Escolar Documentos

Profissional Documentos

Cultura Documentos

Solid End Mills MS2MS PDF

Enviado por

Anderson JuniorTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Solid End Mills MS2MS PDF

Enviado por

Anderson JuniorDireitos autorais:

Formatos disponíveis

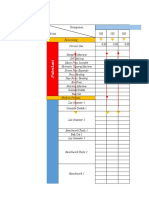

RECOMMENDED CUTTING CONDITIONS

Carbon steel, Cast iron, Alloy steel, Hardened steel (45 ─ 55HRC)

Pre-hardened steel

Work

material

Cf53, GG25 X40CrMoV51

Dia. Revolution Feed rate Depth of cut Revolution Feed rate Depth of cut

(mm) (min-1) (mm/min) (mm) (min-1) (mm/min) (mm)

0.1 40000 40 0.001 40000 40 0.001

0.2 40000 100 0.002 40000 100 0.002

0.3 40000 200 0.005 40000 200 0.005

0.4 40000 600 0.01 40000 600 0.01

0.5 40000 1000 0.015 40000 960 0.015

0.6 40000 1200 0.02 40000 1200 0.02

0.7 40000 1400 0.02 40000 1400 0.02

0.8 40000 1600 0.03 40000 1600 0.03

0.9 40000 1800 0.04 40000 1600 0.04

1 40000 2000 0.06 32000 1600 0.06

1.5 40000 3000 0.12 32000 1900 0.08

2 30000 3000 0.18 24000 1900 0.10

2.5 24000 2600 0.25 19000 1600 0.13

3 20000 2300 0.30 16000 1400 0.15

4 15000 2000 0.40 12000 1200 0.20

5 12000 1600 0.50 9000 900 0.25

6 10000 1400 0.60 7000 700 0.30

8 8000 1000 0.80 5600 550 0.40

10 6400 900 1.00 4500 500 0.50

12 5400 820 1.00 3800 450 0.50

16 2400 380 3.00 1200 100 0.80

20 1900 320 4.00 1000 80 1.00

< Please refer to the list above

for depth of cut. D

Depth of < Please refer to the list above

cut < 1D

for depth of cut.

D:Dia.

1) If the depth of cut is shallow, the revolution and feed rate can be increased.

2) When slotting with end mills with & 3 or larger, reduce the revolution to 50 ─ 70% and the feed rate to 40 ─ 60%.

3) When drilling, please set the feed rate at 1/3 or below the values above.

4) If the rigidity of the machine or the work materials installation is very low, or chattering and noise are generated, reduce the revolution and

feed rate proportionately.

Você também pode gostar

- Shaft Alignment Excel SheetDocumento5 páginasShaft Alignment Excel Sheetpollekeshooter100% (1)

- Database Management Systems: Understanding and Applying Database TechnologyNo EverandDatabase Management Systems: Understanding and Applying Database TechnologyNota: 4 de 5 estrelas4/5 (8)

- 2001 Daewoo Nubira Service Manual2 PDFDocumento685 páginas2001 Daewoo Nubira Service Manual2 PDFalberto 32100% (1)

- Audit Sampling (Chapter 9)Documento25 páginasAudit Sampling (Chapter 9)cris100% (2)

- Bbs FormatDocumento9 páginasBbs Formatlaukesh kumar singhAinda não há avaliações

- Industrial Automation and Control Systems - Chapter 1 - Basic Concepts of MeasurementsDocumento21 páginasIndustrial Automation and Control Systems - Chapter 1 - Basic Concepts of MeasurementsHasan IsmailAinda não há avaliações

- 2 ID FansDocumento43 páginas2 ID Fansshubham vermaAinda não há avaliações

- Koreksi Indeks Absorbansi 5 TitikDocumento9 páginasKoreksi Indeks Absorbansi 5 TitikHasbukin NurAinda não há avaliações

- Toilet Exhaust SystemDocumento3 páginasToilet Exhaust SystemVinay PantAinda não há avaliações

- Book 1Documento72 páginasBook 1TrisgarAdePutraAinda não há avaliações

- Variația: V (KM/H)Documento6 páginasVariația: V (KM/H)Robert BadeaAinda não há avaliações

- Ambion: Wearnes CambionDocumento2 páginasAmbion: Wearnes CambionalexanderAinda não há avaliações

- Calculation Plots Etc Presentation A3Documento13 páginasCalculation Plots Etc Presentation A3alaa adienAinda não há avaliações

- Blade Design Spreadsheet Shape: 7 2.40 2 4 0.8 6 Blue CellsDocumento2 páginasBlade Design Spreadsheet Shape: 7 2.40 2 4 0.8 6 Blue CellsOptimuz TsAinda não há avaliações

- Exam GraphDocumento3 páginasExam GraphSHADES 4 ALLAinda não há avaliações

- CostsDocumento6 páginasCostsChalaAinda não há avaliações

- Injection Timing Calculator 2020Documento43 páginasInjection Timing Calculator 2020Tim JuddAinda não há avaliações

- Optimized Power CA CS Values From 0 To 250000Documento6 páginasOptimized Power CA CS Values From 0 To 250000Anonymous 58eTU1dPDsAinda não há avaliações

- MatekDocumento4 páginasMatekSigit Ayyu's PrabowoAinda não há avaliações

- Viscosity Conversion Chart 2Documento1 páginaViscosity Conversion Chart 2Quan PhanAinda não há avaliações

- Sesion 2. Comparativo DespachosDocumento63 páginasSesion 2. Comparativo DespachosDanny MoshAinda não há avaliações

- Factor XP 02Documento2 páginasFactor XP 02Javier FcAinda não há avaliações

- Calibr of RMC 18+900 - 8thDocumento10 páginasCalibr of RMC 18+900 - 8thaashish patidarAinda não há avaliações

- HW 7Documento9 páginasHW 7RaulAinda não há avaliações

- Calculos SedimentacionDocumento6 páginasCalculos SedimentacionLinaurysAinda não há avaliações

- P (Pa) Q (m3/s) : Pressure Drop Volumetric FlowrateDocumento2 páginasP (Pa) Q (m3/s) : Pressure Drop Volumetric FlowrateMuhammad HamzaAinda não há avaliações

- Abrasive Grit and Particle ConversionsDocumento2 páginasAbrasive Grit and Particle ConversionsEn Tip100% (2)

- Sir Fawad Najam Assignment No 1 FinalDocumento50 páginasSir Fawad Najam Assignment No 1 FinalRajput JanjuaAinda não há avaliações

- U - Imposed (1) (Cylindrical:1) (Lbforce - MM)Documento68 páginasU - Imposed (1) (Cylindrical:1) (Lbforce - MM)LinhcvAinda não há avaliações

- UntitledDocumento6 páginasUntitledVanamamalai JothiAinda não há avaliações

- FJJ Llroo PDocumento294 páginasFJJ Llroo PDhaval PanchalAinda não há avaliações

- Raouff FDocumento6 páginasRaouff FRaouf TitiweAinda não há avaliações

- Chart Title Chart TitleDocumento2 páginasChart Title Chart TitleGilbert JapayAinda não há avaliações

- CBR 04Documento1 páginaCBR 04DODI SOFYANAinda não há avaliações

- ShockDocumento2 páginasShockSam GeorgeAinda não há avaliações

- (-1/KM) 1/vmax KM - 0.83333333 0 Vmax1 0 166.666667 Vamx2 0 250 Vmax3 0 500 500 600Documento6 páginas(-1/KM) 1/vmax KM - 0.83333333 0 Vmax1 0 166.666667 Vamx2 0 250 Vmax3 0 500 500 600elfbilentAinda não há avaliações

- Planilha de Calculo RAIN CRANE WalterDocumento5 páginasPlanilha de Calculo RAIN CRANE WalterThiagoAinda não há avaliações

- KinetikaDocumento3 páginasKinetika'Dora Myron Jeruzielski'Ainda não há avaliações

- Vazão Bomba de ÓleoDocumento2 páginasVazão Bomba de ÓleoFabrício FasoloAinda não há avaliações

- Tolerance TablesDocumento2 páginasTolerance TablesPeter GelburdAinda não há avaliações

- Hpd-Sus Drill Hss 5% Cobalt Cutting Data: DJ543 & DJ544 Series DrillingDocumento1 páginaHpd-Sus Drill Hss 5% Cobalt Cutting Data: DJ543 & DJ544 Series DrillingMario MlinarićAinda não há avaliações

- Ejercicio en ClaseDocumento4 páginasEjercicio en ClaseAndres CevallosAinda não há avaliações

- Calibration LinearDocumento15 páginasCalibration LinearThusith WijayawardenaAinda não há avaliações

- Resistencias en Serie Resistencias en Paralelo: Tabla 1Documento6 páginasResistencias en Serie Resistencias en Paralelo: Tabla 1Danilo BurgosAinda não há avaliações

- Cec 315 Assignment 2 OgbonnaDocumento3 páginasCec 315 Assignment 2 OgbonnaOji IfeanyiAinda não há avaliações

- AaaaaaaaaaaaaaaaaaaaaaaaDocumento3 páginasAaaaaaaaaaaaaaaaaaaaaaaaHarrison DwyerAinda não há avaliações

- B H L FC RHO Asn N As D: Interaction DiagramDocumento17 páginasB H L FC RHO Asn N As D: Interaction DiagramAbid HussainAinda não há avaliações

- Stress-Strain CurvesDocumento4 páginasStress-Strain Curvesskatehabitat24Ainda não há avaliações

- Evaluacion de La Integral de Duhamel para Cargas SismicasDocumento6 páginasEvaluacion de La Integral de Duhamel para Cargas SismicasAngela Odría RubioAinda não há avaliações

- No 4 FixxDocumento19 páginasNo 4 Fixxbalad7998Ainda não há avaliações

- BladedesignDocumento2 páginasBladedesignRaees SwatiAinda não há avaliações

- Blade Design Spreadsheet: 7 2.40 2 4 0.8 6 Blue CellsDocumento3 páginasBlade Design Spreadsheet: 7 2.40 2 4 0.8 6 Blue CellsbadmaAinda não há avaliações

- NR - CRT hp29 (M) hp30 (M) hp31 (M) hp32 (M) hp33 (M) hp34 (M) hp35 (M) hp36 (M) hp37 (M) 1 2 3 4 5 6Documento5 páginasNR - CRT hp29 (M) hp30 (M) hp31 (M) hp32 (M) hp33 (M) hp34 (M) hp35 (M) hp36 (M) hp37 (M) 1 2 3 4 5 6Aanei Ionut LaurentiuAinda não há avaliações

- RM Selection - SolverDocumento10 páginasRM Selection - SolverPoedya Samapta Catur PamungkasAinda não há avaliações

- Orden 0: Experiencia 1Documento20 páginasOrden 0: Experiencia 1abelAinda não há avaliações

- 2nd Moments of Inertia: W F F, U F, L A BDocumento3 páginas2nd Moments of Inertia: W F F, U F, L A Bvortex11Ainda não há avaliações

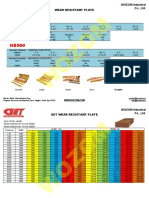

- GET Wear PlateDocumento5 páginasGET Wear PlateIvanAinda não há avaliações

- Adancime Fagas (%) Viteza de Deformatie (mm/1000 Cicluri) : Fagas Def Fagas DefDocumento17 páginasAdancime Fagas (%) Viteza de Deformatie (mm/1000 Cicluri) : Fagas Def Fagas DefthesolomonAinda não há avaliações

- Beam Desain1Documento2 páginasBeam Desain1Astri NgentAinda não há avaliações

- Graph 3 PipesDocumento4 páginasGraph 3 PipesPriyankAinda não há avaliações

- Graph 3 PipesDocumento4 páginasGraph 3 PipesPriyankAinda não há avaliações

- British Commercial Computer Digest: Pergamon Computer Data SeriesNo EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesAinda não há avaliações

- Acer V193 Service ManualDocumento46 páginasAcer V193 Service Manualagun92Ainda não há avaliações

- Phillip Hudson: (813) - 334-3337 PSH5017@psu - EduDocumento1 páginaPhillip Hudson: (813) - 334-3337 PSH5017@psu - Edupsh5017Ainda não há avaliações

- University of Wah Wah Engineering College Assignment # 1: (Reg No.Documento2 páginasUniversity of Wah Wah Engineering College Assignment # 1: (Reg No.Hiba AliAinda não há avaliações

- K230F Equipment ManualsDocumento166 páginasK230F Equipment ManualsHui ChenAinda não há avaliações

- Letter B Lesson PlanDocumento3 páginasLetter B Lesson Planapi-300212612100% (1)

- Additional Instructions For Mailing Your Package: Drop Off LocatorDocumento2 páginasAdditional Instructions For Mailing Your Package: Drop Off LocatorEthanAinda não há avaliações

- Updated Eva ResumeDocumento1 páginaUpdated Eva Resumeapi-534826411Ainda não há avaliações

- Forensic Module 2 MidtermDocumento27 páginasForensic Module 2 MidtermAdrias IvanAinda não há avaliações

- Manonmaniam Sundaranar University: B.Sc. Mathematics - Ii YearDocumento98 páginasManonmaniam Sundaranar University: B.Sc. Mathematics - Ii YearSadia ahmadAinda não há avaliações

- Eng8Quarter1Week1 2Documento6 páginasEng8Quarter1Week1 2Duero-Hadjilatip KayeAinda não há avaliações

- Project Profile AdamaDocumento4 páginasProject Profile AdamaYohannes AlemayehuAinda não há avaliações

- Sınıf 2. Yazılı A-B RelearnDocumento5 páginasSınıf 2. Yazılı A-B RelearncanerAinda não há avaliações

- Transient Thermal Analysis On Re-Entry Vehicle Nose Cone With Tps MaterialsDocumento10 páginasTransient Thermal Analysis On Re-Entry Vehicle Nose Cone With Tps Materialssiva shankarAinda não há avaliações

- MODEL: SC330 Industrial Range Powered by Cummins: Diesel Generating Set 400/230 V - 50 HZ - 3phaseDocumento4 páginasMODEL: SC330 Industrial Range Powered by Cummins: Diesel Generating Set 400/230 V - 50 HZ - 3phaseDefly GustiAinda não há avaliações

- Real Time Manufacturing' Using Oracle Cloud 13: A Manufacturing Execution System by WiproDocumento18 páginasReal Time Manufacturing' Using Oracle Cloud 13: A Manufacturing Execution System by WiproSatya NekkantiAinda não há avaliações

- AMME4710 Chap5 ColourIPDocumento56 páginasAMME4710 Chap5 ColourIPrajeevrajkumarAinda não há avaliações

- Lecture On Dictionaries - Jupyter NotebookDocumento13 páginasLecture On Dictionaries - Jupyter NotebookruchikaAinda não há avaliações

- Physiological, Anthropometric, and Motor Characteristics of Elite Chinese Youth Athletes From Six Different SportsDocumento12 páginasPhysiological, Anthropometric, and Motor Characteristics of Elite Chinese Youth Athletes From Six Different SportsRafida I CAinda não há avaliações

- 제8차 전력수급기본계획Documento51 páginas제8차 전력수급기본계획김명근Ainda não há avaliações

- Tech Com 1Documento16 páginasTech Com 1HawaiiChongAinda não há avaliações

- Effects of Reservoir Heterogeneity in Laminated ReservoirsDocumento3 páginasEffects of Reservoir Heterogeneity in Laminated ReservoirsErik Andres Garcia VillarroelAinda não há avaliações

- HOUSEKEEPING - WEEK 1 UpdatedDocumento5 páginasHOUSEKEEPING - WEEK 1 UpdatedMaria Rizza IlaganAinda não há avaliações

- H-330 Field Installation Manual IndexDocumento11 páginasH-330 Field Installation Manual IndexRamon JimenezAinda não há avaliações

- 11-001 Gergess Author Proof CorrectedDocumento18 páginas11-001 Gergess Author Proof CorrectedJamil JmlAinda não há avaliações

- Carlo Pescio: A Physics of SoftwareDocumento11 páginasCarlo Pescio: A Physics of SoftwareCarlo PescioAinda não há avaliações

- Thomson Catalog CompressedDocumento210 páginasThomson Catalog CompressedCharlesAinda não há avaliações