Escolar Documentos

Profissional Documentos

Cultura Documentos

Amerlock 400C

Enviado por

balangceDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Amerlock 400C

Enviado por

balangceDireitos autorais:

Formatos disponíveis

Protective Coatings

Amerlock 400C

High Solids Epoxy Coating

Product Data/

Application Instructions

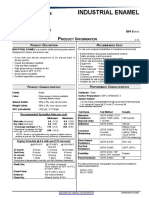

high performance self priming universal epoxy PHYSICAL DATA

high solids, low VOC Colours ................................... RAL and BS colours * – semigloss

surface tolerant and abrasion resistant Mio Colours: Light Grey

compatible with prepared damp surfaces ral 7035 and Grey Aluminium

good adhesion on most existing coatings Ral 9007

available in a wide colour range Components ........................... 2

also available with MIO pigmentation Curing mechanism.................. solvent release and chemical

If required Amerlock 400C can be overcoated reaction between components

with a wide range of topcoats Volume solids ......................... 85% ± 3%

Amerlock 400C is used as a high performance VOC (Directive 1999/13/EC, max. 114 g/kg

SED) .......................................

maintenance coating with excellent adhesion to a wide

VOC (EPA Method 24)............ 180 g/ltr (1.5 lb/gal)

range of existing coatings. Amerlock 400C can be

applied to mechanically cleaned surfaces. Adhesion Recommended dry film 100 - 200 μm (3.9 - 7.9 mils)

is excellent to a wide variety of substrates, including thickness.................................

concrete, aluminium and galvanizing. Amerlock 400C Number of coats ..................... 1 or 2

has excellent application characteristics. It can be

Theoretical spreading rate ...... 8.5 m²/l

applied by conventional and airless spray equipment,

brush or roller. For immersion service in water,

abrasive blasting Sa 2 1/2 is required. However, for

enhanced UV resistance it may be topcoated with a

wide range of different topcoats. Contact your PPG

representative for specific recommendations.

Typical use

Specially formulated as a high performance coating

on steel and concrete structures in industrial facilities,

bridges, tank exteriors, containers, oil tanks, piping,

roofs and other areas subject to moisture, high

humidity, marine weathering and other exposure.

Amerlock 400C has good resistance to splash, spillage

and fumes of acids, alkalies and solvents.

page 1/5 Revision date: 05-12-2012

Amerlock 400C

Recommended systems Application Data

ISO 12944 First Coat Intermediate Finish Coat

ENVIRONMENTAL CONDITIONS

C5 Amercoat 68 Series Amerlock 400C Amercoat 450S, Ambient Temperatures ......... 5 to 5°C (41 to 41°F)

Surface Temperature ........... 5 to 60°C (41 to 140°C)

PSX 700 or

Amershield

CLEANING SOLVENT

C4 Amerlock 400C Amerlock 400C Amercoat 450S, • Thinner: Thinner 91-92

• Cleaner: Thinner 90-58

PSX 700 or

Amershield

OVERCOATING

C3 Amerlock 400C -- Amercoat 450S,

PSX 700 or Recoat or Topcoat times at 125 μm

Amershield substrate 10°C/ 21°C 32°C 40°C

temperature 50°F / 70°F / 90°F / 104°F

IM 1/2 Amerlock 400C -- Amerlock 400C

with minimum 36 16 6 4

Epoxies interval hours hours hours hours

Resistance Guide maximum 3 3 2 1

Temperature Dry Wet interval months months months month

Resistance with maximum 1 1 14 7

Urethane interval month month days days

continuous 93°C/ 200°F 40°C/104°F drying times are dependent on temperature, ventilation and film

thickness.

Short term peak 177°C/ 350°F 40°C/104°F

temperature

note:Amerlock 400C has an extended maximum

overcoating time.Surfaces to be overcoated must be

Approval and Certificates clean and dry.

Systems using Amerlock 400C carry a number of Any contamination must be identified and adequately

approvals and certifications, such as removed.

Approved for Aramco specification APCS 26. particular attention must be paid to surfaces that

Approved by the Bulgarian Ministry of health as a wall have been exposedto heat and/or sunlight and where

and floor coating in the food industry. chalking may be present.

Approved by ACQPA, France. A degree of surface cleaning will be required. Your

“0” class fire rating (UK Building Regulations) based PPG representative can advise on

on testing according BS 476 parts 6 and 7 (fire suitable cleaning methods.

propagation and flame spread). Your PPG representative can advise on suitable

Approved by the UK Navy as a non skid deck coating cleaning methods.

(mixed with Amercoat 4013 NS additive) according Def Pot life

Stan 134/1. 10°C / 50°F 3 hours

Please contact your PPG representative for specific 21°C / 70°F 2 hours

approvals and / or certifications. 32°C / 90°F 1 hour

40°C / 104°F 30 min.

INSTRUCTIONS FOR USE

mixing ratio by volume: base to hardener 1 : 1

page 2/5 Revision date: 05-12-2012

Amerlock 400C

Curing Equipment

The following equipment is listed as a partial guide and

Curing table for dft at 125 μm suitable equipment from other manufacturers may be

substrate touch dry dry to full cure used.

temperature handle Adjustments of pressure and change of tip size may

10°C 24 hours 48 hours 21 days be needed to achieve the proper spray characteristics.

20°C 6 hours 20 hours 7 days AIRLESS SPRAY

Standard airless spray equipment, with a 0.48 mm

30°C 3 hours 12 hours 4 days

(0.019 inch) fluid tip or larger.

40°C 1 hour 8 hours 3 days CONVENTIONAL SPRAY

For optimum curing, surface temperature must be at Industrial equipment , having separate air and fluid

least 3°C/ 5°F above the dew point to prevent moisture pressure regulators, mechanical pot agitator and a

condensation on the surface moisture and oil trap in the main air supply line are

recommended.

Surface Preparation BRUSH/ROLLER

Coatings performance in general, is proportional to the Apply evenly, using a clean well-loaded brush or roller.

degree of surface preparation. Ensure the coating is not brushed or rollered-out too

Abrasive blasting is usually the most effective and far.

economical method. Application by brush or roller will provide

For circumstances where this is impossible or approx. 80 microns dft. in a single coat application.

impractical, Amerlock 400C has been developed. MIXER

STEEL Use power mixer powered by an air motor or an

Blast clean to Sa 2½ (ISO-8501-1) or SSPC-SP-10. explosion proof electric motor.

Amerlock 400C can also be applied over mechanically

cleaned surfaces.

Remove all loose rust, dirt, oil and grease or other

contaminants from the surface.

Power tool clean in accordance with St 3 or SSPC-

SP3 or hand tool clean in accordance with St 2 or

SSPC-SP2, UHPWJ in accordance with WJ2L (SSPC-

VIS-4).

Amerlock 400C can be applied over damp substrates.

For immersion in water abrasive blasting to SA 2 ½ is

required..

CONCRETE

Surfaces must be cured, clean, dry and free of

non-adherent coatings and disintegrated or chalky

materials.

EXISTING AGED COATINGS

Amerlock 400C may be used over most types of

properly cleaned, tightly adhering aged 2 pack

coatings.

For single pack coatings, extra precautions are

necessary.

It is always recommended a test patch is applied

to ensure long-term capability, as performance will

depend on condition of the existing coating such as

age, adhesion and film thickness

page 3/5 Revision date: 05-12-2012

Amerlock 400C

Procedure

Amerlock 400C is packaged in two components in

the proper proportions which must be mixed together

before use (20 litre unit):

1. Flush equipment with recommended cleaner before

use.

2. Stir both resin component and cure component to

an even consistency with a power mixer.

3. Add cure to resin, and continue stirring until

homogeneous.

4. For conventional spray, thin only as needed

for workability with no more than 10 vol % of

recommended thinner. Thinning is normally not

needed for airless spray.

5. Apply a wet coat in even parallel passes. Overlap

each pass 50% to avoid bare areas, pinholes or

holidays. Give special attention to corners, welds,

rough areas, edges.

6. Normal recommended dry film thickness per coat

is 125 μm (5 mil). Maximum dft per coat should not

exceed 250 μm (10 mil) per coat.

7. The application of a wet film thickness of 150 μm

(6 mil) will normally provide 125 μm ( 5 mil) of dry film.

8. Check thickness of dry coating with a non

destructive dry film thickness gauge such as Mikrotest

or Elcometer. If less than specified thickness, apply

additional material as needed.

9. Small damaged or bare areas and random pinholes

or holidays can be touched up by brush.

10. Clean all equipment with recommended cleaner

immediately after use or at least at the end of each

working day or shift. When left in spray equipment,

Amerlock 400C will cure and cause clogging.

page 4/5 Revision date: 05-12-2012

Amerlock 400C

SAFETY PRECAUTIONS is reliable. The product and related information is

Since improper use and handling can be hazardous designed for users having the requisite knowledge

to health and cause of fire or explosion, safety and industrial skills in the industry and it is the end-

precautions included with Product Data/Application user’s responsibility to determine the suitability of

Instruction and Material Safety Data Sheet must the product for its own particular use and it shall be

be observed during all storage, handling, use and deemed that Buyer has done so, as its sole discretion

drying periods. and risk. PPG has no control over either the quality or

condition of the substrate, or the many factors affecting

WARRANTY the use and application of the product. Therefore,

PPG warrants (i) its title to the product, (ii) that the PPG does not accept any liability arising from any

quality of the product conforms to PPG’s specifications loss, injury or damage resulting from such use or the

for such product in effect at the time of manufacture contents of this information (unless there are written

and (iii) that the product shall be delivered free of the agreements stating otherwise). Variations in the

rightful claim of any third person for infringement of application environment, changes in procedures of

any U.S. patent covering the product. THESE ARE use, or extrapolation of data may cause unsatisfactory

THE ONLY WARRANTIES THAT PPG MAKES AND results. This sheet supersedes all previous versions

ALL OTHER EXPRESS OR IMPLIED WARRANTIES, and it is the Buyer’s responsibility to ensure that

UNDER STATUTE OR ARISING OTHERWISE IN this information is current prior to using the product.

LAW, FROM A COURSE OF DEALING OR USAGE Current sheets for all PPG Protective & Marine

OF TRADE, INCLUDING WITHOUT LIMITATION, Coatings Products are maintained at www.ppgpmc.

ANY OTHER WARRANTY OF FITNESS FOR com. The English text of this sheet shall prevail over

A PARTICULAR PURPOSE OR USE, ARE any translation thereof.

DISCLAIMED BY PPG. Any claim under this warranty

must be made by Buyer to PPG in writing within five CONDITIONS OF SALE

(5) days of Buyer’s discovery of the claimed defect, but All our transactions are subject to our Terms and

in no event later than the expiration of the applicable Conditions of Sale.

shelf life of the product, or one year from the date of

the delivery of the product to the Buyer, whichever

is earlier. Buyer’s failure to notify PPG of such non-

conformance as required herein shall bar Buyer from

recovery under this warranty.

LIMITATIONS OF LIABILITY

IN NO EVENT WILL PPG BE LIABLE UNDER ANY

THEORY OF RECOVERY (WHETHER BASED ON

NEGLIGENCE OF ANY KIND, STRICT LIABILITY OR

TORT) FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IN ANY WAY

RELATED TO, ARISING FROM, OR RESULTING

FROM ANY USE MADE OF THE PRODUCT. The

information in this sheet is intended for guidance only

and is based upon laboratory tests that PPG believes

to be reliable. PPG may modify the information

contained herein at any time as a result of practical

experience and continuous product development. All

recommendations or suggestions relating to the use of

the PPG product, whether in technical documentation,

or in response to a specific inquiry, or otherwise, are

based on data, which to the best of PPG’s knowledge,

PPG Coatings Europe BV

www.ppgpmc.com

page 5/5 Revision date: 05-12-2012

Você também pode gostar

- Amercoat: Amerlock 400CDocumento4 páginasAmercoat: Amerlock 400CCad AutocadAinda não há avaliações

- Amerlock 400CDocumento4 páginasAmerlock 400CLalit Bom MallaAinda não há avaliações

- 0400GF Amerlock 400 GF PDS PDFDocumento4 páginas0400GF Amerlock 400 GF PDS PDFRenny DevassyAinda não há avaliações

- 0400GF Amerlock 400 GF PDSDocumento4 páginas0400GF Amerlock 400 GF PDSRenny DevassyAinda não há avaliações

- Amerlock 400gfaDocumento4 páginasAmerlock 400gfaKhaled bouhlelAinda não há avaliações

- Amercoat 400AL PDFDocumento4 páginasAmercoat 400AL PDFLalit Bom MallaAinda não há avaliações

- Amerlock 400 GFADocumento4 páginasAmerlock 400 GFASherif AbdelhameedAinda não há avaliações

- PG400CDocumento4 páginasPG400CSherif AbdelhameedAinda não há avaliações

- Amerlock 400Documento4 páginasAmerlock 400eternalkhutAinda não há avaliações

- Amercoat 391PC: Solvent Free Epoxy Product Data/ Application InstructionsDocumento4 páginasAmercoat 391PC: Solvent Free Epoxy Product Data/ Application InstructionsAchraf BoudayaAinda não há avaliações

- Amerlock 400GFA High Solids Glassflake Epoxy CoatingDocumento4 páginasAmerlock 400GFA High Solids Glassflake Epoxy CoatingSherif AbdelhameedAinda não há avaliações

- 0400MIO Amerlock 400 MIO PDS March 08Documento3 páginas0400MIO Amerlock 400 MIO PDS March 08Maryoto KasriAinda não há avaliações

- Amercoat: Amerlock 400AL/AL WNDocumento4 páginasAmercoat: Amerlock 400AL/AL WNCad AutocadAinda não há avaliações

- Protective & Marine Coatings: Industrial Enamel Voc ComplyingDocumento4 páginasProtective & Marine Coatings: Industrial Enamel Voc ComplyingAna CabreraAinda não há avaliações

- Amerlock 400 Sigmacover 400Documento6 páginasAmerlock 400 Sigmacover 400Vijay KumarAinda não há avaliações

- Derakane Resin Chemical ResistantDocumento50 páginasDerakane Resin Chemical ResistantTim KuAinda não há avaliações

- Amerlock® 400 Voc: Product Data SheetDocumento8 páginasAmerlock® 400 Voc: Product Data SheetCris gomezAinda não há avaliações

- PN78HBCDocumento4 páginasPN78HBCLassadAinda não há avaliações

- Amercoat 68 BSDocumento4 páginasAmercoat 68 BSStephen Francis BothelloAinda não há avaliações

- 7) PPG Amercoat 385 - Pds - AiDocumento4 páginas7) PPG Amercoat 385 - Pds - AididbeauAinda não há avaliações

- Aerospec 100 TdsDocumento2 páginasAerospec 100 TdsHasnain ZaidiAinda não há avaliações

- 134 TDS Updated Feb 2016 78-8141-8528-2 Rev ADocumento6 páginas134 TDS Updated Feb 2016 78-8141-8528-2 Rev AUriel GarciaAinda não há avaliações

- 400 UkDocumento4 páginas400 UkAhmed IbrahimAinda não há avaliações

- 0400 Amerlock 400 PDS March 08Documento2 páginas0400 Amerlock 400 PDS March 08Kalaiyazhagan ElangeeranAinda não há avaliações

- Amercoat 878: Physical DataDocumento2 páginasAmercoat 878: Physical Dataabdulgafoor54Ainda não há avaliações

- Amercoat 450E: Product Data/ Application InstructionsDocumento4 páginasAmercoat 450E: Product Data/ Application Instructions전상문Ainda não há avaliações

- 0400GF Amerlock 400 GF PDSMay 08Documento2 páginas0400GF Amerlock 400 GF PDSMay 08amadan64Ainda não há avaliações

- TDS - 00 - 7466 SigmaCover 456Documento4 páginasTDS - 00 - 7466 SigmaCover 456Mina RemonAinda não há avaliações

- Sigmacover 435Documento5 páginasSigmacover 435M.A.NAinda não há avaliações

- Amerlock 400Documento7 páginasAmerlock 400Satish VishnubhotlaAinda não há avaliações

- Carbocoat 8239: Selection & Specification DataDocumento4 páginasCarbocoat 8239: Selection & Specification DataSHAIK ASIMUDDINAinda não há avaliações

- Amerlock 400BFDocumento6 páginasAmerlock 400BFVijay KumarAinda não há avaliações

- DERAKANECRGuideDocumento74 páginasDERAKANECRGuideBapu612345Ainda não há avaliações

- Pds Psx700 Jan 2008Documento3 páginasPds Psx700 Jan 2008mjayhawk28Ainda não há avaliações

- 253 PDS AiDocumento4 páginas253 PDS AiAchraf BoudayaAinda não há avaliações

- Interline 399+ds+eng PDFDocumento4 páginasInterline 399+ds+eng PDFMohamed NouzerAinda não há avaliações

- DATA SHEET Industrial Enamel BlancoDocumento4 páginasDATA SHEET Industrial Enamel BlancoAlfredo OrellanaAinda não há avaliações

- TDS MarathonDocumento5 páginasTDS MarathonSyamsul MaripAinda não há avaliações

- TDS MarathonDocumento5 páginasTDS MarathonSyamsul MaripAinda não há avaliações

- Amerlock 2C: Fast Drying High Solids Epoxy Product Data/ Application InstructionsDocumento4 páginasAmerlock 2C: Fast Drying High Solids Epoxy Product Data/ Application InstructionsTony KhouryAinda não há avaliações

- Hcs2407 141 Henkel Resin Kit Loctite Ea 9394 AeroDocumento6 páginasHcs2407 141 Henkel Resin Kit Loctite Ea 9394 AeroTimmyAinda não há avaliações

- Carbotherm 3300 PDSDocumento4 páginasCarbotherm 3300 PDS이선엽Ainda não há avaliações

- Sigma Marine Coatings Manual - Part45Documento2 páginasSigma Marine Coatings Manual - Part45EngTamerAinda não há avaliações

- Hempadur 15130Documento2 páginasHempadur 15130MuthuKumarAinda não há avaliações

- Technical Data: P/S 870 Class B Corrosion Inhibitive SealantDocumento2 páginasTechnical Data: P/S 870 Class B Corrosion Inhibitive Sealantlucas laraAinda não há avaliações

- 253 PDS AiDocumento4 páginas253 PDS AiHrvoje RuzicAinda não há avaliações

- E Program Files An ConnectManager SSIS TDS PDF Interplus 256 Eng HK A4 20091005Documento4 páginasE Program Files An ConnectManager SSIS TDS PDF Interplus 256 Eng HK A4 20091005ram_babu_59Ainda não há avaliações

- Fuel Resistant Coatings: EC-776 EC-776SRDocumento6 páginasFuel Resistant Coatings: EC-776 EC-776SRpokleAinda não há avaliações

- Hard Natural Rubber: Technical Data SheetDocumento2 páginasHard Natural Rubber: Technical Data SheetBruno MiguelAinda não há avaliações

- 3M InfnDocumento32 páginas3M InfnAkash AkuAinda não há avaliações

- Intercure 200 (Primer)Documento4 páginasIntercure 200 (Primer)ccode904Ainda não há avaliações

- DS - 122 - Rev-01 - Epilux 4 High Build Epoxy FinishDocumento2 páginasDS - 122 - Rev-01 - Epilux 4 High Build Epoxy Finishvkvc soodAinda não há avaliações

- Amercoat 4801 Glass Flake Vinyl EsterDocumento4 páginasAmercoat 4801 Glass Flake Vinyl Esterilyasmd7Ainda não há avaliações

- Ficha Tecnica Castrol Perfecto X RangeDocumento3 páginasFicha Tecnica Castrol Perfecto X Rangeel pro jajaja GonzalezAinda não há avaliações

- Interzone 954: Modified EpoxyDocumento4 páginasInterzone 954: Modified EpoxyMehman NasibovAinda não há avaliações

- Epoxy Coating Basf-Masterprotect-100 Sewer StructureDocumento3 páginasEpoxy Coating Basf-Masterprotect-100 Sewer StructuresatheeshvmAinda não há avaliações

- PDS SikaTherm 4225 eDocumento2 páginasPDS SikaTherm 4225 eMarian ComaniciAinda não há avaliações

- Material Product Data Sheet Zirconia - Polymer Ceramic Abradable PowdersDocumento4 páginasMaterial Product Data Sheet Zirconia - Polymer Ceramic Abradable PowderskerbaubiruAinda não há avaliações

- Intercure 99Documento4 páginasIntercure 99Doby YuniardiAinda não há avaliações

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Ainda não há avaliações

- Epf Challan Dec-2016Documento1 páginaEpf Challan Dec-2016balangceAinda não há avaliações

- EPF Paid Challan Apr'17 IOCL VadinarDocumento1 páginaEPF Paid Challan Apr'17 IOCL VadinarbalangceAinda não há avaliações

- Letter of Application For Sigmadur Gloss For Camouflaging in TanksDocumento1 páginaLetter of Application For Sigmadur Gloss For Camouflaging in TanksbalangceAinda não há avaliações

- Bergerindia - Zinc Dust CertificateDocumento1 páginaBergerindia - Zinc Dust CertificatebalangceAinda não há avaliações

- Unpriced BidDocumento169 páginasUnpriced BidbalangceAinda não há avaliações

- HSB - Hydro-Slurry BlastingDocumento7 páginasHSB - Hydro-Slurry BlastingbalangceAinda não há avaliações

- CSS - Verbal Communication SkillsDocumento41 páginasCSS - Verbal Communication SkillsMASROOR ALI SOOMROAinda não há avaliações

- Datasheet Tertiary Pump Top 20120625Documento1 páginaDatasheet Tertiary Pump Top 20120625balangceAinda não há avaliações

- List of Products: PDF Created With Pdffactory Trial VersionDocumento1 páginaList of Products: PDF Created With Pdffactory Trial VersionbalangceAinda não há avaliações

- Effective StressDocumento25 páginasEffective StressGungah SaileshAinda não há avaliações

- The World of CyclophanesDocumento6 páginasThe World of CyclophanesDivya NarayanAinda não há avaliações

- APA Tech Bulletin On FormadehydeDocumento4 páginasAPA Tech Bulletin On Formadehydeca_alzuAinda não há avaliações

- Schneider - Chillers Range PDFDocumento27 páginasSchneider - Chillers Range PDFerreagaaAinda não há avaliações

- WPS FormatDocumento2 páginasWPS FormatAmit SarkarAinda não há avaliações

- Constitutive ModelsDocumento8 páginasConstitutive ModelsAnonymous D5s00DdUAinda não há avaliações

- 2 SonicScope SchlumbergerDocumento19 páginas2 SonicScope SchlumbergersudiptodattaAinda não há avaliações

- Anaerobic Fundamentals COD BalanceDocumento28 páginasAnaerobic Fundamentals COD BalanceDavid Sanchez100% (1)

- Multi Field Coupling Dynamic Modeling and Simula 2014 Simulation Modelling PDocumento24 páginasMulti Field Coupling Dynamic Modeling and Simula 2014 Simulation Modelling P刘文Ainda não há avaliações

- Has Got Yes, He Has.: My NotesDocumento1 páginaHas Got Yes, He Has.: My NotesrosaliaAinda não há avaliações

- GenChem2 Q3 Module1A Properties of Matter and Intermolecular Forces of Attraction v4Documento22 páginasGenChem2 Q3 Module1A Properties of Matter and Intermolecular Forces of Attraction v4Junelle Ramos Aquino100% (1)

- P Radiator Valves en PDFDocumento16 páginasP Radiator Valves en PDFpolitoAinda não há avaliações

- Optical Based Non Invasive Glucometer With IoTDocumento3 páginasOptical Based Non Invasive Glucometer With IoTSuwetha I GAinda não há avaliações

- New Substance Is Made, Like When Water Turns To Ice.: Physical and Chemical ChangesDocumento3 páginasNew Substance Is Made, Like When Water Turns To Ice.: Physical and Chemical ChangesAccounting SolmanAinda não há avaliações

- Ullmanns Encyclopedia of Industrial Chemistry Phosphoric Acid and Phosphates 58db177445fedDocumento44 páginasUllmanns Encyclopedia of Industrial Chemistry Phosphoric Acid and Phosphates 58db177445fedMuhammad FirmansyahAinda não há avaliações

- Low Cycle Fatigue in AnsysDocumento20 páginasLow Cycle Fatigue in AnsysSuvarnaAinda não há avaliações

- Modal Damping Estimates From Static Load-Deflection CurvesDocumento8 páginasModal Damping Estimates From Static Load-Deflection CurvesJose ManuelAinda não há avaliações

- Assighnment 1Documento4 páginasAssighnment 1Mouli SenguptaAinda não há avaliações

- Bernoulli Molecular ExplanationDocumento5 páginasBernoulli Molecular ExplanationmdimauroAinda não há avaliações

- (59-68) Monitoring and Modeling of Fayoum Distribution Networks According To Tri Halo Me Thanes FormationDocumento11 páginas(59-68) Monitoring and Modeling of Fayoum Distribution Networks According To Tri Halo Me Thanes FormationAlexander DeckerAinda não há avaliações

- Scaling of MosfetDocumento40 páginasScaling of MosfetSaumitra TripathiAinda não há avaliações

- Science Magazine April 07 2006 PDFDocumento144 páginasScience Magazine April 07 2006 PDFAndrés FrankowAinda não há avaliações

- Pgurl 2679036134142300Documento4 páginasPgurl 2679036134142300Barbara VasquezAinda não há avaliações

- ASTM GradesDocumento4 páginasASTM GradesSaurabh MundheAinda não há avaliações

- EDTA Titration of Calcium and MagnesiumDocumento3 páginasEDTA Titration of Calcium and MagnesiumAnonymous NxpnI6jC67% (3)

- Experiment No 6Documento4 páginasExperiment No 6LJ IDANE ARANASAinda não há avaliações

- 110 WS Solutions KeyDocumento2 páginas110 WS Solutions Keyshanmugam karthickAinda não há avaliações

- What Is A Performance CurveDocumento8 páginasWhat Is A Performance CurveRanjit PaulAinda não há avaliações

- Project Information: Basic Design ParametersDocumento6 páginasProject Information: Basic Design Parametersinterest100Ainda não há avaliações

- Tecnica PC Rapido PDFDocumento6 páginasTecnica PC Rapido PDFEnrique Castrillon AriasAinda não há avaliações