Escolar Documentos

Profissional Documentos

Cultura Documentos

2018 Xometry Partner Reference Guide

Enviado por

Steven DDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

2018 Xometry Partner Reference Guide

Enviado por

Steven DDireitos autorais:

Formatos disponíveis

2018 Partner

Reference Guide

Doc ID: 499363a7b9747d0d197f49c8203220c73cbfa0e7

2 0 18 PA R T NE R R E FE R E NCE GUIDE

Thank you for being a Xometry Partner!

In this guide we will address some common questions as well as our general

Partner policies. Please be sure to read this all the way through before you take on

your first job.

How it Works

Xometry’s proprietary pricing algorithm uses computational geometry and machine learning to

determine the specific requirements of each part. Based on historical data, we derive a price

and lead time- almost instantaneously- as a customer loads their parts to our website. We

welcome you to try out our quoting platform for yourself, as it will give you a sense of what our

typical customers see when quoting a job.

You can access the quoting platform at the following link: get.xometry.com/quote

As you will see, all we need to derive a price is the CAD file. That is why most of our jobs will only

include a 3D geometry and no drawing. The customer then has the option to order directly from

our site, so by the time you see the work, the job is already secured.

Based on your capabilities, our sorting algorithm identifies each job’s requirements and

then matches the job to your shop, i.e. a lathe job is placed with partners who have lathe

capabilities. This holds true for mill and sheet metal capacity, finish specifications, and even shop

certifications. This is why filling out your capabilities online is so important. You are only able to

view jobs that suit your shop’s profile.

2 Doc ID: 499363a7b9747d0d197f49c8203220c73cbfa0e7

2 0 18 PA R T NE R R E FE R E NCE GUIDE

Setting Up Your Account

There are three steps to setting up your account with Xometry.

1. First, add your shop’s capabilities, including machines, finishing capabilities, and

certifications. We will use that information to match jobs that are best suited to your shop.

2. Next, you will need to sign our NDA agreement due to the highly sensitive nature of some

of our customers’ work.

3. Finally, we will send you a short demographic on-boarding questionnaire about your shop.

Once you have filled out the required information, we will reach out to you with instructions for

completing the first job with Xometry, which is the final step in the on-boarding process.

3 Doc ID: 499363a7b9747d0d197f49c8203220c73cbfa0e7

2 0 18 PA R T NE R R E FE R E NCE GUIDE

Job Board Policies

FIR S T T R I A L JOB

Before receiving full approval into the Xometry Partner Network, all new partners are required to

complete one trial job for Xometry

• Chosen parts will be sent to you via email upon completion of the on-boarding questionnaire

• Parts will be shipped back to Xometry for full inspection and acceptance

Once accepted, you will be reimbursed for the cost and permitted access to the live job board

DIR EC T S HIP

All new partners will ship work directly to Xometry for inspection. Partners that possess an

excellent track record of producing high-quality, on-time parts will be approved to ship directly

to our customers. As you will no longer need to ship back to Xometry, direct ship-approved

partners will have an extra two days to complete their parts.

S U S PE N S ION

If Xometry identifies a problem with your work, e.g. lateness or quality related, we will put your

account on a temporary suspension until the issues are resolved. Xometry will work directly with

Partner to resolve the issues and reactivate the account.

4 Doc ID: 499363a7b9747d0d197f49c8203220c73cbfa0e7

2 0 18 PA R T NE R R E FE R E NCE GUIDE

Navigating the Job Board

Xometry will send an email notification to the account holder every time we post a job to your

account (these notifications can be managed in your account settings). If you follow the link in

the email, it will take you to our job board where you will be able to review the parts and their

requirements. Xometry provides all of the job details (price, lead time, material, etc.) for you to view.

You can also access the job board by visiting work.xometry.com and logging in. The 3D CAD files,

drawings (if available), materials, and part quantities are all in one place. If the price, lead time, and

job requirements are a fit, simply accept the job and a PO will be generated automatically.

Accepted Jobs

Once a job has been accepted, jobs are can be managed using Xometry’s web application. You

can easily provide status updates, and and upload inspection reports, CoC’s and photos and

CoC’s when required. You can also communicate directly with Xometry if you have questions

about dimensions or tolerances. Upon acceptance of the job, you are agreeing to complete the

productions of parts in your own facility. These parts cannot be made in alternative locations

without the explicit consent from Xometry.

5 Doc ID: 499363a7b9747d0d197f49c8203220c73cbfa0e7

2 0 18 PA R T NE R R E FE R E NCE GUIDE

Part Photos

Part photos are required to complete the workflow online. This allows us to have clear

documentation of a completed job prior to it being shipped to Xometry or directly to the

customer, and should only take a few moments of your time. Please make sure the photos are

clean and the subject is clearly in view.

GO OD PA R T PHOTO B A D PA R T PHOTO

• Good lighting • Bad lighting

• Parts contrast with background • Hard to distinguish parts from

• Each part is clearly defined background

• Parts overlapping

• Messy

6 Doc ID: 499363a7b9747d0d197f49c8203220c73cbfa0e7

2 0 18 PA R T NE R R E FE R E NCE GUIDE

Inspection and Quality Standards

Delivering high quality parts is incredibly important to us. As a result, all new partners are

required to ship directly to our facility so we can thoroughly inspect all of your work.

We do, however, want our partners to be in the habit of checking their work. As such, we will

require you to inspect each job based on the subsequent inspection requirements and complete

the Xometry Inspection Report which can be downloaded from your Xometry Account Profile in

Xometry Communications.

I N S P E C T I O N C H E C KL I S T

PART ID: DRAWING:

ORDER ID: INSPECTOR:

DATE:

Verify quantity of machined parts is in accordance with purchase order.

Verify that machined parts are free of burrs, sharp edges, blemishes, or discoloration

caused by machining.

When applicable, verify that the part inserts are installed and that the insert quantities

are in accordance with the purchase order.

When applicable, verify that the threaded and tapped hole quantities are in accordance

with the purchase order.

When applicable, verify the part finish is uniform, not flaking, peeling, cracking, or

streaking, and free of runs or blisters.

When applicable, verify that the part welded joints are in accordance with the purchase order.

Verify that all part mechanical dimensions are in accordance with the customer-supplied

or partner generated print. All print dimensions are ballooned and correlated to the

inspection report.

Record tool serial number, last calibration date, and calibration renewal date.

Verify lot contains appropriate documentation to include but not limited to the Purchase

Order, Packing Slip, and any other documentation defined in Purchase Order (such as

Material Test Reports, Plating and Finishing Documents, Certificate of Conformance, etc…)

QC SIGNATURE: DATE:

7 Doc ID: 499363a7b9747d0d197f49c8203220c73cbfa0e7

2 0 18 PA R T NE R R E FE R E NCE GUIDE

IN S PEC T I ON D OCUME N TAT ION R EQUIR E ME N T S

Each order requires inspection documented on the Xometry Inspection Report which can be

downloaded from your Xometry Account Profile in Xometry Communications. Regardless of

order quantity, 100% of all dimensions, attributes, dimensional locations and print notes must

be documented for at least 1 piece. If a print is provided it must be ballooned to correlate with

the inspection report. If a print is not provided we expect our partners to generate a print from

M

the CAD file that is ballooned to correlate with the inspection report. Below is an example of a

S A

completed Xometry Inspection Report and with a correlated ballooned print.

M

FINAL INSPECTION REPORT

A

SHEET 1

S

Characteristic Accountability, Verification, and Compatibility Evaluation

Customer: Sample Customer Contact: Sample Contact Supplier: XOMETRY Cage Code:

E

Part No./Rev: Part Name: Sample Part Order ID / Part ID: Report:

Material: Copper 101 Finish: Standard 004EDCD FINAL

L

Characteristic Accountability Inspection / Test Results

P

Char. Upper Lower Designed Non-

Requirement Results Notes

No. Limit Limit Tooling Con.

M

1 Ø .067 2-56 UNC Go No-Go Go Thread Gauge ^ Conforms

2 .965 0.0970 0.960 0.964 Gauge ^ Conforms

3 .230 0.265 0.225 0.231 Gauge ^ Conforms

4 .292 0.297 0.287 0.293 Gauge ^ Conforms

5 Ø .500 0.505 0.495 0.500 Gauge ^ Conforms

E

6 Ø .085 4-40 UNC Go No-Go Go Thread Gauge ^ Conforms

L

7 .188 0.193 0.183 0.188 Gauge ^ Conforms

P

8 .401 0.406 0.396 0.402 Gauge ^ Conforms

9 .058 0.063 0.053 0.059 Gauge ^ Conforms

M

10 .113 0.118 0.108 0.112 Gauge ^ Conforms

11 .303 0.308 0.298 0.304 Gauge ^ Conforms

SA

12 .041 0.046 0.036 0.042 Gauge ^ Conforms

13 1.500 1.505 1.495 1501 Gauge ^ Conforms

14 .378 0.383 0.373 0.377 Gauge ^ Conforms

The signature indicates that all characteristics are accounted for, meet drawing requirements, or are properly documented for disposition.

E

PREPARED BY: DATE:

E SA

MP L

A

Subsequent inspection documentation required is IAW ANSI/ASQ Z1.4 Level II sampling plan for

AM P

all total tolerances of 0.004”. Some examples of these are +/-0.002” or less for diametrical, linear,

and locational tolerances. Also all GD&T callouts that are 0.004” or less.

8 Doc ID: 499363a7b9747d0d197f49c8203220c73cbfa0e7

2 0 18 PA R T NE R R E FE R E NCE GUIDE

M AT E R I A L T E S T R E P OR T S

When material test reports (MTR’s) are required (requested) by Xometry, they must state both

mechanical and chemical properties of the material, lot or heat number, the specification

which the material complies with (AMS, EN, ASME, ASTM, etc.). There also may be instances

that the material must be DFARS and NAFTA approved by the USA or qualifying country, not

counterfeit and also be mercury free. These cases will be specified on the Purchase Order. The

documentation must be uploaded to the job board and a copy must accompany the shipment.

PL AT ING A ND FINI S H DOCUME N T R EQUIR E ME N T S

In all cases when plating or specific finish requirements are defined, a copy of the certification

stating the process and the applicable specification documented on the cert. must be sent

with the shipment and uploaded with the MTRs. Example: If a print states “Clear Anodize to

MIL-A-8625 TYPE II” the certification must state this wording.

CE R T IFI C AT E OF CONFOR M A NCE

All part ID’s require their own Xometry Certificate of Conformance (C of C) downloaded from the

job portal and then uploaded after completion.

Certification requirements will be identified on both the job board and the purchase order.

When the parts are shipped direct to the customer or to Xometry, the documentation must

be uploaded to the job board and a copy accompanying the shipment. Lack of sending proper

documentation will result in rejection upon receiving and potential return of parts.

R E L AT I ON S HIP B E T W E E N T HE C A D MODE L A ND T HE B LUE PR IN T

All geometry and dimensioning will automatically default to the CAD model. If a print is also

supplied, it is supporting information that a model cannot capture. Examples of this are GD&T

callouts, tap sizes, inserts – helicoil, pem, etc., surface roughness requirements better than a

standard 125, and both general (tolerance block) or specific tolerances i.e. reamed hole size,

press fit, etc. If there are any questions regarding when to apply information contact Xometry at

work@xometry.com.

9 Doc ID: 499363a7b9747d0d197f49c8203220c73cbfa0e7

2 0 18 PA R T NE R R E FE R E NCE GUIDE

TOLE R A NCE S - M ACHINING

If a CAD model only is supplied the following tolerances apply to machined surfaces:

For features of size (Length, width, height, diameter) and location (position, concentricity,

symmetry) +/- 0.005”

For features of orientation (parallelism and perpendicularity) and form (cylindrical, flatness,

circularity, and straightness) apply tolerances as follows:

0-12” Tolerance 0.005” Angularity +/- ½ degree

Over 12”-24” Tolerance of 0.010” Angularity +/- ½ degree

Over 24”-36” Tolerance of 0.015625” (1/64) Angularity +/- 1 degree

Over 36”-60” Tolerance of 0.03125” (1/32) Angularity +/- 1 degree

Over 60” Tolerance of 0.0625” (1/16) Angularity +/- 1 degree

If a blueprint is provided, all tolerances of the print supersede the CAD model tolerancing

above. Any supporting dimensioning on blueprints such as GD&T callouts, tap sizes, inserts,

specific surface roughness must be followed. Parts that do not require plating or surface

treatment must be supplied “as machined” and at most be polished with scotch brite unless

there are requirements for sandblast, bead blast, shot peen, tumble, etc. The surface roughness

requirement for “as machined” surfaces is Ra 125 micro-inches maximum.

10 Doc ID: 499363a7b9747d0d197f49c8203220c73cbfa0e7

2 0 18 PA R T NE R R E FE R E NCE GUIDE

TOLE R A NCE S - S HE E T ME TA L

If a CAD model only is supplied the following tolerances apply to surfaces:

Forming and bending +/- 0.020”

Bend to hole or feature +/- 0.010”

Linear dimensions excluding locations to

+/- 0.005”

bends

Diameters with inserts +0.003/-0

Diameters without inserts +/- 0.005”

Angularity +/- 2 degrees

Blank material: Ra 125 uin max

Surface Roughness

Timesave: Ra 100 uin max

If a blueprint is provided, all tolerances of the print supersede the CAD model tolerancing

above. Any supporting dimensioning on blueprints such as GD&T callouts, tap sizes, inserts,

specific surface roughness must be followed.

TOLE R A NCE S - PL A S T IC

Unless otherwise specified by blueprints, all tolerances are +/- 0.010”

11 Doc ID: 499363a7b9747d0d197f49c8203220c73cbfa0e7

2 0 18 PA R T NE R R E FE R E NCE GUIDE

Shipping Policy

Xometry provides FedEx 2-Day or Ground delivery labels for all jobs unless otherwise noted.

To utilize the Xometry shipping account, you must generate a shipping label through the online

portal. To generate a shipping label, click the Ship button on the Current Jobs page to go to the

Shipping page. Note that the Ship button will not appear in the Job Details page until all stages of

the workflow have been completed.

Once on the Shipping page, click the Print Packing Slip button to generate a packing list. From

there you will be prompted to generate a Shipping Label.

Xometry will not be responsible for organizing FedEx pick-ups. Partners are expected to organize

the truck’s arrival and handle associated fees. To set up a pick-up, please make the label via our

site then log into FedEx.com or call 1-800-463-3339 (1-800-GOFEDEX).

• Partners with a FedEx Account: Can set pick-up via phone or online

• Partners without a FedEx Account: Can set up a pick-up via the phone. Ask representative

to create a Site Profile for future pick-ups.

If you have multiple packages for the same order, please contact Xometry support additional

labels. In the event that Xometry support personnel create shipping label(s) for you offline, you

will still be required to complete the workflow online. If you do not generate a shipping label

through the online portal, you will not be reimbursed for shipping costs incurred.

If expedited shipping is required to meet a lead time, you will be charged a $50 fee.

All shipments must receive an origin scan (e.g. they cannot be deposited in a drop box). We do

not consider an order complete, and you will be solely responsible for all losses, if you do not

receive an origin scan.

12 Doc ID: 499363a7b9747d0d197f49c8203220c73cbfa0e7

2 0 18 PA R T NE R R E FE R E NCE GUIDE

Packaging Policy

Please ensure that all parts have been deburred and are free of dirt and oil prior to shipping.

To ensure all parts are received by the customer unharmed and free of dings and scratches, we

recommend the following packaging procedures:

Bag and bubble wrap

• Bag and tag each part with appropriate part ID

STEP 1

• Use thick protective wrapping for heavy items (we’ve

found that 1/2” bubble wrap from ULINE is most

effective)

Secure wrapped part in standard box

STEP 2

• Include padding on all sides of the part

• Items should not touch exterior walls

Include additional padding

STEP 3

• Fill the box with extra paper

• Make sure the part has no “wiggle room” within the

box

Seal the box

STEP 4

• Tightly tape the box to ensure it will not unfold

• Include packing lists and additional documents in

sealed slip on the exterior of the package

13 Doc ID: 499363a7b9747d0d197f49c8203220c73cbfa0e7

2 0 18 PA R T NE R R E FE R E NCE GUIDE

Invoicing and Payment

Before you tell us, we know! This is the most important section! Xometry strives to pay all of

its Manufacturing Partners in a timely manner. We use a service called Tipalti to manage our

invoicing and payments.

W HE R E D O I S IGN UP A ND W HO S HOULD R EGI S T E R?

You should have received an email from our accounting department with a link to register with

Tipalti. If you haven’t, please reach out immediately to work@xometry.com and we will send you

a new one.

HOW D O I S UB MI T IN VOICE S T HROUGH T IPA LT I ?

Once you have registered and your bank information has been saved, you will be able to submit

invoices via Tipalti’s dashboard. You should submit each invoice separately as soon as you ship

your parts. Please visit: https://suppliers.tipalti.com/xometry/Account/Login to access your

personal dashboard. Logging directly into www.tipalti.com will not take you to the proper page.

W HE N W ILL I R ECE I V E PAY ME N T ?

Xometry pays valid invoices on the 14th and 28th day each month so long as those days fall on

a business day. If not, they will be paid on the first business day subsequent to those dates. The

payments will be issued according to the following schedule:

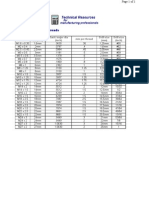

PAY DAT E IN VOICE S UB MI T T E D

14th 10 th -23rd

28 th 24 th -9 th

14 Doc ID: 499363a7b9747d0d197f49c8203220c73cbfa0e7

2 0 18 PA R T NE R R E FE R E NCE GUIDE

There are two conditions that make an invoice valid:

• It must be submitted through Xometry’s Tipalti accounts payable system after Xometry is

properly notified the parts have shipped and tracking information provided.

• The invoice is received no later than 30 days after part shipment from the Partner.

Any invoice submitted later than 30 days is permanently invalid and Xometry will not pay. If you have

any additional questions about how to use the new platform or need assistance signing up, please

reach out to us directly via work@xometry.com and someone will be in touch as quickly as possible!

Reworks and Quality Issues

If the parts delivered by a Partner do not pass our inspection process due to quality issues,

the PO for that job will be placed on hold until there is a resolution. If reworks must be done

by Xometry to make the part acceptable for the customer, the price of those reworks will be

deducted from the PO. If the customer accepts the parts without the need for reworks, the PO

will be taken off hold and the Partner will be paid according to our payment terms. If the parts

are rejected and a resolution cannot be found, the PO will be canceled.

Documents and Security

In order to maintain the security of our customers, we prefer that Partners permanently

delete their online and offline storage of any drawings, models, instructions or specifications

of Xometry jobs for which they have reviewed, quoted or completed production at least once

every 18 months thereafter.

This requirement applies to technical documents and scrapped or extra parts only; not to documents

such as invoices, POs, sales orders, contracts, or any document required to be retained by law.

Always maintain the security of these files in a way that they are not readily accessible to

unauthorized persons, including unauthorized employees.

01/15/2018

15 Doc ID: 499363a7b9747d0d197f49c8203220c73cbfa0e7

Audit Trail

TITLE 2018 Xometry Partner Reference Guide

FILE NAME Xometry_Reference...ners_2018 (5).pdf

DOCUMENT ID 499363a7b9747d0d197f49c8203220c73cbfa0e7

STATUS Completed

01/15/2018 Viewed by - (industrialservicewny@gmail.com)

18:02:20 UTC IP: 192.188.230.2

01/15/2018 Signed by - (industrialservicewny@gmail.com)

21:36:40 UTC IP: 192.188.230.2

01/15/2018 The document has been completed.

21:36:40 UTC

Você também pode gostar

- Car Maintainer, Group B: Passbooks Study GuideNo EverandCar Maintainer, Group B: Passbooks Study GuideAinda não há avaliações

- Report Gundriling AAMAstakhovDocumento27 páginasReport Gundriling AAMAstakhovGyörgy Murvai100% (1)

- Cncpresentation PDFDocumento37 páginasCncpresentation PDFCorey YoungAinda não há avaliações

- Design of Jigs and FixturesDocumento3 páginasDesign of Jigs and FixturesRajueswarAinda não há avaliações

- Buyer's Guide To Controlled Tolerance StampingsDocumento12 páginasBuyer's Guide To Controlled Tolerance StampingsmattgrubbsAinda não há avaliações

- HMT Mandrel Bending 101Documento80 páginasHMT Mandrel Bending 101zaiofracassadoAinda não há avaliações

- Special Electric Motors: High-Speed Machining MotorsDocumento68 páginasSpecial Electric Motors: High-Speed Machining MotorsAbed samadsureyft7vewyrAinda não há avaliações

- 878-Tool Design and Drawing: Part - ADocumento17 páginas878-Tool Design and Drawing: Part - AsandhuAinda não há avaliações

- NC Mill SFTWR ManualDocumento100 páginasNC Mill SFTWR ManualPham LongAinda não há avaliações

- Camworks Manual Based On Vtu SyllabusDocumento25 páginasCamworks Manual Based On Vtu Syllabusviper7887Ainda não há avaliações

- Milling Example 2010-PolarDocumento18 páginasMilling Example 2010-PolarShamsir Ibni ShukriAinda não há avaliações

- Hot Wire Manchine - User Manual-ENDocumento41 páginasHot Wire Manchine - User Manual-ENZoliAinda não há avaliações

- Tap Chart - Metric ThreadsDocumento1 páginaTap Chart - Metric ThreadssonytechoAinda não há avaliações

- Hanita Metric Catalog Complete PDFDocumento132 páginasHanita Metric Catalog Complete PDFCalin CampeanAinda não há avaliações

- Us 4207797Documento7 páginasUs 4207797fghdfjerAinda não há avaliações

- Conceptual Design of Blanking Tool For Washer Special: Nandish Harti DR D. RamegoudaDocumento4 páginasConceptual Design of Blanking Tool For Washer Special: Nandish Harti DR D. Ramegoudaaravindan476Ainda não há avaliações

- MillingCatalog07 08Documento108 páginasMillingCatalog07 08mami_meuAinda não há avaliações

- Heat Treat CatalogDocumento20 páginasHeat Treat CatalogGabriel Gonzalez100% (1)

- Drilling Speeds and FeedsDocumento1 páginaDrilling Speeds and FeedsLe Hoang HiepAinda não há avaliações

- Pioneer Avh-P3100dvd p3150dvd SMDocumento190 páginasPioneer Avh-P3100dvd p3150dvd SMRogerio E. SantoAinda não há avaliações

- SolidCAM 2017 2.5D Milling Training Course PDFDocumento320 páginasSolidCAM 2017 2.5D Milling Training Course PDFAdnan MustafićAinda não há avaliações

- Performance Series 450eDocumento28 páginasPerformance Series 450eR Fonseca GomezAinda não há avaliações

- Chapter 4 - Casting ProcessesDocumento40 páginasChapter 4 - Casting ProcessesErnawati ZailiAinda não há avaliações

- Hand Tools: An Educational Guide ForDocumento20 páginasHand Tools: An Educational Guide Forsaeedbhatti100% (2)

- Metal Matic P 200 ManualDocumento13 páginasMetal Matic P 200 ManualRon BoeserAinda não há avaliações

- Drilling & Related OperationsDocumento11 páginasDrilling & Related OperationsGonKilAinda não há avaliações

- PowerTIG 250EX 2016Documento32 páginasPowerTIG 250EX 2016Bob john100% (1)

- CZ1440G-1 e Manual BookDocumento57 páginasCZ1440G-1 e Manual Bookkurnia wanAinda não há avaliações

- Colt Custom Shop Order FormDocumento8 páginasColt Custom Shop Order FormAmmoLand Shooting Sports NewsAinda não há avaliações

- T&D - Core 4 Tool & DieDocumento44 páginasT&D - Core 4 Tool & Dietisha revillaAinda não há avaliações

- Gs 3 MDocumento316 páginasGs 3 MNazielAinda não há avaliações

- 2012 - Formability Studies On AA6061 For Automotive Body Structures Using DEFORM-2DDocumento7 páginas2012 - Formability Studies On AA6061 For Automotive Body Structures Using DEFORM-2DSupriya SahuAinda não há avaliações

- How To Wire An Arduino Based 3 Axis CNC MachineDocumento11 páginasHow To Wire An Arduino Based 3 Axis CNC MachineSetyo WidodoAinda não há avaliações

- Design and Analysis Using AutocadDocumento9 páginasDesign and Analysis Using AutocadsudhakarAinda não há avaliações

- Design of CNC Machine Based Laser Engraver With Arduino UNODocumento7 páginasDesign of CNC Machine Based Laser Engraver With Arduino UNOIJRASETPublicationsAinda não há avaliações

- Cadcam Module 2Documento433 páginasCadcam Module 2Ahsan IftikharAinda não há avaliações

- Development of Milling Strategy For Optimum Tool Life and Production Cost PDFDocumento90 páginasDevelopment of Milling Strategy For Optimum Tool Life and Production Cost PDFManoj KulkarniAinda não há avaliações

- Lecture 1 - Intro To Single Point Cutting Tool GeometryDocumento16 páginasLecture 1 - Intro To Single Point Cutting Tool GeometryMuhammad Umar IqtidarAinda não há avaliações

- How To Use A Milling MachineDocumento44 páginasHow To Use A Milling MachineGhazali ZuberiAinda não há avaliações

- Catalogo Componentes 2007Documento39 páginasCatalogo Componentes 2007DANIZACHAinda não há avaliações

- Dimensioning: Chapter TenDocumento42 páginasDimensioning: Chapter TenBolWolAinda não há avaliações

- MILL PPS006 Full Dividing Heads and Rotary Tables PDFDocumento32 páginasMILL PPS006 Full Dividing Heads and Rotary Tables PDFChandran Pandiyan100% (1)

- EDM Wire Cut ReportDocumento12 páginasEDM Wire Cut ReportAidilAinda não há avaliações

- Dbs22 enDocumento14 páginasDbs22 enmilivoj11Ainda não há avaliações

- Laser Marking-Engraving Parameters 3Documento14 páginasLaser Marking-Engraving Parameters 3Damian erevefAinda não há avaliações

- PRO E LibraryDocumento11 páginasPRO E LibrarygokulahbAinda não há avaliações

- TD Synchrobelt HTD enDocumento82 páginasTD Synchrobelt HTD enReparatii CncAinda não há avaliações

- Hurco Lathe Conversational r0115-201Documento84 páginasHurco Lathe Conversational r0115-201rastaeggAinda não há avaliações

- Shellholder Cross ReferenceDocumento9 páginasShellholder Cross ReferenceIM_JohnnyVAinda não há avaliações

- Machining FundamentalsDocumento32 páginasMachining FundamentalsCh TalhaAinda não há avaliações

- Gun ManufacturingDocumento11 páginasGun ManufacturingTarun GuptaAinda não há avaliações

- Press Tools ProjectDocumento19 páginasPress Tools ProjectKanahaiya100% (1)

- Manual de CNC TornoDocumento147 páginasManual de CNC TornoAbraham Pool100% (1)

- CMMG MK47 Mutant Black Rifle DetailsDocumento2 páginasCMMG MK47 Mutant Black Rifle DetailsAmmoLand Shooting Sports NewsAinda não há avaliações

- ??????zzzzzzzzzzzzzzzzzzzzzz!é:1: Patented Sept. 24, 1901Documento7 páginas??????zzzzzzzzzzzzzzzzzzzzzz!é:1: Patented Sept. 24, 1901Слэйтер Строительная компания100% (1)

- Functional Composite Materials: Manufacturing Technology and Experimental ApplicationNo EverandFunctional Composite Materials: Manufacturing Technology and Experimental ApplicationAinda não há avaliações

- Spitfire MKI 1500 InstructionsDocumento13 páginasSpitfire MKI 1500 InstructionsSteven D100% (1)

- About Our FuelDocumento3 páginasAbout Our FuelSteven DAinda não há avaliações

- John Deere 1025R TSM TM149119 PDFDocumento2 páginasJohn Deere 1025R TSM TM149119 PDFSteven DAinda não há avaliações

- Adaptation BMWDocumento3 páginasAdaptation BMWVadim UrupaAinda não há avaliações

- Vxdiag Multi Diagnostic Tool User Manual Vxdiagshop - 2018111401903117Documento18 páginasVxdiag Multi Diagnostic Tool User Manual Vxdiagshop - 2018111401903117Jhon Jairo BernalAinda não há avaliações

- 3DLabPrint F4U UserguideDocumento23 páginas3DLabPrint F4U UserguideAnonymous EXDp9upKMUAinda não há avaliações

- Technical Manual: John Deere AgricultureDocumento1.399 páginasTechnical Manual: John Deere AgricultureSteven D80% (5)

- Army Ammo Data Tm43-0001-27Documento325 páginasArmy Ammo Data Tm43-0001-27cactus319Ainda não há avaliações

- 6 Speed Automatic Transaxle AWF21 PDFDocumento66 páginas6 Speed Automatic Transaxle AWF21 PDFMihai Mitrea100% (3)

- Application For Federal Firearms LicenseDocumento12 páginasApplication For Federal Firearms LicenseSteven DAinda não há avaliações

- GarandDocumento8 páginasGarandSteven DAinda não há avaliações

- P8X32A Web PropellerManual v1.2 PDFDocumento399 páginasP8X32A Web PropellerManual v1.2 PDFSteven DAinda não há avaliações

- Pid Without A PHD PDFDocumento14 páginasPid Without A PHD PDFGiovanni Eliezer100% (2)

- Fanuc Oi Model FDocumento426 páginasFanuc Oi Model FSteven D100% (3)

- B-64414EN 01 0i-D DataServerDocumento358 páginasB-64414EN 01 0i-D DataServerLuciano Alberto Lopez CastroAinda não há avaliações

- Lynx2100M InstructionsDocumento267 páginasLynx2100M InstructionsSteven D100% (7)

- Lynx2100M OperationsDocumento343 páginasLynx2100M OperationsSteven D100% (3)

- TB6600 User Guide V1.2Documento11 páginasTB6600 User Guide V1.2Anonymous gdJiDHAinda não há avaliações

- MagPi54 PDFDocumento100 páginasMagPi54 PDFAl100% (1)

- Basics of Machining 2010 2011Documento189 páginasBasics of Machining 2010 2011Steven DAinda não há avaliações

- FANUC Series Lathe OiDocumento464 páginasFANUC Series Lathe OiSteven DAinda não há avaliações

- B-63874en 11Documento900 páginasB-63874en 11Steven D100% (1)

- History of The MicrometerDocumento36 páginasHistory of The MicrometerSteven DAinda não há avaliações

- Omega PID TunningDocumento4 páginasOmega PID TunningOwaisAinda não há avaliações

- Tuning of PID Controllers: I Am Responsible of This NameDocumento8 páginasTuning of PID Controllers: I Am Responsible of This Nameata lonAinda não há avaliações

- PID Tuning Guide 022810Documento28 páginasPID Tuning Guide 022810Darren AshAinda não há avaliações

- Blueprint Reading For Manufacturing Applications - 2017Documento8 páginasBlueprint Reading For Manufacturing Applications - 2017hoyempAinda não há avaliações

- TheFiveDeadliestMistakesofPIDTuning PDFDocumento10 páginasTheFiveDeadliestMistakesofPIDTuning PDFSteven DAinda não há avaliações

- Tomas Claudio CollegesDocumento16 páginasTomas Claudio CollegesGemmillyn DigmaAinda não há avaliações

- Leonardo Roth, FLDocumento2 páginasLeonardo Roth, FLleonardorotharothAinda não há avaliações

- Marketing Management Question Paper 2Documento1 páginaMarketing Management Question Paper 2Jeevan PradeepAinda não há avaliações

- 73 220 Lecture07Documento10 páginas73 220 Lecture07api-26315128Ainda não há avaliações

- 12 Key Result AreasDocumento2 páginas12 Key Result AreasMichelle Quiquino Foliente100% (4)

- RBI FAQ of FDI in IndiaDocumento53 páginasRBI FAQ of FDI in Indiaaironderon1Ainda não há avaliações

- Sales Flow Chart 2019Documento2 páginasSales Flow Chart 2019grace hutallaAinda não há avaliações

- FOD Awareness: Basic Training in Foreign Object Damage PreventionDocumento35 páginasFOD Awareness: Basic Training in Foreign Object Damage PreventionHumberto AnguloAinda não há avaliações

- Companies in UAEDocumento1 páginaCompanies in UAEChelle Sujetado De Guzman50% (2)

- Advanced Competitive Position AssignmentDocumento7 páginasAdvanced Competitive Position AssignmentGeraldine Aguilar100% (1)

- Capstone Project Final Report - PatanjaliDocumento60 páginasCapstone Project Final Report - PatanjaliSharvarish Nandanwar0% (1)

- Kuis PDFDocumento4 páginasKuis PDFZhay Anty0% (1)

- Work Instruction For Bin Management (From Customer) : Doc#: Issue No./Dt:01/10-10-18 Rev No./DtDocumento3 páginasWork Instruction For Bin Management (From Customer) : Doc#: Issue No./Dt:01/10-10-18 Rev No./Dtyathish babu M AAinda não há avaliações

- ACFE Fraud Examination Report (Short)Documento8 páginasACFE Fraud Examination Report (Short)Basit Sattar100% (1)

- Module 8 Benefit Cost RatioDocumento13 páginasModule 8 Benefit Cost RatioRhonita Dea AndariniAinda não há avaliações

- Assignment Agreement1Documento1 páginaAssignment Agreement1Joshua Schofield100% (2)

- Revionics - White.paper. (Software As A Service A Retailers)Documento7 páginasRevionics - White.paper. (Software As A Service A Retailers)Souvik_DasAinda não há avaliações

- Yoox AssessmentDocumento11 páginasYoox AssessmentGeorge KolliasAinda não há avaliações

- Save Capitalism From CapitalistsDocumento20 páginasSave Capitalism From CapitalistsLill GalilAinda não há avaliações

- Convergence JournalismDocumento34 páginasConvergence Journalismali3800Ainda não há avaliações

- Judith Rivera Tarea 2.2 Acco 1050Documento4 páginasJudith Rivera Tarea 2.2 Acco 1050Judy RiveraAinda não há avaliações

- Case Study 1Documento6 páginasCase Study 1Narendra VaidyaAinda não há avaliações

- Supply Chain 101 - SAPDocumento34 páginasSupply Chain 101 - SAPuddinn9Ainda não há avaliações

- PARCOR-SIMILARITIESDocumento2 páginasPARCOR-SIMILARITIESHoney Lizette SunthornAinda não há avaliações

- 01 Pengantar SCMDocumento46 páginas01 Pengantar SCMAdit K. BagaskoroAinda não há avaliações

- Cultural Norms, Fair & Lovely & Advertising FinalDocumento24 páginasCultural Norms, Fair & Lovely & Advertising FinalChirag Bhuva100% (2)

- Project ManagementDocumento2 páginasProject ManagementJohanChvzAinda não há avaliações

- Tax Invoice: U64204GJ2008PTC054111 24AADCG1959N1ZA 9984 GJDocumento1 páginaTax Invoice: U64204GJ2008PTC054111 24AADCG1959N1ZA 9984 GJMrugesh Joshi50% (2)

- Solutions ArtLog Edition9Documento15 páginasSolutions ArtLog Edition9scottstellAinda não há avaliações