Escolar Documentos

Profissional Documentos

Cultura Documentos

Organica FCR Brochure

Enviado por

Ahmed AsemDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Organica FCR Brochure

Enviado por

Ahmed AsemDireitos autorais:

Formatos disponíveis

ORGANICA FCR

Solution in Brief

The Solution

Organica is the world leader in Fixed-Bed Activated Sludge

(FBAS) technology. FBAS leverages the use of various natural

THE BIOMODULE

This is the basic unit of the Organica Solution.

and engineered media to provide a fixed habitat for a diverse Conditions are created to promote the consumption

fixed-film bacterial culture which metabolizes the contaminants AQUATIC PLANTS

of contaminants by thousands of species of

in wastewater. These populations of organisms live in an attached Important from a organisms living within the root zone and the

form on fixed bed media inside the reactors, as opposed to being technological viewpoint engineered media.

in constant motion as is the case with conventional technologies in providing an ideal fixed

film substrate, plants

such as Activated Sludge or MBBR. Providing a stationary habitat uniquely enhance

allows an incredibly diverse and robust biofilm to grow and thrive aesthetics with little

inside the reactors, ultimately offering significantly improved additional maintenance.

nutrient removal, energy efficiency, and resiliency, all in much

less space than conventional technologies. ENGINEERED MEDIA

Organica’s Food-Chain-Reactor (FCR) represents the best-of-bre- A patented woven

ed in FBAS wastewater treatment plants. The FCR is a complete textile which provides a

wastewater treatment solution incorporated into a compact, place for organisms to

attach and thrive.

single structure.

ROOT SYSTEM

ORGANICA TREATMENT PLANT Provides an ideal habitat for organisms

to live. After establishing in the root

The complete system; from solids removal, biological treatment,

zone, species thrive not only on the

phase separation, and final treatment to reuse quality fits inside an

DIFFUSED AERATION waste stream, but benefit from symbi-

attractive structure which in itself provides a space for passive

enjoyment in a garden-like setting. Traditional fine bubble aeration otic relationships with the plant roots.

used for aerobic phases.

FINAL TREATMENT

Polishing, disinfection depending

ENCLOSURE on local regulatory standards

Be it glass, membrane, or an

attractive shading structure,

a decentralized wastewater

solution must have a sense

of containment from its

surroundings while protecting

the garden within.

Effluent to

PRETREATMENT Influent Recipient/

Recycling

Solids removal can be coupled

with other options depending

Internal Recycling

on the influent quality.

Sludge Recycling Sludge

Disposal

REACTOR CASCADE

The wastewater flows through a PHASE SEPARATION

series of reactors that are Very low TSS in the last reactor

configured and operated to allows discf ilters to be used for

allow the development of phase separation.

distinct ecosystems arranged to

form a complex network. Unique Look and Feel

Far from being a set of unpleasant concrete structures, the

Organica treatment plants are visually pleasing and

odor-free. Because they enhance their surroundings, the

sustainable designs can be easily located close to the

wastewater source, making water reuse feasible.

The solution is very flexible in terms of size, spanning a wide

range of capacities. Additionally, the solution can easily be

applied to the upgrade market adding capacity and efficiency

to existing treatment facilities.

EXTERIOR OF AN ORGANICA WWTP INSIDE AN ORGANICA TREATMENT PLANT

This facility serves a population of 8000 people. In their ideal environment, plants thrive to create a

lush botanical garden.

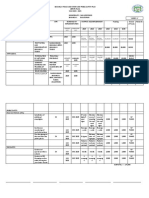

ENERGY SAVINGS CLEANER WATER

The cooperation of complex living systems, small Research is showing that the broader and more

footprint, proximity to wastewater source all complex ecology is able to break down a wider

contribute to siginificant energy savings. range of emerging pollutants of concern such as

medicines and other xenobiotics with higher

efficiency.

Xenobiotic removal efficiency

Energy consumption comparison 100%

120%

80%

100%

80% 60%

60% 40%

40%

20%

20%

0% 0%

Activated MBR ORGANICA Naproxen Ibuprofen Diclofenac

Sludge

Activated Sludge Organica Solution

CONVERGENCE OF DISCIPLINES

The treatment plants are places where advanced ecological

sciences and biotechnology meet hard core engineering and

information technologies; this intersection of innovation EASY OPERATION FOOTPRINT SAVINGS

delivers breakthrough advances in performance, cost, footprint The intelligent process control allows for very Highly intensified biology and compact,

and aesthetics. flexible and highly automated low-cost operation. architectural designs make the footprint of Organica

The plants are designed for trouble-free facilities up to 40% smaller than any

maintenance and manageability. state-of-the-art technology and significantly

The Benefits smaller than conventional activated sludge plants.

Organica Solution ensures: CONVENTIONAL ACTIVATED SLUDGE PLANT

Operational costs

• Better treatment characteristics 120%

100%

and high water quality;

80%

• No impact on real estate values; 60%

• Pleasing and odor-free environment; 40% ORGANICA TREATMENT

PLANT

• Lower energy consumption; 20%

• Cost Savings in operations and in overall footprint; 0%

Activated MBR ORGANICA

• Competitive investment costs. Sludge

Applications MUNICIPAL INDUSTRIAL

The solution is very flexible in terms of size, spanning a

wide range of capacities. Additionally, the Organica

Solution can easily be applied to the upgrade market

adding capacity and efficiency to existing treatment

facilities.

Attractive architectural solutions make possible The solution easily fits into any industrial campus for

seamless integration into the urban landscape greatly on-site water recycling; an appropriate solution for any

facilitating water reuse. A wide range of capacities can biodegradable waste stream, for example, food and

be implemented depending on the need and available beverage industries. Other treatment technologies can

footprint. be easily integrated if necessary.

city montage

UPGRADE COMMERCIAL

In the past 100 years, only 150000 WWTPs have been The solution is ideal for any place where people gather:

built globally. Organica's upgrade capabilities can airports, rest stops, schools, shopping malls, etc.; and

transform aging and obsolete infrastructure to reflect provides onsite recycling of water for irrigation, cooling

modern needs without replacing the existing facility. towers, toilets or any other non-potable use.

Interested? GET IN TOUCH WITH US TODAY! Visit our website: www.organicawater.com or contact us via email: info@organicawater.com

Você também pode gostar

- Corrosion Failures: Theory, Case Studies, and SolutionsNo EverandCorrosion Failures: Theory, Case Studies, and SolutionsAinda não há avaliações

- MM2100 Case Study 11feb2016Documento20 páginasMM2100 Case Study 11feb2016kushar_geoAinda não há avaliações

- Clean Ganga ProjectDocumento15 páginasClean Ganga ProjectRahul Ravi Singh100% (1)

- CMQ 3Documento2 páginasCMQ 3kalslingamAinda não há avaliações

- CMQ 4Documento1 páginaCMQ 4kalslingamAinda não há avaliações

- CMQ 5Documento1 páginaCMQ 5kalslingamAinda não há avaliações

- Biodigester Technology GuideDocumento42 páginasBiodigester Technology GuideRahul Ravi SinghAinda não há avaliações

- Biosolids MGMT Plan by Stantec Band CDocumento232 páginasBiosolids MGMT Plan by Stantec Band CAdrian FrantescuAinda não há avaliações

- Saes A 120Documento11 páginasSaes A 120Walid MegahedAinda não há avaliações

- Food Chain ReactorDocumento3 páginasFood Chain ReactorkgmcvAinda não há avaliações

- TMECC Field Sampling ProtocolDocumento26 páginasTMECC Field Sampling ProtocolAnish GhimireAinda não há avaliações

- CMQ Practise TestDocumento1 páginaCMQ Practise TestkalslingamAinda não há avaliações

- National Plumbing Code of Trinidad and TobagoDocumento51 páginasNational Plumbing Code of Trinidad and Tobagosam smithAinda não há avaliações

- Icc 1200 Off-Site Construction Plandesignfabricassemb Standard 1st PTGDocumento33 páginasIcc 1200 Off-Site Construction Plandesignfabricassemb Standard 1st PTGNguyễn Hữu ThoạiAinda não há avaliações

- Design Audit ReportDocumento53 páginasDesign Audit Reportdishazb4u6473Ainda não há avaliações

- IR No CE-C1352 Witness to test concrete cubes (compressive strength at 7 days) for containment of pump in DS6. - ف뻵£شDocumento1 páginaIR No CE-C1352 Witness to test concrete cubes (compressive strength at 7 days) for containment of pump in DS6. - ف뻵£شNassim SabriAinda não há avaliações

- Air Filter Compressed DesignDocumento17 páginasAir Filter Compressed DesignMuhammad SaadullahAinda não há avaliações

- Mission, SWOT, Strategic Management, Strategic Plan Execution, Strategic Plan StrategyDocumento1 páginaMission, SWOT, Strategic Management, Strategic Plan Execution, Strategic Plan StrategykalslingamAinda não há avaliações

- 9101 Form 4: Nonconformity Report (NCR)Documento3 páginas9101 Form 4: Nonconformity Report (NCR)GCERTI ITALY srlAinda não há avaliações

- Wimpey Laboratories DUBAI AccreditationDocumento49 páginasWimpey Laboratories DUBAI AccreditationomerAinda não há avaliações

- Packaged Plant Prefab Tank SPAN 1401 A1 Publication 2013 (Part2)Documento25 páginasPackaged Plant Prefab Tank SPAN 1401 A1 Publication 2013 (Part2)gkjimAinda não há avaliações

- Compaction of Dune Sand Backfill Concrete Shaft VibratorsDocumento7 páginasCompaction of Dune Sand Backfill Concrete Shaft VibratorsmranAinda não há avaliações

- Analysisof Silicon Carbide Abrasive Grainand Abrasive CrudeDocumento23 páginasAnalysisof Silicon Carbide Abrasive Grainand Abrasive CrudeCristiano Cabral MüllerAinda não há avaliações

- Waste Water Test Report No 20 0 33467 Sam Ree Dyeing BD LTDDocumento15 páginasWaste Water Test Report No 20 0 33467 Sam Ree Dyeing BD LTDImrul KayeshAinda não há avaliações

- Download Aci 309r 05 Concrete Specification PDFDocumento3 páginasDownload Aci 309r 05 Concrete Specification PDFShokhieb Showbad CarriebAinda não há avaliações

- Is 5267 2002Documento16 páginasIs 5267 2002Gourav SharmaAinda não há avaliações

- Qa ProcessmanualDocumento40 páginasQa ProcessmanualSagar Raj GiriAinda não há avaliações

- Pag-IBIG Housing Loan CalculatorDocumento2 páginasPag-IBIG Housing Loan CalculatorkiraAinda não há avaliações

- Foaming of Rubber Wood Plastic CompositeDocumento65 páginasFoaming of Rubber Wood Plastic CompositeAwad M. El ArabyAinda não há avaliações

- Complying With The 2014 FGIDocumento36 páginasComplying With The 2014 FGIJihad Elias ChahlaAinda não há avaliações

- Simpson CatlogDocumento56 páginasSimpson CatlogAnil JindalAinda não há avaliações

- World Quality Day - WikipediaDocumento3 páginasWorld Quality Day - Wikipediabala subramanyam0% (1)

- Nitocote EP415 PDFDocumento4 páginasNitocote EP415 PDFdejanmicic972Ainda não há avaliações

- Concresive 2200: High Strength, Thixotropic, Epoxy Bedding MortarDocumento4 páginasConcresive 2200: High Strength, Thixotropic, Epoxy Bedding MortarFrancois-Ainda não há avaliações

- Indian Standard: Qualjty Systefds - Model For Quality Assurance in Final Inspection and Te STDocumento13 páginasIndian Standard: Qualjty Systefds - Model For Quality Assurance in Final Inspection and Te STproxywar100% (1)

- Water Treatment Program - Training Manual - Alberta Infrastructure and TransportaionDocumento82 páginasWater Treatment Program - Training Manual - Alberta Infrastructure and TransportaionAugustoPertotAinda não há avaliações

- GRP Brochure AmiantitDocumento6 páginasGRP Brochure Amiantitbhathiya8Ainda não há avaliações

- ADFCA Food Hygiene PDFDocumento18 páginasADFCA Food Hygiene PDFUsman Cheema100% (1)

- Hse Approved SpecificationDocumento16 páginasHse Approved SpecificationPrasit MeeboonAinda não há avaliações

- Standard Test Method Organic Impurities in Fine Aggregates For Concrete'Documento2 páginasStandard Test Method Organic Impurities in Fine Aggregates For Concrete'ayan3176Ainda não há avaliações

- Moving Towards International Standards in The Oil and Gas IndustryDocumento17 páginasMoving Towards International Standards in The Oil and Gas IndustrySayed Saad ShehataAinda não há avaliações

- DFM and DFA Approach On Designing Pressure Vessel PDFDocumento6 páginasDFM and DFA Approach On Designing Pressure Vessel PDFOmkar MohiteAinda não há avaliações

- Occupational Safety and Health StandardsDocumento85 páginasOccupational Safety and Health StandardsCharlie OriasAinda não há avaliações

- APQPDocumento2 páginasAPQPdanielsasikumarAinda não há avaliações

- Hot-Dip Galvanizing Vs Continuous Sheet GalvanizingDocumento2 páginasHot-Dip Galvanizing Vs Continuous Sheet GalvanizingSreedhar Patnaik.M100% (1)

- FoodWatch - Registration GuideDocumento10 páginasFoodWatch - Registration GuideAnonymous BZR3ZjP1Ainda não há avaliações

- Hashim Hanif CVDocumento6 páginasHashim Hanif CVHashim HanifAinda não há avaliações

- 01 Samss 024Documento7 páginas01 Samss 024Awais CheemaAinda não há avaliações

- 13 Samss 003 PDFDocumento7 páginas13 Samss 003 PDFMohamed SolimanAinda não há avaliações

- DRINKING WATER WELL DESIGN CHECKLISTDocumento7 páginasDRINKING WATER WELL DESIGN CHECKLISTBhuiyan RazonAinda não há avaliações

- Saes A 208Documento14 páginasSaes A 208nadeemAinda não há avaliações

- 146 10 HPV Material Compatibility WebDocumento52 páginas146 10 HPV Material Compatibility WebrahulanandoneAinda não há avaliações

- Materials Acceptance by Certification and Laboratory StandardizationDocumento106 páginasMaterials Acceptance by Certification and Laboratory StandardizationAyman KandeelAinda não há avaliações

- 04 - TDS - Concresive 2200Documento3 páginas04 - TDS - Concresive 2200aahtagoAinda não há avaliações

- QC PVC 18373Documento4 páginasQC PVC 18373Andrei SimionAinda não há avaliações

- Industrial Site Allocation Request & ESQDocumento33 páginasIndustrial Site Allocation Request & ESQAmer Zubaidi100% (1)

- Quality System Manual: Issue Date: Sep. 12/17 - 1 - Rev.: 8Documento30 páginasQuality System Manual: Issue Date: Sep. 12/17 - 1 - Rev.: 8Arun ByakodAinda não há avaliações

- Design—Operation Interactions at Large Treatment Plants: Proceedings of a Workshop Held in ViennaNo EverandDesign—Operation Interactions at Large Treatment Plants: Proceedings of a Workshop Held in ViennaS. H. JenkinsAinda não há avaliações

- Reinforcing Effects of Graphene Oxide On Portland Cement Paste PDFDocumento6 páginasReinforcing Effects of Graphene Oxide On Portland Cement Paste PDFAhmed AsemAinda não há avaliações

- Nvestigation of The Effects of Graphene and Graphene Oxide PDFDocumento13 páginasNvestigation of The Effects of Graphene and Graphene Oxide PDFAhmed AsemAinda não há avaliações

- Use of Graphene Oxide Nanosheets To Regulate The Microstructure of Hardened Cement PasteDocumento9 páginasUse of Graphene Oxide Nanosheets To Regulate The Microstructure of Hardened Cement PasteAhmed AsemAinda não há avaliações

- Reinforcing Effects of Graphene Oxide On Portland Cement Paste PDFDocumento6 páginasReinforcing Effects of Graphene Oxide On Portland Cement Paste PDFAhmed AsemAinda não há avaliações

- Rafiee Et Al-2013-Advanced Functional MaterialsDocumento7 páginasRafiee Et Al-2013-Advanced Functional MaterialsAhmed AsemAinda não há avaliações

- Rafiee Et Al-2013-Advanced Functional MaterialsDocumento7 páginasRafiee Et Al-2013-Advanced Functional MaterialsAhmed AsemAinda não há avaliações

- Mechanical Properties and Microstructure of A Graphene Oxide-CementDocumento20 páginasMechanical Properties and Microstructure of A Graphene Oxide-CementAhmed AsemAinda não há avaliações

- Reinforcing Effects of Graphene Oxide On Portland Cement Paste PDFDocumento6 páginasReinforcing Effects of Graphene Oxide On Portland Cement Paste PDFAhmed AsemAinda não há avaliações

- Reinforcing Effects of Graphene Oxide On Portland Cement Paste PDFDocumento6 páginasReinforcing Effects of Graphene Oxide On Portland Cement Paste PDFAhmed AsemAinda não há avaliações

- W4D.1.CC1203 3825F1 PDFDocumento14 páginasW4D.1.CC1203 3825F1 PDFAhmed AsemAinda não há avaliações

- Reinforcing Effects of Graphene Oxide On Portland Cement Paste PDFDocumento6 páginasReinforcing Effects of Graphene Oxide On Portland Cement Paste PDFAhmed AsemAinda não há avaliações

- The Effect of Graphene Oxide On Cement MortarDocumento12 páginasThe Effect of Graphene Oxide On Cement MortarAhmed AsemAinda não há avaliações

- Feasibility of Nano Graphene Oxide Powde PDFDocumento4 páginasFeasibility of Nano Graphene Oxide Powde PDFAhmed AsemAinda não há avaliações

- Reinforcing Effects of Graphene Oxide On Portland Cement Paste PDFDocumento6 páginasReinforcing Effects of Graphene Oxide On Portland Cement Paste PDFAhmed AsemAinda não há avaliações

- Experimental Study of The Effects of Graphene Oxide PDFDocumento26 páginasExperimental Study of The Effects of Graphene Oxide PDFAhmed AsemAinda não há avaliações

- Effects of Nanoalumina and Graphene Oxide On Early-Age Hydration PDFDocumento9 páginasEffects of Nanoalumina and Graphene Oxide On Early-Age Hydration PDFAhmed AsemAinda não há avaliações

- Effects of Graphene Oxide Agglomerates On Workability, Hydration, Microstructure and Compressive Strength of Cement Paste PDFDocumento9 páginasEffects of Graphene Oxide Agglomerates On Workability, Hydration, Microstructure and Compressive Strength of Cement Paste PDFAhmed AsemAinda não há avaliações

- Effects of Nanoalumina and Graphene Oxide On Early-Age Hydration PDFDocumento9 páginasEffects of Nanoalumina and Graphene Oxide On Early-Age Hydration PDFAhmed AsemAinda não há avaliações

- Feasibility of Nano Graphene Oxide Powde PDFDocumento4 páginasFeasibility of Nano Graphene Oxide Powde PDFAhmed AsemAinda não há avaliações

- Sndtde 341Documento2 páginasSndtde 341Ahmed AsemAinda não há avaliações

- 11 Years LSAW Pipe Fabrication ExpertiseDocumento4 páginas11 Years LSAW Pipe Fabrication ExpertiseAhmed AsemAinda não há avaliações

- Sndtde 341Documento2 páginasSndtde 341Ahmed AsemAinda não há avaliações

- Farag Farag I El-Hamaky: Sr. Electrical Engineer, Building Electrical SystemDocumento5 páginasFarag Farag I El-Hamaky: Sr. Electrical Engineer, Building Electrical SystemAhmed AsemAinda não há avaliações

- Informal Job Offer Email Template Download 20170818Documento1 páginaInformal Job Offer Email Template Download 20170818madhan jpAinda não há avaliações

- Name: Ahmed Fouad Abdou Mohammed: Electrical Power EngineerDocumento4 páginasName: Ahmed Fouad Abdou Mohammed: Electrical Power EngineerAhmed AsemAinda não há avaliações

- Egypt Civil Engineer Kareem AlyDocumento15 páginasEgypt Civil Engineer Kareem AlyAhmed AsemAinda não há avaliações

- Mohamed Adel PDFDocumento4 páginasMohamed Adel PDFAhmed AsemAinda não há avaliações

- CV Highlights Egyptian Electrical EngineerDocumento3 páginasCV Highlights Egyptian Electrical EngineerAhmed AsemAinda não há avaliações

- Egyptian Engineer ResumeDocumento1 páginaEgyptian Engineer ResumeAhmed AsemAinda não há avaliações

- Egypt Civil Engineer Kareem AlyDocumento15 páginasEgypt Civil Engineer Kareem AlyAhmed AsemAinda não há avaliações

- Form16 (2021-2022)Documento2 páginasForm16 (2021-2022)Anushka PoddarAinda não há avaliações

- Deltair BrochureDocumento4 páginasDeltair BrochureForum PompieriiAinda não há avaliações

- Trinidad and Tobago Budget 2022 focuses on resilience amid pandemicDocumento167 páginasTrinidad and Tobago Budget 2022 focuses on resilience amid pandemicAliyah AliAinda não há avaliações

- Fuel System D28Documento4 páginasFuel System D28Ian MuhammadAinda não há avaliações

- Community Medicine DissertationDocumento7 páginasCommunity Medicine DissertationCollegePaperGhostWriterSterlingHeights100% (1)

- Writing About Emotional Experiences As A Therapeutic Process PDFDocumento6 páginasWriting About Emotional Experiences As A Therapeutic Process PDFOscarAinda não há avaliações

- Respiration PHYSIODocumento23 páginasRespiration PHYSIOTauseef AfridiAinda não há avaliações

- Empower Second Edition B1 Unit Progress Test 5 - Version ADocumento12 páginasEmpower Second Edition B1 Unit Progress Test 5 - Version Atheencarnated93Ainda não há avaliações

- Maret 2021Documento36 páginasMaret 2021Muhammad Pahlan PiruzziAinda não há avaliações

- Human Resource Management: Submitted By: Group # 6 Submitted To: Sir Usama NajamDocumento23 páginasHuman Resource Management: Submitted By: Group # 6 Submitted To: Sir Usama NajamkamranAinda não há avaliações

- Greenhouse Effect: Greenhouse Gases and Their Impact On Global WarmingDocumento9 páginasGreenhouse Effect: Greenhouse Gases and Their Impact On Global WarmingrabiulAinda não há avaliações

- Case Combine Axialflow 140 PDFDocumento32 páginasCase Combine Axialflow 140 PDFLagu GodfreyAinda não há avaliações

- Employment Law Lubs 3915Documento4 páginasEmployment Law Lubs 3915ogunsatoAinda não há avaliações

- Introduction To Iron Metallurgy PDFDocumento90 páginasIntroduction To Iron Metallurgy PDFDrTrinath TalapaneniAinda não há avaliações

- Texture Crystallisation and Freezing Point DepressionDocumento18 páginasTexture Crystallisation and Freezing Point DepressionJán PeterAinda não há avaliações

- Louise L HAY AffirmationsDocumento10 páginasLouise L HAY AffirmationsEvi Kutasi100% (2)

- Food Regulations MalaysiaDocumento4 páginasFood Regulations MalaysiaSyafi'ie Syukri100% (1)

- Campus Waste Lab Proposal To Substitute Single-Use Plastic With Paper Products and Plastic Utensils For BambooDocumento14 páginasCampus Waste Lab Proposal To Substitute Single-Use Plastic With Paper Products and Plastic Utensils For Bambooapi-529878933Ainda não há avaliações

- Atlas Copco Generators: 15-360 kVA 15-300 KWDocumento10 páginasAtlas Copco Generators: 15-360 kVA 15-300 KWAyoub SolhiAinda não há avaliações

- Tata Bluescope Steel Limited, Jamshedpur.: Liquefied Petroleum Gas Material Safety Data SheetDocumento6 páginasTata Bluescope Steel Limited, Jamshedpur.: Liquefied Petroleum Gas Material Safety Data Sheetsujit5584Ainda não há avaliações

- Everything You Need to Know About VodkaDocumento4 páginasEverything You Need to Know About Vodkaudbhav786Ainda não há avaliações

- Physical Therpay Protocols For Conditions of Neck RegionDocumento74 páginasPhysical Therpay Protocols For Conditions of Neck Regionjrpsaavedra4599Ainda não há avaliações

- QS - HM - Freight Express Indonesia - Cipta HarapanDocumento4 páginasQS - HM - Freight Express Indonesia - Cipta HarapanAKHMAD SHOQI ALBIAinda não há avaliações

- Refrigeration and Air Conditioning Technology 8th Edition Tomczyk Silberstein Whitman Johnson Solution ManualDocumento5 páginasRefrigeration and Air Conditioning Technology 8th Edition Tomczyk Silberstein Whitman Johnson Solution Manualrachel100% (24)

- Laccase Mediator Pretreatment of Wheat StrawDocumento15 páginasLaccase Mediator Pretreatment of Wheat StrawMeyerling RandfordAinda não há avaliações

- Arthropods: A Guide to the Diverse PhylumDocumento10 páginasArthropods: A Guide to the Diverse Phylumpkkalai112Ainda não há avaliações

- Fundamentals of Plant BreedingDocumento190 páginasFundamentals of Plant BreedingDave SubiyantoAinda não há avaliações

- Barangay Peace and Order and Public Safety Plan Bpops Annex ADocumento3 páginasBarangay Peace and Order and Public Safety Plan Bpops Annex AImee CorreaAinda não há avaliações

- Makalah ThoughtDocumento5 páginasMakalah Thoughtifa safiraAinda não há avaliações

- Adrv9008 1Documento68 páginasAdrv9008 1doubleAinda não há avaliações