Escolar Documentos

Profissional Documentos

Cultura Documentos

Applications of Steel-Fibre-Reinforced Ultra-High-Strength Concrete

Enviado por

Alejandro Rodríguez0 notas0% acharam este documento útil (0 voto)

7 visualizações4 páginasApplications of Steel-Fibre-Reinforced Ultra-High-Strength Concrete

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoApplications of Steel-Fibre-Reinforced Ultra-High-Strength Concrete

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

7 visualizações4 páginasApplications of Steel-Fibre-Reinforced Ultra-High-Strength Concrete

Enviado por

Alejandro RodríguezApplications of Steel-Fibre-Reinforced Ultra-High-Strength Concrete

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 4

Applications of Steel-Fibre-Reinforced Ultra-High-Strength

Concrete

Bjame C. Jensen, Prof

Carl Bro as, Odense, Denmark

Summary

In this paper, the properties of a steel-fibre-reinforced ultra-high-strength con-

crete are discussed. The matrix is a silica-fume-based concrete with a compres-

sion strength of 140-200 MPa. Among other excellent properties, the bonds be-

tween reinforcement bars and the concrete are very good. Thus, the anchorage

length of the reinforcement bars is very small. Taking advantage of this, a new

building system made up of precast elements has been designed. The building

system is composed of columns and slab elements only, which are cast together in

a very simple process. The system can produce flat-slab buildings that have large

spaces between the columns, making it possible to design buildings with a high

degree of flexibility in terms of usage

The Material

Demands for structures with reduced

dead loads and increased durability

have led to the development of high-

strength and ultra-high-strength con-

cretes. In ultra-high-strength con-

cretes, the binder is often composed of

Portland cement powder and other

fine particles, such as fly ash, steel

powder or Al,O;, Ultra-fine particles,

‘often round silica fume partictes (ci-

ameter 0.1-0.2 mm) with high SiO:

content, are then added to the binder.

Such binders are very dense and

strong, thus producing ultra-high-

strength concrete. However, such

types of concrete are very brittle,

which is not good for structural pur-

poses. The problem can be solved

though by adding steel fibres to the

concrete.

In the work presented here, the con-

crete used is a silica-fume-based con-

crete known as Compresit. It is chara

terised by its dense, durable and very

strong binder (Densit), which contains

tightly packed fine and ultra-fine parti-

cles. ‘The characteristic strength of

Compresit is 140-200 MPa

The water/powder ratio of Compresit

is 0.15-0.18, the silica fume content is

20-25% (by vol.), and the steel fibre

content is 6% (by vol.). The length and

diameter of the fibres are 12 mm and

0.4 mm, respectively, and the fibres

have a tensile strength of about 1600

Peer-eviewed by international

‘experts and accepted by the TABSE.

Publications Commitee

Structural Engineering International 2/99

kPa. The fibres are of Bakaert Stan-

dard, and are made of plain straight

cut wire. Quartz sand is used as the ag-

gregate, with particle diameters of up

to4mm.

Performance of the Material

The matrix material has been tested in

several research works, including the

Eureka and Brite-EuRam projects,

and in individual projects [1-3]

Due to the low water/powder ratio,

large amounts of anhydrous particles

are present in the matrix. These act as

‘an effective barrier to any soluble sub-

stance because the water is used to

produce new hydrates that block the

pores of the matrix and prevent fur

ther penetration.

‘The matrix is alkaline and it seems to

have no capillary-free water. Capillary

porosity has not been detected, and all

pore diameters are less than 6 nm. The

small cracks in the concrete are not in-

terconnected, partly due to the large

number of fibres.

In the dense Compresit matrix, water

absorption and air permeability are

very low, and the chemical resistance is

very good. Freeze/thaw damages were

not detected after tests according to

RILEM Recommendation no. 117-

FDC. The matrix is practically immune

to carbonation, and the extent of chlo-

ride diffusion is extremely low com-

pared with that of ordinary concrete.

Resistance to fire could be a problem

because the Compresit matrix is ex-

tremely dense. The risk of explosive

spalling due to vapour pressure from

heated water has been investigated,

and it was found that, after a reason-

able drying period, no spalling oc:

curred during exposure to high tem-

peratures. This is due to the low water

content and the presence of the steel

fibres.

Another advantage of Compresit is

that, in contrast to ordinary concrete,

the strength of Compresit does not de-

crease when it is heated to more than

300-350°C. In addition, due to the

composition of the binder, the decom-

posing processes in Compresit are dif-

ferent from those in ordinary concrete

(4)

The failure criterion for Compresit has

been investigated intensively [5]. It

has been determined that Coulomb's

modified failure hypothesis can be

used as a failure criterion and that the

theory of plasticity can be used in the

ultimate limit state, The modification

that occurs upon failure will normally

result in a tensile strength of zero, and

the failure criterion in the plane stress

field will be the square failure criteri-

on, which also occurs with convention-

al concrete (Fig. 1). Therefore, designs

can be carried out according to mod-

ern theories of conerete design [6] as

used in Eurocode 2 in the design of

shear in beams and in construction

joints, However, the coefficient of effi

2

f,

Fig I: Failure criterion

Reports 143

66/2 youoweuzayu Sopoouysug jeamroans

asevasd wrosy sBuypying yons sonpord

OF 1oNaMOHL AUTIGIOY stp 190 (SBut

-puyng wuunjos-qeys) sBuipying guise.

“Bupyng ay

Jo ast 941 uo Supuadap *(aaeid ayer

Inoys 40) aoeid sayea uayo SuIpunqas

araym Suorninsut pu sFurpping 29130

40} Ajperpadsa ‘pansap uayjo axe AILq

Nay Jo aaiop uty e MUN SBuIpENG

woaysig Surpring Man VW

‘WYN ST-ZI Jo AB1aua omoesy v pur

ced 81-21 JO yiduans apsuar v *egD

(¢ Jo entzaut Jo snynpour perm we “egy

002-0PT Jo WPBuaNs uorssaaduod v o1e

usadwo Jo saniadod yeods any,

swujo! yo sodA1 mou uo s1sa1 1anpuos

‘01 Azessaaau Ins sting ‘stutof usisap

01 pasn aq ue uonenba ayy, [or] ssau

-y8nor 31 uo pusdap 1ou sop Yrs

“eA09 aiaiouos ay) wos; uoRngtiuo9

ayi siuasaidar (4'Sc0) uonenba ayy

Jo ued Ise] ou, ‘Spuens Sussonsard

40} o19z se waxe) 9g IsMUT 1 ‘JeQ aut

Jo ssauyBnoy ay Jo spuadap ose fun

jd at asnesog “o1ar9u09 ay jo Buna

ads stuaard yoy “quowoouoyutas

(2 =u) sing osuaasuons

‘on yp 40g » fo womomrs puogy

m4

ass Suypying qoys og +p By

Testansuen ayy Woy uoHMattuoD om

stuasoidaz ('6/1) uonenba ayy Jo ized

Puodds af 0182 01 jenba aq 01 pouns

Se 99 URD aNqea iy) Spuens BuIssons

sod 104 ‘S1Eq pagal auf Jo ssouysinos

ay1 wosy uoNNgUOS ay siuasoidox

$0 ‘I “ba Jo apis puey-aysir ay) uD

‘sivg [estoasueat Jo saquinu ay) st

vu pue *1eq wawao.ojulox Jesi9AsUEN v

Jo Pare [eUONIZ9S-sso19 ay) st" a194a6

P

oH

”

won

senbs ay jo suvaui

x00} 2YL “gels Wonog ayy UF sieq e018 WA sluawafa araiquoD uN se peut st warsKs HOMULIOJ YL “pasn u99q SOY, warsKs lomuLOy waueULIed F LOO, dot ayy ur pue “usardwoy jo apeu age syuauia]a ses aly ‘wopUuoT “TuDuL sysiqeisa yoreasay Suiping oy we Azovexogey v ut Ing waaq sey armanzIs geis-tey a1aisu0s Aaioys-uanas-y ‘soseo jeigads ut fuo nsaidwo3 paaioy “uaz Jono apeur oq Aiqeqoud | squow[o jeanyonus “([Z] stvaq autos ‘woyy pue suuNjoo HoYS WON] Pato aq vo sdnuins ‘ajdurexa 103) poo Aza age saudwio;) pue_yua1w2010} -urar waamiag spuog ay7 yBnowp uaAT aoejd aye) 10U jIIm ysarduto.) kq 21219 -wo9 AreuIp10 JO uonnninsqns yPx.UDe © 1eUN sNOIAgo st ‘aroFaz9uT ‘aI9zu09 Axeurpso Jo 1ey) wer 94814 proprnoy o1 -aaiyp st wsaudwiod Jo aoud ou, FEA 2p JO 987) [eANPNAS “yarou09 [euonuesuos 10) se eNOS owes ay) Sursn parejnores aq touues suoneinoye> soy o1ut pasnpoxnut st yey ‘A “Koua!9 12109 unvap fo uonras sso49 :2 Sty ———————— le [ape concrete elements is not easy. Trans- portation of slab elements, and some- times the crane capacity, limits the size of the slab elements and conse- quently the space available between the columns. The situation could be changed, however, if it were possible to connect the slab elements in such a way that columns are not necessary at each corner of the elements (Fig. 4) A flat-slab building system as shown in Fig. 4 has been developed, tested and built. The joints between the slab ele- ments are placed above the supports and at the centre of the span between the supports. A building can be erect- ed by placing the columns in their foot- ings and temporary columns at the crossings of the joints. Then, the slab elements can be mounted on top of the columns, simple scaffolding work be- neath the joints can be carried out, and the joints can be executed. After a few days, the scaffolding and the tempo- rary columns can be moved, and the result is a “monolithic” slab supported by columns. ‘The joints between the slab elements are placed where the most extreme moments appear in the slab. If can- tilever slabs are used, the shear force will also be of extreme importance. ‘The system requires a very high per- formance of the joints, but the erection process is rather simple. Fig. 5: Building system during erection Structural Engineering International 2/99 ‘The simple process saves some costs, but the additional cost of using the expensive fibre-reinforced Compresit in the joints makes the whole system only slightly cheaper than traditionally column-beam-slab buildings. The flexi- bility of the building is, however, much better. Furthermore, if the capacity of the mo- ‘ment transfer between the slab and the columns can be taken into account, shear walls can be omitted and the flexibility of the system can be opti- mised. Tests have indicated that this can be achieved, provided that the buildings have only a few stories and are located outside seismic areas, for example in Northern Europe. The sys- tem has already been used in Den- mark, with a column space of 6 m and with slab element dimensions of 5.9 m 2.9 m, leaving a joint opening of 100 mm (Figs. 5 and 6). Fig. 6: Joint between column and slab ele- Connections ‘To connect the slab elements in the above-mentioned building system, the excellent bond between reinforcement bars and steelibre-reinforced Com- presit has been used. The joints are de- signed as shown in Fig. 7. ‘The reinforcement bars (8 mm in dia- meter) are extended 80 mm from the slab into the joint, Longitudinally, bars (6 mm in diameter) are placed in the joint on top of the bars from the slabs. ‘All the joints are cast with Compresi Tests on the moment capacity of the joint have been carried out with differ- ent lengths of extension of the bars into the joint [11]. The aim of the tests was to find the length of anchorage that ensured yielding in the bars dur- ing the load. The tests showed that an ss poco enh Fig, 7: Joints between slab elements extension length of 80 mm or even 60 mm was enough to ensure yielding in the reinforcement. With an extension length of 40 mm, anchorage failure was observed. A typical load-deflec- tion curve from a test with yielding in the reinforcement is shown in Fig. 8. Fire tests have also been carried out [11]. The thermal fire load was deter- wed according to the standard time- temperature curve given in ISO 834. ‘The fire resistance can be taken as 60 min, and it can easily be extended to 90 min, Itis notable that, even though the gree of steel fibres in the Compresit is high, the casting process at the site is, not difficult. The casting is of course not as easy as that for ordinary con- crete, but more importantly the strength of the joint is very sensitive to the execution of the casting. In Japan, connections between large concrete elements (cross section 900 mm x 500 mm) have been tested [12], and researchers are now focussing on the bonding of thick reinforcement bars (up to 51 mm). In Sweden, inves- tigations on connections between bridge beams are in progress, having. been initiated by the highway authori- ties, 0 ojo Fig. 8: Load-deflection curve at bending Reports 145 66/2 (wuopeusayuy Supaoussug jeun}onNg suodey ort / LOTELOTE Sp+ sng CTLLLOTE Sp+ souoNd > | ssanbax jepads uo ajqi 184) PUB SUOHEA}SUoMap ‘a>fA198 BUNINSUOD wadequado> 00¢7-4d suraisdg ssa miig-uy S/V SINAWNULSNI NNVAYAD swouruac 701 foadnapurg suaquio 9}2:9u09 Jo ssaunppqy} Jo JuDUIBINSEI|A, suawdojanop yiBuans aBe Kure seys-22904 20 SY SurssauBo2d Jo wopeNfes suey parsafut 20 stamp aqquo Jo “3-2 ‘uonsafur yo Keng syper Sujuado aonans jo ydaq -103 dunaeys éq pasnes 3-9 ‘oyar5u0> pure [99}s u9944jaq BuspuOdaC, stej190 eydse mojoq souesquiou aan29}02d Jo Bunsoy AyU30}U] ‘suai aay H9IATOG KHOI, uosou siepaao yeydse nouns 40 ype ‘quis 20 syuatajo Suquy jouumy ‘9}230}0ys Jo sKaaans woNTUIUTE|Og + ‘SEDIE JuOUIIDEOJUIaZ pI}S93 14 us uaa “Buyquioadouoy pue spIoA ‘syDRID Jo UONEIO'T + of anbyuysay aaponsisap wou “yoas-y8ty ssomou ay, saanjanays Dy fo uoysajap mupf sof wajsky Isa], oyaq-1avduy 121900 (osouedey ut) ot ¢1-soet A 2661 2 ON “ot 10a ‘samansey o1oz9u05, uedep jo Sur P2200Kd udDde4) spun ZOUOW tBuaate Wir pediofiney agg pawy Bass soy SmaoU09 180-044 TEI WH VXOIHS [2th $1-£9 1 Gogh stony Sioaiey ‘samnsig. s101000), wiapoy UO wns dwg o1ps0N. ‘aiaoua> posrofus axgif tnduanryiiy tay Suasn sBiapyng tsbo0ud tn suousouey ‘We 18 “98 NASNAE [VI] L661 “Vay 2295, suonuosuoy Buds [py s1o.000 poner snoy soaig yduous ysis, Jo sovtodoug puog OA ‘NASNAL “8 anyvv [oll Le6t Van =p895 “uonuantog funds [oy sung Sutoofiaoy paonds stg. Suzy azooue pooeef “mea toaig isu Wie “a AAW [ol £9661 0quaRON “OPI ouatayuo uortutpie pig “woluon0 tio ~ ypavaieg aaumusojiad Spying nny YW 'SOOW *D ‘aOdnfs “4 “WNVHO [8] L661 Vax ‘9m89§ “uonuasue> BuUds [Dy aioe) poouofury augry yuans-ySiH ain Jo suowwayddy anonas N°XAOM W “INOTHaA@ °O ‘waINwaa [/] “6d 8 “F861 TN “SHIID poosoysiug, vouy WeH-2anuas nse 21242002 pup sssjouy mnury “dW 'NASTAIN [6] ‘Gast HeUACT 10 AussOAIUA, eowypay, SupaauZug yemonng Jo Wout suedog “pz¢ Pur ¢Ze SON suOdoy 7] 42g Puo J ung 2121200) parsofuiry 24g 1224 yiSuaus-y8H van ‘A’ ‘NASTAIN [s] 9661 ‘Sed ‘2te19u0> souews royod-ysIMBuDNS-RIY Jo voNRATIN, wo uimisodunsg Jeuoneusoiuy yp 21212409 pasog auf vaqis parxofuaa vugrf Jo 20u0y sso utd“ ANA °'a ‘NASNAL [P] ‘9661 Sued ‘2Io19U05 aoueUULO}ad-YRIE miuans-y8iH] Jo uoneZINA uo umisod “wag Juonewauy Wp (DYD) susodwoy paoiojuysy ss0duio) 224309 ypSuaus y8ry nan fo npqung “a aCIVY °WSIVad SOW “a7avwanv[e] “9661 =8p14q swe “wonsnnstoy s15!mDuE UF THOU! s2010]uI2y JO UoISOUI0:) UO uINISoduIks Ieuoneusouy wp 1220u09 ySuauis S14 pup fo Sunqoanp uo syooro.onu Jo 12f S40 AASAOHONITS “4 AAV [Z] “£8 dd “1961 “puetuog Boqiey “1p ON, uioday Tq) sediouuy 230g ‘ssodwory poswofusy ieeduioy “HH “AHOVA IT sanuarajoy sem ajduns $198 e ur squat -2]9 otf) 1aUUOD OF ajqIssod 1 sayEUE ‘a1@19UOD pasioyutar-auqy-[9a1S axp ue sieq quawanioyutas ay) u9>¥19q Plog qwayjADX ayp aLayNs ‘SpuoU9}9 2}920U09 aseoaid Jo pasuuduios worsks Bumping mau e st ajduexa remo oy, ‘papueut -op Augean ayy or anp Aressooou av YEH SHE WOUWADIOPUIOY ay] 01 19 -s09 Jo TunoUte at 40 yPBuaNs 217 aptA oad 10W pInoo ayassuos Areurpi0 pur pany st y8r=y eto ayy az94m ‘Sqes [ets st aU “aAoge UaArB axe sojduzexa tyons om, Stonpoid jeisads 7 port, aq asns Asn sit “az0yazayp Sonssuadxo st leyaiew ayy, “Buuaauu9 pemonns Ww psn aq we 16M sionpord Aupenb-y8ry are ‘isosduso3 ajdurexa 105 ‘Saroz0009 UBuans-ya-eNN pantoyuos-a1gy-joorg suojsnpuoy

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Pa PB PHN PC PD Pe PF PG: @brace @brace @braceDocumento1 páginaPa PB PHN PC PD Pe PF PG: @brace @brace @braceAlejandro RodríguezAinda não há avaliações

- A Simple Guide To in - Situ Ground Testing Part 1Documento4 páginasA Simple Guide To in - Situ Ground Testing Part 1Alejandro RodríguezAinda não há avaliações

- GMPTRM3004 1 PDFDocumento1 páginaGMPTRM3004 1 PDFAlejandro RodríguezAinda não há avaliações

- Removal and Reuse of Hardened ConcreteDocumento13 páginasRemoval and Reuse of Hardened ConcreteAlejandro RodríguezAinda não há avaliações

- Specific Heat and Thermal Diffusivity of Hardening ConcreteDocumento6 páginasSpecific Heat and Thermal Diffusivity of Hardening ConcreteAlejandro RodríguezAinda não há avaliações

- Applications of Steel Fiber Reinforced ConcreteDocumento6 páginasApplications of Steel Fiber Reinforced ConcreteAlejandro RodríguezAinda não há avaliações

- 305CR Mini Hydraulic Excavator-Before OperationDocumento6 páginas305CR Mini Hydraulic Excavator-Before OperationAlejandro Rodríguez80% (5)

- Weld and Base Metal Discontinuities: Module 9 - 1Documento13 páginasWeld and Base Metal Discontinuities: Module 9 - 1Alejandro RodríguezAinda não há avaliações

- Simple Guide To in - Situ Ground Testing Part 2Documento4 páginasSimple Guide To in - Situ Ground Testing Part 2Alejandro RodríguezAinda não há avaliações

- Weld Joint Geometry Welding and NDE Symbols: Module 4 - 1Documento124 páginasWeld Joint Geometry Welding and NDE Symbols: Module 4 - 1Alejandro RodríguezAinda não há avaliações

- RT Equipment: Radiation Source Densitometer / Film Density Strips Film ProcessorDocumento30 páginasRT Equipment: Radiation Source Densitometer / Film Density Strips Film ProcessorAlejandro RodríguezAinda não há avaliações

- Effects of Fire On Concrete - AjmDocumento5 páginasEffects of Fire On Concrete - AjmAlejandro Rodríguez100% (1)

- Applications of Ferrocement in Low-Cost Housing in MéxicoDocumento14 páginasApplications of Ferrocement in Low-Cost Housing in MéxicoAlejandro RodríguezAinda não há avaliações

- Visual Inspection and Other NDE Methods and SymbolsDocumento17 páginasVisual Inspection and Other NDE Methods and SymbolsAlejandro RodríguezAinda não há avaliações

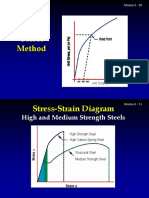

- Metal Properties and Destructive Testing: Module 6 - 1Documento49 páginasMetal Properties and Destructive Testing: Module 6 - 1Alejandro RodríguezAinda não há avaliações

- CWI-VIW Gray Case ChecklistDocumento10 páginasCWI-VIW Gray Case ChecklistAlejandro RodríguezAinda não há avaliações

- How To Read Welding SymbolsDocumento17 páginasHow To Read Welding SymbolsAlejandro RodríguezAinda não há avaliações

- VIW2006RTDocumento80 páginasVIW2006RTAlejandro RodríguezAinda não há avaliações

- Offset Method: Unit StrainDocumento9 páginasOffset Method: Unit StrainAlejandro RodríguezAinda não há avaliações

- Module 6 CDocumento26 páginasModule 6 CAlejandro RodríguezAinda não há avaliações

- Module 10 DDocumento30 páginasModule 10 DAlejandro RodríguezAinda não há avaliações