engine load % 100

Mechanical output kW 5410

Alternator efficiency, cosφ=0,8 % 97,17

Electrical output, cosφ=0,8 kW 5255

Nom. el. efficiency, cosφ=0,8 % 48,0

Fuel gas consumption

Specific fuel gas consumption (guidance only) kJ/kWh 7290

Fuel gas consumption kW 10955

Lub.oil consumption g/kWh 0,4

Heat dissipation

Charge air cooler LT/HT kW 335 / 1215

Lub.oil cooler kW 535

Jacket water cooler kW 680

Exhaust mass kg/h 28200

Exhaust gas temperature °C 375

Exhaust gas emissions @ 5%O2

NOx mg/nm³ 500

CO mg/nm³ 750

NMHC mg/nm³ 225

Cooling water data

LT Inlet temp to charge air cooler (max) °C 45

Maximum cooling water LT flow to charge air cooler m³/h 97

Electrical system

Frequency Hz 50

Voltage kV 11

Reference site conditions

Altitude above sea level (max) 100 m

Turbocharger air intake temp (max) 35 °C

Turbocharger air intake temp (min) 5 °C

Relative Humidity (max) 60 %

Exhaust back pressure (max) 400 mmWG

Minimum fuel gas pressure to fuel gas module 5,3 barg

Lower heating value 36 MJ/m³n

Methane number 80 MN

.· Reference fuel is natural gas with lower heating value and methane number as given above

· All technical data are valid at 100% load, incl. two engine driven pumps (lub. oil and jacket water).

· Engine power definitions and fuel gas consumption are acc. to ISO 3046-1 (ICFN) and ISO 8528-1.

· Generator rating and performance in accordance with IEC 60034-1.

· Nox Emmisions are according to the World Bank EHS Guidelines to Thermal Power Plants.

· Electrical Efficiency may vary, dependent upon alternator.

· Data for heat dissipation and exhaust gas are based on a tolerance of ± 5%, turbocharger air suction temp. 25°C.

· Due to continuous development, some data may change.

Você também pode gostar

- Scansteering CatDocumento16 páginasScansteering CatosamaAinda não há avaliações

- LV Generator Catalogue - Standard Marine EN LR 201205 PDFDocumento30 páginasLV Generator Catalogue - Standard Marine EN LR 201205 PDFPutra Kusuma HarditoAinda não há avaliações

- Marine Emergency Diesel Generator SetDocumento2 páginasMarine Emergency Diesel Generator SetVicky ZulfikarAinda não há avaliações

- GTG 1383om Piel Sul 48mchpDocumento18 páginasGTG 1383om Piel Sul 48mchpjohn smithyAinda não há avaliações

- LSC 54Documento4 páginasLSC 54pankaj tyagiAinda não há avaliações

- Project Guide L2330HMDocumento274 páginasProject Guide L2330HMLeonidas Galanis100% (1)

- JCB Broadcrown Generator BrochureDocumento28 páginasJCB Broadcrown Generator BrochureRachmat ZakariailyasAinda não há avaliações

- Dong Fang HistoryDocumento55 páginasDong Fang Historyramnadh803181Ainda não há avaliações

- DV 10 Techical Leaflet PDFDocumento12 páginasDV 10 Techical Leaflet PDFbalu9999Ainda não há avaliações

- QSK60 G6 PDFDocumento2 páginasQSK60 G6 PDFShahzad Ali100% (2)

- Himoinsa BrochureDocumento12 páginasHimoinsa BrochurePowerTechAinda não há avaliações

- Altronic EPC 110-120 Operating Manual (FORM EPC-110/120 OM)Documento55 páginasAltronic EPC 110-120 Operating Manual (FORM EPC-110/120 OM)francis_mouille_iiAinda não há avaliações

- Control AFR CAT Gas Engine Management eDocumento68 páginasControl AFR CAT Gas Engine Management eJaime CalmetAinda não há avaliações

- 2-Pole Turbine Driven Generators - Brushless ExcitationDocumento2 páginas2-Pole Turbine Driven Generators - Brushless ExcitationChandrasekar Karuppasamy100% (1)

- IMC-800-catalog HOTSTART PDFDocumento52 páginasIMC-800-catalog HOTSTART PDFEfrain MarceloAinda não há avaliações

- COPPUS Steam Turbines PRODUCT GUIDEDocumento6 páginasCOPPUS Steam Turbines PRODUCT GUIDEaminardakaniAinda não há avaliações

- Technical Specification: (Engine, Alternator, Engine Auxiliaries)Documento30 páginasTechnical Specification: (Engine, Alternator, Engine Auxiliaries)Shihab AhmedAinda não há avaliações

- Caterpillar RC1000 Containerized Diesel Generator SetDocumento4 páginasCaterpillar RC1000 Containerized Diesel Generator SetMacAllister MachineryAinda não há avaliações

- Hurto A PDVSA: Sobreprecio de $18,2MM Rolls Royce Trent60Documento23 páginasHurto A PDVSA: Sobreprecio de $18,2MM Rolls Royce Trent60Tomás LanderAinda não há avaliações

- DECS 150 Kamal TextileDocumento252 páginasDECS 150 Kamal TextileengrjwadAinda não há avaliações

- MAN - Power Plants PDFDocumento100 páginasMAN - Power Plants PDFBárbara LeitãoAinda não há avaliações

- BCP Technical & Operating DataDocumento24 páginasBCP Technical & Operating DataKrishnan SanthanarajAinda não há avaliações

- May Phat Dien Cummins C275D5 (6CTAA8.9G2)Documento1 páginaMay Phat Dien Cummins C275D5 (6CTAA8.9G2)Long StevenAinda não há avaliações

- M+S Bót LáiDocumento54 páginasM+S Bót LáidoanmdatAinda não há avaliações

- Faraz Ahmed C.VDocumento3 páginasFaraz Ahmed C.Vfaraz24Ainda não há avaliações

- GE's Jenbacher Gas Engines - Advantage Austria (PDFDrive)Documento23 páginasGE's Jenbacher Gas Engines - Advantage Austria (PDFDrive)saman karbasiAinda não há avaliações

- TECHNICAL DATA Cogeneration Unit IET BIO 520 V01 - 50Documento7 páginasTECHNICAL DATA Cogeneration Unit IET BIO 520 V01 - 50Elias RizkAinda não há avaliações

- Catalogo Genalt English EmailDocumento33 páginasCatalogo Genalt English EmailKhaleel Qatanani100% (1)

- MtuDocumento2 páginasMtuGerman O.Ainda não há avaliações

- Turbine Cat SolarDocumento2 páginasTurbine Cat SolarAbid Lakhani100% (1)

- Compreso 4ves-10 R507a t0 - 8 TC 45 Cuarto 0cDocumento5 páginasCompreso 4ves-10 R507a t0 - 8 TC 45 Cuarto 0cArturo 1Ainda não há avaliações

- Axial Fan AC HyBlade enDocumento48 páginasAxial Fan AC HyBlade enevrimkAinda não há avaliações

- L7044gsi 7045 0710Documento2 páginasL7044gsi 7045 0710Martin Alejandro NievaAinda não há avaliações

- Quick Closing Valve WorkingDocumento22 páginasQuick Closing Valve WorkingVivek JayagopinathanAinda não há avaliações

- Data JohnsonControlDocumento233 páginasData JohnsonControlQuyết Nguyễn MạnhAinda não há avaliações

- Siemens SGT-300 MD. Brian M Igoe Product Manager SGT-300. Trevor Mapleston Project Manager SGT-300Documento36 páginasSiemens SGT-300 MD. Brian M Igoe Product Manager SGT-300. Trevor Mapleston Project Manager SGT-300benlahcene100% (1)

- Siemens Sge 2mwDocumento2 páginasSiemens Sge 2mwmohsen_cumminsAinda não há avaliações

- Specification For Hyundai Synchronous GeneratorDocumento27 páginasSpecification For Hyundai Synchronous Generatorwin htikeAinda não há avaliações

- C6200 Presentation PDFDocumento38 páginasC6200 Presentation PDFRajneesh PatelAinda não há avaliações

- Eddy Probe Systems PDFDocumento44 páginasEddy Probe Systems PDFVanessa Pajares LanciatoAinda não há avaliações

- Zelda Welding Machine CatalogDocumento72 páginasZelda Welding Machine CatalogJuan Manuel Suarez OreAinda não há avaliações

- Mitsubishi Diesel Engine - S16R-Y2PTAW2Documento2 páginasMitsubishi Diesel Engine - S16R-Y2PTAW2Christian Rivera FloverAinda não há avaliações

- DEIFDocumento6 páginasDEIFnhocti007Ainda não há avaliações

- Agn013 CDocumento10 páginasAgn013 Cmohsen_cumminsAinda não há avaliações

- P I F 3000 PSI B A: Recharging Nstructions OR Ladder CcumulatorsDocumento2 páginasP I F 3000 PSI B A: Recharging Nstructions OR Ladder CcumulatorsRonaldAinda não há avaliações

- Steam Turbine and Governor (SimPowerSystems)Documento5 páginasSteam Turbine and Governor (SimPowerSystems)hitmancuteadAinda não há avaliações

- ABB M2QA CatalogueDocumento16 páginasABB M2QA CatalogueMaiPrachanartAinda não há avaliações

- Axial-Fan Transformers enDocumento36 páginasAxial-Fan Transformers enEko SusantoAinda não há avaliações

- Cat Gas Genset Markets and ProductsDocumento266 páginasCat Gas Genset Markets and ProductsDjebali Mourad100% (1)

- Abb FlowmetersDocumento84 páginasAbb FlowmetersAna QuintanaAinda não há avaliações

- J612V22 enDocumento4 páginasJ612V22 enMartin Kratky100% (1)

- Principle of Engine Operation PDFDocumento56 páginasPrinciple of Engine Operation PDFatulsemilo100% (1)

- Perkins Diesel Generator P400pub 360kwDocumento4 páginasPerkins Diesel Generator P400pub 360kwTariq KoyrattyAinda não há avaliações

- Gas Generator Set of MTU Engine Tech JBG1000Documento7 páginasGas Generator Set of MTU Engine Tech JBG1000Pankaj KambleAinda não há avaliações

- RdO Power Island - Allegato E - Data Sheet MotoreDocumento1 páginaRdO Power Island - Allegato E - Data Sheet Motoreufficio.tecnicoAinda não há avaliações

- JMS-320 GS NL (1065kw)Documento4 páginasJMS-320 GS NL (1065kw)Dexterous EngineeringAinda não há avaliações

- J 312Documento4 páginasJ 312shahzad 28390% (1)

- Janbacher 312 MergedDocumento10 páginasJanbacher 312 MergedБогдан СендецькийAinda não há avaliações

- SES 400kWDocumento1 páginaSES 400kWJafar ShojaAinda não há avaliações

- Technical Data D2842LE301 1999 07 13Documento2 páginasTechnical Data D2842LE301 1999 07 13scrollock0428Ainda não há avaliações

- Engine Log Sheet: Oil Running Hour Modl P.F Lub Oil J/W Battery Cooling Tower Time K.W Amp Volt HZ R/H KWHDocumento1 páginaEngine Log Sheet: Oil Running Hour Modl P.F Lub Oil J/W Battery Cooling Tower Time K.W Amp Volt HZ R/H KWHRashid MahmoodAinda não há avaliações

- Roll Number Slip PDFDocumento1 páginaRoll Number Slip PDFRashid MahmoodAinda não há avaliações

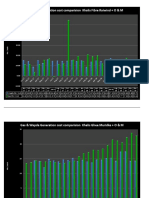

- Generation Cost Comparision O & MDocumento3 páginasGeneration Cost Comparision O & MRashid MahmoodAinda não há avaliações

- Gas Engine PDFDocumento1 páginaGas Engine PDFRashid MahmoodAinda não há avaliações

- Gas Engine PDFDocumento1 páginaGas Engine PDFRashid MahmoodAinda não há avaliações

- Engine Log Sheet: Oil Running Hour Modl P.F Lub Oil J/W Battery Cooling Tower Time K.W Amp Volt HZ R/H KWHDocumento1 páginaEngine Log Sheet: Oil Running Hour Modl P.F Lub Oil J/W Battery Cooling Tower Time K.W Amp Volt HZ R/H KWHRashid MahmoodAinda não há avaliações

- Fatima Masjid Generator Log Sheet: GAS Meter ON Off KWH P.F Lub Oil J/W Battery Cooling Tower Time K.W Amp Volt HZ R/HDocumento1 páginaFatima Masjid Generator Log Sheet: GAS Meter ON Off KWH P.F Lub Oil J/W Battery Cooling Tower Time K.W Amp Volt HZ R/HRashid MahmoodAinda não há avaliações

- Waukeshau - Installation and Application Manual PDFDocumento272 páginasWaukeshau - Installation and Application Manual PDFRashid Mahmood100% (1)

- Ad Agency SynopsisDocumento19 páginasAd Agency SynopsisRaj BangaloreAinda não há avaliações

- SWIMS Directory of LibrariesDocumento17 páginasSWIMS Directory of LibrariessudakshinaroyAinda não há avaliações

- District CoolingDocumento16 páginasDistrict Coolingmazzam75Ainda não há avaliações

- Pocket PDFDocumento437 páginasPocket PDFFranko MilovanAinda não há avaliações

- Diseño de Tuberías C-10 Y C-40Documento1 páginaDiseño de Tuberías C-10 Y C-40samuelcordova36Ainda não há avaliações

- About Some Important Items of Composite Insulators Design: February 1999Documento6 páginasAbout Some Important Items of Composite Insulators Design: February 1999ipraoAinda não há avaliações

- Solution of Tutorial Sheet-3 (Three Phase Networks) : Ans. Given, - Vab - 45kV, ZL (0.5 + j3), Z (4.5 + j9)Documento10 páginasSolution of Tutorial Sheet-3 (Three Phase Networks) : Ans. Given, - Vab - 45kV, ZL (0.5 + j3), Z (4.5 + j9)Shroyon100% (2)

- Hong Kong International Airport Instrument Approach ChartDocumento21 páginasHong Kong International Airport Instrument Approach ChartThamaroj ChansawangAinda não há avaliações

- Advant Controller 4050series eDocumento124 páginasAdvant Controller 4050series eABVSAIAinda não há avaliações

- Case Study Analysis of Apex Corporation PDFDocumento2 páginasCase Study Analysis of Apex Corporation PDFAJAinda não há avaliações

- Structural Equation Model : Determinant of Customer Satisfaction and It S Implications On Customer EngagementDocumento15 páginasStructural Equation Model : Determinant of Customer Satisfaction and It S Implications On Customer EngagementGSA publishAinda não há avaliações

- Acquisition (Pagtamo) Meaning-Making (Pag-Unawa) Transfer (Paglilipat)Documento2 páginasAcquisition (Pagtamo) Meaning-Making (Pag-Unawa) Transfer (Paglilipat)MAY BEVERLY MORALES100% (8)

- Washpipe Assembly Washpipe Assembly: Service ManualDocumento60 páginasWashpipe Assembly Washpipe Assembly: Service ManualIvan Kawempy100% (4)

- Community Building PDFDocumento2 páginasCommunity Building PDFLauren100% (1)

- Media and Information Literacy: ACTIVITY 1: Forget Me NotDocumento5 páginasMedia and Information Literacy: ACTIVITY 1: Forget Me NotShaina Fe RabaneraAinda não há avaliações

- LPIC-2 Exam PrepDocumento882 páginasLPIC-2 Exam PrepcuthieuAinda não há avaliações

- 2 Combined Dci Standards 6 13 13Documento7 páginas2 Combined Dci Standards 6 13 13api-32776059Ainda não há avaliações

- Whirlpool SPIW318A2WF Air ConditionerDocumento324 páginasWhirlpool SPIW318A2WF Air ConditionerAxxAinda não há avaliações

- Vogt Valves: Catalog & Application ManualDocumento161 páginasVogt Valves: Catalog & Application ManualAngelique DeanAinda não há avaliações

- Lec 1 - SuperelevationDocumento24 páginasLec 1 - SuperelevationMohamedAinda não há avaliações

- BPQ REV. 0 Interactive FormDocumento2 páginasBPQ REV. 0 Interactive FormcosmicbunnyAinda não há avaliações

- 6.hydraulic Pressure SpesificationDocumento3 páginas6.hydraulic Pressure SpesificationTLK ChannelAinda não há avaliações

- PR-1078 - Hydrogen Sulphide Management ProcedureDocumento22 páginasPR-1078 - Hydrogen Sulphide Management Procedureromedic360% (1)

- Software Quality Assurance IntroductionDocumento72 páginasSoftware Quality Assurance Introductionfmohiy100% (6)

- NORMA TORRO Datasheet en PDFDocumento11 páginasNORMA TORRO Datasheet en PDFvikaslashkariAinda não há avaliações

- Dialogues in French and EnglishDocumento62 páginasDialogues in French and Englishmiki1222Ainda não há avaliações

- 990 Vibration Transmitter Datasheet-141612mDocumento14 páginas990 Vibration Transmitter Datasheet-141612mloopkkAinda não há avaliações

- Module Tes Answer Key: Student B Student ADocumento2 páginasModule Tes Answer Key: Student B Student AKremena KoevaAinda não há avaliações

- Sanjay ProjectDocumento41 páginasSanjay ProjectPrynka RawatAinda não há avaliações