Escolar Documentos

Profissional Documentos

Cultura Documentos

Product Brochure Quarrying Industry

Enviado por

Enzo Miguel Sarabia MontesDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Product Brochure Quarrying Industry

Enviado por

Enzo Miguel Sarabia MontesDireitos autorais:

Formatos disponíveis

Liebherr Special Machines

for the Quarrying Industry

Liebherr Special Machines for the Quarrying Industry

2 Liebherr Special Machines for the Quarrying Industry

Liebherr has decades of experience in the development

and production of class-leading machines for the quarrying

industry, including crawler and mining excavators, wheel

loaders, crawler dozers, dump trucks and duty cycle crawler

cranes. With innovative design and major components all

produced by Liebherr, the machines can be deployed with

great efficiency and performance in the most challenging

and difficult environments in the quarrying world. Quarry

machines from Liebherr perform all tasks perfectly, and

every component has been purpose-designed. They

feed breakers, sifting systems and trucks, and transport

the surface mine material. Liebherr machines work with

immense power, and advanced technology reduces down

fuel consumption – the perfect machines for economical use

in the quarrying industry.

Large Hydraulic Excavators

Wheel Loaders

Crawler Dozers

Duty Cycle Crawler Cranes

Customer Service

Liebherr Special Machines for the Quarrying Industry 3

Large Hydraulic Excavators

4 Liebherr Special Machines for the Quarrying Industry

Performance Comfort

Liebherr’s large hydraulic excavators follow our principle of Liebherr large hydraulic excavators provide the driver with

maximising machine performance by improving the efficiency ideal conditions for fatigue-free and effective working. All

of all of the individual parts. Each machine is designed for of the excavators feature large and spacious cabs that are

optimum serviceability and minimum downtimes. An ultra- comfortably equipped and comply with the latest ergonomic

modern engine management system maintains perfect conventions. This maintains the driver’s concentration and

performance, under the toughest of working conditions. safety over many hours. Cab windows with impact-resistant

reinforced glass enable safe working and an optimal view

Economy over the working space and surrounding area. For easy

For Liebherr, protection of the environment is one of our access during maintenance work, Liebherr large hydraulic

guiding principles and the most important challenge for excavators feature safe and comfortable catwalks as well as

the present and future. Environmentally-configured power an innovative layout of the components and service points on

regulation of the hydraulic system and engine performance the uppercarriage.

optimises the fuel efficiency of the machine to match the

application. The automatic idling system reduces engine Maintainability

speed when the machine is stationary, and if less power is The Liebherr excavators offer perfect safety for the operator

required, “eco mode” can be selected on the control panel to and maintenance team. As it is serviced from just one side,

reduce the engine load, further improving the fuel efficiency the machine offers trouble-free access to the main service

and reducing CO2 emissions. points for fast and safe maintenance in the field. The cab

has been designed with further reinforcement for the safety

Reliability of the driver.

As an original equipment manufacturer, Liebherr has a leading

and healthy reputation in the development and production of

high quality major components. All large hydraulic excavators

from Liebherr feature robust and reliable components that

have been optimised for the unique conditions of mining

and are designed and manufactured by Liebherr to ensure

reliabiltity, high performance and longevity. Liebherr excavator

customers can expect lasting performance throughout the

whole service life of the machine.

Liebherr Special Machines for the Quarrying Industry 5

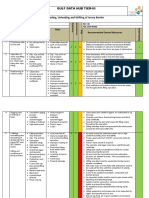

Overview of Large Hydraulic Excavators

with Backhoe Attachment

Stick and Bucket Cylinders

• With increased diameter in

combination with adapted kinematics

• Higher breakout and digging forces

Stick with Internal Protection

• For a longer service life

• Protection from bulky

material in the bucket

Cab on Hydraulic Mountings

• For optimal vibration insulation

Standard HD Bucket

• For increased service life

• Other types available

6 Liebherr Special Machines for the Quarrying Industry

Standard Reinforced

Glass Window

• At front and in roof

Standard Automatic Air

Conditioning

• With 13 diffusers

Standard Counterweight

• For greater stability and

performance

Angled Track Pads

• For better manoeuvrability on

difficult terrain

Liebherr Special Machines for the Quarrying Industry 7

Overview of Large Hydraulic Excavators

with Face Shovel Attachment

Built for Mining

• Liebherr tooth system

• Liebherr customized wear package

• Automatic central greasing system

for all lubrication points

• Automatic closing of the bucket

• Ram guard for the lift cylinder

(optional)

• Cover protection for front swing

gear (optional)

Sturdy Structure

• Heavy duty undercarriage

• Additional full length chain guide

(optional)

• Rock protection for track wheels

(optional)

8 Liebherr Special Machines for the Quarrying Industry

Efficient Work

• Electronic control

• Rear- and side-view cameras

• Semi-automatic swing brake

• Operator Comfort Kit (optional)

• Various optional protective

equipment (optional)

• Cab pressurisation

• Standard automatic air conditioning

Liebherr Vertical Integration

• Diesel engine USA / EPA Tier 2

• Hydraulic pumps and motors

• Splitter box

• Electronic and control technology

• Hydraulic cylinders

• Swivel bearing

• Swing and travel drives

First Class Service

• Single side service access

• Wide catwalk and railings

• Hydraulically operated 45° access

ladder (optional)

• Quick-release coupling for filling

from ground level (optional)

• Fuel filling system with Multiflo

Hydrau-Flo (optional)

Liebherr Special Machines for the Quarrying Industry 9

Technical Data

R 950 SME Litronic R 956 Litronic

Operating weight BH t 44 to 46 51 to 60

Bucket capacity* m3 up to 3.0 up to 3.5

Operating weight FS t - approx. 57

Shovel capacity* m3 - up to 3.1

Engine power kW / HP 220 / 299 240 / 326

Emission standard IV / Tier 4f IV / Tier 4f

R 960 SME Litronic R 966 Litronic

Operating weight BH t approx. 61 68 to 78

Bucket capacity* m3 up to 3.7 up to 5.5

Operating weight FS t approx. 62 67 to 70

Shovel capacity* m3 up to 3.5 up to 5.0

Engine power kW / HP 250 / 340 320 / 435

Emission standard IV / Tier 4f IV / Tier 4f

R 970 SME Litronic R 976 Litronic

Operating weight BH t 78 to 80 86 to 96

Bucket capacity* m3 up to 5.0 up to 6.6

Operating weight FS t 79 to 81 91 to 93

Shovel capacity* m3 up to 5.0 up to 6.5

Engine power kW / HP 330 / 449 400 / 544

Emission standard IV / Tier 4f IV / Tier 4f

R 980 SME Litronic R 9100

Operating weight BH t 95 to 97 108,5

Bucket capacity* m3 up to 6.8 7.0

Operating weight FS t 99 to 101 112.5

Shovel capacity* m3 up to 6.5 7.0

Engine power kW / HP 420 / 571 565 / 757

Emission standard IV / Tier 4f II / Tier 2

R 9150

Operating weight BH t 128

Bucket capacity* m3 8.3

Operating weight FS t 130

Shovel capacity* m3 8.3

Engine power kW / HP 565 / 757

Emission standard II / Tier 2

* HD backhoe and face shovel bucket at 1.8 t / m3

10 Liebherr Special Machines for the Quarrying Industry

Examples of Use

Liebherr Special Machines for the Quarrying Industry 11

Wheel Loaders

12 Liebherr Special Machines for the Quarrying Industry

Performance Comfort

The powerful Liebherr L 550 XPower® – L 586 XPower® wheel The modern ergonomic cab design provides the operator with

loaders excel with their high handling capacity in quarrying maximum comfort enabling him to concentrate on accurate

operations. XPower® offers the greatest level of efficiency operation without fatigue, which once again means more

and maximum output in all areas, regardless of whether the safety and productivity. The Liebherr control lever, which

distances are long or short, or whether the ground is level or is built into the operator’s seat as standard, allows precise

even has an incline. This increases productivity in all work and sensitive control of the machine. The generous glass

cycles and improves profit for the customer. surfaces and the design of the engine hood, which has been

optimised for viewing, provide excellent all-round visibility.

Economy This ensures maximum safety for people, the machine and

The Liebherr-XPower driveline with Liebherr-Power-Efficiency the load.

(LPE) achieves a reduction in fuel consumption of up to

30 %. In addition there is minimal tyre wear and hardly any Maintainability

brake wear. At maximum handling capacity and efficiency, The most important points for daily maintenance can be

this reduces operating costs significantly, further increasing seen at a glance in the access area of Liebherr-XPower

profitability. wheel loaders. Quick and safe control saves time and money.

Reliability

Liebherr wheel loaders provide maximum performance

even under the toughest and most challenging conditions

in surface mines. The components of the Liebherr-XPower

wheel loaders are extremely rugged and low-wear. XPower®

ensures a long machine life and reliability in use.

Liebherr Special Machines for the Quarrying Industry 13

Wheel Loaders L 550 XPower® – L 586 XPower® Overview

Maximum Operator Comfort for

Greater Productivity

• Automatic central lubrication system

(L 550 – L 580 optional / L 586 as

standard)

• Premiumdisplay (Touchscreen)

• Joystick steering or 2-in-1 steering

(optional)

• 3-way continuously adjustable

steering column

• Ride control

• Steering stabilisation

Ruggedness and Quality

for Durable Machines

• Tilt cylinder protection (optional)

• Special buckets in HD or rock

version (optional)

• Lamp carrier in steel design

(optional)

• Guard for headlights (optional)

• Fuel tank steel version

• Special tyres for quarrying industry

(optional)

• Tyre protection chains (optional)

Highest Level of Performance

• Powerful and efficient Liebherr-

XPower® driveline

• Automatic self-locking differentials

in both axles

14 Liebherr Special Machines for the Quarrying Industry

Productive and Safe Working

• Soundproof ROPS / FOPS cab

• Safety roof over cab (optional)

• Additional working lights, rear

(optional)

• Adaptive working lighting (optional)

• Skyview 360° (optional)

• Safe, non-slip ladder access

to cabin

• Anti-slip step with door locking

• Access assistance to facilitate

cleaning windscreen

• Folding windscreen guard for

increased safety and easy access

for cleaning (optional)

Short Service Times for

Greater Productivity

• Important maintenance points

visible in access area

• Radiator easy to maintain

• Reversible fan drive (optional)

• Air pre-cleaner TOP AIR (optional)

Ruggedness and Quality

for Durable Machines

• Crash protection, rear (optional)

• Widening for fender and rear

mudguard (optional)

Productive and Safe Working

• Anti-slip steps and sturdy handrails

• Rear space monitoring camera

via Liebherr display

• Headlights halogen

(double design on engine hood)

Liebherr Special Machines for the Quarrying Industry 15

Technical Data

L 550 XPower® L 556 XPower®

Tipping load kg 12,000 – 12,200 13,500 – 13,700

Bucket capacity m3 3.2 – 3.6 3.6 – 4.0

Operating weight kg 17,700 – 17,800 18,400 – 18,500

Engine output (ISO 14396) kW / HP 140 / 191 165 / 224

Emission standard IV / Tier 4f IV / Tier 4f

L 566 XPower® L 576 XPower®

Tipping load kg 15,650 – 15,900 17,400 – 17,600

Bucket capacity m3 4.2 – 4.7 4.7 – 5.2

Operating weight kg 23,900 – 24,000 25,700 – 25,800

Engine output (ISO 14396) kW / HP 200 / 272 215 / 292

Emission standard IV / Tier 4f IV / Tier 4f

L 580 XPower® L 586 XPower®

Tipping load kg 18,700 – 19,500 21,000 – 22,500

Bucket capacity m3 5.2 – 5.7 5.5 – 6.5

Operating weight kg 27,650 – 28,800 32,600 – 33,700

Engine output (ISO 14396) kW / HP 230 / 313 260 / 354

Emission standard IV / Tier 4 IV / Tier 4f

16 Liebherr Special Machines for the Quarrying Industry

Examples of Use

Liebherr Special Machines for the Quarrying Industry 17

Crawler Dozers

18 Liebherr Special Machines for the Quarrying Industry

Power and innovative technology: These are the trademarks of the Liebherr crawler

dozers. Whether in tough ripping operations or for pushing heavy material, the

PR 756, PR 766 and PR 776 impress in every scenario with outstanding

performance and economy.

Performance Comfort

To mechanically dig and break out hard rock, high Liebherr crawler dozers offer operators a generously

penetration and pushing forces are required. The Liebherr proportioned workspace, designed with the latest ergonomic

crawler dozers PR 756, PR 766 and PR 776 offer the ideal aspects in mind. The spacious and comfortable cabin enables

performance capacities with operating weights of 40, 50 an optimal overview of the working area and the equipment.

and 70 tonnes respectively in conjunction with the innovative With the intuitive single joystick control, the machine can be

hydrostatic drive concept. Engine power is constantly controlled accurately and safely at all times.

transmitted through a positive connection without slippage,

which means that the material is worked loose evenly and Maintainability

efficiently pushed away. Thanks to their minimal maintenance requirements, Liebherr

crawler dozers make a reliable contribution to your economic

Economy success. A dense service network means short distances,

The latest generation Liebherr diesel engines combine high efficient systems and fast response times for the user.

performance with frugal operation. Thanks to the consistently

low engine speed, fuel is saved and a high service life of

the components is achieved. Additional clear economical

advantages speak in favour of Liebherr: as with all Liebherr

equipment, the PR 756, PR 766 and PR 776 models also

benefit from being user-friendly. This reduces maintenance

costs and downtime.

Reliability

Tough and sturdy: Liebherr crawler dozers are designed for a

long operational lifetime with careful attention to construction

and material quality. All parts that are subject to particularly

heavy loads are made from the strongest materials available,

whilst sensitive areas are optimally protected. All of these

factors make Liebherr crawler dozers reliable machines with

the highest level of availability.

Liebherr Special Machines for the Quarrying Industry 19

Overview of Crawler Dozers

Cab with Integrated

ROPS / FOPS Protection

• Best all-around view for the operator

• Higher safety and productivity

Separate Hydraulic Oil Cooler

• Reliable cooling performance even in

the hottest ambient temperatures

• Reduced fuel consumption due to

demand-controlled fan

HD-Ripper

• Excellent ripping performance in

hard underground conditions

• Robust design for longevity

Bogie Suspension (optional)

• Smoother operation

• Optimal traction

20 Liebherr Special Machines for the Quarrying Industry

LED-Lighting (optional)

• Guarantees best illumination

of the working area

• Better working performance even in

the dark / bad light conditions

Hydrostatically Driven Cooling Fan

• Fast engine warm-up and reliable

cooling in each situation

• Laminar air flow facilitates a

long radiator-life

Different Types of Blades

With HD-Cutting Edge

• High flexibility for all kind of material

• High productivity

HD-Tilt Cylinder Cover and

Wear-Plates on Push Arm

and Blade (all optional)

• Best possible protection against

large rocks

• Extended lifetime of components

exposed to wear

HD-Track Pads

• Highly wear-resistant in hard

applications

• Longer uptime

Liebherr Special Machines for the Quarrying Industry 21

Examples of Use and Technical Data

PR 756 Litronic1 PR 766 Litronic2 PR 776 Litronic3

Operating weight* kg 38,300 46,225 71,800

Blade capacity semi U-blade m3 8.9 13.6 18.5

Blade capacity U-blade m3 - 17.0 22.0

Ground clearance mm 635 680 703

Max. ripping depth of ripper mm 1,203 1,300 1,445

Max. penetration force of ripper kN 123.9 166.9 237

Max. pryout force of ripper kN 208.8 291.5 441

Track shoe width mm 560 – 711 610 – 760 610 – 762

Engine output kW / HP 250 / 340 310 / 422 440 / 598 Forward 565 / 768 Reverse

Emission standard IV / Tier 4f IV / Tier 4f II / Tier 2

1

Semi U-blade, 560 mm track shoes, single-shank ripper

2

Semi U-blade, 610 mm track shoes, single-shank ripper

3

Semi-U-blade, 610 mm track shoes, single-shank ripper

22 Liebherr Special Machines for the Quarrying Industry

Liebherr Special Machines for the Quarrying Industry 23

Duty Cycle Crawler Crane HS 8300 HD

24 Liebherr Special Machines for the Quarrying Industry

Performance Reliability

With an operating weight of 350 tonnes the HS 8300 HD from In the design phase of the HS 8300 HD Liebherr paid particular

Liebherr is one of the largest duty cycle crawler cranes. It can attention to an extended service life. The uppercarriage has

be equipped with various high-volume dragline buckets and a box design and is mounted on a large undercarriage. This

grabs. The duty cycle crawler crane is suitable for various composition ensures stability and is suitable for dynamic

material handling and excavation applications, for example, continuous performance. The service life of the HS 8300 HD

dredging or surface excavation in opencast mines. has been doubled in comparison to that of the standard

series.

Economy Liebherr places great emphasis on safety. The walkways as

A modern drive system, consisting of a high performance well as the roof of the uppercarriage are fitted with railings to

diesel engine as well as an innovative hydraulic concept, ensure safe and easy access for the operator as well as for

ensures economic machine operation. As an option the maintenance staff.

duty cycle crawler crane can be fitted with Pactronic®, a

hydraulic hybrid drive which provides both economical as Comfort

well as ecological advantages. Through the storage and The cabin is designed for optimum operator comfort. This

subsequent reactivation of surplus energy the turnover can includes a clear field of vision as well as an ergonomic cabin

be increased and, at the same time, the fuel consumption concept. Furthermore, operators of the HS 8300 HD profit

can be significantly reduced. Without Pactronic® the V12 from an intelligent control system with diverse program and

diesel engine offers an output of 725 kW. Together with the control functions. Service and machine functions are clearly

hybrid drive, however, it achieves a system performance displayed on colour monitors. All movements can be carried

comparable to a conventional drive system with 1250 kW. out simultaneously.

Quick set-up further contributes to the efficiency of the duty

cycle crawler crane. A sophisticated design concept ensures Maintainability

that the machine is ready for operation within only one week. All components of the HS 8300 HD are designed for easy

maintenance. Liebherr’s worldwide service network offers

quick availability of parts and therefore maximum productivity

of the machine.

Liebherr Special Machines for the Quarrying Industry 25

Examples of Use and Technical Data

HS 8300 HD

Max. capacity t 300

Min. transport width mm 3,980

Min. transport height mm 3,260

Min. transport weight t 69

Engine power kW 725

Max. winch line pull kN 2 x 500

Max. boom length m 68.00

Max. boom length for duty cycle operation m 68.00

Boom length in dragline operation m 50.00

Operating weight t 352

Max. depth in dragline operation m 25.00

Max. capacity dragline bucket m³ 10.80

Max. capacity grab m³ 15.00

26 Liebherr Special Machines for the Quarrying Industry

Liebherr Special Machines for the Quarrying Industry 27

Customer Service

28 Liebherr Special Machines for the Quarrying Industry

Partnership and Convenience Safety and Economy

Reliable Service Today and in the Future Intelligent Solutions –

With Liebherr you can put your trust in the continued support an Additional Service from Liebherr

and partnership-based security. The Liebherr factories and Forward planning, short response times and effective

service partners have been guaranteeing this for over 60 implementation of the service work will save you money.

years. Service outlets all over the world make the close Liebherr offers you an optimal base with innovative software

proximity to you a reality. The well-equipped expert team solutions such as LiDAT, the customer portal MyLiebherr, as

of Liebherr service partners is available to support you well as oil analyses, service agreements and supplementary

competently and reliably. services.

Professional Care from Customized Service Agreements for

Professionals to Professionals Consistently Excellent Service

Competent advice is a matter of pride at Liebherr. Service agreements from Liebherr are a convincing way of

Experienced professionals support your decision-making increasing the profitability of your machine over the long term.

process for specific requirements: application-oriented

sales consultation, customized service agreements, repairs, Reman Program –

Liebherr original parts management and remote diagnosis the Right Solution to Extend Equipment Life-Cycle

for fault analysis. In addition to new parts, Liebherr also offers you a three-stage

Reman program for your machines from the repair to general

Optimal Availability at any Time overhaul through to the use of replacement components.

Regular maintenance and repair is necessary for efficient

machine operation. It is important that this maintenance Liebherr Lubricants

work can be carried out efficiently, fast and in a convenient Liebherr offers you an extensive range of high-quality

manner. With excellent availability and clever logistics of lubricants and operating fluids that are specifically designed

original parts, service agreements and supporting services, to meet the requirements of your Liebherr machines.

Liebherr provides the foundation for convenient and fast Optimised work processes and high machine availability, as

maintenance for your Liebherr machine. well as minimal wear, are thus possible.

Qualifications and Professional Development Retrofit

The focus is on people: training and education of the service With the extensive retrofit program Liebherr provides an

teams in the Factory Training Centres are the basis for attractive alternative to increase the economy and comfort

reliable, first-class service. of your machines. Adaptations to new regulations can be

carried out efficiently.

Convenient Software Solutions

• MyLiebherr is your gateway to the Liebherr service

world. In the Liebherr customer portal you benefit from

comprehensive and additional services around the world

of construction machines, mining, mobile and crawler

cranes, material handling technology and maritime cranes.

• LiDAT offers you a comprehensive fleet management tool

for different machine categories from a single source.

Liebherr Special Machines for the Quarrying Industry 29

Notes

30 Liebherr Special Machines for the Quarrying Industry

Liebherr Special Machines for the Quarrying Industry 31

The Liebherr Group of Companies

Wide Product Range State-of-the-art Technology

The Liebherr Group is one of the largest construction To provide consistent, top quality products, Liebherr attaches

equipment manufacturers in the world. Liebherr’s high- great importance to each product area, its components and

value products and services enjoy a high reputation in many core technologies. Important modules and components are

other fields. The wide range includes domestic appliances, developed and manufactured in-house, for instance the entire

aerospace and transportation systems, machine tools and drive and control technology for construction equipment.

maritime cranes.

Worldwide and Independent

Exceptional Customer Benefit Hans Liebherr founded the Liebherr family company in 1949.

Every product line provides a complete range of models in Since that time, the enterprise has steadily grown to a group

many different versions. With both their technical excellence of more than 130 companies with over 41,000 employees

and acknowledged quality, Liebherr products offer a maxi- located on all continents. The corporate headquarters of the

mum of customer benefits in practical applications. Group is Liebherr-International AG in Bulle, Switzerland. The

Liebherr family is the sole owner of the company.

www.liebherr.com

Printed in Germany by Typodruck BK-OT LFR / SP 11161643-2-07.17_enGB

Subject to technical modifications.

Liebherr-Werk Bischofshofen GmbH Liebherr-Hydraulikbagger GmbH Liebherr-Werk Telfs GmbH

Postfach 49, A-5500 Bischofshofen Liebherrstraße 12, D-88457 Kirchdorf/Iller Hans Liebherr-Straße 35, A-6410 Telfs

+43 50809 1-0, Fax +43 50809 11385 +49 7354 80-0, Fax +49 7354 80-72 94 +43 50809 6-100, Fax +43 50809 6-7772

www.liebherr.com, E-Mail: info.lbh@liebherr.com www.liebherr.com, E-Mail: info.lhb@liebherr.com www.liebherr.com, E-Mail: lwt.marketing@liebherr.com

www.facebook.com/LiebherrConstruction www.facebook.com/LiebherrConstruction www.facebook.com/LiebherrConstruction

Liebherr-Werk Nenzing GmbH Liebherr-France SAS Liebherr-Mining Equipment Colmar SAS

Dr. Hans Liebherr Straße 1, A-6710 Nenzing 2 avenue Joseph Rey, B.P. 90287, FR-68005 Colmar Cedex 49 rue Frédéric Hartmann, FR-68025 Colmar Cedex

+43 50809 41-473, Fax +43 50809 41-499 +33 3 89 21 30 30, Fax +33 3 89 21 37 93 +33 369 49 20 00, Fax +33 369 49 23 18

www.liebherr.com, E-Mail: crawler.crane@liebherr.com www.liebherr.com, E-Mail: info.lfr@liebherr.com www.liebherr.com, E-Mail: info.lec@liebherr.com

www.facebook.com/LiebherrConstruction www.facebook.com/LiebherrConstruction www.facebook.com/LiebherrMining

Você também pode gostar

- 3c7f664e-d03c-4b0b-ae07-659f328f5a72Documento16 páginas3c7f664e-d03c-4b0b-ae07-659f328f5a72viktormarioAinda não há avaliações

- Liebherr R9100 Ilovepdf CompressedDocumento22 páginasLiebherr R9100 Ilovepdf CompressedMohamed Badian TraoreAinda não há avaliações

- LIEBHERR PR 736 - PR 756 LitronicDocumento32 páginasLIEBHERR PR 736 - PR 756 LitronicGoran MatovicAinda não há avaliações

- Bildprospekt AbfallwirtschaftDocumento24 páginasBildprospekt AbfallwirtschaftenmardukgalAinda não há avaliações

- Liebherr ComponentsDocumento36 páginasLiebherr Componentsناجى ابوعورة100% (2)

- Mining Excavator: Operating Weight With Backhoe Attachment: Shovel Attachment: Engine: Bucket Capacity: Shovel CapacityDocumento22 páginasMining Excavator: Operating Weight With Backhoe Attachment: Shovel Attachment: Engine: Bucket Capacity: Shovel Capacityalviar nurihsanAinda não há avaliações

- Liebherr Components PDFDocumento36 páginasLiebherr Components PDFequipment9278Ainda não há avaliações

- Mining Excavator: Operating Weight With Backhoe Attachment: Shovel Attachment: Engine: Bucket Capacity: Shovel CapacityDocumento22 páginasMining Excavator: Operating Weight With Backhoe Attachment: Shovel Attachment: Engine: Bucket Capacity: Shovel CapacityYudi AriantoAinda não há avaliações

- Product Brochure PR 736 - PR 756 LitronicDocumento32 páginasProduct Brochure PR 736 - PR 756 LitronicRasoolKhadibi100% (1)

- NTB R9350 enGB-US PDFDocumento22 páginasNTB R9350 enGB-US PDFHarishAinda não há avaliações

- Product Brochure PDFDocumento22 páginasProduct Brochure PDFAli özkanlıAinda não há avaliações

- NTB PR754-PR764 11003722 02.11 enUS 11012-0Documento18 páginasNTB PR754-PR764 11003722 02.11 enUS 11012-0Diego Pacheco VelaAinda não há avaliações

- ManualBook Liebherr PR756Documento32 páginasManualBook Liebherr PR756Hanafi AhmadAinda não há avaliações

- Hoja Técnica R 9800Documento12 páginasHoja Técnica R 9800ForomaquinasAinda não há avaliações

- Bildprospekt SchrottumschlagDocumento24 páginasBildprospekt SchrottumschlagFirman ArifinAinda não há avaliações

- R9100 G6 Brochure - enGB USDocumento24 páginasR9100 G6 Brochure - enGB UShina8086Ainda não há avaliações

- BP Holzumschlag enGB 16-03Documento48 páginasBP Holzumschlag enGB 16-03Miguel FiallosAinda não há avaliações

- New Generation LoadersDocumento6 páginasNew Generation LoadersMacrotek ArequipaAinda não há avaliações

- PR776-Bull DozerDocumento24 páginasPR776-Bull Dozerhendryn100% (1)

- NTB R9800 enGB-USDocumento22 páginasNTB R9800 enGB-USEnzo Miguel Sarabia Montes100% (1)

- Liebherr R9400Documento22 páginasLiebherr R9400Rohman FashihinAinda não há avaliações

- Liebherr Intermat 2018 PR 776 Crawler Tractor en PDFDocumento24 páginasLiebherr Intermat 2018 PR 776 Crawler Tractor en PDFCristianoAinda não há avaliações

- Website Docs To Be Pasted.10Documento1 páginaWebsite Docs To Be Pasted.10paulBennetts2yAinda não há avaliações

- Buldozer Sa Ceonom KasikomDocumento28 páginasBuldozer Sa Ceonom KasikomDunja KrtinicAinda não há avaliações

- Wheeled Excavator: Generation Operating Weight EngineDocumento24 páginasWheeled Excavator: Generation Operating Weight Enginepebi liveAinda não há avaliações

- Product Brochure L 524 - L 580Documento40 páginasProduct Brochure L 524 - L 580Jenriel CatulingAinda não há avaliações

- Backhoe LoaderDocumento43 páginasBackhoe Loadertarsono sonoAinda não há avaliações

- r9800 2011 (8a4)Documento12 páginasr9800 2011 (8a4)Nguyen Phuc LinhAinda não há avaliações

- 6 Website Docs To Be Pasted Page08Documento1 página6 Website Docs To Be Pasted Page08emad AhmadAinda não há avaliações

- 950K Aehq6251-00Documento4 páginas950K Aehq6251-00percyAinda não há avaliações

- Liebherr T284Documento28 páginasLiebherr T284Igor VianaAinda não há avaliações

- Brochure R 9350 English 2013-04 - 11723-0 PDFDocumento22 páginasBrochure R 9350 English 2013-04 - 11723-0 PDFJulhefry Maroan Situngkir100% (1)

- RL44 RL54 RL64 - GBDocumento26 páginasRL44 RL54 RL64 - GBBoban Stanojlović100% (1)

- Crawler Excavator: Operating Weight: Engine OutputDocumento12 páginasCrawler Excavator: Operating Weight: Engine OutputGoran MatovicAinda não há avaliações

- CAT 930D Excavator C620823Documento28 páginasCAT 930D Excavator C620823Dutchie169Ainda não há avaliações

- ERKE Group, Soilmec SM-8G AnchoringDocumento12 páginasERKE Group, Soilmec SM-8G Anchoringerkegroup100% (1)

- Transmission Xs Fe 75W-80: Very High Performance Lubricant For Heavy Duty Manual and Automated TransmissionsDocumento2 páginasTransmission Xs Fe 75W-80: Very High Performance Lubricant For Heavy Duty Manual and Automated Transmissionsayman akrabAinda não há avaliações

- Brochure 23Documento4 páginasBrochure 23brujula24100% (1)

- NTB R9150 enGB-USDocumento22 páginasNTB R9150 enGB-USJuvencio Maquera AtencioAinda não há avaliações

- RG Integrally Geared Compressors PDFDocumento6 páginasRG Integrally Geared Compressors PDFJaswindersingh BhatiaAinda não há avaliações

- Bildprospekt AbfallwirtschaftDocumento36 páginasBildprospekt AbfallwirtschaftFirman ArifinAinda não há avaliações

- ред поворот PDFDocumento20 páginasред поворот PDFrenatAinda não há avaliações

- BFM 2011 Mobile Machinery enDocumento2 páginasBFM 2011 Mobile Machinery enSebasthian Caceres SaavedraAinda não há avaliações

- R996B - EnglishDocumento20 páginasR996B - EnglishHelio RibeiroAinda não há avaliações

- Mining Truck: Nominal Payload Gross Vehicle Weight (GVW) Engine PowerDocumento24 páginasMining Truck: Nominal Payload Gross Vehicle Weight (GVW) Engine Powerfoca88Ainda não há avaliações

- 2019 Feb DF 4E Series Brochure 4pp LRDocumento4 páginas2019 Feb DF 4E Series Brochure 4pp LRNezrin BesirovaAinda não há avaliações

- Rotrex Technical Datasheet C30 RangeDocumento7 páginasRotrex Technical Datasheet C30 RangeeduardodemarcoAinda não há avaliações

- Rotrex Technical Datasheet C30 RangeDocumento7 páginasRotrex Technical Datasheet C30 RangeSidney RiveraAinda não há avaliações

- Wheel Loaders L 538 / L 556 / L 580: Effi CiencyDocumento26 páginasWheel Loaders L 538 / L 556 / L 580: Effi CiencyDunja Krtinic100% (1)

- Transmission Syn FE 75W-90 A 0410Documento1 páginaTransmission Syn FE 75W-90 A 0410Fer EmilAinda não há avaliações

- PC350 350LC-8 Cen00222-05 PDFDocumento14 páginasPC350 350LC-8 Cen00222-05 PDFRobert RobertsAinda não há avaliações

- Specifications: Ibratory OIL OmpactorDocumento2 páginasSpecifications: Ibratory OIL OmpactorMohamad NuhAinda não há avaliações

- LEHH0551Documento4 páginasLEHH0551Lore ChAinda não há avaliações

- Liebherr ComponentsDocumento36 páginasLiebherr ComponentsTchad SafkabuhireAinda não há avaliações

- ZF Katalog Swing Gearboxes GFBDocumento12 páginasZF Katalog Swing Gearboxes GFBIsac Medeiros de AraújoAinda não há avaliações

- CS54 Cs533e en PDFDocumento16 páginasCS54 Cs533e en PDFXavier Millan100% (1)

- Page: M-1 of M-3 © 2018 Caterpillar All Rights Reserved MSS-IND-18374262-022 PDFDocumento3 páginasPage: M-1 of M-3 © 2018 Caterpillar All Rights Reserved MSS-IND-18374262-022 PDFبحب اصحابيAinda não há avaliações

- NTB R9600-G8 enGB-USDocumento28 páginasNTB R9600-G8 enGB-USOrso OsvaldAinda não há avaliações

- Backhoe Loader 310J: EngineDocumento5 páginasBackhoe Loader 310J: EngineEnzo Miguel Sarabia MontesAinda não há avaliações

- J Backhoes 12 21 06 PDFDocumento18 páginasJ Backhoes 12 21 06 PDFEnzo Miguel Sarabia MontesAinda não há avaliações

- 7495 Con Hydracrowd Pala Eléctrica de Cable CaterpillarDocumento3 páginas7495 Con Hydracrowd Pala Eléctrica de Cable CaterpillarEnzo Miguel Sarabia MontesAinda não há avaliações

- Left Joystick Backhoe Position PDFDocumento1 páginaLeft Joystick Backhoe Position PDFEnzo Miguel Sarabia MontesAinda não há avaliações

- Left Joystick Loader Position PDFDocumento1 páginaLeft Joystick Loader Position PDFEnzo Miguel Sarabia MontesAinda não há avaliações

- Selective Flow Control Valve: Monitor Flex Load Controller ECUDocumento1 páginaSelective Flow Control Valve: Monitor Flex Load Controller ECUEnzo Miguel Sarabia MontesAinda não há avaliações

- Total Machine Control: BackhoesDocumento10 páginasTotal Machine Control: BackhoesEnzo Miguel Sarabia MontesAinda não há avaliações

- Serv1837 - 01 - TXT C6.6 CatDocumento1.273 páginasServ1837 - 01 - TXT C6.6 CatEnzo Miguel Sarabia Montes100% (2)

- TMC Features Loader Position PDFDocumento1 páginaTMC Features Loader Position PDFEnzo Miguel Sarabia MontesAinda não há avaliações

- D 16eDocumento7 páginasD 16eEnzo Miguel Sarabia MontesAinda não há avaliações

- TMC Features Backhoe Positions PDFDocumento1 páginaTMC Features Backhoe Positions PDFEnzo Miguel Sarabia MontesAinda não há avaliações

- SDM Backhoe Menu Hierarchy 15feb06 PDFDocumento10 páginasSDM Backhoe Menu Hierarchy 15feb06 PDFEnzo Miguel Sarabia MontesAinda não há avaliações

- Archivo Adjunto 4Documento63 páginasArchivo Adjunto 4Enzo Miguel Sarabia MontesAinda não há avaliações

- Archivo Adjunto 3Documento40 páginasArchivo Adjunto 3Enzo Miguel Sarabia MontesAinda não há avaliações

- 06a 320D.AuxDocumento19 páginas06a 320D.AuxEnzo Miguel Sarabia Montes100% (3)

- CodigosDocumento73 páginasCodigosEnzo Miguel Sarabia MontesAinda não há avaliações

- 140MDocumento2 páginas140MEnzo Miguel Sarabia Montes100% (1)

- Fig. 5: Caterpillar 3126B HEUI Full Feature Vehicle Harness Wiring Diagram Courtesy of Caterpillar Tractor CoDocumento1 páginaFig. 5: Caterpillar 3126B HEUI Full Feature Vehicle Harness Wiring Diagram Courtesy of Caterpillar Tractor CoEnzo Miguel Sarabia MontesAinda não há avaliações

- NTB R9800 enGB-USDocumento22 páginasNTB R9800 enGB-USEnzo Miguel Sarabia Montes100% (1)

- Uenr6313uenr6313 01 ScoopDocumento1 páginaUenr6313uenr6313 01 ScoopEnzo Miguel Sarabia MontesAinda não há avaliações

- Is 13558 (Part-1) Cranes-Controls-Layout and CharacteristicsDocumento6 páginasIs 13558 (Part-1) Cranes-Controls-Layout and Characteristicspramodgupta97Ainda não há avaliações

- Almar PresentationDocumento18 páginasAlmar PresentationhaciiiAinda não há avaliações

- VOLVO EC360B LR EC360BLR EXCAVATOR Service Repair Manual PDFDocumento19 páginasVOLVO EC360B LR EC360BLR EXCAVATOR Service Repair Manual PDFfjjsjekdmme75% (4)

- Crane SafetyDocumento21 páginasCrane Safetytusharhse100% (1)

- Project Report On Hydromechanical CraneDocumento16 páginasProject Report On Hydromechanical Cranekml636Ainda não há avaliações

- Lifting Plan For Installation of SPACE FRAMES at Ma'aden Facility Security Gate 3-SignedDocumento23 páginasLifting Plan For Installation of SPACE FRAMES at Ma'aden Facility Security Gate 3-SignedGufran ImamAinda não há avaliações

- Lift CylindersDocumento30 páginasLift CylindersHector PuacAinda não há avaliações

- Ikpp MerakDocumento2 páginasIkpp MerakSignore DwiczAinda não há avaliações

- MANUALDocumento12 páginasMANUALmimi lrAinda não há avaliações

- LR / LM Side - Entry Agitators: Installation, Service and Maintenance InstructionsDocumento22 páginasLR / LM Side - Entry Agitators: Installation, Service and Maintenance InstructionsPetros IosifidisAinda não há avaliações

- Model 1: XCMG QY50KA QY50K-II QY50K 50 Tons Truck CraneDocumento4 páginasModel 1: XCMG QY50KA QY50K-II QY50K 50 Tons Truck CraneJia Yiin100% (1)

- Service Booklet HMF CranesDocumento18 páginasService Booklet HMF CranesLisa ToddAinda não há avaliações

- En Operators Manual Tb175w Aw3e004 175400095Documento221 páginasEn Operators Manual Tb175w Aw3e004 175400095grunwald100% (1)

- Development Project of The Port of NacalaDocumento18 páginasDevelopment Project of The Port of Nacalajoao carlos protzAinda não há avaliações

- Aramco PDFDocumento38 páginasAramco PDFMuhammad Farooq Malik100% (1)

- Pole Assembly and Installation For Street Light PolesDocumento3 páginasPole Assembly and Installation For Street Light Polestsraj10Ainda não há avaliações

- Gd555-3a Sebm021007 Shop PDFDocumento680 páginasGd555-3a Sebm021007 Shop PDFVolmir Hentges100% (2)

- Sample: Crane Inspection & Maintenance RecordDocumento4 páginasSample: Crane Inspection & Maintenance RecordHamzaNoumanAinda não há avaliações

- WMSRA For Loading Unloading of Office Containers and Installation of Office ContainersDocumento30 páginasWMSRA For Loading Unloading of Office Containers and Installation of Office ContainersFurqan AfzalAinda não há avaliações

- PSGC Version 30Documento156 páginasPSGC Version 30Natalia DominiciAinda não há avaliações

- Contrx Full Product CatalogDocumento48 páginasContrx Full Product Catalogtvmehta01Ainda não há avaliações

- CR 1Documento39 páginasCR 1KrunoslavAinda não há avaliações

- Method of Statement Hydraulic Cylinder Bearing Replacement-Tian Kun HaoDocumento5 páginasMethod of Statement Hydraulic Cylinder Bearing Replacement-Tian Kun HaoFebilaAinda não há avaliações

- 02 - Safety InformationDocumento20 páginas02 - Safety InformationYuri FaroAinda não há avaliações

- Viking Neptun: New Generation Heavy Construction/pipelay Vessel Prepared For Deep-Water Operations WorldwideDocumento2 páginasViking Neptun: New Generation Heavy Construction/pipelay Vessel Prepared For Deep-Water Operations WorldwideBagus Bagaskara PutraAinda não há avaliações

- Container TerminalsDocumento5 páginasContainer TerminalsPRmani RamalingamAinda não há avaliações

- MazzellaCatalog13 RiggingHardware LRDocumento108 páginasMazzellaCatalog13 RiggingHardware LRShakeb Rahman100% (1)

- RAMS-Loading, Unloading and Shifting of MaterialDocumento5 páginasRAMS-Loading, Unloading and Shifting of MaterialEm Niax50% (2)

- EhsliftingequipmentprotocolDocumento15 páginasEhsliftingequipmentprotocoljohnsonpintoAinda não há avaliações