Escolar Documentos

Profissional Documentos

Cultura Documentos

Soap Making Secret

Enviado por

Tony JuanDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Soap Making Secret

Enviado por

Tony JuanDireitos autorais:

Formatos disponíveis

Soap Making Secrets

All you need to know to make every soap

and cleaner you will need for the entire

household!

By Sara Kate Wilson

CONTENTS

Page

Acknowledgements 4

Chapter One: A Brief History Of Soap 5

Chapter Two: Why Make Your Own Soaps? 12

Chapter Three: Getting Started 19

What you will need

Recipes

Create your own Recipes

Oil Properties

Saponification Numbers

Manually Calculating Lye

Lye Calculators

Chapter Four: Step by Step 34

– Cold Process Soap Making

Chapter Five: Re-batching Secrets 41

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Chapter Six: Step by Step – Laundry Soap 50

Chapter Seven: Step by Step – Dish Soap 54

Chapter Eight: Step by Step

– Multi Purpose Cleaner 58

Chapter Nine: Step by Step – Shampoo 65

Chapter Ten: Selling your Soaps! 74

Appendix: References and Resources 78

Acknowledgements:

Special thanks to two dear friends and catalysts of this project Katrina

Rainoshek and Silya Wiggins.

3

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Many thanks to the friends who encouraged me and helped to make

this instructional e-book and video happen;

David Rainoshek, and Kacper Postowski,

Thank you, to my husband, Luke Wilson for your support,

encouragement, honest feedback, and willingness to always be the

‘test market’ on all of my new developments in product.

Thanks also to the person who first showed me the cold process

soap making technique and sent me on my way soaping – Glory

O’Brian.

Thank you as always, to Spirit for guiding me.

Chapter One:

A Brief History Of Soap

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Personal cleanliness has been important to humans since prehistoric

times. As water is essential for life, the earliest people lived near

water and used it for many purposes, including its cleansing

properties.

The name soap, according to an ancient Roman legend, comes from

Mount Sapo, where animals were sacrificed. The rains would wash a

mixture of melted animal fat, or tallow, and wood ashes down the

hillside into the clay soil along the Tiber River. Women found, as they

washed their clothing, that this clay mixture made their wash cleaner

with much less effort. This mixture was in fact the first soap.

Soap-making became an established craft in Europe by the seventh

century. Soap-maker guilds guarded their trade secrets carefully.

Vegetable and animal oils were used with ashes of

plants, along with fragrance to make soaps. Gradually, as the soap

crafters worked with their ingredients and experimented, more

varieties of soap became available for shaving and shampooing, as

well as bathing and laundering.

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Italy, Spain and France were early centers of soap making, due to

their ready supply of raw materials such as oil from olive trees.

The English began making soap during the 12th century. Well into the

19th century, soap was a heavily taxed luxury item in several

countries. When the high tax was removed, soap became available to

ordinary people, and standards of cleanliness, and thus health

improved.

An important discovery to the advancement of soap manufacturing

was the mid-1800s invention by the Belgian chemist, Ernest Solvay,

of the ammonia process, which used common table salt, or sodium

chloride, to make soda ash. Solvay's process reduced the cost of

obtaining this alkali, and increased both the quality and quantity of the

soda ash available for manufacturing soap.

This, and other scientific discoveries relating to the production of

alkalis or strong bases, together with the development of power to

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

operate factories, made soap-making one of North America's fastest-

growing industries by 1850. At this same time, its broad availability,

and less expensive cost, changed soap from a luxury item to an

everyday necessity. With this widespread use came the development

of milder soaps used for bathing and other soaps used in the early

washing machines available to consumers by the turn of the century.

The chemistry of soap manufacturing stayed essentially the same

until 1916, when the first synthetic detergent was developed from

petroleum in Germany in response to a World War I-related shortage

of fats for making soap. Today, these are known simply as

detergents. Synthetic detergents are washing and cleaning products

made without soap, they are "synthesized" or put together chemically

from a variety of raw materials.

Production of household detergents in North America began in the

early 1930s, but it was not until after World War II that it really took

off. The war-time interruption of fat and oil supplies and the military's

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

need for a cleaning agent that would work in mineral-rich sea water

and in cold water had further stimulated detergent research and

development.

The first detergents were used primarily for hand dishwashing and for

fine fabric laundering. The development of detergents for all-purpose

laundry uses came in 1946, when the first "built" detergent (detergent

that contains a surfactant/builder combination) was introduced in the

United States. The surfactant is a detergent product's basic cleaning

ingredient, and is synthetically derived from petroleum. The builder

helps the surfactant to work more efficiently and comes from

Phosphate compounds.

By 1953, sales of synthetic detergents in the United States had

surpassed those of soap. Today, chemical based detergents have all

but replaced soap-based products for laundering, dishwashing and

household cleaning. Detergents (alone or in combination with soap)

are also found in most all of the bars and liquids used for personal

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

cleansing – like hand and body bars, and liquid body washes,

shampoos and facial cleansers too.

So, we can see through this brief history of soap, that we are no

longer using much soap at all, but instead we are plastering

ourselves with synthetic chemical detergents that can cause us harm

through absorption of petrochemicals, carcinogens, and toxins.

Additionally, they leave our skin and hair dry and brittle forcing us to

use additional chemical laden products to combat the drying effect of

the detergents. Our hair then produces more oils to protect us from

these chemicals, and we of course keep washing it to get the grease

out creating a viscous cycle that is harmful to our health! Many of us,

have never even known that what we call soap is not at all soap, but

harmful detergents made from unsustainable petro-chemicals.

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Chapter Two:

Why Make Your Own Soaps?

So why should I make my own soap anyhow? Take your pick at any

or all of the following great reasons to make your own soaps and

cleaners:

• Improve your overall health and

• Stop poisoning yourself, your family, your pets and your

environment with the toxic chemicals that are poured into even

10

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

some of the best, most expensive ‘organic’ personal care and

cleaning products.

• Do no harm to the environment

• Prevent illness, and serious disease,

• Protect your children from accidental poisoning occurring in

your home by eliminating all chemical laden personal care and

cleaning products from your home.

• Save Money $$

Here are just a few facts regarding the chemicals in cleaning and

personal care products:

Chlorine is used in nearly every dishwashing detergent, and many

people report having headaches, fatigue, burning eyes, and difficulty

breathing when exposed to even small amounts of chlorine.

The US National Research Counsel has no information on the toxic

effects for a large percentage of synthetic chemicals listed by the

11

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

EPA, and used in our household cleaners and personal cleansing

agents like shampoo and body wash.

Over 1100 toxic chemicals banned in Europe are still being used

today in the USA in your personal care products.

A handful of dishwasher soap eaten by a one - year old girl caused

extensive damage to her esophagus that required 8 operations and

several months to repair.

Each year 5 to 10 MILLION poisonings are reported in households

throughout North America, many are fatal, most of course are

children. These poisonings are the result of accidental ingestion of

common household substances found in just about every home.

The Consumer Safety Commission has determined that cleaning

products are some of the most dangerous substances in the home.

12

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

According to the Consumer Product Safety Commission, "Of

chemicals commonly found in homes, 150 have been linked to

allergies, birth defects, cancer, and psychological abnormalities."

Back in 1989 the National Institute of Occupational Safety and Health

analyzed 2,983 chemical used in personal care products, like soaps,

shampoos, deodorants etc, take a look at the results:

884 are toxic

778 cause acute toxicity

376 cause skin and eye irritation

314 cause biological mutation

218 cause reproductive disorders

146 cause tumors

The most offensive common ingredients, according to a 2006 study

by the University of California Berkeley and Lawrence Berkeley

National Laboratory, are ethylene-based glycol, used commonly as a

water-soluble solvent in cleaning agents and classified as a

hazardous air pollutant by the U.S. Environmental Protection Agency

(EPA)

13

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Also, chlorine, often labeled as “sodium hypochlorite” or

“hypochlorite,” is almost ubiquitous in household cleaners,

unfortunately for the inhabitants of many homes. Breathing in its

fumes can irritate the lungs, and as such poses a serious health risk

to those with pre-existing heart or respiratory problems.

Gaiam reports that the average American household contains

between three and 25 gallons of toxic materials, mostly in the form of

household cleaners filled with petrochemical solvents designed to

dissolve dirt. The fact that no law requires cleaning products

manufacturers to list ingredients on their labels or to test their

products for safety, leaving it up to consumers to make sure their

homes are not only clean, but also non-toxic.

You may already be aware of the other very common and highly

offensive ingredient found in most all commercial, and many ‘natural’

and or ‘organic’ shampoos and body washes; Sodium Lauryl Sulfate

14

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

(SLS). This chemical is disguised by being listed with over 150

names. It is highly toxic, a skin irritant, and a carcinogenic. SLS and

its close relatives are eye irritants, and are not well metabolized by

the liver. Continued exposure can lead to hormone imbalance, and

protein denaturing of our cells.

I am certain an entire book could be written on the numerous different

types of chemicals that are found in all of our household cleaning

products, and the harmful effects of those chemicals. With this in

mind it is easy to see how much suffering and hardships one will save

by making your own soaps and cleaners, not to mention the money

savings as well!

The average North American household spends almost $90 per

month on personal, and household cleaning products. WOW, that is

nearly $1100 per year. It is reported that most consumers are

spending 15-20% of their grocery store bill on personal and

household cleaning products. That includes soaps and shampoos,

body washes, toilet bowl cleaner, window cleaner, carpet cleaners,

15

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

floor cleaners, and multi-purpose cleaners as well as dish washing

detergents, and laundry detergents. Looking at theses numbers, and

the previous reports of health issues it makes perfectly good sense to

make all your own soaps and cleaners and go the all-natural way

from here on out!

Chapter Three:

Getting Started

You will be so happy to see for your self how easy it is to make all of

your own soaps and cleaners that are healthy and safe for you, your

family, your pets, and your environment! Here is a list of equipment

that you will need to get started creating all of your own soaps and

cleaners!

What You Will Need: Equipment

Stainless steel pot – a large soup pot works best

Candy Making Thermometer

Plastic Pitcher with a lid

16

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Long heavy - duty rubber gloves

Safety goggles

Dust mask/ handkerchief to cover your mouth and nose

Stainless steel long handle / serving spoon

Silicon/rubber scraper/spatula

Hand held power mixer/blender

Kitchen Scale

2 recycled plastic tubs /containers that you can then pitch

Measuring container

Large towel

White Vinegar – precaution to counter lye if spilled on skin.

Soap mold - Plastic or silicon mold to pour your soap in – this can be

any form you like, I will show you later how to figure out how much

soap will fit in any mold you find you would like to use.

Ingredients:

Oils or Fats, distilled water, sodium hydroxide/Lye (NaOH).

Here is the equation that yields soap:

17

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Oils + lye (with distilled water) = soap + glycerin

I can purchase Lye at the grocery store as I live in South America. If

you are living in North America, you may not be able to purchase lye

at your grocer any longer. Once it was readily available as a product

called Red Devil drain cleaner. So if you are living in North America,

or Europe, you may need to purchase Lye online or from a different

retailer in your area . There are plenty of vendors of soap making

supplies, and because lye is used in so many processes you can find

it elsewhere also.

You can purchase Lye or Sodium Hydroxide from any of the following

reputable online vendors:

www.essentialdepot.com

* www.brambleberry.com

* www.thelyeguy.com

* boyercorporation.com

* www.aaa-chemicals.com/sodium-hydroxide.html

* www.texasnaturalsupply.com

18

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

*www.candlesupply.com

*www.lehmans.com

* www.snowdriftfarm.com

* www.thesoapdish.com

* biodieselbarn.com

You can purchase lye from a chemical supply house if you have one

in your area. And you may be able to purchase lye at a hardware

store. Lowe's hardware stores sell Roebic Crystal Drain Opener,

which is 100% lye or .

You can always do a search online, check in with your local chemical

supply store, and hardware store no matter where you live in the

world. You may still be able to get it at the grocery store in the

cleaner isle depending on your location.

Here are a few other sources if you are living in the UK or EU:

* www.justasoap.co.uk

* www.butterburandsage.com

* www.thesoapkitchen.co.uk

19

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

And if you are living in Canada:

* www.creationsfromeden.com

* soapandmore.com (Alberta)

* www.cranberrylane.com (British Columbia)

* www.saffireblue.ca

Recipes:

There are countless recipes online that you can draw from, and I will

show you how to create your own recipes too! Here are just a few

tried and true recipes for cold process bar soaps.

I am including only the ingredients and the amounts in theses recipes

as the directions are always the same, and we will go through them

step by step in the next chapter. The first recipe is my personal

development, and the base I use for almost every bar of soap I make!

I just add whatever essential oils, herbs, or other additional ingredient

at trace.

20

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Creamy Coco Palm Base

14 ounces Palm Oil 35%

12 ounces Olive Oil 30%

8 ounces Cocoa Butter 20%

4 ounces Sunflower Oil10%

2 ounces Castor Oil 5%

5.25 ounces Lye dissolved in 14ounces distilled water

Blend at temperatures from 110-120 degrees.

At trace add any herbs you choose, pulverized oats, honey, and or

essential oils of your choice. This is the base I always use for bar

soap, it works great no matter what I add, lathers consistently foamy

and rich and is nourishing for the skin. We even wash our hair with

this bar.

There are a wealth of other recipes you can find through a simple

google search. My favorite resource pages are:

www.millersoap.com

www.Soap-making-resource.com

www.soap-making-essentials.com

Each of the recipes I have personally developed are included in this e-book and will

be listed in the pages that follow. I use 3 different recipes to create all of the soaps

in my home because of what I am ultimately looking for in the end product, and also

21

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

due to what oils I am able to easily obtain. I use the above creamy cocoa palm for

all the bar soaps that I make, and I use a different base for my laundry soap, and a

third base for the multi-purpose cleaner, the dish soap, and the shampoo. All of this

will come step by step in the pages that follow.

Oatmeal, Milk and Honey Miller’s soap pages

48 ounces shortening (a 3# can)

18 ounces coconut oil

12 ounces soybean oil

10 ounces canola oil (olive can be used as well)

12 ounces lye crystals dissolved into 18 ounces cold water

One 12 oz. can of evaporated goat's milk added at light trace (for

lighter colored soap with a firmer texture, you may use 6 oz.

evaporated milk and increase the water to 22 oz.)

Blend at Temps: 95-100 degrees

Add at trace 1 cup pulverized (blender) oats

1/4 cup honey

22

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

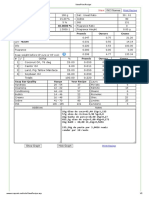

Hard/Sof

oil or fat (acid) SAP cleansing fluffy lather stable lather skin care

t

avocado oil .133 soft fair yes no amazing!

coconut oil .191 hard great yes no fair

castor oil .128 soft fair yes yes great

Cocoa butter .137 hard good yes yes Amazing!

olive oil .135 soft good no no great

palm oil 142 hard great no yes fair

peanut oil 137 soft fair no yes great

Shortening (veg) .136 Hard Good No No great

soybean oil .135 soft good no yes fair

Sunflower oil .134 Soft Fair Yes no good

sweet almond oil .137 soft good no yes amazing!

jojoba oil .069 soft fair no yes great

kukui nut oil .135 soft good no yes great

Create Your Own Recipes:

Designing your own cold process soap recipe is really very easy.

This chart provides you information about the properties of some oils,

and the Saponification values of those oils. This is invaluable if you

want to design your own recipes. It is important to know what oils will

give you the soap you are looking for. What do you want from your

soap? A hard bar, a rich foamy lather, or are you looking for a creamy

soap that is very nourishing to the skin, or maybe you just want a

great cleaner but don’t care much about how hard the bar is, or how

rich the lather is or how conditioning the soap is?

23

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Once you choose the oils you would like to try all you need to do is

calculate how much lye you’ll need to use to get soap. You can do

this manually with the Saponification numbers above doing a few

simple calculations with a calculator. Or you can use a lye calculator

online. They are a great resource and super helpful!

I like to use the online lye calculator at mountain sage herbs;

www.thesage.com/calcs/lyecalc2.php the calculator works out for

you in ounces or grams how much lye and how much water to use.

They can resize or edit your formula with the click of your mouse.

There are plenty of other options out there also. Any of the sites have

simple to follow instructions, and you basically just enter the amount

of each oil you plan to use, and it spits out the exact amount of lye

you will need to fully saponify the oils into soap on up to a 10% super

fat or lye discount. Here are a few other options. Try them out and

see what suits you.

www.cranberrylane.com/calculator.htm

24

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

www.sudsandscents.com/lye_calculator.htm

To calculate lye manually just follow these simple instructions:

Step 1:

Create the oil mixture for your soap formula. Choose the oils and the

amounts of each you will use. Below is an example:

This is also the recipe for my Laundry soap base

Sun-Palm-Olive Laundry Soap Base Recipe:

45 ounces Palm Oil

30 ounces Olive Oil

20 ounces Sunflower Oil

5 ounces Castor Oil

100 ounces total combined oils

Step 2:

Find the Saponification number or SAP value for each of the oils. You

can use the chart above.

Palm Oil SAP value .142

Olive Oil SAP value .135

25

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Sunflower Oil SAP value .134

Castor Oil SAP value .128

Step 3:

Now using basic multiplication we can calculate how much lye is

needed to enable the oil to fully saponify and turn into soap and

glycerin. Simply multiply the SAP value of the oil and multiply it by the

number of ounces in your formula. Like this:

45 ounces Palm Oil x .142 = 6.39 ounces lye

30 ounces Olive Oil x .135 = 4.05 ounces lye

20 ounces Sunflower Oil x .134 = 2.68 ounces lye

5 ounces Castor Oil x .128 = .64 ounces lye

Step 4:

Now add the 4 values of lye to get one

total amount of lye needed.

6.39

4.05

26

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

2.68

.64

13.76 ounces lye are needed to fully saponify the combined 100

ounces of oils. Now, this will be fully saponified, and may be a bit

harsh for the skin. So we do one final calculation to discount the lye

by 5%. This ensures that the soap is really moisturizing and

nourishing and is never harsh. This is recommended because both

the lye quality can vary slightly, and the SAP values are averages

given on each oil. There are many variables that can cause the SAP

value to drift or change slightly. Season, location, or external

environmental conditions.

To calculate the discount we simply multiply the number of ounces of

lye needed by .95

13.76x .95 = 13.072 ounces of lye for 5% super fat/lye discount.

When rounding, always round up - 13.1

You can manually determine the amount of water that you will use to

dissolve the lye into in 3 different ways.

27

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

• Use 38% of the amount of oils to calculate water so for 100

ounces of oil, you would dissolve the lye in 38 ounces of water.

• Calculate the water by using a ratio of 2:1 lye. So for 13.1

ounces of lye you use 26.2 ounces of distilled water.

• Use the general rule of 1:3 ratio with fats. So for 100 ounces of

fat, 33 ounces of water.

So now you have all the information you need to get going lets make

some soap!

28

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Chapter 4:

Step by Step – Cold Process Soap Making

Prepare Your Area

Get your molds and work area ready first. Soap can get going very

quickly once the batch is started. Remember that cleanliness counts:

keep your counters and work areas clean from debris and dust. Keep

your molds covered with the lid and or towels to keep dust out.

Use plastic, stainless steel, ceramic or glass containers and utensils

only. Do not use aluminum ever, it will react with the Saponification

process. Unbreakable containers are preferable for obvious reasons.

Wear long rubber gloves, & safety glasses plus a dust mask when

29

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

measuring and mixing the lye. Do not allow any skin to be exposed to

lye.

Prepare the lye solution first, this will heat up and needs time to cool

down before it can be mixed with the oils. following the safety

precautions carefully, weigh the lye very accurately. Higher amounts

of excess fat give softer soap. Excessive lye can cause irritation or

burning from the finished soap. Excess fat ranges from 5 to 8 % are

recommended. Most people use 5%.

Lye Safety VERY IMPORTANT!!!!

Always wear safety glasses and gloves. Lye can cause severe burns

including blindness. Lye should be added to water. If water is poured

onto lye, the reaction can cause a volcano of lye water and serious

injury. Avoid breathing fumes. Wear a dust mask or wrap and

handkerchief around your nose and mouth. Label your containers.

Never leave lye unattended & keep away from children & pets. If Lye

is spilled on your skin counteract it by pouring vinegar over the area

30

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

immediately. Lye is a strong base, the acidic vinegar will neutralize

the base and stop the burn.

The Process

Let’s use the recipe I use to make all our bar soaps, it is so simple

and easy. You can make up 100+ ounces of soap, that will yield 30 or

more large bars of soap, plenty to last the whole year through!

Here’s the recipe:

Creamy Coco Palm Base

35 ounces Palm Oil 35%

30 ounces Olive Oil 30%

20 ounces Cocoa Butter 20%

10 ounces Sunflower Oil 10%

5 ounces Castor Oil 5%

13 ounces* Lye dissolved in 32 ounces distilled water

*the lye is calculated for 5% discount ( 5% super fat )

Pour distilled water in a large plastic pitcher or stainless mixing vessel

and carefully add lye to water & mix well. I do not recommend using

glass as it is breakable, and this lye solution is caustic. Because this

31

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

mix will become very hot and give off strongly irritating fumes, it is

best to mix in a well ventilated area, while wearing safety goggles and

a dust mask. Avoid breathing the fumes. Set aside to cool in a

protected area while preparing the oils. Cover the pitcher to avoid

dust and debris entering the solution.

Measure each of the oils and fats individually and accurately and

combine them in a stainless steel pot. I like to use a large soup pot as

there is plenty of space for blending.

Melt the solid oils, butters and waxes and combine with the liquid oils.

Temperature measurements are important, as you do not need or

really want to over heat the oils. This can change the properties of

some oils. The oils should not need to go above 120 degrees

Fahrenheit. Turn the heat off when oils have melted and are heated

to at least 110 degrees.

Stir the lye solution again to ensure all the crystals have dissolved,

and check the temperature. Add the lye solution into the oils when the

lye solution has cooled to about 110 degrees. Both the oils and the

32

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

lye solution should be between 105 and 115 degrees. Mix well using

a stick blender like a Braun. Mix for 3-5 minutes to begin the

Saponification process. You will know that the process has begun

when ‘trace’ occurs. Trace is visible usually within 5 minutes of

blending with a stick blender. Do not worry if it takes a little longer.

Make sure that the temperature is within range, if it is a little low, it

could take longer for trace. Trace becomes obvious as you can see

the mixture begin to form a trail behind the stick blender and when

you lift the blender out of the pot, (turned off of course )the

drippings land on top of the liquid and form a line or trace across the

top as would a thick honey if poured on itself.

Tracing soap appears like a thickened cooked custard. Add any

fragrances and other non-fragile additives quickly. Give one thorough

mix with the stick blender. Mix in fragile additives such as herbs, and

essential oils with a spoon or rubber/silicon spatula.

Pour into molds. Cover and insulate with a large towel, allow to set up

undisturbed. I put my soaps in the back corner of the closet. The

soap will go through a clear gel phase as it goes through the

33

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Saponification process. Leave the soap in the molds for 24-36 hours.

Remove them carefully and place them on a kitchen cooling rack. It

will not be hot, it just allows for air to flow all around the soap. After

3-5 days, cut the soap into bars and allow it to cure in a protected

cool dry area. Cover the soap as it is curing with a linen cloth to allow

airflow and prevent dust and debris from settling in the soap. The

bars will take one month to finish curing and harden for use. Soap,

like wine gets better as it sits. The longer it cures the harder it gets,

and the more stable the lather it produces.

Clean your equipment with hot water. Do not pour large amounts of

raw soap down the drain. It can cure in place and create plumbing

problems, particularly with septic systems. I wash my equipment after

24 hours, as the pot is then lined with soap, and I can just add water

and have an easy clean up of all my dishes instead of a greasy mess

that can be a bit ‘stingy’ on the hands. Freshly mixed soap is still

loaded with lye solution, but 24 hours later it is all soap and the lye is

gone.

Chapter 5:

34

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Re -batching Secrets

Re-batching is a term used to describe several methods of making

hand milled soaps at home. The advantages of doing so are to

maximize the retention of benefits of more fragile or expensive

additives and to use less fragrance or essential oils. For example,

rose essential oil or frankincense essential oil.

For best results, use an unscented base to start from for re-batching.

You can also melt down and re-use soap scraps, and left over bits, or

re-batch to fix a botched batch for example, too much or too little lye,

honey that did not melt in, or any imperfection you would see/find to

your own preferences.

Okay, so here is the truth on re-batching: It is an art in and of itself.

Many people find it very tricky, some even find it more trouble than it

is worth. I think it is very individual, and in playing with it, you just may

discover something that you love. I did, and now I get to share it with

you. When I make laundry soap, dish soap, shampoo, and multi-

35

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

purpose cleaner, I am also re-batching, just going for a liquid to solid-

cream consistency for the end product. It took me some time to

develop the exact consistency that I desired and I am so glad to

share it with you now!

Hand milling, or re-batching to a bar gives you a hard and solid bar

as if it were just cured cold process soap. There are several methods

or techniques to hand milling you can play with if you get into it. As it

is an art, you may find that you love it just as described, or that

tweaking these methods works better for you. Either way, these

instructions will get you started on your way.

Method 1:

My personal favorite, Double Boiler Method.

Shred/grate up scraps in a food processor, put them in a stainless

steel double boiler top pot and just cover with water or milk. let it sit

out overnight so the soap can totally soak up and incorporate the

water or milk.

In the morning, when the grated soap is soft, and saturated

with liquid, heat them with lid on pan in double boiler for about 10

minutes. You will get a beautiful gel! Add the fragile fragrances, or

36

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

essential oil or herb that you like now. Stir and pour into mold. If you

don’t have a double boiler, you can make one by placing one pan

over the top of another that has boiling water in it. You may need to

baby-sit it the pot a bit more than the real thing, but it will work.

Method 2:

Boil in Bag:

This method is great because you don't have to worry about

scorching and there is very little clean up.

This method works best for hand milling small amounts of soap

scraps. You can only fit so much into a zip lock bag.

* Grate up your soap scraps and mix up to blend well

* Place grated soap into a large freezer zip lock bag along with any

extra oils, color, etc.

* If the soap is really dry, you may want to add a small amount of

water. One or two tablespoons should be enough.

Put in Ziplocs

37

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

* Squeeze bag out of air and seal. Place that bag into a second zip

lock, squeeze out air and seal.

* Once the bag is sealed, place it into a pot of simmering water and

put on the lid. Periodically check the bag to see if the soap is melting.

Turn up the heat a little if nothing happens after 1/2 hour.

* When the soap begins melting, remove the bag and mush or

squeeze the mixture to blend it. You may want to wear oven mitts or

gloves to do this. It's HOT!

* Return to pot until the mixture is completely melted.

* Place the bag into water.

* When the soap has melted completely, quickly remove the bag

from the pot and squeeze the soap to one corner.

* Clip the corner of the bag at the bottom of the soap and pipe it

into a lined soap mold to cool.

* Remove and cut the re-batched bars when the soap is completely

cool and has hardened.

That's it.....you're done!

38

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Method 3:

Crock-pot Method

* Grate up the soap to be re - batched and place into your crock-

pot.

* add about 3 tablespoons of water to help prevent scorching.

* Turn on the crock-pot to low and put the lid on the pot.

* Keep an eye on the soap to make sure it is melting and isn't

burning.

* Once the grated soap bits are transparent, you can add your color,

oil or scent.

* Just gently mix the additives in and when it is blended, spoon it into

your mold.

* If you like, add a small amount of goats milk, whole milk or coconut

milk to make the soaps creamier.

* You'll want to work quickly so the mix doesn't cool before you get

it all in the mold.

* Once it has cooled completely, it can be cut and cured as usual.

39

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Method 4:

Re - batching to new product, softer consistency.

This is what we will cover in great detail in the following pages.

These methods are less well known and can be totally adapted and

refined by you for your own personal needs/desires.

It is simple and fun to do, and this is where you really SAVE the BIG

$$$ MONEY! Here you combine a certain amount of distilled water, -

I use double filtered and boiled rain water – distilled by nature, and

other natural products and your own soap to make all the products

you need for your home, and family. By using different ratios of the

above ingredients, including a variety of natural ingredients including,

herbal and other plant derived extracts and or essential oils, you can

make all of your own laundry soap, dish washing soap, body - bath,

hand, and face soaps, plus your own shampoos and all natural, all

purpose cleaner concentrate! WOW! How much money will

you save when you can make a batch of soap in just a

few hours that will cover all of your LAUNDRY, DISH

WASHING, SHAMPOO, BODY, FACE AND HAND SOAPS,

40

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

PLUS YOUR *TOILET BOWL CLEANER, YOUR

*COUNTER TOP SPRAY, *THE CERAMIC OR LAMINATE

FLOOR CLEANER, THE ONE *FOR THE SINKS, THE

*TUB & TILE CLEANER AND ANY OTHERS YOU MAY BE

BUYING for a full year for under $50 US? * All in one

cleaner concentrate as described in the following pages. Your final

price may vary by a few dollars based on where you live in the world.

It will vary also depending on the oils you choose to use, however,

the savings will likely vary in an equal or greater proportion

depending on where you live, and what brand names you have been

purchasing for these products already. If you have been green or

health conscience and have been buying the more expensive

‘natural’, ‘organic’, or ‘green’ products, you have likely been paying

even more than the average statistics show, and you may not even

realize but even some of the most expensive brands are still using

natural sourced surfactants, derived using petrochemicals.

They may be biodegradable, but that does not mean that

they are necessarily sustainable, or that they are not

harmful to our bodies. All of these products enter our bodies

41

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

through the largest methods of absorption – the skin, and

the airways.

SO LETS GET GOING ON LAUNDRY SOAP!

Chapter 6:

Step by Step – Make your own Laundry Soap

Get ready for simplicity here.

For every 1 Liter, or 33 ounces of distilled water, add 1.25 ounces of

grated soap from the following recipe for cold process soap making:

LAUNDRY SOAP BASE:

Castor Oil 5 ounces 5%

Sunflower Oil 20 ounces 20%

Olive Oil 30 ounces 30%

Palm Oil 45 ounces 45%

13.15 ounces Lye, dissolved in

32 ounces distilled water.

You will Need:

• large soup/stock stainless steel pot

• wire whisk

• 1 Tbsp dried rosemary leaves or 2 fresh whole sprigs

• tea ball, or tea sack, or nut milk bag to place herbs in.

• Measuring container

• 4 L Distilled water, and 6 oz grated soap

42

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

• Kitchen scale

• Essential oils of your liking (optional)

1. In a large soup/stock stainless steel pot bring 4 Liters of distilled

water to a rolling boil.

2. Turn off the heat and add the rosemary and any other fresh or

dried herbs you desire. Be careful – too many or the wrong kind

can spoil your laundry soap. For instance, citrus peel works

best added at the end when no further heat will be applied. . I

prefer to add the herbs in a filter bag/cloth so as not to need to

strain to soap. I only use other herbs that are very cleansing or

antibacterial in nature – rosemary is great because it grows

easily in the yard, or in a pot so you can have it on hand. It is a

natural preservative, is antibacterial, and smells nice too! Leave

the herbs to steep, covered for 10-15 minutes.

3. Remove the herbs and return the heat to the pot, SET ON LOW

NOW.

4. Add the grated soap – 6 ounces and allow it to slowly melt

down over low heat, uncovered

5. Check back on the soap in 5-10 minutes, if it has begun to

soften and become translucent, stir it in gently with the wire

whisk.

43

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

6. Check again in 10 minutes and stir gently. By now, the soap

will likely be incorporated into the water and you will no longer

see any shreds, only a creamy and sudsy liquid.

7. Turn off the flame, and cover the pot. Leave it sit covered

overnight or at least 8-12 hours. I often make this in the

morning, and let it sit 24 hours. Don’t let it go too much longer.

8. Add 5 drops per liter (20 drops) of any essential oil you would

like for smell or anti-bacterial or other benefit. (OPTIONAL)

9. Stir vigorously with a wire whisk. if you have added essential

oils or not

10.Pour your soap through a funnel into a recycled 1 gallon/ 4 Liter

container.

11. Enjoy your new chemical free Laundry Soap!

What is the cost on this product for you?

Roughly 65 cents plus essential oils if you choose to add

them. You may use this up in a month, so your annual cost

here – $7.80 US

44

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

based on the base cost of $.65/ 4 Liter per month.

Chapter 7:

Step by Step – make you own dish soap

Making dish soap is almost as simple as the laundry soap. It

needs to be watched a tiny bit more only because it is a

much higher concentration of soap to water. You will end up

with a creamy solid soap. This is different than what many

of us are used to in dish soap but it works great and is truly

ALL NATURAL!

45

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

TO USE: you simply wet your sponge and rub it over the tub

of soap. The sponge will lather up as you wash your dishes.

It creates a nice consistent foamy lather and really does a

great job of cleaning your dishes!

To make the dish soap, calculate 2.5 times the amount of

water for the amount of grated soap you will use. You can of

course use any base recipe you like for this re-batch to dish

soap process, and here is the one I have developed and

perfected over the last 3 years:

Almond Joy Base

Castor Oil 5 oz 5%

Sunflower Oil 15oz 15%

Olive Oil 15 oz 15%

Almond Oil 30 oz 30%

Palm Oil 35 oz 35%

13.2 ounces of Lye dissolved in 32-33 ounces distilled

water. This gives a 4.75% lye discount, or super fat. Perfect for

this oil combination. Tried and tested by yours truly.

46

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Ready to get started re-batching to make your own Dish

Soap?

1. Gather your materials:

• large soup/stock stainless steel pot

• wire whisk

• Measuring container

• 115 ounces Distilled water, and 45 oz grated soap

• Kitchen scale

• ½ c sea salt

• Essential oils of your liking (optional)

• 10 - 1lb sealable containers. (recycled butter tubs, ice cream,

hummus, dips, etc.)

2. Bring 115 ounces of distilled water to a rolling boil

3. REDUCE HEAT TO LOW, add 45 ounces of grated soap.

4. Check back on the soap in 5-10 minutes, if it has begun to

soften and become translucent, stir it in gently with the wire

whisk. BE CLOSE ALWAYS, CAN SUDS UP AND OVER

QUICKLY!! KEEP HEAT LOW, BE PATIENT

47

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

5.Check back again in 5 minute increments and stir gently

again. After 15 minutes or so, the soap will likely be

incorporated into the water and you will no longer see any

shreds, only a creamy and sudsy liquid.

6. Turn off the heat, and allow to cool 5 - 10

minutes uncovered.

7. Add ½ cup sea salt and stir with a wire whisk until

dissolved.

8. Cover, and allow soap to cool and sit 8-12 hours. Try not

to let it sit any longer than this.

9. Add any essential oils that you would like, I add just a bit

of Almond extract, or almond essential oil if I can as the

soap already has a nice almond scent. I just want to

accentuate it a bit more. You could add any scent you wish.

10. Stir vigorously with a wire whisk until the soap is a

creamy thick liquid. You may need to use your stick blender

if you have waited too long. The soap can harden in the pot

but won’t harden all the way through like it will in the tubs

48

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

you pour it into. The stick blender will work nicely and

quickly to get it to a pour-out consistency.

11. Pour out the soap into your sealable containers.

12. Cover them and allow them to cure a minimum of 5-7

days before use for maximum suds and longer lasting soap.

13. Enjoy your new Chemical Free Dish Soap!!

What is the cost on this product for you?

Roughly $6.30 US for 10 pounds of dish soap – will

likely last the year through.

Chapter 8:

Step by Step make your own

Multi-Purpose Cleaners!

49

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Next we will go through the process to making a soap

based multi-purpose cleaner concentrate. This can be used

in many ways, straight, or diluted and mixed with vinegar,

baking soda, and or just plain water.

Before we get started I just want to list a few great natural

cleaning solutions that you may or may not already be

aware of:

White distilled vinegar, baking soda, lemon juice, and salt

are superb all natural cleaners that are easy to obtain, and

usually found around the house. Here are a few tips in

using them:

• Shine chrome fixtures with a paste made of 2 tablespoons salt

and 1 teaspoon white distilled vinegar.

• Clean counter tops and make them smell sweet again with a

cloth soaked in undiluted white distilled vinegar.

50

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

• Clean and deodorize a drain by pouring in 1 cup baking soda,

then one cup hot white distilled vinegar. Let this sit for 5

minutes or so, then run hot water down the drain.

• Deodorize the garbage disposal by pouring in 1/2 cup baking

soda and 1/2 cup hot white distilled vinegar. Let sit for 5

minutes then run hot water down the disposal.

• Clean the refrigerator shelves and walls with a half-and-half

solution of water and white distilled vinegar.

• Cut grime full-strength white distilled vinegar.

• Clean your ceramic, and linoleum floors with 1 cup vinegar for

every gallon of water.

If you would like to see 1001 uses for white distilled vinegar, check

out this link:

http://www.vinegartips.com/Scripts/

Vinegar kills bacteria mold and germs and is useful as a multi-

purpose cleaner all on its own, however some people find the aroma

offensive, our household finds, we like to mix it with our own home

made cleaner, or dilute it much more than what is recommended.

51

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

I use the multi-purpose cleaner we will make in the following pages

full strength to clean the toilets, I have friends who prefer to use this

for their dish washing as they just prefer a liquid. I dilute it with just

water or with vinegar and water in a spray bottle for cleaning

counters, spills and messes, the table, and any other light cleaning

job I have. I also use it to wash any outside furniture and toys, my

daughters swing, tricycle, and slide for example . It works great as a

stain/spot remover for clothes too because of the citrus oils. I put it

on full strength and leave the item in the sun. The spot/stain is usually

gone from this treatment, and for sure after a wash in the machine.

Always double check if you are drying your clothes in a heated dryer

as the stain will set with heat if it is still there. So here we go step by

step for Multi Purpose Cleaning Concentrate:

Either of the last two soap bases that we have recipes for above will

work great for this process. Again, it is super simple!

1 ounce of grated soap to every 16 ounces of water.

1. Gather your materials:

• large soup/stock stainless steel pot

• wire whisk

• Measuring container

52

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

• 144 ounces Distilled water, and 9 oz grated soap

• Kitchen scale

• 1/4 c sea salt

• ½ c fresh or dried citrus zest – lemon, or orange

• 10 16 oz bottles. (recycled water bottles, or other clean

recycled plastic bottles. )

• funnel

2. Bring 144 ounces distilled water to a rolling boil.

3. REDUCE HEAT TO LOW, add 9 ounces of grated soap.

4. Check back on the soap in 10 - 15 minutes, if it has begun to

soften and become translucent, stir it in gently with the wire

whisk.

5.Check back again in 10 minutes and stir again. By now, the

soap will likely be incorporated into the water and you will no

longer see any shreds, only a creamy and sudsy liquid.

6.Turn off the flame, and add the ½ cup citrus zest. Stir with wire

whisk until well incorporated. Leave it sit to cool 5-10 minutes.

7. Add the ¼ cup sea salt, stir with wire whisk until dissolved.

53

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

8. Allow to sit covered overnight or at least 8-12 hours. I often

make this in the morning, and let it sit 24 hours. Don’t let it go too

much longer.

9. Stir vigorously with a wire whisk.

10.Pour your soap through a sieve or fine mesh strainer and

then through a funnel into recycled bottles. This is to remove any un -

dissolved citrus zest.

11. Enjoy your new chemical free Multi-Purpose Concentrated

Cleaner!

Chapter 9:

Step by Step, make your own shampoo!

54

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Making your own shampoo is so rewarding and fun! This process

is a bit more time consuming than the others, and well worth it.

You can still make up all that you will need for the year in just a

few hours and while you are doing other things in the kitchen.

It is important to realize that what you have most likely been using

to wash your hair is loaded with petro chemicals. Yes, even the all

natural, and the organic very expensive brands are LOADED

WITH CHEMICALS! These chemicals make your hair follicles

toxic, sick, and confused. They create more oil and grease while

all those harmful chemicals have a chance to get in, right through

the skin on your head. Look at the label, anything that you can not

easily pronounce or do not easily recognize, check it out look it

up, I am sure you will find, petrochemicals, and synthetic

surfactants.

Because of the long-term use of chemicals on our scalps, it is

important to give your hair a bit of a de-tox. It will be much easier

55

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

to accomplish this by washing your hair with your own shampoo

that you will learn how to make here, than by just going cold

turkey – no kidding, cold turkey no more washing with anything

but water. You can also go cold turkey and avoid making your

own shampoo, and ever having to wash your hair again. You

should be warned however that you MUST go without washing

your hair with anything other than water for 3 weeks to 3 months

until your hair stops looking like you dressed it with your favorite

salad dressing! I tried to make it and could not, but using the

shampoo we are about to make solved all of my problems! I got

my hair de-toxed, and I get it really clean, and have never had to

make it through the 3 months of grease head!

We will use a number of herbs that you may have growing, or if

not, can easily find at your grocer or natural food store

I will go over the herbs and their benefits for your hair. You can of

course use these and or others, I am simply sharing what I have

found through lots of experimentation works really well to clean

your hair!

56

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Rosemary - Balances oils, nourishing, promotes hair growth,

Sage - Irrigates hair follicle, moisturizes, soothes the scalp

Horsetail - Contains silica, repairs split ends, promotes hair

growth, treats dandruff

Thyme- Irrigates the hair follicle, soothes the scalp, treats

dandruff

Aloe Vera Gel – This is a must have! Aloe contains saponins, so it

helps the lather and suds to come out more, it works to clean the

hair. It contains over 200 different nutrients for your hair and

scalp! Detoxifies the hair, follicle, and scalp. It is anti fungal, and

antibacterial, aloe promotes new cell growth, new hair growth,

moisturizes and envelopes every hair strand with its nutrients.

Optional herbs/flowers :

Lemongrass, chamomile, lavender and calendula are all

cleansing for the hair. Chamomile can help to bring out blonde

highlights, and is also moisturizing. For more information on plant

extracts and what they can do for your hair check out

www.carrubba.com

57

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

For re- batching to shampoo, you can once again, use any base

soap that you prefer, and the one that I have found to work best,

is made with 30% Almond Oil and follows :

Almond Joy shampoo base

Castor Oil 5 oz 5%

Sunflower Oil 15oz 15%

Olive Oil 15 oz 15%

Almond Oil 30 oz 30%

Palm Oil 35 oz 35%

13.2 ounces of Lye dissolved in 32-33 ounces distilled

water. This gives a 4.75% lye discount, or super fat. Perfect for

this oil combination. Tried and tested by yours truly.

So here we go Step by step to make your own shampoo!

58

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

1. Gather your materials:

• large soup/stock stainless steel pot

• wire whisk

• Measuring container

• 100 ounces Distilled water, and 10 oz grated soap

• Kitchen scale

• Measuring Spoons

• Fresh or dried herbs and plants: Rosemary, thyme, sage,

horsetail, oats, 1-2 aloe plant leaves, or pure Aloe gel

chamomile*, lemongrass*, lavender*, calendula flowers*, (* =

optional addition)

• 7 - 16 oz bottles. (recycled water bottles, or other clean

recycled plastic bottles. )

• funnel

• Vitamin E as a preservative

• Essential oils – Rosemary, Lavender, or any other you like

2. Bring 100 ounces of distilled water to a rolling boil.

3. Turn off the heat, add all of the plant materials, cover and

steep for 15-20 minutes.

PLANT MATERIALS TO ADD:

1Tablespoon dried, or 4 tablespoons fresh each;

Sage, Rosemary, Thyme, Horsetail, any of the optional

59

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

herbs /flowers you like

¼ cup rolled oats

2 Tablespoons Aloe Vera gel removed from the leaf yourself, or

purchased at the store. If you remove the gel from the leaf, be

sure to leave the yellow sap behind by cutting off the green hard

leaf entirely.

You can add all of the plant materials in a nut milk bag or cloth

filter bag or you can add them into the pot directly and then strain

them through when finished. It is best to crush, grind, or macerate

the plant material to expose the most amount of surface area for

extracting it into the shampoo.

I like to incorporate the aloe vera into the shampoo by blending

once the plant extracts are completed through the steeping

process. I just pull it out, wipe or rinse it off, then add it back to

the water loaded with plant extracts and blend with the stick

blender.

60

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

4. Remove the plant material by straining through a nut milk bag,

filter cloth, or sieve. Squeeze all of the liquid out of the filter

device to get the best of the extracts into your shampoo.

5. Place the aloe leaf ,if used and not gel used, back into the pot

and blend with the stick blender.

6. Turn the heat on – KEEP ON LOW NOW. It is very important

not to allow the water to boil again at this point, just remain warm

to hot so as not to damage your plant extracts. You do not need

to raise the temperature above 110F from this point. Add 10

ounces of grated soap.

7. Watch over your shampoo a bit more than the previous re-

batches of other products. You have a number of lovely plant

extracts in there, you do not want to have them ruined by too

much heat! Check back every few minutes and stir gently with a

wire whisk to incorporate the soap.

61

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

8. Once the soap is incorporated, and completely melted into

solution. Turn off the heat. Stir once more, cover and let it sit

overnight and up to 24 hours.

9. The longer it sits, the thicker the shampoo will be become.

When you come back to it. Add 1-2 vitamin E gel capsules – up to

1000 units for this 100 ounce recipe. Also add any essential oils

you would like. I recommend Rosemary as it is so good for the

hair, acts as a preservative and stabilizer, and smells good. I

often add lavender and or others as well for the scent and other

benefits. General rule of thumb here, add what you like to have it

smell and feel the way you prefer. You don’t need so much so

start with a few drops and add more if you like.

Blend well using a stick blender.

10. Pour out into bottles using a funnel.

11. Enjoy your own chemical free shampoo!

62

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Chapter 10:

Selling your Soaps!

So now you have all the information you need, plenty of

resources, and some practice under your belt, would selling your

soaps be right for you?

It worked out great for me. I have a lovely little cottage industry

selling all of the above products that you have just learned to

make. It may be just the thing for you too. Here’s what you should

ask yourself to see if it is a good fit for you.

63

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Do you LOVE making soap, experimenting, refining, and playing

with all of your soap creations?

Do you have a market? – Like a weekly farmers market, or a co-

op that lacks hand made soaps and products like those you have

learned to make here?

Does your community need and want these products?

If you answered YES to these questions, then selling your soaps

may be a perfect fit for you!

It is simple to start slow and sell to your friends, neighbors, and

community. If you have a farmers market or co-op it is the ideal

place to get started. Packaging and labeling can be very simple

and rustic to start with and get more elaborate if you choose as

you expand your business.

You can of course set up a website and sell your soaps online as

well. You may do best with bar soaps and shampoos here, but

64

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

plenty of people order natural cleaning products and laundry

soaps online so why not yours as well.

Play with the recipes I gave you, and make your own up too, have

fun and NEVER worry about making a mistake. This is an art form

– there are no mistakes in art, just new creations. So be free, let

go, and have FUN!

Your hand made soaps will make fantastic gifts regardless if you

sell them or not. Giving them away may even be how you get

started in selling them. That is how I got going – I gave some

soap as gifts to friends and soon they were back asking for more.

I live in a community that has a weekly artisan market, farmers

market, and has a HUGE need for all natural alternatives for

personal hygiene and cleaning supplies. I LOVE SOAPING, so it

all made perfect sense for me. If you love it, you may find yourself

selling soaps soon also.

Appendix:

65

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

References and Resources

Anything and Everything you could ever need to know about cold

process soap making that you could not find in the pages above or

the instructional videos you can find out here:

www.millersoap.com

www.Soap-making-resource.com

www.soap-making-essentials.com

Lye Calculators:

www.thesage.com/calcs/lyecalc2.php

www.cranberrylane.com/calculator.htm

www.sudsandscents.com/lye_calculator.htm

Lye Suppliers:

www.brambleberry.com

www.boyercorporation.com

www.essentialdepot.com

www.thelyeguy.com/store/store.php

www.snowdriftfarm.com

www.thesoapdish.com

Plant extracts www.carrubba.com

Vinegar – 1001 uses www.vinegartips.com/Scripts/

66

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Other Alternatives to cleaning with Chemicals:

housekeeping.about.com/cs/environment/a/alternateclean.htm

greenlivingideas.com/2008/04/27/natural-cleaning-recipes/

67

Sara Kate Wilson – Soap Making Secrets www.Soapinar.com

Você também pode gostar

- African Holistic Health - Llaila o Afrika PDFDocumento305 páginasAfrican Holistic Health - Llaila o Afrika PDFGnostic the Ancient One93% (176)

- Alkaline Herbal Medicine Reverse Disease and Heal The Electric Body Aqiyl AniysDocumento123 páginasAlkaline Herbal Medicine Reverse Disease and Heal The Electric Body Aqiyl AniysSantiago Rivero97% (65)

- Soap Making - 365 Days of Soap Making - 365 Soap Making Recipes For 365 Days (Soap Making, Soap Making Books, Soap Making For Beginners, Soap Making Guide, ... Making, Soap Making Supplies, Crafting)Documento1.182 páginasSoap Making - 365 Days of Soap Making - 365 Soap Making Recipes For 365 Days (Soap Making, Soap Making Books, Soap Making For Beginners, Soap Making Guide, ... Making, Soap Making Supplies, Crafting)Rafael Castelfranchi100% (1)

- Natural Beauty Recipes 37pagesDocumento37 páginasNatural Beauty Recipes 37pagesanky100% (18)

- Charms, Spells and FormulasDocumento99 páginasCharms, Spells and FormulasMarin Goode94% (100)

- Making Natural Products - Complete GuideDocumento307 páginasMaking Natural Products - Complete Guidemolesag97% (69)

- Recipe Booklet CompressedDocumento32 páginasRecipe Booklet Compressedxiuhtlati100% (2)

- The Ankh African Origin of Electromagnetism by Nur Ankh Amen PDFDocumento139 páginasThe Ankh African Origin of Electromagnetism by Nur Ankh Amen PDFTom100% (2)

- How To Make Your Own Soap ... in Traditional Bars, Liquid or CreamDocumento370 páginasHow To Make Your Own Soap ... in Traditional Bars, Liquid or Creamkothura100% (1)

- Liquid Soap Making TechniqueDocumento4 páginasLiquid Soap Making Techniqueluchoosorio100% (3)

- Soap Making BusinessDocumento8 páginasSoap Making Businessak123456100% (1)

- How To Make Your Own SoapDocumento267 páginasHow To Make Your Own Soapsantorini192797% (34)

- Homemade Recipes Book Soaps Ointments Candles Shampoos and BalmsDocumento196 páginasHomemade Recipes Book Soaps Ointments Candles Shampoos and BalmsRachel Ward100% (15)

- Easy Natural Soapmaking - How To Make Natural Soaps That Rejuvenate, Revitalize, and Nourish Your Skin. (PDFDrive)Documento100 páginasEasy Natural Soapmaking - How To Make Natural Soaps That Rejuvenate, Revitalize, and Nourish Your Skin. (PDFDrive)Nova Erxa100% (3)

- Homemade Recipes BookDocumento202 páginasHomemade Recipes BookJoy Nelson-Graham100% (17)

- Soap Making ManualDocumento264 páginasSoap Making ManualRamniaa100% (7)

- Bath and Body Recipes Collected From Various PlacesDocumento16 páginasBath and Body Recipes Collected From Various PlacesBexy Brennan100% (1)

- Soap Making Step by Step Guide To Make Homemade Soaps Advanced Beginner Recipes IncludedDocumento206 páginasSoap Making Step by Step Guide To Make Homemade Soaps Advanced Beginner Recipes Includedroland yapi100% (1)

- Creating Natural Essentials EbookDocumento119 páginasCreating Natural Essentials EbookMayerlin Castillo100% (2)

- 50 Shea Butter DIY RecipesDocumento46 páginas50 Shea Butter DIY RecipesNigh100% (7)

- Diy Organic Beauty RecipesDocumento198 páginasDiy Organic Beauty RecipesElla Allerton100% (7)

- Soap Making - Kelly Kohn (CreateSpace, 2012)Documento108 páginasSoap Making - Kelly Kohn (CreateSpace, 2012)ShadabAhmad100% (1)

- Beginner Soapmaking Instructions and Recipes Revised PDFDocumento37 páginasBeginner Soapmaking Instructions and Recipes Revised PDFstefanovicsanjaAinda não há avaliações

- Soap Making: 71 Homemade Soap RecipesDocumento64 páginasSoap Making: 71 Homemade Soap RecipesLyubomyr Yatsyk89% (27)

- DIY-GUIDE - SkincareDocumento25 páginasDIY-GUIDE - Skincarepriyankitha100% (2)

- Liquid Soap MakingDocumento14 páginasLiquid Soap MakingAldjo Sjaaf83% (6)

- Candle and Soap EbookDocumento125 páginasCandle and Soap EbookBonFiyah100% (3)

- Soap Making A Quick Soap Making BookDocumento109 páginasSoap Making A Quick Soap Making Bookloay2008100% (19)

- BSB Recipes 0319 PDFDocumento26 páginasBSB Recipes 0319 PDFJay Parte100% (3)

- Natural Facial Soaps EbookDocumento39 páginasNatural Facial Soaps EbookRiddhima Singh100% (6)

- How To Make Bar SoapDocumento140 páginasHow To Make Bar SoapmesfinAinda não há avaliações

- Soap BusinessDocumento46 páginasSoap BusinessAndrea Fabiana Blaschi100% (1)

- Natural Soap: Techniques and Recipes for Beautiful Handcrafted Soaps, Lotions, and BalmsNo EverandNatural Soap: Techniques and Recipes for Beautiful Handcrafted Soaps, Lotions, and BalmsAinda não há avaliações

- Soap Making Business Startup: How To Start, Run & Grow A Million Dollar Success From Home! - Suzanne CarpenterDocumento6 páginasSoap Making Business Startup: How To Start, Run & Grow A Million Dollar Success From Home! - Suzanne Carpenterzitutija0% (3)

- Formulating Tips For Creams and LotionDocumento3 páginasFormulating Tips For Creams and LotionDewi Sekar AyuAinda não há avaliações

- The Art of Soap-MakingDocumento324 páginasThe Art of Soap-MakingKristos Bakayiannis86% (7)

- SoapsDocumento413 páginasSoapsKathryn Bax83% (6)

- My Buttered Life Personal Care Edition FinalDocumento18 páginasMy Buttered Life Personal Care Edition Finalxiuhtlati100% (1)

- Bar ShampooDocumento10 páginasBar ShampooKathy Kemmis O'Driscoll100% (1)

- Herbal Soap Making How To Make H-Asin - B00QFYAORY-type - EBOK-v - 0 PDFDocumento24 páginasHerbal Soap Making How To Make H-Asin - B00QFYAORY-type - EBOK-v - 0 PDFAeglee Patricia Garrido0% (2)

- Ookie Shoes Coat Meat Bread Socks Truck: WTTFL FFLLL H - P H Tui WR? T U - 'Documento60 páginasOokie Shoes Coat Meat Bread Socks Truck: WTTFL FFLLL H - P H Tui WR? T U - 'VhiknaRhubanNavindranAinda não há avaliações

- Argan Soapmaking RecipesDocumento7 páginasArgan Soapmaking RecipesGua Da100% (3)

- Preservatives in Cosmetic ProductsDocumento35 páginasPreservatives in Cosmetic Productsketchito100% (2)

- Soap Detergent MFG DD 1974Documento217 páginasSoap Detergent MFG DD 1974Noman Sunny100% (1)

- Formula Botanica Ingredients ClassificationDocumento1 páginaFormula Botanica Ingredients ClassificationKarina0% (1)

- Handmade Soap Book: Easy Soapmaking with Natural IngredientsNo EverandHandmade Soap Book: Easy Soapmaking with Natural IngredientsNota: 5 de 5 estrelas5/5 (2)

- Basic Cold Process Soap Making Guide: by Amanda AaronDocumento26 páginasBasic Cold Process Soap Making Guide: by Amanda AaronRo BellingeriAinda não há avaliações

- Cosmetics 11112 PDFDocumento37 páginasCosmetics 11112 PDFcacolina100% (4)

- Detailed Lesson Plan TEMPLATE09Documento4 páginasDetailed Lesson Plan TEMPLATE09carAinda não há avaliações

- HLTH 634 - Final Program PlanDocumento11 páginasHLTH 634 - Final Program Planapi-232845707Ainda não há avaliações

- Castile Soapmaking: The Smart Guide to Making Castile Soap, or How to Make Bar Soaps From Olive Oil With Less Trouble and Better Results: Smart Soap Making, #4No EverandCastile Soapmaking: The Smart Guide to Making Castile Soap, or How to Make Bar Soaps From Olive Oil With Less Trouble and Better Results: Smart Soap Making, #4Ainda não há avaliações

- The Natural Soap Chef: Making Luxurious Delights from Cucumber Melon and Almond Cookie to Chai Tea and Espresso ForteNo EverandThe Natural Soap Chef: Making Luxurious Delights from Cucumber Melon and Almond Cookie to Chai Tea and Espresso ForteNota: 5 de 5 estrelas5/5 (3)

- Basic Beginner Soap Making Checklist PDFDocumento7 páginasBasic Beginner Soap Making Checklist PDFMarco Cervantes100% (1)

- Dairy Technology 9002 01 07 2008 GBDocumento110 páginasDairy Technology 9002 01 07 2008 GBThaVinci100% (1)

- Soap TrainingDocumento40 páginasSoap Training2manyMembers100% (1)

- ENGLISH YEAR 5 Paper 1Documento10 páginasENGLISH YEAR 5 Paper 1Syahidah Sukhaimi50% (2)

- Textbook of CosmetologyDocumento96 páginasTextbook of CosmetologyHanabi_MineAinda não há avaliações

- Soap Making Business Startup: Start and Run a Successful Soap Making Business from HomeNo EverandSoap Making Business Startup: Start and Run a Successful Soap Making Business from HomeNota: 4.5 de 5 estrelas4.5/5 (5)

- Big Batch Soap MakingDocumento24 páginasBig Batch Soap MakingAnonymous Vu1R35s4WZ100% (2)

- Soap Making BooksDocumento17 páginasSoap Making BooksAntingero0% (2)

- Soap Production FiguresDocumento29 páginasSoap Production Figuresmbame100% (1)

- Soap Making: A Beginner's Guide for Making Handmade Soaps from ScratchNo EverandSoap Making: A Beginner's Guide for Making Handmade Soaps from ScratchAinda não há avaliações

- Soap Making Like A Pro: The Complete Guide with Recipes on How to Make Colorful & Fragrant Soap at Home for Fun & ProfitNo EverandSoap Making Like A Pro: The Complete Guide with Recipes on How to Make Colorful & Fragrant Soap at Home for Fun & ProfitNota: 4 de 5 estrelas4/5 (4)

- Soap Making Reloaded: How To Make A Soap From Scratch Quickly & Safely: A Simple Guide For Beginners & BeyondNo EverandSoap Making Reloaded: How To Make A Soap From Scratch Quickly & Safely: A Simple Guide For Beginners & BeyondNota: 3 de 5 estrelas3/5 (4)

- The Present Perfect With Ever' and Never'Documento9 páginasThe Present Perfect With Ever' and Never'Yaina Ivanova100% (1)

- Dancing For HathorDocumento264 páginasDancing For Hathorsanaamikhail100% (6)

- Homemade Soap Recipes: Learn Simple DIY Soap Recipes Step By Step Using All-Natural Ingredients, Essential Oils, Herbs And Much MoreNo EverandHomemade Soap Recipes: Learn Simple DIY Soap Recipes Step By Step Using All-Natural Ingredients, Essential Oils, Herbs And Much MoreAinda não há avaliações

- Cold Process Soap Making: Mary Sheldon Green Forests WorkDocumento18 páginasCold Process Soap Making: Mary Sheldon Green Forests WorkSeemaMainkarAinda não há avaliações

- Haskin 2016Documento9 páginasHaskin 2016Tony JuanAinda não há avaliações

- Fuhrman - Vegan AthleteDocumento9 páginasFuhrman - Vegan Athleteryan9871Ainda não há avaliações

- Terneli - ExtraçãoDocumento8 páginasTerneli - ExtraçãoTony JuanAinda não há avaliações

- Sodium Lauroyl IsethionateDocumento24 páginasSodium Lauroyl IsethionateTony JuanAinda não há avaliações

- Calvi - ExtraçãoDocumento12 páginasCalvi - ExtraçãoTony Juan100% (1)

- Sodium Lauroyl IsethionateDocumento24 páginasSodium Lauroyl IsethionateTony JuanAinda não há avaliações

- Lye Concentration 40.0000 %: Soapcalc ©Documento2 páginasLye Concentration 40.0000 %: Soapcalc ©Tony JuanAinda não há avaliações

- Lye Concentration 40.0000 %: Soapcalc ©Documento2 páginasLye Concentration 40.0000 %: Soapcalc ©Tony JuanAinda não há avaliações

- Lye Concentration 40.0000 %: Soapcalc ©Documento2 páginasLye Concentration 40.0000 %: Soapcalc ©Tony JuanAinda não há avaliações

- UlmDocumento16 páginasUlmM Arslan AshrafAinda não há avaliações

- Antibacterial and Antifungalactivity of Jambolao SeedsDocumento4 páginasAntibacterial and Antifungalactivity of Jambolao SeedsTony JuanAinda não há avaliações

- Artigo-Mechanical Properties of Epoxided Hemp Oil - Preliminary StudiesDocumento6 páginasArtigo-Mechanical Properties of Epoxided Hemp Oil - Preliminary StudiesTony JuanAinda não há avaliações

- Novel Linseed Oil-Based Monomers Synthesis - Balanuca2014Documento12 páginasNovel Linseed Oil-Based Monomers Synthesis - Balanuca2014Tony JuanAinda não há avaliações

- 109 113Documento5 páginas109 113swetakokaAinda não há avaliações

- Artigo-Development of Hemp Oil Based BioresinsDocumento203 páginasArtigo-Development of Hemp Oil Based BioresinsTony JuanAinda não há avaliações

- Fuhrman - Vegan AthleteDocumento9 páginasFuhrman - Vegan Athleteryan9871Ainda não há avaliações

- Artigo-Shelf Life of OilsDocumento1 páginaArtigo-Shelf Life of OilsTony JuanAinda não há avaliações

- Artigo-MWCNTs - Reinforced Epoxidized Linseed Oil PlasticizedDocumento14 páginasArtigo-MWCNTs - Reinforced Epoxidized Linseed Oil PlasticizedTony JuanAinda não há avaliações

- IRB Certificate 07-04-2012Documento1 páginaIRB Certificate 07-04-2012Tony JuanAinda não há avaliações

- Time: 3.00 HR Marks:100 6 Class Grand Skill - 2Documento9 páginasTime: 3.00 HR Marks:100 6 Class Grand Skill - 2Rama Mohana Rao BhandaruAinda não há avaliações

- Town of Hounsfield Zoning Law Revised January 2016Documento72 páginasTown of Hounsfield Zoning Law Revised January 2016pandorasboxofrocksAinda não há avaliações

- Iari PHD Question PaperDocumento12 páginasIari PHD Question Papernarendra singhAinda não há avaliações

- Canvas Monthly Magazine - February IssueDocumento32 páginasCanvas Monthly Magazine - February IssuegoodproduceAinda não há avaliações

- Canal Life in ThailandDocumento9 páginasCanal Life in ThailandJohn M. WatkinsAinda não há avaliações

- Budget Request DSPC 2019-2020Documento1 páginaBudget Request DSPC 2019-2020JOHN MC RAE RACINES100% (1)

- NearDocumento8 páginasNeardddddAinda não há avaliações

- Semester I Lesson 1 FamilyDocumento60 páginasSemester I Lesson 1 FamilyPuspita Purnama SariAinda não há avaliações

- Shel-Life and Mechanisms of Destabilitation in Dilute Beverage EmulsionsDocumento6 páginasShel-Life and Mechanisms of Destabilitation in Dilute Beverage EmulsionsRayito HernándezAinda não há avaliações

- BDMax EntericViralPanel PDFDocumento24 páginasBDMax EntericViralPanel PDFTAinda não há avaliações

- Bottel Water List - FinalDocumento14 páginasBottel Water List - FinalSandunika Lakmali100% (1)

- Reading and Writing Practice 4 DAYS With AnswersDocumento30 páginasReading and Writing Practice 4 DAYS With AnswersNông Thị ThắmAinda não há avaliações

- Restaurant Week Delhi Menu: Choice of Any OneDocumento4 páginasRestaurant Week Delhi Menu: Choice of Any OneMegha SudheeshAinda não há avaliações

- Worksheet 1Documento6 páginasWorksheet 1Mohan SaiAinda não há avaliações

- Nutrition Month Narrative Report FinalDocumento6 páginasNutrition Month Narrative Report FinalLucille Lu100% (1)

- Great Scot AdDocumento6 páginasGreat Scot AdcommunitymarketsAinda não há avaliações

- Exercise On Simple PresentDocumento5 páginasExercise On Simple PresentTeodor MățăuAinda não há avaliações

- Lincoln County School District # 2 Elementary Lunch Menu January-11Documento1 páginaLincoln County School District # 2 Elementary Lunch Menu January-11anon-579447Ainda não há avaliações

- IFRJ 2017, Sri Winarti, Colonic MicrobiotaDocumento8 páginasIFRJ 2017, Sri Winarti, Colonic MicrobiotaSri WinartiAinda não há avaliações

- Community Pharmacy PracticeDocumento18 páginasCommunity Pharmacy Practiceكسلان اكتب اسميAinda não há avaliações