Escolar Documentos

Profissional Documentos

Cultura Documentos

1253 s10 Scaler

Enviado por

pauloDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

1253 s10 Scaler

Enviado por

pauloDireitos autorais:

Formatos disponíveis

1253-S10 Scaler - Rev.

1/2012- Page 1 of 5

...the people who care !

Main Features

Carrier – Main Features:

The Paus Scaler 1253 S10 is a hydrostatically driven machine with hydraulic hammer NPK GH-2S made for min-

ing and tunneling applications. The articulated scaler is equipped with a water-cooled 98 KW Deutz BF4M 2012

C. Further details are four-wheel drive, oscillation of the rear axle and the parallel guided dozer blade. The height

of the turret of the new scaler 1253 S10 is reduced by 300 mm for better visibility and safety during driving opera-

tion. Additional safety features are automatic lock for rear axle during scaling, ROPS/FOPS cabin with guard grid

and deflectors on the telescopic boom. The compact dimension of the machine enables the use of the scaler in

minimal gallery sizes. Due to the double telescopic boom the scaler can cover gallery width of 12 m and height of

10 m. The hydraulic hammer has a vertical swiveling range of 100°, this and the swiveling boom guarantees an

excellent operator’s view to the chisel. To avoid contaminations of the hydraulic oil and faster aging of compo-

nents, a separate hydraulic tank for hammer operation is integrated in the machine.

IntelliScale:

The IntelliScale concept allows the operator to choose from different pre-programmed modes. The programmed

modes are configured for different conditions in an optimal way. These modes help the operator to be focused on

daily work and on hammer operation, to avoid failures in operation and to work more efficiently. The modular con-

trol and the display replace a lot of control elements and indicators. Different kind of machine data like tempera-

tures, pressures or maintenance intervals are available via display – this improves the availability of the machine

and makes service much easier. Due to the fact that all alarms are shown on the display, failures diagnostic could

be done much faster and preventive maintenance is possible. The machine can be easily equipped with a “Plug

In” radio remote control solution for operations in extremely hazard areas.

Hermann Paus Maschinenfabrik GmbH, Siemensstr. 1 – 9, 48488 Emsbüren, Germany

Tel.: +49-5903-707-0, Fax.: -33, email: info@paus.de, internet: www.paus.de

1253-S10 Scaler - Rev. 1/2012- Page 2 of 5

...the people who care !

Technical Data

DIESEL ENGINE STEERING

Type DEUTZ BF4M2012 C Articulated steering, steering angle ± 40°

water-cooled Diesel engine Hydraulic steering, emergency steering features in

Power 98 kW @ 2.300 RPM case of switched off engine

Automatic engine control

TURRET AND BOOM

Dry air filter, silencer

Swivelling angel ±45°

HYDRAULIC HAMMER Double telescopic boom, all bearing points of the

Type NPK GH2 telescopic system made from extremely wear-

Weight 260 kg resistant bearing bronze, friction bearing screws

Impact rate 560 to 1,200 BPM glued on the telescopic conduit, fixing screws of

Operation pressure 127 bar the friction bearing mechanically screwed, excess

Tipping angle 100° flow cut-off/countersunk brake valve in the lifting

Hammer operation by foot push bottom and joy- cylinder, tip cylinder reinforced version, protection

stick against down falling rocks, cover for cylinders and

DRIVE LINE hoses on the telescopic conduit, protected fitting

Hydrostatic drive consisting of an adjustable DOZER BLADE

pump, adjustable motor, continuously variable Hydraulically manoeuvrable, pivoted mechanically

speed, reversible forward/backward under full

by ±8°, applicable for support of the vehicle, dozer

load, four-wheel drive.

blade hose protection

AXLES

HYDRAULIC SYSTEM

DANA axles, fixed planetary-rigid axle with self-

Pumping power 120 l/min

locking differential, fixed front axles and rear axles

Operating pressure 180-200 bar

as oscillating planetary rigid axle mounted on the

JIC 37° fittings

chassis, pendulum angle +/-10°

Separate hydraulic circuits and tanks for drive unit

Automatic locking of oscillating axle while swivel-

and hydraulic operating, hydraulic tank in high-

ling the loading equipment

pressure design with vacuum/return flow filter,

BRAKES grade of filtration 10 ym, display of filter pollution in

Even braking of both axles by transfer case and driver’s visibility

universal shafts:

ELECTRIC SYSTEM

Service brake: hydrostatic drive, closed circuit Main battery switch

Parking brake: spring applied/hydraulically re- Operation voltage 24 V

leased multiple-disc brake Alternator 28 V 55 A

Auxiliary brake: spring applied/hydraulically re- Battery 2 x 12 V 110 Ah

leased multiple-disc brake, operated hydraulically 2 headlights in front of the compartment, 2 brake

by brake pedal lights, 4 flashers, 2 stop lights, 2 reversing lights, 2

TIRES working lights at the telescopic boom

Mining tires 15.5 R 25, foamed WEIGHTS

Total weight 13,000 kg

DRIVER’S COMPARTMENT

Axle loads, front 9,500 kg

Large, elastically supported open driver’s canopy

Axle load, rear 7,000 kg

“ROPS/FOPS”, hinged rock fall protective grid for

front/roof window, wipers for front and roof screen, Automatic locking of oscillating axle while swivel-

rear window screens made by ESG, access left ling the loading equipment

side, emergency exit on the right side, driver’s PERFORMANCE

seat with safety belt, clearly arranged dashboard Working operation up to 6 km/h

and easily accessible operating devices, propor- Max. speed up to 20 km/h

tionally load-independent for lifting cylinder, tipping

cylinder, swivelling cylinder and telescopic cylinder

Hermann Paus Maschinenfabrik GmbH, Siemensstr. 1 – 9, 48488 Emsbüren, Germany

Tel.: +49-5903-707-0, Fax.: -33, email: info@paus.de, internet: www.paus.de

1253-S10 Scaler - Rev. 1/2012- Page 3 of 5

...the people who care !

Variants, Options and Accessories

HYDRAULIC HAMMER

Atlas Copco

Model: SB 302 SC

Weight: 304 kg

Oil flow rate: 50-83 l/min

Operation pressure: 100-150 bar

-1

Blow frequency: 600-1380 min

Working tool diameter: 80 mm

Working length: 420 mm

Dust Suppression System

Pressurization of Hammer

DRIVER’S COMPARTMENT

Closed cabin

Air-conditioning

FIRE SUPPRESSION SYSTEM

Full-automatic system

Semi-automatic system

TIRES

Spare tire 15.5 R25, foamed

LUBRICATION SYSTEM

Central lubrication, full automatic

Central lubrication, semi-automatic

Central lubrication, hammer

LED Light Package

2 headlights in front of the compartment, 2 brake

lights, 4 flashers, 2 stop lights, 2 reversing lights, 2

working lights at the telescopic boom, all lights are

designed in LED

Radio Remote Control

Radio Remote Control, Plug In

Radio Remote Control, pre-arrangement „Plug In“

Hermann Paus Maschinenfabrik GmbH, Siemensstr. 1 – 9, 48488 Emsbüren, Germany

Tel.: +49-5903-707-0, Fax.: -33, email: info@paus.de, internet: www.paus.de

1253-S10 Scaler - Rev. 1/2012- Page 4 of 5

...the people who care !

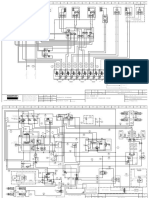

Dimensions

Hermann Paus Maschinenfabrik GmbH, Siemensstr. 1 – 9, 48488 Emsbüren, Germany

Tel.: +49-5903-707-0, Fax.: -33, email: info@paus.de, internet: www.paus.de

1253-S10 Scaler - Rev. 1/2012- Page 5 of 5

...the people who care !

Performance

Coverage

Hermann Paus Maschinenfabrik GmbH, Siemensstr. 1 – 9, 48488 Emsbüren, Germany

Tel.: +49-5903-707-0, Fax.: -33, email: info@paus.de, internet: www.paus.de

Você também pode gostar

- Manual TurbineDocumento61 páginasManual TurbineDana SandruAinda não há avaliações

- Th430 Specification Sheet EnglishDocumento8 páginasTh430 Specification Sheet EnglishAmanda TaylorAinda não há avaliações

- Jumbo Ficha TecnicaDocumento4 páginasJumbo Ficha TecnicaRodrigo FooAinda não há avaliações

- DS312 Specification Sheet EnglishDocumento4 páginasDS312 Specification Sheet EnglishAntonio BocanegraAinda não há avaliações

- Spraymec 6050 WPCDocumento3 páginasSpraymec 6050 WPCPatop CofréAinda não há avaliações

- Sandvik Rd525 Rock Drill: Technical SpecificationDocumento2 páginasSandvik Rd525 Rock Drill: Technical SpecificationWaltherEnriqueAlcocerAinda não há avaliações

- Datos Tecnicos LH202Documento8 páginasDatos Tecnicos LH202Roel Aroni CuaresmaAinda não há avaliações

- DD310-26 6232sfDocumento4 páginasDD310-26 6232sfRoger TrujilloAinda não há avaliações

- Boomer S1D Series Rigs: Atlas Copco Underground Drill RigsDocumento2 páginasBoomer S1D Series Rigs: Atlas Copco Underground Drill RigsRubelinho PomaAinda não há avaliações

- Mr-hl500 Data SheetDocumento1 páginaMr-hl500 Data SheetAlmaAinda não há avaliações

- Sandvik Du411 Underground Drill Rig: Technical SpecificationDocumento4 páginasSandvik Du411 Underground Drill Rig: Technical SpecificationIng del Pele0% (1)

- 13.atlas Copco ROCKET BOOMER E1-E2 SerijaDocumento8 páginas13.atlas Copco ROCKET BOOMER E1-E2 Serijaadamajaks1985Ainda não há avaliações

- Dumper TH 540 PDFDocumento13 páginasDumper TH 540 PDFhernan avAinda não há avaliações

- Ejc 145 4ydDocumento3 páginasEjc 145 4ydAngel Medina CutiAinda não há avaliações

- Safety Data Sheet: Acinol 1415 ASCDocumento5 páginasSafety Data Sheet: Acinol 1415 ASCdieseljccAinda não há avaliações

- 9851 3543 01a - Simba S7 - Technical Specification - EnglishDocumento8 páginas9851 3543 01a - Simba S7 - Technical Specification - EnglishMiguel Angel Otiniano ParedesAinda não há avaliações

- Sandvik Dd311 Development Drill: Technical SpecificationDocumento4 páginasSandvik Dd311 Development Drill: Technical SpecificationJuan David Rondinel BulejeAinda não há avaliações

- 12hhchuck PDFDocumento2 páginas12hhchuck PDFBambang Sumoto100% (1)

- Service News: DIAMEC 232 - Spare Parts ListDocumento2 páginasService News: DIAMEC 232 - Spare Parts Listorlando chullo llave100% (1)

- Axera D06Documento2 páginasAxera D06Cristián Fernando Cristóbal RoblesAinda não há avaliações

- Ds311-Ficha Tecnica PDFDocumento4 páginasDs311-Ficha Tecnica PDFAnonymous qnRoeLRiyAinda não há avaliações

- LH201 9900sbDocumento4 páginasLH201 9900sbmarix12Ainda não há avaliações

- LF230 Manual de Operaciones y Servicios (2016) - 1Documento444 páginasLF230 Manual de Operaciones y Servicios (2016) - 1osvaldo jesus fernandez100% (1)

- Sistema Hco EJC 145 (Colores)Documento92 páginasSistema Hco EJC 145 (Colores)JorgeAinda não há avaliações

- Minetruck MT42 - Technical Specification - English - High ResDocumento8 páginasMinetruck MT42 - Technical Specification - English - High Resd86299878Ainda não há avaliações

- Quasar NV: Technical Specification 9-601 S-FDocumento4 páginasQuasar NV: Technical Specification 9-601 S-FJean Carlos RomanAinda não há avaliações

- Muki Bolter: Roof Bolter For Small SectionsDocumento4 páginasMuki Bolter: Roof Bolter For Small SectionsJose Antonio Sanchez SegoviaAinda não há avaliações

- 00-01 Boltec S - Course IntroductionDocumento6 páginas00-01 Boltec S - Course IntroductionALVARO ANTONIO SILVA DELGADOAinda não há avaliações

- Espec DL310 PDFDocumento4 páginasEspec DL310 PDFFranklin LabbeAinda não há avaliações

- DS421 8-4301-ADocumento4 páginasDS421 8-4301-AchristianAinda não há avaliações

- Utimec LF 600 Agitator 100018506Documento7 páginasUtimec LF 600 Agitator 100018506lucas0% (1)

- Sandvik Lh204 Underground Loader: Technical SpecificationDocumento7 páginasSandvik Lh204 Underground Loader: Technical SpecificationRigo McFly Casanova ArmijoAinda não há avaliações

- DD311 Planos HidráulicosDocumento8 páginasDD311 Planos HidráulicosBrayan vidal López GuzmánAinda não há avaliações

- Bracket Assy CP - Ph2Documento3 páginasBracket Assy CP - Ph2cristian nahuelcuraAinda não há avaliações

- Ficha Tecnica Alpha 30Documento7 páginasFicha Tecnica Alpha 30jonathan francisco allende escobarAinda não há avaliações

- Boltec M, L and SDocumento3 páginasBoltec M, L and SDamian SaldarriagaAinda não há avaliações

- Dd421 Specification Sheet EnglishDocumento4 páginasDd421 Specification Sheet Englisheduama0% (1)

- LF 700 Cylinder Rope Feed: Technical Specification 3-1545 2005-01-11Documento2 páginasLF 700 Cylinder Rope Feed: Technical Specification 3-1545 2005-01-11Max RojasAinda não há avaliações

- 9851 3586 01 COP MD20 BrochureDocumento4 páginas9851 3586 01 COP MD20 BrochureEduardo MassainiAinda não há avaliações

- Joy Face Drilling JumboDocumento5 páginasJoy Face Drilling JumboMoodAinda não há avaliações

- Itc Te210eDocumento2 páginasItc Te210ezliang100% (2)

- AC2 Specification SheetDocumento4 páginasAC2 Specification SheetWiwa Hernandez DonosoAinda não há avaliações

- GENDocumento117 páginasGENdevgahlotAinda não há avaliações

- TransmisioDocumento34 páginasTransmisioWilliams ArayaAinda não há avaliações

- ONRAM 1500: Diamond Core Drill Technical SpecificationDocumento7 páginasONRAM 1500: Diamond Core Drill Technical SpecificationFedericoButronAinda não há avaliações

- DE700 Series PDFDocumento5 páginasDE700 Series PDForlando chullo llave100% (1)

- Boltec DS411Documento4 páginasBoltec DS411fabian castroAinda não há avaliações

- Especificaciones DT820Documento5 páginasEspecificaciones DT820Jorge Cid BlancoAinda não há avaliações

- Manual de Fallas y Mantenimiento de Aceros Atlas CopcoDocumento80 páginasManual de Fallas y Mantenimiento de Aceros Atlas CopcoLuis AsfuraAinda não há avaliações

- Preforadoras DS311Documento1 páginaPreforadoras DS311Gerardo RiosAinda não há avaliações

- Atlas Copco Wagner Scooptram ST-2DDocumento13 páginasAtlas Copco Wagner Scooptram ST-2Dait mimoune100% (1)

- Diamec Brochure PDFDocumento12 páginasDiamec Brochure PDFDangol RupeshAinda não há avaliações

- Boltec S: Start The EngineDocumento2 páginasBoltec S: Start The EngineerwinAinda não há avaliações

- Single & Dual Load Sensing, Accumulator Charging ValveDocumento8 páginasSingle & Dual Load Sensing, Accumulator Charging Valvetystar_21Ainda não há avaliações

- ST2G FolletoDocumento4 páginasST2G Folletomarcelonieto761Ainda não há avaliações

- 853 s8 ScaleDocumento5 páginas853 s8 ScaleMauro GalgoAinda não há avaliações

- Paus-853-Tsl MantenimientoDocumento8 páginasPaus-853-Tsl MantenimientoYoel Gabriel QuispeAinda não há avaliações

- PMK M 12010Documento4 páginasPMK M 12010pauloAinda não há avaliações

- Elevacion Camion PausDocumento6 páginasElevacion Camion PausMiguel FarahAinda não há avaliações

- PMK T 10010Documento4 páginasPMK T 10010Andrea ZagastizabalAinda não há avaliações

- DIA Hora Tajo Placa #Peso TMHDocumento15 páginasDIA Hora Tajo Placa #Peso TMHpauloAinda não há avaliações

- PMK T 10010Documento4 páginasPMK T 10010Andrea ZagastizabalAinda não há avaliações

- DG ConverterDIP DIPDirectionDocumento1 páginaDG ConverterDIP DIPDirectionpauloAinda não há avaliações

- PMK M 12010Documento4 páginasPMK M 12010pauloAinda não há avaliações

- PMK T 8010Documento4 páginasPMK T 8010pauloAinda não há avaliações

- Made in Abyss Tomo - 3Documento157 páginasMade in Abyss Tomo - 3paulo100% (2)

- Kingmaker With Mike Rashid - 4 Weeks To Fighting ShapeDocumento6 páginasKingmaker With Mike Rashid - 4 Weeks To Fighting ShapeRayAinda não há avaliações

- Vestiaire Collective The Challenges of Second-Hand LuxuryDocumento13 páginasVestiaire Collective The Challenges of Second-Hand LuxuryNikith NatarajAinda não há avaliações

- Adobe Scan 08-Sep-2023Documento2 páginasAdobe Scan 08-Sep-2023Diptiranjan SahuAinda não há avaliações

- Manuale StoegerDocumento107 páginasManuale StoegerPaolo Marcello BattianteAinda não há avaliações

- The Ellesmerian 1923 - September - XXXV - 001Documento30 páginasThe Ellesmerian 1923 - September - XXXV - 001Ellesmere College Archive / The Old Ellesmerian ClubAinda não há avaliações

- The End of The Gpu Roadmap: Tim Sweeney CEO, Founder Epic GamesDocumento74 páginasThe End of The Gpu Roadmap: Tim Sweeney CEO, Founder Epic Gamesapi-26184004Ainda não há avaliações

- My House Reading ComprehensionDocumento1 páginaMy House Reading Comprehensionnora rodriguezAinda não há avaliações

- Hangman Report1Documento10 páginasHangman Report1RenjithAinda não há avaliações

- Crazy Gang PDFDocumento3 páginasCrazy Gang PDFstartrekgameAinda não há avaliações

- Exercitii AbdomenDocumento30 páginasExercitii Abdomencamelia_ioana_14100% (3)

- Specs CodeDocumento4 páginasSpecs Codemelinda bulosAinda não há avaliações

- Table Manners: MaterialsDocumento8 páginasTable Manners: MaterialsStacey LiuAinda não há avaliações

- 3 The Swimming DeclineDocumento29 páginas3 The Swimming DeclinejkgfgAinda não há avaliações

- Unit 1 Expressing OfferingDocumento7 páginasUnit 1 Expressing OfferingMoh FaisolAinda não há avaliações

- User Manual Titan MuxDocumento81 páginasUser Manual Titan Muxak1828100% (1)

- Chess Life 2018-10Documento76 páginasChess Life 2018-10PabloLedesmaAinda não há avaliações

- Dadaist FilmsDocumento4 páginasDadaist FilmsDiego GrañenaAinda não há avaliações

- Apax EnglishDocumento4 páginasApax EnglishJayzAinda não há avaliações

- How To Build A Robot at Home - 9 Steps (With Pictures) - WikiHowDocumento3 páginasHow To Build A Robot at Home - 9 Steps (With Pictures) - WikiHowPonggey YabolAinda não há avaliações

- New Year's EveDocumento1 páginaNew Year's EveEdyta MacAinda não há avaliações

- Adiff - Clothing System Top ExtDocumento14 páginasAdiff - Clothing System Top ExtsoledadAinda não há avaliações

- Eisenman Canadian CenterDocumento4 páginasEisenman Canadian CentersolosogoodAinda não há avaliações

- xlr8 Carb CyclingDocumento67 páginasxlr8 Carb CyclingH DrottsAinda não há avaliações

- Tuskish Basics 12Documento115 páginasTuskish Basics 12Antonis HajiioannouAinda não há avaliações

- User-Agents Facebook-Messenger ApplicationDocumento140 páginasUser-Agents Facebook-Messenger ApplicationGenivee BuensalidoAinda não há avaliações

- S2-2nd Edit Unit-6 (6.4 Colours of Light)Documento18 páginasS2-2nd Edit Unit-6 (6.4 Colours of Light)Kyaw Sit Nyein MaungAinda não há avaliações

- CP PT Fuma 2022Documento26 páginasCP PT Fuma 2022Radziel EngineeringAinda não há avaliações

- Sunflower - Juliia Phya: MaterialsDocumento15 páginasSunflower - Juliia Phya: MaterialsJessi Rojas50% (2)

- Characteristics of Middle English LiteratureDocumento2 páginasCharacteristics of Middle English Literature221670135Ainda não há avaliações

- 0471 w12 Ms 2 PDFDocumento9 páginas0471 w12 Ms 2 PDFMuhammad Talha Yousuf SyedAinda não há avaliações