Escolar Documentos

Profissional Documentos

Cultura Documentos

Sakura Inspection

Enviado por

WACHDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Sakura Inspection

Enviado por

WACHDireitos autorais:

Formatos disponíveis

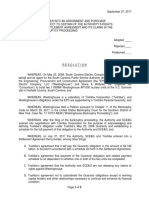

Commonwealth of Pennsylvania

Department of Agriculture 2301 N CAMERON ST

HARRISBURG, PA 17110

Bureau of Food Safety and Laboratory Services 717-787-4315

Retail Food Facility Inspection Report

Facility: SAKURA JAPANESE STEAKHOUSE Facility ID: 37526 Insp. ID: 660107

Owner: SAKURA JAPANESE STEAK HOUSE LLC Insp. Date: 2/26/2018

Address: 415 ORCHARD PLAZA Insp. Reason: Regular

City/State: ALTOONA PA No. of Risk Factors: 5

Zip: 16602 County: Blair Region: Region 5 No. of Repeat Risk Factors: 1

Phone: (814) 941-8588 Overall Compliance: OUT

FOODBORNE ILLNESS RISK FACTORS AND PUBLIC HEALTH INTERVENTIONS

Risk Factors are important practices and procedures identified as the most prevalent contributing factors of foodborne illness or injury.

Public Health Intervention are control measures to prevent foodborne illness or injury.

IN = In Compliance, OUT = Out of Compliance, N/O = Not Observed, N/A = Not Applicable, C = Corrected On Site, R = Repeat Violation

Supervision Protection From Contamination

1. Person in charge present, demonstrates knowledge, & Out 14. Food separated & protected Out, R

performs duties 15. Food-contact surfaces: cleaned & sanitized Out, R

Employee Health 16. Proper disposition of returned, previously served, In

2. Management, food employee & conditional food employee In reconditioned, & unsafe food

knowledge, responsibilities & reporting Time/Temperature Control for Safety

3. Proper use of restriction & exclusion In 17. Proper cooking time & temperatures N/O

4. Procedure for responding to vomiting & diarrheal events In 18. Proper reheating procedures for hot holding N/O

Good Hygienic Practices 19. Proper cooling time & temperatures N/O

5. Proper eating, tasting, drinking, or tobacco use In 20. Proper hot holding temperatures In

6. No discharge from eyes, nose, & mouth In 21. Proper cold holding temperatures In

Preventing Contamination by Hands 22. Proper date marking & disposition Out

7. Hands clean & properly washed In 23. Time as a public health control: procedures & records N/A

8. No bare hand contact with RTE food or a pre-approved In Consumer Advisory

alternate method properly followed 24. Consumer advisory provided for raw / undercooked foods In

9. Adequate handwashing sinks properly supplied & accessible Out Highly Susceptible Population

Approved Source 25. Pasteurized foods used; prohibited foods not offered N/A

10. Food obtained from approved source In Food/Color Additives & Toxic Substances

11. Food received at proper temperature N/O

26. Food additives: approved & properly used N/A

12. Food in good condition, safe, & unadulterated In

27. Toxic substances properly identified, stored & used; held for In

13. Required records available: shellstock tags, parasite N/A retail sale, properly stored

destruction

Conformance with Approved Procedures

28. Compliance with variance, specialized process, reduced N/A

oxygen packaging criteria or HACCP plan

GOOD RETAIL PRACTICES

Good Retail Practices are preventative measures to control the addition of pathogens, chemicals, and physical objects into foods.

Safe Food & Water Proper Use of Utensils

29. Pasteurized eggs used where required In 42. In-use utensils: properly stored Out

30. Water & ice from approved source In 43. Utensils, equipment & linens: properly stored, dried & In

31. Variance obtained for specialized processing methods In handled

Food Temperature Control 44. Single-use/single-service articles: properly stored & used Out

45. Gloves used properly In

32. Proper cooling methods used; adequate equipment for In

temperature control Utensils, Equipment & Vending

33. Plant food properly cooked for hot holding In 46. Food & non-food contact surfaces cleanable, properly Out

34. Approved thawing methods used Out designed, constructed, & used

35. Thermometers provided & accurate In 47. Warewashing facilities: installed, maintained & used; test In

strips

Food Identification

48. Non-food contact surfaces clean Out

36. Food properly labeled; original container In

Physical Facilities

Prevention of Food Contamination

49. Hot & cold water available; adequate pressure In

37. Insects, rodents & animals not present Out

50. Plumbing installed; proper backflow devices Out

38. Contamination prevented during food preparation, storage & Out

51. Sewage & waste water properly disposed In

display

52. Toilet facilities: properly constructed, supplied, cleaned In

39. Personal cleanliness In

53. Garbage/refuse properly disposed; facilities maintained In

40. Wiping cloths: properly used & stored Out

54. Physical facilities installed, maintained, & clean Out, R

41. Washing fruit & vegetables In

55. Adequate ventilation & lighting; designated areas used In

FOOD EMPLOYEE CERTIFICATION

Certified Food Employee Certificate

56. Certified Food Employee employed; acts as PIC; accessible In 57. Certified food manager certificate: valid & properly displayed In

Visit Date Person In Charge Person In Charge Sig. Date Sanitarian Sanitarian Signature Sig. Date Time In Time Out

Signature

2/26/2018 Zhen Chen 2/26/2018 Nannett Peterman 2/26/2018 12:30 PM 4:00 PM

3/1/2018 2:45:29 PM Page 1 of 3

Commonwealth of Pennsylvania

Department of Agriculture 2301 N CAMERON ST

HARRISBURG, PA 17110

Bureau of Food Safety and Laboratory Services 717-787-4315

Retail Food Facility Inspection Report

Facility: SAKURA JAPANESE STEAKHOUSE Facility ID: 37526 Insp. ID: 660107

Owner: SAKURA JAPANESE STEAK HOUSE LLC Insp. Date: 2/26/2018

Address: 415 ORCHARD PLAZA Insp. Reason: Regular

City/State: ALTOONA PA No. of Risk Factors: 5

Zip: 16602 County: Blair Region: Region 5 No. of Repeat Risk Factors: 1

Phone: (814) 941-8588 Overall Compliance: OUT

OBSERVATIONS AND CORRECTIVE ACTIONS

Violations cited in this report must be corrected within the timeframes below

Item Violation of Comment Correct By Date Repeat Violation

Number Code

1. 2 - 102.11(A- The Person in Charge does not have adequate knowledge of food safety in this food facility as

C1)(C4-16) evidenced by this non-compliant inspection.

9. 6 - 301.11 NO SOAP NOTED AT KITCHEN HANDSINK.

9. 6 - 301.12 NO PAPER TOWELS NOTED AT THE HANDSINK IN THE KITCHEN AND WAITRESS

STATION.

14. 3 - 302.11 Bowls of salads and containers of vegetables noted to be nested on top of each other with bottom Repeat Violation

of one container in direct contact with food. Instructed firm to dispose of foods.

14. 3 - 302.11 SHRIMP AND CUT VEGETABLES NOTED TO BE STORED IN OPEN PANS/BOWLS IN THE Repeat Violation

WALKIN COOLER WITHOUT ANY COVERING.

14. 3 - 302.11 Several raw animal foods(beef and chicken) were stored above ready to eat food(vegetables) in Repeat Violation

the walkin cooler.

15. 4 - 601.11(A) ROUND CLEAN DISHES AT THE COOKLINE WERE NOTED TO HAVE DRIED FOOD DEBRIS

AND THE RED SALAD BOWLS BESIDES THE WALKIN FREEZER HAD FOOD DEBRIS IN

BOWLS. INSTRUCTED FIRM TO RE WASH-RINSE-SANITIZE.

15. 4 - 602.11 TWO CUTTING BOARDS ARE HEAVILY STAINED. Repeat Violation

22. 3 - 501.17 BOWLS REFRIGERATED SALADS HELD MORE THAN 24 HOURS WERE NOT DATE

MARKED.

34. 3 - 501.13 VACUUM PACKED OF PREVIOUSLY FROZEN TUNA WERE NOT REMOVED FROM

PACKAGE WHEN THAWED.

37. 6 - 501.111 AT LEAST 280 MOUSE DROPPINGS NOTED ON FLOOR UNDER THE BAR, IN THE OFFICE,

WAITRESS STATION AND UNDER DRY INGREDIENTS STORED ON PALLETS IN STORAGE

ROOM.

37. 6 - 202.15 EXTERIOR DOOR ARE BADLY RUSTED AND DETERIORATED ON THE EXTERIOR OF THE

FACILITY. SCREEEN DOORS WERE NOTED TO HAVE 1 FOOT TEARS IN THE SCREENS.

DOORS DO NOT PROTECT AGAINST RODENT AND INSECT ENTRY.

38. 3 - 305.12 TRAY OF MEAT NOTED TO BE STORED UNDER DUSTY CONDENSER UNIT IN THE

WALKING COOLER.

38. 3 - 303.12 WALMART BAG FILLED WITH CUT LEMONS NOTED TO BE STORED DIRECTLY IN ICE

MACHINE DRINKING ICE.

38. 3 - 305.11 BAGS OF DRY INGREDIENTS ARE NOT STORED 6 INCHES OFF THE FLOOR, FOOD IS

STORED ON PALLETS THAT CANNOT BE EASILY MOVED.

40. 3 - 304.14 Observed wet wiping cloths in the kitchen, sushi area, not being stored in sanitizer solution.

42. 3 - 304.12 FIRM IS USING PLASTIC SCOOPS TO SCOOP OUT INGREDIENTS AND THESE SCOOPS

DO NOT HAVE ANY HANDLES TO PREVENT CONTAMINATION.

44. 4 - 502.13 FIRM RE-USING SINGLE USE PLASTIC CONTAINERS OF SEAWEED SALAD AND

WALMART BAGS.

46. 4 - 101.11 FIRM USING LINOLEUM 2X2 FOOT PIECES TO LINE SHELVES OF 2 DOOR UPRIGHT

COOLER. FIRM USING SARAN WRAP COVERED CARDBOARD BETWEEN LAYERS OF

SALAD BOWLS. MATERIALS ARE NOT EASILY CLEANABLE.

48. 4 - 602.13 TOP OF COOKLINE, AROUND WOK HOLDER WAS NOTED TO HAVE GREASY, CHARRED

BUILDUP.

48. 4 - 602.13 WIRE SHELVING IN THE WALKIN COOLER AND 2 DOOR UPRIGHT COOLERS WERE

NOTED TO HAVE HEAVY BUILDUP OF OLD STICKY FOOD RESIDUE.

48. 4 - 601.11(B- PLASTIC SHELF LINER IN WALKIN COOLER WAS NOTED TO HAVE POOLED STAGNANT

C) WATER AND MOLD ON SURFACES.

50. 5 - 205.15 RIGHT SIDE BOWL OF THE THREE BOWL DRAIN LINE WAS NOTED TO BE LEAKING.

50. 5 - 205.15 FLOOR DRAIN UNDER 3 BOWL SINK WAS NOTED TO DRAIN SLOWLY, TOP OF GREASE

TRAP HAD STAGNANT WATER.

54. 6 - 501.11 4 CEILING TILES WERE NOTED TO BE STAINED FROM PRIOR ROOF LEAK Repeat Violation

54. 6 - 201.11 WOODEN FLOOR AT THE ENTRY WAY TO THE KITCHEN IS DRY ROTTED AND

DETERIORATING. COUNTER TOP AT WAITRESS STATION WAS NOTED TO BE PEELING

AND FLAKING.

3/1/2018 2:45:29 PM Page 2 of 3

Commonwealth of Pennsylvania

Department of Agriculture 2301 N CAMERON ST

HARRISBURG, PA 17110

Bureau of Food Safety and Laboratory Services 717-787-4315

Retail Food Facility Inspection Report

Facility: SAKURA JAPANESE STEAKHOUSE Facility ID: 37526 Insp. ID: 660107

Owner: SAKURA JAPANESE STEAK HOUSE LLC Insp. Date: 2/26/2018

Address: 415 ORCHARD PLAZA Insp. Reason: Regular

City/State: ALTOONA PA No. of Risk Factors: 5

Zip: 16602 County: Blair Region: Region 5 No. of Repeat Risk Factors: 1

Phone: (814) 941-8588 Overall Compliance: OUT

OBSERVATIONS AND CORRECTIVE ACTIONS

Violations cited in this report must be corrected within the timeframes below

Item Violation of Comment Correct By Date Repeat Violation

Number Code

54. 6 - 501.12 WALLS, FLOOR, CEILING AND EXTERIOR DOOR OF THE WALKIN COOLER WERE NOTED

TO HAVE BLACK,STICKY, GREASY FOOD BUILDUP. CEILING WAS NOTED TO HAVE

DUST BUILDUP. FLOORS UNDER 5 GALLON CONTAINERS OF OIL, BEHIND COOKLLINE,

UNDER DISHWASHER, UNDER 2 DOOR UPRIGHT COOLER,HIBACHI STATIONS, UNDER 3

BOWL SINK AND UNDER WOODEN PALLETS WAS NOTED TO HAVE OLD GREASY BLACK

FOOD BUILDUP AND RICE. MOLD NOTED ON THE CAULKING BEHIND THE 3 BOWL SINK.

PUBLISHED COMMENTS

PURPOSE FOR VISIT WAS A ROUTINE INSPECTION. TEMPERATURES 36, -7, 38, 34.

46.1144 - The Retail Food Facility license will not be renewed until such time as this facility is compliant as per Pa. Code §46.1143 (FDA Food Code 8-304.11(B))

regulations, and this facility may be subject to $150 or $300 inspection fees if a 2nd or 3rd follow-up inspection is necessary to achieve compliance. The facility has been

closed by order, and shall not reopen until approved by this Department. The Closure Order posted by the Department shall not be removed, altered or concealed in any

way, under penalty of Law. (FDA Food Code 8-304.11(E))

The person in charge stated that the report will be provided to the owner for review. JOINT INSPECTION WITH BRENDA TYLER, RICK CHOBOY. INSPECTION

REVIEWED WITH ZHEN CHEN. INSPECTION WILL BE POSTED ON THE DEPARTMENTS WEBSITE.

3/1/2018 2:45:29 PM Page 3 of 3

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Clearfield School Safety LetterDocumento2 páginasClearfield School Safety LetterWACHAinda não há avaliações

- Sakura ReinspectionDocumento2 páginasSakura ReinspectionWACHAinda não há avaliações

- Pennsylvania Redistricting Case - Emergency Application To SCOTUS For Stay 2-21-2018Documento50 páginasPennsylvania Redistricting Case - Emergency Application To SCOTUS For Stay 2-21-2018Legal Insurrection50% (2)

- Pennsylvania Redistricting Map Challenge - Corman V Torres Complaint (MD PA)Documento44 páginasPennsylvania Redistricting Map Challenge - Corman V Torres Complaint (MD PA)Legal Insurrection100% (1)

- Clearfield School Safety LetterDocumento2 páginasClearfield School Safety LetterWACHAinda não há avaliações

- New KFCDocumento1 páginaNew KFCWACHAinda não há avaliações

- Cresco Yeltrah ProductsDocumento7 páginasCresco Yeltrah ProductsWACH83% (6)

- Dunchin StatementDocumento1 páginaDunchin StatementWACHAinda não há avaliações

- Order Adopting PA Remedial MapDocumento48 páginasOrder Adopting PA Remedial MapDaily Kos ElectionsAinda não há avaliações

- Sunoco Pipeline LP, Consent Order and Agreement - February 8, 2018Documento102 páginasSunoco Pipeline LP, Consent Order and Agreement - February 8, 2018WACHAinda não há avaliações

- Congressional MapDocumento1 páginaCongressional MapWACHAinda não há avaliações

- College Tuition CostsDocumento32 páginasCollege Tuition CostsWACHAinda não há avaliações

- NTSB Safety Recommendation Amtrak Crash Cayce, SCDocumento4 páginasNTSB Safety Recommendation Amtrak Crash Cayce, SCWLTXAinda não há avaliações

- Westmont ResponseDocumento1 páginaWestmont ResponseWACHAinda não há avaliações

- Butterbaugh StatementDocumento1 páginaButterbaugh StatementWACHAinda não há avaliações

- Barto Suspension OrderDocumento25 páginasBarto Suspension OrderWACH100% (1)

- Piazzas Comment 1 Year LaterDocumento2 páginasPiazzas Comment 1 Year LaterWACHAinda não há avaliações

- Ebensburg Plane Crash ReportDocumento3 páginasEbensburg Plane Crash ReportWACHAinda não há avaliações

- Westmont Hilltop On ThreatDocumento1 páginaWestmont Hilltop On ThreatWACHAinda não há avaliações

- Westmont ThreatDocumento1 páginaWestmont ThreatWACHAinda não há avaliações

- Central PA HospitalsDocumento32 páginasCentral PA HospitalsWACHAinda não há avaliações

- Western PA Hospital ReportDocumento32 páginasWestern PA Hospital ReportWACHAinda não há avaliações

- 12 New Members ChargedDocumento5 páginas12 New Members ChargedWACHAinda não há avaliações

- DEP OrderDocumento24 páginasDEP OrderWACHAinda não há avaliações

- HUD FindingsDocumento6 páginasHUD FindingsWACHAinda não há avaliações

- Tobacco FreeDocumento34 páginasTobacco FreeWACHAinda não há avaliações

- Clearfield District On Whooping CoughDocumento2 páginasClearfield District On Whooping CoughWACHAinda não há avaliações

- Final Board ResolutionDocumento3 páginasFinal Board ResolutionWACHAinda não há avaliações

- 2017-33 SC National Guard On State Duty in Support of Puerto RicoDocumento2 páginas2017-33 SC National Guard On State Duty in Support of Puerto RicoWACHAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- Model FSPDocumento40 páginasModel FSPAnous AlamiAinda não há avaliações

- Dollar General Health InspectionDocumento2 páginasDollar General Health InspectionMatt Stevens100% (1)

- LP Market Forms of EggDocumento7 páginasLP Market Forms of Eggmay anne Francisco100% (2)

- ED Most Essential Learning CompetenciesDocumento13 páginasED Most Essential Learning CompetenciesKathryn EugenioAinda não há avaliações

- MLG 4Documento20 páginasMLG 4GS ShawonAinda não há avaliações

- Microbial Safety of Minimally Processed FoodsDocumento357 páginasMicrobial Safety of Minimally Processed FoodsGaganpreet KaurAinda não há avaliações

- Tle-Cookery: Market Forms of EggsDocumento17 páginasTle-Cookery: Market Forms of EggsMichael AmoresAinda não há avaliações

- Navy Manual of Naval Preventive MedicineDocumento561 páginasNavy Manual of Naval Preventive MedicinePlainNormalGuy2Ainda não há avaliações

- FPC Manual PDFDocumento75 páginasFPC Manual PDFD'Shea OllivierreAinda não há avaliações

- Food Protection Training ManualDocumento97 páginasFood Protection Training Manualpalaniappan1989Ainda não há avaliações

- Chapter 8 - Servsafe - 6e EditedDocumento6 páginasChapter 8 - Servsafe - 6e Editeddevvy anneAinda não há avaliações

- Pasteurized EggsDocumento8 páginasPasteurized Eggsapi-202950260Ainda não há avaliações

- Johnstown Save-A-Lot Inspection ReportDocumento2 páginasJohnstown Save-A-Lot Inspection ReportRyan GraffiusAinda não há avaliações