Escolar Documentos

Profissional Documentos

Cultura Documentos

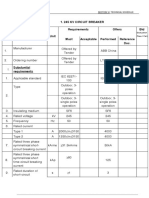

Design Features of GIS: A. Development and Manufacturing

Enviado por

Thành DanhTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Design Features of GIS: A. Development and Manufacturing

Enviado por

Thành DanhDireitos autorais:

Formatos disponíveis

1

Design Features of GIS in industrial areas to fulfill high-energy demands by space

saving design with a minimum of cost. Only SF6 insulated

switchgear is able to fulfill these requirements.

Arun Arora, IEEE Substations Committee Today’s GIS has its origin in the metal enclosed concept,

Hermann Koch, IEEE Substations Committee first applied at high voltage in the 1920’s, using oil as the

insulating medium. The first gas insulated metal enclosed

The design of GIS is based on the long experiences of AIS switchgear used Freon as the insulating gas, a technology

equipment with all its improvements since then. However the already known since the 1930`s (see figure 1).

use of pressurized SF6 as insulating and arc extinguishing The world’s first high-voltage gas-insulated switchgear

medium since 1967 within gastight housings brought up a new using SF6 as the insulating and arc-quenching medium was

design for the main elements of a substation. introduced in 1968. In another development step a SF6

GIS technology typically is being of very compact and switchgear installed in Canada in a 550kV substation achieved

modular design, and used for indoor and outdoor applications. the highest breaking capacity ever with 100kA. Consistent

The housings are sealed and the required density of the research and development and innovative energy led to the

pressure system is continuously monitored. All parts of the current third generation of compact and overall optimized

main circuit and the primary insulation is completely protected switchgear.

from the polluting and aging effects of the atmosphere by the

enclosure, so that no environmental impact on the service

performance is possible. View ports allow to control the

position of the disconnector contacts. The compact design

leads to small dimensions; especially in comparison to an AIS

substation space savings of more than 70% are possible.

Furthermore the compact design with its low centre of gravity

offers a high seismic withstandability.

Considering all this a GIS ends up with remarkable low

Life Cycle Cost LCC.

GIS provides also inherent benefits when compared to con-

ventional AIS with regard to environmental impact, generation

of EMF and susceptibility to EMC and we can expect in-

creased selection of GIS in the future for these benefits.

There is now much more awareness of the vulnerability of

transmission systems regarding terrorist attack. Reviews of

existing substations may lead to changes in design and opera-

tional philosophies. For future substations the issue of security

will become even more important than in the past and GIS

solutions might have some inherent advantages in relation to

security. Fig. I-1. Early GIS 1936 using Freon gas as insulating media

An ongoing continual development of GIS technology

GIS technology is typically of modular design and filled

involving the integration of primary functions into single

with a minimum of SF6. It is characterized by its low life-

elements can be seen. The objectives of such developments

have been to make the GIS of today: cycle cost (LCC) and can be used for indoor and outdoor

application.

• More compact

GIS has the following major features:

• Simpler, involving fewer components

• Factory pre-assembled and tested units

• Increased performance and reliability

• Operating life > 50 years

• Less costly

• Major inspection not before 25 years

Today also changes in the general substation layout, • Motor-operated self-lubricated mechanisms

making use of the specific design features of a GIS, are • Minimal cleaning requirement

considered. • Corrosion-resistant

• Low fault-probability / high availability

A. Development and Manufacturing • Protected against aggressive environmental conditions

Reliable and economical power transmission and distribu- • Seismic resistant

tion are key functions of the future electric power supply. • Space requirement less than 20 % of comparable AIS

High-voltage switchgear and equipment for voltages above

1 kV up to 800 kV are safety elements within the electrical 1960 Start of fundamental studies in research and develop-

energy supply and therefore subjected to a very high standard ment of SF6 technology

of availability and reliability. Gas insulated switchgear is used 1964 Delivery of the first SF6 single-pressure circuit-

2

breaker electrical fields for they have a screening effect, and they re-

1968 Delivery of first GIS by major manufacturers duce magnetic fields depending on the reverse current within

1974 Delivery of first GIL (420 kV) the housing.

1976 Delivery of first 550 kV GIS However, the most important task of the encapsulation is to

1983 Delivery of the world's largest GIS for Itaipu, Brazil safely and permanently enclose the insulating and arc extin-

1984 Delivery of 550 kV GIS for severe network conditions guishing gas SF6, which is until today not replaceable in high-

(rated current 8000 A, rated short circuit breaking cur- voltage equipment.

rent 100 kA, 17 circuit-breakers) The breaking capacity and the dielectric withstand capa-

1986 Delivery of first 800 kV GIS bilities of the switchgear depend on the gas density, which is

1996 Introduction of the smallest 123kV GIS continuously controlled by density monitors. Leakages of gas-

1997 Introduction of intelligent bay control, monitoring and ket O-rings at the enclosure flanges will lead automatically to

diagnostics a malfunction of the equipment.

1999 Introduction of the smallest 145 kV and 245 kV GIS To guarantee a reliable and safe behavior of the switchgear

2000 Introduction of new compact and hybrid solutions the tolerances of possible changes of the density value are

• more than 20000 bays in over 2000

very restricted. Accordingly, the requirements for gas

tightness are very high. Therefore only completely sealed and

substations

installed worldwide closed gas tight pressure systems are in service nowadays.

• more than 200,000 bay-years of operation 1) Design

Fig. I-2. More than 40 years of experience with gas-insulated switchgear of

major manufacturers

Since it its first introduction in 1968 metal-enclosed SF6 in-

sulated switchgear (GIS) has accumulated a long service ex-

Together with the initial equipment cost of a GIS many perience and has become an interesting and economical alter-

other criteria/advantages need to be considered in the process native to conventional air insulated substations. The GIS tech-

of deciding between a GIS and an AIS substation. The funda- nology started based on extensive fundamental research and

mental factors for the application of a GIS are its high reliabil- since then the service experience together with innovative

ity and availability, its encapsulation and its compactness. All development work has brought this technology forward to a

these qualities have a direct impact on land requirement, land safe and environmentally compatible, most reliable and avail-

cost, visual impact and possible technical applications, from able element of the energy supply. The tremendous progress in

which further advantages can be derived. The compact size development can be seen as an example of the classic three

offers a high design flexibility which in turn opens options for phase enclosure of a 72.5-170kV GIS on the following picture.

indoor, outdoor, underground, hybrid and containerized in-

stallations, either for temporary or continuous operation. For

certain applications these advantages are the key factor which

make GIS the only possible solution.

For the entire service life the secure performance depends

on the optimized quality of all switchgear components The

quality of the encapsulation is of major importance and is in-

fluenced by its material, the machining process, the design of

gaskets and the sealing material itself . The tightness of the

gas-insulated switchgear over the entire service life is not only

a condition for reliable function of the switchgear but also for Fig. I-3. Classic three phase cross-section of a 72.5-170kV GIS

a prevention of SF6 leakages.

The advantages of gas-insulated switchgear are its compact

In general, the encapsulation of high-voltage switchgear

design and modularity. The standardized modular structure is

and substation equipment is housing the electrical components

made to match the various customers’ specifications and

and in many cases also the structure of the mechanical layout.

allows realization of almost all substation configurations in

The design of the enclosure is more determined by the dielec-

compliance with them.

tric requirements than by mechanical ones. The choice of the

material and the mechanical dimensioning is done according

to the state of the art of engineering techniques.

The encapsulation protects the electrical components from

external influences and environmental effects. The easily

coated aluminum enclosure provides all-round protection

against contamination and mechanical damage. Furthermore,

the grounded metallic encapsulation reliably prevents that

energized parts can be touched. It also protects the service

personnel from direct consequences of arcs from internal

dielectric failures. Metallic encapsulations avoid emission of

3

Circuit- Current Extension Busbars Termination

breakers transformers modules modules

Cables

Transformers

Disconnectors Outdoor

and earthing Voltage Surge Expansion bushings

switches transformers arresters joints

Fig. I-4. Typical Modules of a 245 kV - GIS

Fig. I-7. Disconnector module of a 245 kV - GIS

In the following major components of the GIS are shown in

detail as schematic cross sections. A wide range of bay varia- Specially developed "load break disconnectors", which

tions can be achieved using only 20 different standard mod- cannot interrupt short-circuit current, only the load current of

ules. This applies even to unconventional arrangements such the switchgear, can fulfill the functions of the disconnector as

as the triplicate bus bypass or the 1 1/2 circuit-breaker well.

arrangement.

Fig. I-8. Load-break disconnector module of a 245 kV - GIS

Fig. I-5. Circuit-breaker module of a 245 kV – GIS

The modular system of GIS components allows the creation

of any single-line diagrams (circuit configurations / busbar

schemes) in a most effective way corresponding to the specific

conditions of each individual construction. Recently a new

three-position type of integrated disconnecting and grounding

switch with common moving contact and common drive was

introduced for single-phase enclosed constructions as well.

Fig. I-6. 3-phase busbar module of a 245 kV - GIS

Fig. I-9. 3-phase disconnector/grounding switch module of a 145 kV – GIS

4

Figure I-12 shows the inside of a three-phase voltage

transformer.

Fig. I-10. Current transformer module

Fig. I-12. Three-phase voltage transformer

Figure I-13 shows the inside of a three-phase current

transformer.

Fig. I-11. Voltage transformer module

In comparison to AIS layouts, the GIS grounded modular

system with its compactness and minimal dimensions offers a

much wider range of different combinations. These may be

characterized e.g. by the following:

• Three- or single-phase encapsulation or combinations

thereof

• Mixed, separated or coupled phases of busbars and/or bay

arrangements

• Single-, two- or more-line arrangement of circuit-breakers

• Horizontal or vertical ("U" or "Z") circuit-breaker designs

• Vertical, horizontal, triangle or upper or lower flange-con-

Fig. I-13. Three-phase current transformer

nected busbar arrangements

The bay design and the construction of the GIS switchgear

have a wide variation according to its voltage range from

72.5 kV to up to 800 kV. They have been tailored to the de-

mands of all kinds of substations with their different circuit

arrangements such as bypass and ring-bus systems as well as

sectionalizers and bus couplers. The next picture gives exam-

ples of typical switchgear designs in dependence of the

voltage level. The small overall dimensions due to the

compact design lead to reduced space requirements in smaller

buildings. The comparison of the dimensions between a 145

kV bay from 1968 and one from 1991 shows a reduction of

the required space by 26.5%.

Você também pode gostar

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsNo Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsNota: 4 de 5 estrelas4/5 (1)

- Gallium Nitride-enabled High Frequency and High Efficiency Power ConversionNo EverandGallium Nitride-enabled High Frequency and High Efficiency Power ConversionGaudenzio MeneghessoAinda não há avaliações

- Gas Insulated Substation GIS: Committee Committee A. DevelopmentDocumento3 páginasGas Insulated Substation GIS: Committee Committee A. DevelopmentInmusta GisinAinda não há avaliações

- Gas-Insulated Switchgear and InterrupterDocumento5 páginasGas-Insulated Switchgear and InterrupterMorro DelArrabalAinda não há avaliações

- Compact and Reliable Switching - Smaller, More Efficient and Simpler Gas-Insulated Switchgear (GIS)Documento6 páginasCompact and Reliable Switching - Smaller, More Efficient and Simpler Gas-Insulated Switchgear (GIS)qxzyAinda não há avaliações

- 07 Chapter 02 PDFDocumento38 páginas07 Chapter 02 PDFhabib AnsariAinda não há avaliações

- Gas-Insulated Switchgear For Substations: Common Characteristic Features of Switchgear InstallationDocumento10 páginasGas-Insulated Switchgear For Substations: Common Characteristic Features of Switchgear InstallationNur FajarAinda não há avaliações

- Gas-Insulated Switchgear For Substations: Common Characteristic Features of Switchgear InstallationDocumento10 páginasGas-Insulated Switchgear For Substations: Common Characteristic Features of Switchgear InstallationbdikicAinda não há avaliações

- Gas-Insulated Switchgear For Substations: Common Characteristic Features of Switchgear InstallationDocumento10 páginasGas-Insulated Switchgear For Substations: Common Characteristic Features of Switchgear InstallationNur FajarAinda não há avaliações

- Gas Insulated Substation (Gis) Vs Conventional Outdoor Substation (Ais)Documento12 páginasGas Insulated Substation (Gis) Vs Conventional Outdoor Substation (Ais)Sa'dun ArifAinda não há avaliações

- Gas Insulated Substation 11405 IIumEUfDocumento10 páginasGas Insulated Substation 11405 IIumEUfSowmyaAinda não há avaliações

- Gas Insulated Substation: by Shuhaib Nassar Roll No: 46 S EEE REG No: 17030177Documento27 páginasGas Insulated Substation: by Shuhaib Nassar Roll No: 46 S EEE REG No: 17030177shuhaib nassarAinda não há avaliações

- Gas Insulated Substation: by Shuhaib Nassar Roll No: 46 S EEE REG No: 17030177Documento27 páginasGas Insulated Substation: by Shuhaib Nassar Roll No: 46 S EEE REG No: 17030177shuhaib nassarAinda não há avaliações

- Fdocuments - in Gas Insulated Substation 1Documento16 páginasFdocuments - in Gas Insulated Substation 1debasishAinda não há avaliações

- Esp PDFDocumento8 páginasEsp PDFOmkar KhopadeAinda não há avaliações

- A Technical Seminar OnDocumento29 páginasA Technical Seminar OnRajat SinghAinda não há avaliações

- Gas Insulaled Switchyard (Gis)Documento42 páginasGas Insulaled Switchyard (Gis)cmverma82Ainda não há avaliações

- GIS Technical PresentationDocumento106 páginasGIS Technical Presentationvenkatws190% (10)

- Tugas TTT (GIS) Hafiz Patria Akbar 1910952028Documento8 páginasTugas TTT (GIS) Hafiz Patria Akbar 1910952028Fajar AsheqafAinda não há avaliações

- EzzahDocumento18 páginasEzzahRashida TabassumAinda não há avaliações

- Session 2000: Evaluation of Total Life Cycle Cost of GIS Substation and Development of Portable Diagnosis DeviceDocumento6 páginasSession 2000: Evaluation of Total Life Cycle Cost of GIS Substation and Development of Portable Diagnosis DeviceNur FajarAinda não há avaliações

- S17A - Kel.5 - Laporan Ujian Akhir SemesterDocumento133 páginasS17A - Kel.5 - Laporan Ujian Akhir SemesterWahyu Anantyo AkbarAinda não há avaliações

- GIS and Hybrid Switchgear TechnologyDocumento5 páginasGIS and Hybrid Switchgear TechnologyAnandAinda não há avaliações

- Gas Insulated SubstationDocumento6 páginasGas Insulated SubstationSravani Daggubati100% (1)

- IEE GIL Ref 0306 PDFDocumento5 páginasIEE GIL Ref 0306 PDFJie ChuAinda não há avaliações

- Types of Grid StationDocumento17 páginasTypes of Grid StationTahirAinda não há avaliações

- Gas Insulated SwitchgearDocumento118 páginasGas Insulated SwitchgearMA Ahmed100% (9)

- Gas Insulated SubstationDocumento21 páginasGas Insulated SubstationMeghana BRAinda não há avaliações

- Siemens Power Engineering Guide 7E 83Documento1 páginaSiemens Power Engineering Guide 7E 83mydearteacherAinda não há avaliações

- GIS FinalDocumento26 páginasGIS FinaldharmatejakademAinda não há avaliações

- Substation Designing - GISDocumento11 páginasSubstation Designing - GISBalu M100% (1)

- GisDocumento319 páginasGisKhalid MazharAinda não há avaliações

- Gis PDFDocumento29 páginasGis PDFKarunAinda não há avaliações

- Compact Substation SolutionsDocumento6 páginasCompact Substation SolutionsVICTORMARCEAinda não há avaliações

- GisDocumento319 páginasGisSaurabh Manglik100% (6)

- Gas Insulated Substations: 7 Sem. Seminar Presentation 2013, EEE DeptDocumento18 páginasGas Insulated Substations: 7 Sem. Seminar Presentation 2013, EEE Deptsatvik100% (1)

- Report On Gis Substation SectorDocumento6 páginasReport On Gis Substation SectorKarunAinda não há avaliações

- Gas Insulated LinesDocumento6 páginasGas Insulated LinesEl SharaawyAinda não há avaliações

- Economics of GIS: The CostDocumento2 páginasEconomics of GIS: The Costrasheed313Ainda não há avaliações

- Gas Insulation SubstationDocumento15 páginasGas Insulation Substationajit moreAinda não há avaliações

- Gis SubstationDocumento17 páginasGis SubstationAnbarasan AnnamalaiAinda não há avaliações

- Shashi Om Katiyar NTPC ConsultantDocumento55 páginasShashi Om Katiyar NTPC Consultant2K20CEEE23 Nishi Kant KumarAinda não há avaliações

- Gis - Elk-04 - 170 - 1HC0130351 - Ag21 - enDocumento16 páginasGis - Elk-04 - 170 - 1HC0130351 - Ag21 - enCLAVOTAinda não há avaliações

- Gas Insulated Substations: GisDocumento1 páginaGas Insulated Substations: Gisanon_829283562Ainda não há avaliações

- Wa0000Documento13 páginasWa0000Rajat SinghAinda não há avaliações

- 72kV GIS CatalogueDocumento8 páginas72kV GIS CatalogueLeonardo Henao LopezAinda não há avaliações

- Analysis of Project Alternatives: 10.1 GENERALDocumento5 páginasAnalysis of Project Alternatives: 10.1 GENERALsanaAinda não há avaliações

- Gas Insulated Substation DescriptionDocumento24 páginasGas Insulated Substation DescriptionAnonymous BZQOJwWIh6Ainda não há avaliações

- ELK-3 550 1HC0000742AGEnDocumento24 páginasELK-3 550 1HC0000742AGEnVivek SinghalAinda não há avaliações

- SF6 Gas Insulated Switch Gear (GIS)Documento12 páginasSF6 Gas Insulated Switch Gear (GIS)Rakesh Reddy100% (1)

- Lav C., Staley D. & Olsen T., (2004), Practical Design Considerations For Application of GIS MV SwitchgearDocumento8 páginasLav C., Staley D. & Olsen T., (2004), Practical Design Considerations For Application of GIS MV SwitchgearRicardo Rivas ZuñigaAinda não há avaliações

- PhilosophyDocumento92 páginasPhilosophyvijayAinda não há avaliações

- Substations That Also Comprise All Secondary Technology, Procurement, Installation andDocumento5 páginasSubstations That Also Comprise All Secondary Technology, Procurement, Installation andChhinPidenAinda não há avaliações

- GIS PresentationDocumento16 páginasGIS PresentationShubham Srivastava100% (1)

- Advantages and Economics of GSIDocumento9 páginasAdvantages and Economics of GSIguru kiranAinda não há avaliações

- GIL C37 122 4 Tutorial PJF Comments 1 Hour Version PDFDocumento48 páginasGIL C37 122 4 Tutorial PJF Comments 1 Hour Version PDFJUAN CESAR ATALAYA SANCHEZAinda não há avaliações

- GIS SubstationsDocumento10 páginasGIS SubstationsahdabmkAinda não há avaliações

- "Classic Range" Aluminium Connectors - 63/220 KV: Simel ProductsDocumento4 páginas"Classic Range" Aluminium Connectors - 63/220 KV: Simel ProductsThành DanhAinda não há avaliações

- Circuit Breaker Configuration of LTB245E1-1PDocumento2 páginasCircuit Breaker Configuration of LTB245E1-1PThành Danh100% (1)

- LTD245E1-Tech Data - 220kV Trang Bang Sub-ChinaDocumento6 páginasLTD245E1-Tech Data - 220kV Trang Bang Sub-ChinaThành DanhAinda não há avaliações

- Technical Datasheet of 3AP1FI-245kVDocumento2 páginasTechnical Datasheet of 3AP1FI-245kVThành DanhAinda não há avaliações

- LTB EnglishDocumento20 páginasLTB EnglishThành DanhAinda não há avaliações

- Product Test Report: Bosch Autodome Ip 5000 IrDocumento3 páginasProduct Test Report: Bosch Autodome Ip 5000 IrThành DanhAinda não há avaliações

- High Voltage Circuit Breakers 3AP Type 72.5 KV To 800 KV: Answers For EnergyDocumento12 páginasHigh Voltage Circuit Breakers 3AP Type 72.5 KV To 800 KV: Answers For EnergyThành DanhAinda não há avaliações

- Grid AIS L3 HYpact 0124 2017 - 02 ENDocumento24 páginasGrid AIS L3 HYpact 0124 2017 - 02 ENThành DanhAinda não há avaliações

- L90 Ge Protection RelayDocumento8 páginasL90 Ge Protection RelayThành DanhAinda não há avaliações

- Siemens Slide 2008Documento53 páginasSiemens Slide 2008Thành DanhAinda não há avaliações

- GL312F1 DrawingsDocumento2 páginasGL312F1 DrawingsThành DanhAinda não há avaliações

- Panasonic SA-AK960 Mini ComboDocumento121 páginasPanasonic SA-AK960 Mini Comboppstone100% (3)

- BrosurDocumento68 páginasBrosurKiki Xhui7Ainda não há avaliações

- FC700A HardwareDocumento36 páginasFC700A HardwaremohammedrezaeeAinda não há avaliações

- 2012 ELECTRICAL Connectors and Harnesses - TL PDFDocumento66 páginas2012 ELECTRICAL Connectors and Harnesses - TL PDFsoftallAinda não há avaliações

- Instruments For Electrochemical ResearchDocumento12 páginasInstruments For Electrochemical ResearchAgus JatmikoAinda não há avaliações

- Misubishi M720BM HandbookDocumento366 páginasMisubishi M720BM HandbookNam Ngô PhươngAinda não há avaliações

- SAJ General Purpose VFD CatalogueDocumento16 páginasSAJ General Purpose VFD CatalogueOdali BatistaAinda não há avaliações

- Advanced Course Chapter 14 Transmission LinesDocumento235 páginasAdvanced Course Chapter 14 Transmission LinesSampson MikeAinda não há avaliações

- AQA AS Physics A Chapter 4 Textbook AnswersDocumento4 páginasAQA AS Physics A Chapter 4 Textbook AnswerscathylisterAinda não há avaliações

- Buchholz Relay in Transformer - Buchholz Relay Operation and Principle - Electrical EngineeringDocumento3 páginasBuchholz Relay in Transformer - Buchholz Relay Operation and Principle - Electrical EngineeringfurkandarAinda não há avaliações

- Design and FPGA Implementation of Vending Machine: Submitted To: Submitted byDocumento39 páginasDesign and FPGA Implementation of Vending Machine: Submitted To: Submitted byManish SarohaAinda não há avaliações

- M28 BluetoothModulesDocumento5 páginasM28 BluetoothModulessouwestrubiAinda não há avaliações

- Maty ProposalDocumento27 páginasMaty Proposalkassahun meseleAinda não há avaliações

- Calibration of Linear Displacement Sensor Systems Used To Measure MicromotionDocumento4 páginasCalibration of Linear Displacement Sensor Systems Used To Measure MicromotionAhmad Zubair RasulyAinda não há avaliações

- Akai Dv-p4785kdsm DVD PlayerDocumento50 páginasAkai Dv-p4785kdsm DVD PlayerhussainArifAinda não há avaliações

- DCD 435Documento1 páginaDCD 435ojhabreAinda não há avaliações

- Question BankDocumento7 páginasQuestion BankAvinash ChauhanAinda não há avaliações

- DSR Electrical 2012Documento60 páginasDSR Electrical 2012vijay_raina31140% (1)

- Datos D Emotor DC WGMDocumento1 páginaDatos D Emotor DC WGMjosue perezAinda não há avaliações

- Embedded Systems and Its ScopeDocumento81 páginasEmbedded Systems and Its Scopenanobala15Ainda não há avaliações

- TP of AutomobileDocumento20 páginasTP of AutomobileHicham Salahdine100% (1)

- Compter ComponentsDocumento7 páginasCompter Componentsapi-251329131Ainda não há avaliações

- Applied Hydralics and Pneumatics 2 MarksDocumento10 páginasApplied Hydralics and Pneumatics 2 MarksVignesh VickyAinda não há avaliações

- Energizer E91 Max: Product DatasheetDocumento1 páginaEnergizer E91 Max: Product DatasheetVince WaldonAinda não há avaliações

- DIAL's RequirementsDocumento57 páginasDIAL's RequirementsShaikh Saeed AlamAinda não há avaliações

- AppleDocumento22 páginasApplePhuong Nhung100% (1)

- University of Engineering and Technology: Power Supply and BreadboardDocumento7 páginasUniversity of Engineering and Technology: Power Supply and BreadboardEtsham Amjad100% (1)

- User's Guide: Smartpack2 Basic ControllerDocumento16 páginasUser's Guide: Smartpack2 Basic ControllerIsac ClaroAinda não há avaliações

- On Load Tap Changer For TransformerDocumento7 páginasOn Load Tap Changer For Transformerabs4everonlineAinda não há avaliações

- Bei Drawworks Encoder Hs35Documento2 páginasBei Drawworks Encoder Hs35pr_oilAinda não há avaliações