Escolar Documentos

Profissional Documentos

Cultura Documentos

Review On Spray Dried Solid Dispersion

Enviado por

Baru Chandrasekhar RaoTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Review On Spray Dried Solid Dispersion

Enviado por

Baru Chandrasekhar RaoDireitos autorais:

Formatos disponíveis

IAJPS 2018, 05 (03), 1532-1539 Zambre Radhika Ashok et al ISSN 2349-7750

CODEN [USA]: IAJPBB ISSN: 2349-7750

INDO AMERICAN JOURNAL OF

PHARMACEUTICAL SCIENCES

http://doi.org/10.5281/zenodo.1205433

Available online at: http://www.iajps.com Review Article

REVIEW ON SPRAY DRIED SOLID DISPERSION

Zambre Radhika Ashok, Dr. Shendge R.S, Narode Pravin Ravindra,

Sonawane Swapnil Prakash

Sanjivani College of Pharmaceutical Education and Research Kopargoan.

Abstract:

The drug solubility is the most challenging aspect for the formulation development. The poorly soluble drug has

poor dissolution and absorption of drug. The low aqueous solubility of drug is required to formulate the drug into

more soluble and hence bioavailable drug product. The different technique is being used to enhance the solubility of

poorly water soluble drugs. Spray dried solid dispersion of drug is one of the most widely used technology to

enhance the solubility of the poorly water soluble drug. For the manufacturing of solid dispersion Spray drying is

efficient technology. It converts the liquid drug solution to solid powder form by rapid evaporation of solvent. This

method has a contribution to form amorphous solid dispersion.

The formulation parameters such as feed concentration and solvent type and process parameters such as drying gas

flow rate or solution spray rate that influence the final physical structure of the solid dispersion particles.

Key words: Solid dispersion, carriers, spray drying, solubility.

Corrosponding author:

Zambre Radhika Ashok, QR code

Shevge, PT. Jalgoan [NEUR], Tal. Yeola, Dist.Nashik

Sanjivani College of Pharmaceutical Education and Research,

Kopargoan.

E-Mail:radhikazambare21@gmail.com

Please cite this article in press Zambre Radhika Ashok et al., Review on Spray Dried Solid Dispersion, Indo Am. J. P. Sci,

2018; 05(03).

www.iajps.com Page 1532

IAJPS 2018, 05 (03), 1532-1539 Zambre Radhika Ashok et al ISSN 2349-7750

INTRODUCTION: different ratios of PVP were prepared to increase the

Many recently developed pharmaceutical drug has a solubility and bioavailability. [9] Ke Wu et. al.(2008)

low aqueous solubility due to low solubility drug has studied and prepared spray dried solid dispersion the

poor bioavailability and therapeutic effect. This low aqueous soluble piroxicam with

situation provides the opportunities to pharmaceutical polyvinylpyrrolidone (PVP) were prepared by

scientist pharmaceutical companies to advance precipitation with compressed antisolvent (PCA) and

multiple methods to solubilize the molecules. [1] spray drying techniques for enhance the solubility

Most important parameter is solubility to get a and bioavilability.[10] Ilse Weuts et.al.(2005) was

desired concentration of drug in systemic circulation prepared Solid dispersions of loperamide a poorly

for therapeutic response. The solubility is defined as water-soluble agent with polyethyleneglycol 600

the maximum quantity of solute that can dissolve in a were prepared by spray drying to increase the

specific quantity of solvent at specified temperature. solubility and dissolution.[11] Hirofumi Takeuchi

It is also define as the ability of one solid substance et.al.(2004) Solid dispersion particles of tolbutamide

to form a solution with another liquid substance. The spray dried with nonporous (Aerosil 200

solid substance to be dissolved is called as solute and (hydrophilic), Aerosil R972 (hydrophobic)) or porous

the other dissolving liquid fluid in which the solute (Sylysia 350 (hydrophilic), Sylophobic 200

dissolve is called as solvent, which together form a (hydrophobic)) silica as a carrier and applying the

solution. [2] Oral route is most common route for spray-drying method.[12] Eun-Sol Ha (1014) was

drug delivery. Absorption of drug from the studied to investigate the effect of Soluplus® on the

gastrointestinal tract is limited by different factors. solubility of atorvastatin calcium and develop a solid

Major factor is poor aqueous solubility and low dispersionby spray drying to improve the oral

permeability of the drug. Drug is administered by bioavailability of atorvastatin calcium.[13]Nirmal

oral route first it dissolve in gastric or intestinal fluids Marasinia et.al (2013) telmisartan was spray dried

and permeable through the GIT membranes before to with dpolyvinylpyrrolidone (PVP), hydroxypropyl

reach systemic circulation. Hence, two areas are cellulose (HPC), hydroxypropyl methyl cellulose

available to pharmaceutical research that improving (HPMC) and sodium carboxymethyl cellulose (Na

the oral bioavailability of active agents including CMC).[14] Sahilhusen I Jethara et al studied the

enhancing of solubility and dissolution rate of poorly spray dried solid dispersion improvement in aqueous

aqueous soluble drugs. The BCS is a scientific solubility of aceclofenac with different ratios using

system for classifying a drug substance based on its HPMC K-15M, PVP-K30 and Eudragit RS-100 at

aqueous solubility and permeability of drug.[3] Many optimized condition. [15] S.Rajarajan et al.(2009)

methods are available for the enhancement of was spray dried itraconazole with Hydroxypropyl

solubility. Spray Dried solid dispersion is the one of Methylcellulose, Polyethyleneglycol 6000 for

most convenient technique for the enhancement of incrsease the solubility.[16]

the drug solubility. Spray dried solid dispersions Methods for solubility enhancement: [17]

(SDs) widely studied recently as an option to Physical Modifications

improve dissolution rate and in turn bioavailability of a) Particle size reduction

poorly water-soluble drugs particularly BCS class II Micronization

dugs.[4] Spray drying is a unit process have a ability Nanosuspension,

to transforming solutions or suspensions into a solid b) Modification of the crystal habit

product.[5] Many poorly water soluble drug Polymorphs,

solubility is improved spray dried solid dispersion Amorphous form

technology. Bhaskar Chauhan et al. (2005) was Cocrystallization,

studied solid dispersions of poorly water-soluble drug c)Drug dispersion in

etoricoxib using lipid carriers such as Gelucire 50/13 Eutectic mixtures,

and Compritol 888 ATO by spray drying for the Solid dispersions,

improve the dissolution rate.[6] E. M. Holman Solid solutions

et.al(1984) was spray-dried Hydroflumethiazide with d)Cryogenic techniques.

polyvinylpyrrolidone to increase the solubility.[7] Chemical Modifications.

Makoto Otsuka et.al.(1993) was prepaired Spray- a) Change of pH,

dried solid dispersions of furosemide-Eudragit RS100 b) Use of buffer,

and RL100 were studied to determine their stability c) Derivatization,

and dissolution characteristics. Solid dispersions of d) Complexation,

curcumin in different ratios with PVP were prepared e) Salt formation.

by spray drying. [8] Anshuman A.et.al. (2004) was Miscellaneous Methods.

studied spray dried solid dispersion of curcumin with a) Supercritical fluid process,

www.iajps.com Page 1533

IAJPS 2018, 05 (03), 1532-1539 Zambre Radhika Ashok et al ISSN 2349-7750

b) Use ofadjuvant like surfactant, solubilizers, Methods of preparation of solid dispersion:

cosolvency, hydrotrophy, 1) Melting method

and novel excipients. In this method melting of a physical mixture of

carrier and drug convert into the liquid state cool

Solid dispersion: until solidification. Disadvantage of this method is

The concept of solid dispersions was originally not useful for thermolabile drugs and thus incomplete

proposed by Sekiguchi and Obi.[17] Solid dispersion miscibility is observed between the molten carrier

is a term defined as the dispersion of one or more and solid drug.[24]

active ingredients in an inert polymer or polymer 2) Solvent method:

matrix or in a carrier, where the active ingredients In this method, the polymer and drug mixture

exist in finely crystalline, solubilised or amorphous dissolved in a common solvent, which is until a clear,

form. [18] The solid dispersion consists containing at solvent free film is left evaporated. The film is

least two different components, such as a water further dried. The main

soluble polymer matrix and a water insoluble drug. benefits of this method is thermal decomposition of

The matrix may be either crystalline or amorphous API or polymers can be prevented because of organic

form. The drug can be dispersed in amorphous solvent required relatively low temperature.[25]

particles or in crystalline particles molecularly. [19] 3) Hot-Melt Extrusion:

Molecularly dispersing a poorly water-soluble drug Hot melt exstrusion is defined as the process of

in a hydrophilic carrier leads to increased dissolution formation a new material under controlled condition

and supersaturation of the drug when this system is such as temperature, mixing, feed-rate and pressure

contact with the water. This is improves a number of by forcing it through an orifice or die. It is different

factors such as increased wettability of the drug by from simple extrusion; in this process polymer, drug

the polymer, reduces particle size of the drug, and excipients blends are mixed in the molten state,

separation of individual drug particles by polymer solvents not for granulation. The molten polymer use

particles, and prevent the drug precipitation in as the thermal binder. [26]

contact with aqueous media.[20] 4) Spray drying:

First generation solid dispersion: In this type of preparation, the carrier and the drug

The first generation solid dispersions prepare using are suspend or dissolved in a common solvent. In this

crystalline carriers like urea, technique by applying hot air solvent is evaporated. It

mannitol. Eutectic mixtures are binary systems is fast and quick method because of due to the large

containing poorly water soluble drug and high water surface area of the droplets, the solvent fast

soluble carrier and at eutectic point. Only in the evaporates and solid dispersion is formed fast. [27]

specific composition drug crystallizing out Spray drying technique is a particle processing

simultaneously. When in aqueous medium eutectic technology that liquid feed convert into a powder by

mixture is dissolved, the carrier part will dissolve spraying the feed to form a droplets, and then

quickly and in the form of fine crystals drug will be evaporating the liquid feed by using a heated drying

released. [21] medium commonly air. The liquid feed may be in the

Second generation solid dispersion: form of a solution, suspension, or emulsion; it should

Second generation solid dispersions containing be easily pumpable and capable to droplet formation.

amorphous carriers instead of crystalline. The most [28] The spray drying process works on principle the

common solid dispersions use amorphous carriers. removal of solvent by heat, the continuous spraying

The drugs are molecularly dispersed in amorphous of drug and carrier matrix mixture into the hot drying

carrier they are usually called polymers. polymers chamber gives the dried particles. [29]Spray drying is

like fully synthetic polymers such as povidone (PVP) a faster, time- saving technique for obtaining even the

polyethyleneglycols (PEG) and polymethacrylates smallest quantities of sample in powder form. For

and Natural polymers are cellulose derivatives such particle formation and drying Spray drying is the

as hydroxypropylmethylcellulose (HPMC), most widely used industrial process. Spray drying is

ethylcellulose hydroxypropylcellulose and starch suitable method to continuous production of dry

derivates, like cyclodextrins.[22] solids in powder, granulate or agglomerate particle

Third generation solid dispersion: form of liquid feed stock. This technique the ideal

In third generation solid dispersion the surface active end product properties complies with quality

self emulsifying carriers are use.the carriers are standards that are particle size distribution, residual

Poloxamer 407, tween 80, gelucire 44/14, compritol moisture content, bulk density and particle

888 ATO +/- polymer. [23] morphology must comply with precise quality

standards.[30]

www.iajps.com Page 1534

IAJPS 2018, 05 (03), 1532-1539 Zambre Radhika Ashok et al ISSN 2349-7750

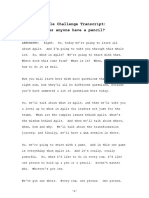

1. Feed

2. Feed flow

3. Nozzle gas flow

4. Heater

5. Fluid nozzle

6. Drying chamber

7. Cyclone

8. Waste material

9. Collecting vessel

10. Exhaust air

11. Filter bag

Solvent system: a common solubility of feed components in a solvent

Different solvents, separately or in combination, has to obtain molecularly dispersed solid dispersions. [31]

been used to prepare feed stock solutions for spray Carriers:

drying. These solvents are aqueous, alcohols such as Carriers used for solid dispersion:

methanol, ethanol or isopropanol and some organic The carriers should be melted elevated temperatures

solvents such as dichloromethane (DCM), acetone, and in melted carriers drug should be dissolved in

methyl ethyl ketone, dioxane, tetrahydrofuran (THF), carriers. Surface-active agents are adsorb on the

chloroform, ethyl acetate, and acetonitrile. Out of surface and alter the surface energy and surface

these, the most commonly used solvent system is tension at low concentration. They have polar and

DCM.DCM has low boiling point (39.8 °C), non-polar region in same molecule. They should have

excellent solubilizing power and high volatility for soluble in water and gastrointestinal fluid ,thermally

various drug and polymers. The critical parameter is stable ,low vapour pressure and carrier not have

www.iajps.com Page 1535

IAJPS 2018, 05 (03), 1532-1539 Zambre Radhika Ashok et al ISSN 2349-7750

melting point much higher than the drug, should be Increasing feed flow rate causes increasing particle

nontoxic in nature.[32] size and increasing bulk

Ideal properties of carriers: density this is resulting higher water content in the

It should have improves wettability and enhances particles and increase density as compare to dry

dissolution. solids and this causes the decreasing solubility. [37]

It should be improving stability. Atomizing Air Pressure:

It should have Minimum uptake water. Atomization refers a formation of droplets or mist by

It should be Soluble in common solvent with drug. transfer of bulk liquid solution through a

It should have relatively low melting point. [33] nozzle.[38]If the atomization air pressure is increase

Examples of carriers: [31] then the mist size will be decreases, then the

Polymers: Hydroxypropyl-methyl cellulosephthalate, Possibility of agglomeration will also decrease.

EudragitL100 However, if the Atomization air pressure set high in

Polymeric materials: Povidone (PVP), Poly- lab model, then the pilot scale process also required

ethyleneglycols (PEG) too high atomization pressure. The atomization air

Insoluble or enteric Surfactants: Polyoxyethylene must be maintained to avoid agglomeration. Droplets

stearate, Renex, Poloxamer 188, Spans are very small to achieve fastest possible process

Sugars: Dextrose, Sucrose, Galactose, Sorbitol, during the optimization of spray rate. Droplet will be

Maltose, Xylitol small in case of pressure is high. It is also necessary

Acids: Citric acid, Succinic acid to understand that beyond a certain pressure the

Miscellaneous: Pentaerythritol, Pentaerythrityl particle size reduction will be negligible. [39]

Process variables of spray drying: Evaluation parameters:

The operation of the process of spray drying Saturation solubility:

considered as one of the most complicated The saturation solubility of drug and Sold dispersion

types of drying. The operator of a spray dryer has is determined in distilled water and phosphate buffer

direct influence on: saline (PBS pH 7.4) by adding an excess of drug and

Inlet temperature of the drying air; SD to sufficient quantity of distilled water or PBS in

Flow rate glass stoppered tubes. The stoppered tubes rotate

The supply rate of the liquid stream for24 h in water bath shaker at 37oC. The saturated

Atomizing air pressure solutions filtered through a 0.45 μm membrane filter,

(For the pneumatic nozzle, for other atomizing suitably diluted with water and analyzed by UV-

devices—other appropriate parameters related spectrophotometer. [40]

to atomization) Drug content determination:

Other process parameters, such as: The drug content percentage of solid dispersions

Outlet temperature of the drying air determine by dissolving the solid dispersions

The droplet size; equivalent to10 mg of drug in 100 mL of given

The drying efficiency solvent. Each of these aliquots ware further diluted

The physical properties of the dried product (e.g., the with phosphate buffer of suitable pH and absorbance

particle size, moisture content, and hygroscopicity); were measure by UV –spectroscopy. [41]

are depends on the parameters adjusted by the Differential scanning calorimetry (DSC):

operator, on drying air humidity, and on the feed Thermal characteristics of the solid dispersions were

properties. [34] determined by a differential scanning calorimeter.

Inlet temperature and outlet temperature: Samples placed in aluminum pans. [42] Accurately

Inlet air temperature and aspirator capacity both weighed samples placed in aluminum pans heat at

increased and that increases the outlet air temperature constant rate and by purging a nitrogen gas inert

due to the increased supply of heat energy. Due to atmosphere maintain. [43]

Increasing feed flow rate it lowers the outlet air Transform infrared spectroscopy (FT-IR):

temperature hence the volume of evaporation of the IR spectra of the spray-dried products

liquid is increase. [35] determined by IR-spectrophotometer. [44’45]

Due to increasing heater outlet or air inlet X-Ray Diffraction studies (XRD):

temperature causes increasing outlet temperature. The powder X-ray diffraction patterns were

[36] determined for pure drug, and SSDs. X-ray

Flow rate: diffractograms were obtained using the X-ray

The effect of flow rate on process of spray drying due diffractometer. [46]

to increasing feed flow rate decreasing total solid X-Ray Powder Diffraction (XRPD):

product because of increase in water introduction in The crystalline state of drug and solid dispersion in

drying chamber under constant drying conditions. the different samples determine by XRPD. A

www.iajps.com Page 1536

IAJPS 2018, 05 (03), 1532-1539 Zambre Radhika Ashok et al ISSN 2349-7750

diffraction pattern is obtained on X-ray racemization, photo oxidation to stabilize

Diffractometer. [47] unstable drugs.

Dissolution study: 4. For the formulation of a fast release dose in

Dissolution study carried in triplicate according to the a sustained release dosage form.

United States Pharmacopeia Paddle method 5. The damage to the stomach mucous

(Apparatus II). Take a solid dispersion equivalent membranes by certain non-steroidal anti-

quantity of drug weigh and placed into inflammatory drugs can be reduced by

900 ml of pH 1.2 Hcl or pH 6.8 phosphate-buffered administration as an inclusion compound.

saline(PBS) or distilled water as dissolution media.50 6. Unpleasant taste and smell of drug masked

rpm paddle revolution speed 37.0+/- 0.5 0C by complex with different polymers.

temperature should be set respectively. The samples 7. Used to convert liquid compounds into solid

(2 ml or 5ml) collect at specific time interval formulations like powders, capsules or

replacement by an equal volume of dissolution tablets.

medium. Drug content determine by UV-

spectrophotometer. [47, 48] CONCLUSION:

Spray drying is an efficient drying technique and

Advantages: [49, 50] particle engineering for the formulation of the

1. Spray drying has been used to for sterile pharmaceutical product. By using the spray drying

pharmaceutical processing to ceramic powder we can formulate the dry amorphous powder of the

production. product we can use this for direct compression or for

2. It can be designed to virtually any capacity the encapsulation. Spray drying technique is helpful

required. (Feed rates range from a few pounds per to enhance the solubility of the poorly water soluble

hour to over 100 tons per hour). drug. It converts the liquid drug solution dry

3. The spray drying process is very fast, with the amorphous form of drug by using hot air and

major quantity of evaporation taking place in less increases the bioavailability and oral absorption of

than a few seconds. the drug. Spray drying is a unit operation produces a

4. It is fully automated control system that allows uniform quantity of the product with constant

continuous monitoring and recording of very large physical properties.

number of process variables simultaneously.

5. Wide ranges of different spray dryer designs are REFERENCES:

available to get various product specifications. 1.Dwayne T. F.Ravi S, Crew M, Smithey

6. It can be used for both heat-resistant and heat D.T.,Curatolo W. J., and Nightingale J. A. S.

sensitive compounds. Hydroxypropyl Methylcellulose Acetate Succinate-

7. Spray-drying method mostly used in the BasedSpray-Dried Dispersions: An

pharmaceutical, chemical, cosmetic and food Overview,molecular pharmaceutics,2008; 5 [6]:

industries 1003–1019

Disadvantages: [49] 2. Patel J.N, Rathod D.M, Patel N.A, Modasiya M.K,

There is a some disadvantages of spray drying; Techniques to improve the solubility of poorly

1. The equipment is very heavy and equipment is soluble drugs, International journal of pharmacy &

expensive. life sciences, 2012; 3[2]:1459-1469.

2. The overall thermal efficiency is low, as the large 3. Kumar S, Singh P, Various techniques for

volumes of heated air pass through the chamber solubility enhancement: An overview, The Pharma

without contacting a particle, thus not contributing Innovation Journal 2016; 5[1]: 23-28.

directly to the drying. 4.Chauhan B, Shimpi S, Paradkar A, Preparation and

3. Product yield is very low and high quantity of evaluation of glibenclamide polyglycolized

sample is required. glycerides solid dispersions with silicon dioxideby

spray drying technique, European Journal of

Applications: [51] Pharmaceutical Sciences 2005: 26: 219–230.

1. To improve the solubility absorption of 5.Paudel A, Zelalem A. W., Joke M., Guns S.,

active pharmaceutical ingredient. Mooter G. V. d.,Manufacturing of solid dispersions

2. In small quantity of drug to get a of poorly water soluble drugs by spray drying:

homogeneous distribution of drug in solid Formulation and process considerations, International

state. Journal of Pharmaceutics,2012; 1-31

3. Protect drug against decomposition 6. Chauhan B, Shimpi S,Paradkar A.Preparation and

processes like hydrolysis, oxidation Characterization of Etoricoxib Solid Dispersions

www.iajps.com Page 1537

IAJPS 2018, 05 (03), 1532-1539 Zambre Radhika Ashok et al ISSN 2349-7750

Using Lipid Carriers by Spray Drying Technique, 19. Mogal S. A, Gurjar P. N,Yamgar D. S, Kamod

AAPS Pharm SciTech 2005; 6 [3]:405-412. A.C, Solid dispersion technique for improving

7. Corrigan O. I, Holohan E.M, Amorphous spray- solubility of some poorly soluble drugs, Der

dried hydroflumethiazide-polyvinylpyrrolidone Pharmacia Lettre, 2012;4 [5]:1574-1586.

systems: physicochemical properties, J. Pharm. 20. Riikka L,Priemel P A, Surwase S,Graeser K,

Pharmacol. 1984; 36: 217-221. Strachan C.J, Holger G,Rades T, Theoretical

8. Tsuka M', Mlka O, and Yoshlhlsa M, Hygroscopic Considerations in Developing Amorphous Solid

Stability and Dissolution Properties of Spray- Dispersions, Advances in Delivery Science and

DriedSolid Dispersions of Furosemide with Eudragit, Technology, 2014

Journal of Pharmaceutical Sciences, 1993; 82[1]: 32- 21. Argade P.S, Magar D.D, Saudagar R.B, Solid

38. Dispersion: Solubility Enhancement Technique for

9. Paradkar A, Ambike A.A,Jadhav B.K, Mahadik poorly water soluble Drugs, Journal of Advanced

K.R., Characterization of curcumin–PVP solid Pharmacy Education & Research, 2013; 3[4]:427-

dispersion obtained by spray drying, International 239.

Journal of Pharmaceutics,2004; 271 :281–286 22.Vasconcelos T., Sarmento B,Costa P, Solid

10. Ke W, Jing L, Wayne W, Winstead D.A , dispersion as a strategy to improve the oral

Formation and Characterization of Solid Dispersions bioavailability of poorly water soluble drugs, Drug

of Piroxicam and Polyvinylpyrrolidone Using Spray Discovery Today, 2007; 12[23/24]:1068-1075.

Drying and Precipitation with Compressed 23. Kamalakkannan V ,Puratchikody A, Masilamani

Antisolvent,Journal of pharmaceutical sciences,2009; K , Senthilnathan B, Solubility enhancement of

98[7]: 2422–2431 poorly soluble drugs by solid dispersion technique –

11. Ilse W, Dieter K, Geert V, Annelies D, Koen H, A review, Journal of Pharmacy Research 2010;

Jef P, Marcus B, Mooter G. V. d, Study of the 3[9]:2314-2321.

physicochemical properties and stability of solid 24. Singh N, Sarangi M.K, Solid Dispersion - a

dispersions of loperamide and PEG6000 prepared by Novel Approach for Enhancement of Bioavailability

spray drying, European Journal of Pharmaceutics and of Poorly Soluble Drugs in Oral Drug Delivery

Biopharmaceutics,2005; 59 :119–126. System, Global journal of

12. Takeuchi H, Shinsuke N, Hiromitsu Y, Yoshiaki Pharmacy & pharmaceutical Science,2017;3[2]:1-8

K, Solid dispersion particles of tolbutamide prepared 25. Patil A.N, Shinkar D.M, Saudagar R.B, Review

with fine silica particles by the spray-drying method, article: solubility enhancement by solid dispersion,

Powder Technology,2004; 141: 187– 195. International Journal of Current Pharmaceutical

13. Ha E, Baek I, Cho W, Hwang S, Kim M, Research, 2017; 9[3]: 15-18.

Preparation and Evaluation of Solid Dispersion of 26. Kadam S.V, Shinkar D.M, Saudagar R.B, Review

Atorvastatin Calcium with Soluplus® by Spray on solubility enhancement techniques, International

Drying Technique, Chem.Pharm.Bull. 2014; 62[6]: Journal of Pharmacy and Biological

545–551. Sciences,2013;3[3]:462-475.

14. Nirmal M, Trana T.H, Poudela B, Choa H.J, 27.Kumar P, Singh C, A Study on Solubility

Choia Y.K, Chib S, Choic H,Yonga C.S, Kima J, Enhancement Methods for Poorly Water Soluble

Fabrication and evaluation of pH-modulated solid Drugs, American Journal of Pharmacological

dispersion for telmisartan by spray-drying technique, Sciences, 2013; 1[4]: 67-73.

International Journal of Pharmaceutics,2013; 28. Ramesh K, Bonagiri. Chandra shekar, Podile.

441:424– 432. Khadgapathi, Formulation and evaluation of poorly

15. Jethara S.I, Patel M.R, Enhanced Solubility and soluble etravirine by spray drying method, 2015;

Dissolution Rate of Aceclofenac by Using Spray 7[4]:98-103

Drying Techniques, Intellectual Property Rights: 29.Pagara R.Y, Dr.Gangurdea A.B,Dr.Bairagib V.A,

Open Access 2015;3[2]:1-2. Solid dispersion by spray drying for increasing

16. Rajarajan S, Baby B, Ramesh K, Singh D, solubility of poorly soluble drug, World journal of

Preparation and evaluation of ternary mixing pharmacy and pharmaceutical sciences, 2017; 6[5]

itraconazole solid dispersions by spray drying 342-356.

method, Journal of Pharmaceutical Sciences and 30.Sathyaraj A, Palraja M, Preparation and

Research, 2009;1[1]:22-25. comparative evaluation of Loratadine solid

18. Sharma D. K. and s. B. Joshi, solubility dispersions with various binders by spray drying

enhancement strategies for poorly water-soluble technique, International journal of research in

Drugs in solid dispersions: a review,Asian journal of pharmacy and chemistry, 2012; 2[1]:37-45.

pharmaceutics,2007;1[1]:9-19. 31.Phapale B.N, Patil A.P, Application of spray

drying technique for preparation amorphous solid

www.iajps.com Page 1538

IAJPS 2018, 05 (03), 1532-1539 Zambre Radhika Ashok et al ISSN 2349-7750

dispersion, International journal of Pharmaceutical International Journal of Pharmaceutics 187 (1999)

sciences and research,2018,1-7. 209–218.

32.Kaur J, Aggarwal G,Singh G, Rana A.C., 43.Pawar R, Swapnila V, Shinde S.V, Deshmukh S,

Improvement of drug solubility using solid Solubility enhancement of pioglitazone by spray

dispersion, International Journal of Pharmacy and drying techniques using hydrophilic carriers, Journal

Pharmaceutical Sciences, 2012;4[2]:47-53. of Pharmacy Research,2012;5[5]:2500-2504.

33.Sharma R, Mazumder R, Sharma A, Verma P, A 44. Lin S, KaoY, Solid particulates of drug-b-

review on: Solid dispersion, International Journal of cyclodextrin inclusion complexes directly prepared

pharmacy & Life Sciences,2013;4[7]: 2845-2854. by a spray-drying technique , International Journal of

34. Krzysztof S, Krzysztof C, Spray Drying Pharmaceutics,1989; 56:249-259.

Technique: II. Current Applications in 45. Ghanem A, Mohamed Ali H, El-Shanawany S,

Pharmaceutical Technology, Journal of El-Sayed I, Solubility and dissolution enhancement of

Pharmaceutical Sciences, 2010; 99[2]: 587–597 quercetin viapreparation of spray dried

35.Stahl K , Claesson M ,Lilliehorn C,Linde H, microstructured solid dispersions, Thai J. Pharm.

Backstrom K, The effect of process variables on the Sci.2013; 37:12-24

degradation and physical properties of spray dried 46.Alireza H, Sadeghi A, Nokhodchi A, Varshosaze

insulin intended for Inhalation, International Journal J, Garekani H. A, Preparation and Characterization of

of Pharmaceutics, 2002; 233: 227–237. Celecoxib Dispersions in Soluplus®: Comparison of

36. Littringer E.M, Mescher A ,Eckhard S ,Schrottner Spray Drying and Conventional Methods, Iranian

H, Langes C ,Fries M, Griesser U ,Walzel P, Journal of Pharmaceutical Research, 2015; 14 [1]:

Urbanetz N.A, Spray Drying of Mannitol as a Drug 35-50.

Carrier—The Impact of Process Parameters on 47.Swathi T, Vamashi K, Kumar S, Krishnaveni J,

Product Properties, Drying Technology: An Enhancement of solubility and dissolution rate of

International Journal, 2012;30: 114–124. rosuvastatin by using solid dispersion technique,

37. Banat F, Jumah R, Al-Asheh Hammad S,Effect of Journal of pharmaceutical and scientific innovation,

operating parameters on the spray drying of Tomato 2013;2[6]:36-40.

paste,Eng.Life. Sci.2002,2[12],403-407 48.Mahajan H.S, Girnar G.A, Nerkar P.P, Dissolution

38. Singh S, Dixit D, A Review on spray drying: and Bioavailability Enhancement of Gliclazide by

emerging technology in food industry, International Surface Solid Dispersion Using Spray Drying

Journal of Applied Engineering and Technique, Indian Journal of Novel Drug

Technology,2014: 4 [1]:1-8. Delivery,2012; 4[2]:115-124.

39. Shetty V,Wurster Coating - Scale Up and Scale 49.Paudel A, Mooter G, Influence of Solvent

Out, Pharma Times, 2010; 42 [11]:33-37. Composition on the Miscibility and Physical Stability

40. Shinde S. S, Patil M. V,Shete A.S, Disouza J, of Naproxen/PVP K 25 Solid Dispersions Prepared

Atpadikar P, Solid Dispersions of Poorly Water by Cosolvent Spray-Drying, Pharm

Soluble Drug Using Spray Drying Technique, Res.2012;29:251–270.

International Journal of Drug Delivery 2013;5, 323- 50.Jang D, Sim T, Oh E, Formulation and

330. optimization of spray-dried amlodipine

41.Dangre P. V, Sormare V.B, Godbole M.D, solid dispersion for enhanced oral absorption, Drug

Improvement in Dissolution of Bosentan Development and Industrial Pharmacy, 2012,1-9.

Monohydrate by Solid Dispersions Using Spray 51. Sharma A, Jain C.P, Solid dispersion: A

Drying Technique, Open Pharmaceutical Sciences promising technique to enhance solubility of poorly

Journal, 2017:4, 23-31. water soluble drug, International Journal of Drug

42.Jae-Young Jung a, Sun Dong Yoo b,*, Sang-Heon Delivery, 2011; 3,149-170.

Lee a, Kye-Hyun Kim a, Doo-Sun Yoon a, Kyu-

Hyun Lee, Enhanced solubility and dissolution rate

of itraconazole by a solid dispersion technique,

www.iajps.com Page 1539

Você também pode gostar

- Simultaneous Estimation of Rosuvastatin Calcium and Ezetimibe As Bulk Drug and in Tablet Dosage Form by RP-HPLC MethodDocumento6 páginasSimultaneous Estimation of Rosuvastatin Calcium and Ezetimibe As Bulk Drug and in Tablet Dosage Form by RP-HPLC MethodBaru Chandrasekhar RaoAinda não há avaliações

- Knowledge On Antibiotics Use and Its Storage Among Saudi Arabia Residents: A Cross Sectional StudyDocumento8 páginasKnowledge On Antibiotics Use and Its Storage Among Saudi Arabia Residents: A Cross Sectional StudyBaru Chandrasekhar RaoAinda não há avaliações

- Development of Cell Culture System From Selected Tissues of Pangaius HypopthalmusDocumento6 páginasDevelopment of Cell Culture System From Selected Tissues of Pangaius HypopthalmusBaru Chandrasekhar RaoAinda não há avaliações

- Formulation, Optimization and Evaluation Colon Targated Drug Delivery System For OrniadazoleDocumento9 páginasFormulation, Optimization and Evaluation Colon Targated Drug Delivery System For OrniadazoleBaru Chandrasekhar RaoAinda não há avaliações

- Development and Validation of Stability Indicating Assay Method For Estimation of Teriflunomide in Tablet Dosage FormDocumento11 páginasDevelopment and Validation of Stability Indicating Assay Method For Estimation of Teriflunomide in Tablet Dosage FormBaru Chandrasekhar RaoAinda não há avaliações

- Genetic Enhancment of Groundnut (Arachis Hypogaea L.) Through Induced Muiation.Documento5 páginasGenetic Enhancment of Groundnut (Arachis Hypogaea L.) Through Induced Muiation.Baru Chandrasekhar RaoAinda não há avaliações

- Gastroprotective Activity of Methanolic Extract of Phyllanthus Acidus Fruit Against Indomethacin-Induced Gastric Ulcers in RatsDocumento7 páginasGastroprotective Activity of Methanolic Extract of Phyllanthus Acidus Fruit Against Indomethacin-Induced Gastric Ulcers in RatsBaru Chandrasekhar RaoAinda não há avaliações

- Preparation of Silver Nanoparticles From Herbal PlantDocumento9 páginasPreparation of Silver Nanoparticles From Herbal PlantBaru Chandrasekhar RaoAinda não há avaliações

- A Brief Review On YawsDocumento7 páginasA Brief Review On YawsBaru Chandrasekhar RaoAinda não há avaliações

- Analytical Method Development and Validation of Stability Indicating RP-HPLC Method For Estimation of Lercanidipine Hydrochloride and Enalapril Maleate in CombinationDocumento8 páginasAnalytical Method Development and Validation of Stability Indicating RP-HPLC Method For Estimation of Lercanidipine Hydrochloride and Enalapril Maleate in CombinationBaru Chandrasekhar RaoAinda não há avaliações

- The Bordering Areas (Nine Areas of Panjgur District) Issue of Pakistan About Human Malaria Prevalence: A Cross-Sectional Research of Malaria Parasites Identification in Blood SlidesDocumento8 páginasThe Bordering Areas (Nine Areas of Panjgur District) Issue of Pakistan About Human Malaria Prevalence: A Cross-Sectional Research of Malaria Parasites Identification in Blood SlidesBaru Chandrasekhar RaoAinda não há avaliações

- Descriptive Study Knowing The Patients Load in The Neonatal Icu at The Tertiary Care Hospital LahoreDocumento4 páginasDescriptive Study Knowing The Patients Load in The Neonatal Icu at The Tertiary Care Hospital LahoreBaru Chandrasekhar RaoAinda não há avaliações

- Review On: Inventory ManagementDocumento8 páginasReview On: Inventory ManagementBaru Chandrasekhar RaoAinda não há avaliações

- An Incidence of Hypertension Among People and Its Association To Consumption of Hard Water: A Cross-Sectional ResearchDocumento6 páginasAn Incidence of Hypertension Among People and Its Association To Consumption of Hard Water: A Cross-Sectional ResearchBaru Chandrasekhar RaoAinda não há avaliações

- Relationship of Testosterone With Body Mass Index in Infertile Males in Local CommunityDocumento4 páginasRelationship of Testosterone With Body Mass Index in Infertile Males in Local CommunityBaru Chandrasekhar RaoAinda não há avaliações

- Nephroprotective Activityof Acorus Calamus Leaves Extract Against Lithium Induced Nephrotoxicity in Wistar RatsDocumento12 páginasNephroprotective Activityof Acorus Calamus Leaves Extract Against Lithium Induced Nephrotoxicity in Wistar RatsBaru Chandrasekhar RaoAinda não há avaliações

- Non-Adherence in Hyppertensive Patients of Peshawar, PakistanDocumento13 páginasNon-Adherence in Hyppertensive Patients of Peshawar, PakistanBaru Chandrasekhar RaoAinda não há avaliações

- Assessment of Correlation Between Physical Activity and Academic Performance Among The Students of Gujranwala Medical College, GujranwalaDocumento7 páginasAssessment of Correlation Between Physical Activity and Academic Performance Among The Students of Gujranwala Medical College, GujranwalaBaru Chandrasekhar RaoAinda não há avaliações

- Role of Simvastatin in Addition To Metformin in Polycystic Ovarian Syndrome Patients, A Randomized Controlled Trial On Pakistani WomenDocumento4 páginasRole of Simvastatin in Addition To Metformin in Polycystic Ovarian Syndrome Patients, A Randomized Controlled Trial On Pakistani WomenBaru Chandrasekhar RaoAinda não há avaliações

- C-Reactive Protein Levels Preoperatively and Postoperatively Effect On Cardiovascular Surgery ComplicationsDocumento5 páginasC-Reactive Protein Levels Preoperatively and Postoperatively Effect On Cardiovascular Surgery ComplicationsBaru Chandrasekhar RaoAinda não há avaliações

- Association of Socioeconomic Status, Hypertension and Treatment Modality With Diabetic Amputation - A Case Control StudyDocumento4 páginasAssociation of Socioeconomic Status, Hypertension and Treatment Modality With Diabetic Amputation - A Case Control StudyBaru Chandrasekhar RaoAinda não há avaliações

- Pharmaceutical Sciences: IAJPS 2018, 05 (04), 3075-3081 Aneeqa Ali RaoDocumento7 páginasPharmaceutical Sciences: IAJPS 2018, 05 (04), 3075-3081 Aneeqa Ali RaoBaru Chandrasekhar RaoAinda não há avaliações

- Isolation and Identification of Clostridium Perfringens Causing Enterotoxaemia in Bovine of Kacchi District Balochistan.Documento8 páginasIsolation and Identification of Clostridium Perfringens Causing Enterotoxaemia in Bovine of Kacchi District Balochistan.Baru Chandrasekhar RaoAinda não há avaliações

- An Exploratory Review of The Myths and Common Beliefs About Acne and Its TreatmentDocumento6 páginasAn Exploratory Review of The Myths and Common Beliefs About Acne and Its TreatmentBaru Chandrasekhar RaoAinda não há avaliações

- An Epidemiological Survey About The Infections Caused by Dengue in The Perspective of Hematological, Clinical and Demographic Risk FactorsDocumento6 páginasAn Epidemiological Survey About The Infections Caused by Dengue in The Perspective of Hematological, Clinical and Demographic Risk FactorsBaru Chandrasekhar RaoAinda não há avaliações

- Study of Clinical Profile of Transfused Thalassemic Childrens With Special Reference To Hepatitis B Profile and Liver Function.Documento6 páginasStudy of Clinical Profile of Transfused Thalassemic Childrens With Special Reference To Hepatitis B Profile and Liver Function.Baru Chandrasekhar RaoAinda não há avaliações

- Oppertunistic Hypertension Screening in Rural Health Population of Umar Abad Tehsil Kharezat Disrtrict Pishin Balochistan. A Cross Sectional StudyDocumento10 páginasOppertunistic Hypertension Screening in Rural Health Population of Umar Abad Tehsil Kharezat Disrtrict Pishin Balochistan. A Cross Sectional StudyBaru Chandrasekhar RaoAinda não há avaliações

- The Role of Clinical Pharmacist in Pharmacovigilance and Drug Safety in Teritiary Care Teaching HospitalDocumento11 páginasThe Role of Clinical Pharmacist in Pharmacovigilance and Drug Safety in Teritiary Care Teaching HospitalBaru Chandrasekhar RaoAinda não há avaliações

- A Cross Sectional Survey Information About Weaning Process Among Mothers of Infants Above 6 Months of Age in Opd Pediatrics at Kishwer Fazal Teaching Hospital LahoreDocumento8 páginasA Cross Sectional Survey Information About Weaning Process Among Mothers of Infants Above 6 Months of Age in Opd Pediatrics at Kishwer Fazal Teaching Hospital LahoreBaru Chandrasekhar RaoAinda não há avaliações

- After Acute Myocardial Infarction End Result of Cardiogenic Shock in Hospitalized PatientsDocumento4 páginasAfter Acute Myocardial Infarction End Result of Cardiogenic Shock in Hospitalized PatientsBaru Chandrasekhar RaoAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Pests and Diseases Identification in MangoDocumento4 páginasPests and Diseases Identification in MangoBaino Olpugad Gerald100% (1)

- Variable Frequency DriveDocumento8 páginasVariable Frequency DriveNAYEEM100% (1)

- Oakite 61B - TIDocumento2 páginasOakite 61B - TI顏煥杰Ainda não há avaliações

- Project 8 - Part 1 - ResumeDocumento2 páginasProject 8 - Part 1 - Resumeapi-275234784Ainda não há avaliações

- Transco Summary Gudinace For Work Method Statements R 0 300912Documento12 páginasTransco Summary Gudinace For Work Method Statements R 0 300912kla_alk100% (2)

- Uvm UnderstandingDocumento8 páginasUvm UnderstandingLokesh KumarAinda não há avaliações

- FAUDI Aviation Diesel - Company Profile-ENDocumento6 páginasFAUDI Aviation Diesel - Company Profile-ENAttila HontváriAinda não há avaliações

- Very High Frequency Omni-Directional Range: Alejandro Patt CarrionDocumento21 páginasVery High Frequency Omni-Directional Range: Alejandro Patt CarrionAlejandro PattAinda não há avaliações

- Guidelines For The Oral Presentation Bands Singers e MusicDocumento2 páginasGuidelines For The Oral Presentation Bands Singers e Musicjuliusdelazare100% (1)

- SAP TestingDocumento7 páginasSAP Testingpvpreddy67Ainda não há avaliações

- Report On Mango Cultivation ProjectDocumento40 páginasReport On Mango Cultivation Projectkmilind007100% (1)

- 10 AI Summer Vacation HWDocumento2 páginas10 AI Summer Vacation HWAyushi SinghAinda não há avaliações

- Chapter 1 To7 With Course OutlineDocumento34 páginasChapter 1 To7 With Course Outlinerk_kamatchi3483Ainda não há avaliações

- 2013 - To and Fro. Modernism and Vernacular ArchitectureDocumento246 páginas2013 - To and Fro. Modernism and Vernacular ArchitecturesusanaAinda não há avaliações

- Arts NPSH TutorialDocumento3 páginasArts NPSH TutorialDidier SanonAinda não há avaliações

- 01 Agile Challenge-Does Anyone Have A PencilDocumento13 páginas01 Agile Challenge-Does Anyone Have A PencilAbhisek MukherjeeAinda não há avaliações

- Current Office Phone Number Vijayawada, Andhra Pradesh (A.p.)Documento11 páginasCurrent Office Phone Number Vijayawada, Andhra Pradesh (A.p.)Manoj Digi Loans100% (1)

- The Big Table of Quantum AIDocumento7 páginasThe Big Table of Quantum AIAbu Mohammad Omar Shehab Uddin AyubAinda não há avaliações

- LED Lighting Applications Design GuideDocumento20 páginasLED Lighting Applications Design GuideBank100% (3)

- Ruskin As A Social Reformer - Docx ADocumento2 páginasRuskin As A Social Reformer - Docx AAtif Hayat50% (2)

- Mars Climate Orbiter ReportDocumento27 páginasMars Climate Orbiter Reportbiguelo100% (1)

- 10th Syllbus PDFDocumento104 páginas10th Syllbus PDFGagandeep KaurAinda não há avaliações

- Questionaire Abusive Supervision SurveyDocumento2 páginasQuestionaire Abusive Supervision SurveyAabee SyedAinda não há avaliações

- Frequency Spectrum On XXX OperatorsDocumento4 páginasFrequency Spectrum On XXX OperatorsPeng Yuan FengAinda não há avaliações

- Multidimensional Flow Modeling of The Compression Test of A Gaede Pump Stage in The Viscous RegimeDocumento9 páginasMultidimensional Flow Modeling of The Compression Test of A Gaede Pump Stage in The Viscous RegimeAsif HameedAinda não há avaliações

- Sika Decap PDFDocumento2 páginasSika Decap PDFthe pilotAinda não há avaliações

- Removal Processes and Machine Tools: Indian Institute of Technology DelhiDocumento28 páginasRemoval Processes and Machine Tools: Indian Institute of Technology DelhiEthan HuntAinda não há avaliações

- Multidisciplinary Research: EPRA International Journal ofDocumento5 páginasMultidisciplinary Research: EPRA International Journal ofMathavan VAinda não há avaliações

- ASN PyariViswamResumeDocumento3 páginasASN PyariViswamResumeapi-27019513100% (2)

- AWS Lecture NotesDocumento4 páginasAWS Lecture NotesAsad Bin Ala Qatari0% (1)