Escolar Documentos

Profissional Documentos

Cultura Documentos

Point Fixing Without Penetrating Glass

Enviado por

Stefan Jakovljevic0 notas0% acharam este documento útil (0 voto)

16 visualizações1 páginaThis document provides construction details for point fixing glass without penetrating the glass. It describes three options: a four-point clamp, point fixing in joints, and a shingle-type overlap fixing. The four-point clamp holds glass corners with an aluminum clamp. Point fixing in joints transfers glass weight via setting blocks to steel bolts welded to supports. Shingle-type overlap fixings use stainless steel brackets to overlap glass like shingles and allow for adjustment.

Descrição original:

444047

Título original

04

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoThis document provides construction details for point fixing glass without penetrating the glass. It describes three options: a four-point clamp, point fixing in joints, and a shingle-type overlap fixing. The four-point clamp holds glass corners with an aluminum clamp. Point fixing in joints transfers glass weight via setting blocks to steel bolts welded to supports. Shingle-type overlap fixings use stainless steel brackets to overlap glass like shingles and allow for adjustment.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

16 visualizações1 páginaPoint Fixing Without Penetrating Glass

Enviado por

Stefan JakovljevicThis document provides construction details for point fixing glass without penetrating the glass. It describes three options: a four-point clamp, point fixing in joints, and a shingle-type overlap fixing. The four-point clamp holds glass corners with an aluminum clamp. Point fixing in joints transfers glass weight via setting blocks to steel bolts welded to supports. Shingle-type overlap fixings use stainless steel brackets to overlap glass like shingles and allow for adjustment.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 1

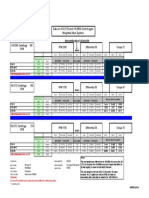

Construction details

Point fixing without penetrating glass

Discrete support

3.1.28 Four-point clamp

3.1.29 Point fixing in the joint

Elevations and vertical sections

scale 1:2.5

3.1.30 Fixing for shingle-type overlap

Horizontal and vertical sections

scale 1:5

Figs 3.1.28–3.1.30 show options for point fix-

ings where the glass does not have to be 1

drilled. With these details, too, it should be

ensured that the glass is held with minimal

restraint. A local clamping arrangement should

never be allowed to fix the glass rigidly. If rigid-

ity due to the clamp cannot be completely

9

ruled out, this should be taken into account

4

when sizing the glass. 5

The cast aluminium clamp shown in fig. 3.1.28 9

holds the corners of the panes. 10

Fig. 3.1.29 illustrates one possible detail for

point fixings in the joint. The self-weight of the

glass is transferred via setting blocks to steel

bolts (brackets) welded or bolted to the sup- 5

porting construction. This method of point fix-

ings in the joints is normally less expensive 3.1.28

than point fixings through the panes because 2

expensive drilling (and provision of a hermetic

edge seal around the holes in the case of insu-

lating units) is unnecessary.

Fig. 3.1.30 shows a detail of a stainless steel

bracket that enables the glass panes to be 3

overlapped like shingles. Such brackets are

6

normally designed specifically for a particular

4

project. The design should allow for subsequent 7

adjustment in order to accommodate tolerances

4

in the loadbearing structure or the supporting

framework. 8

3

3.1.29

1 Single glazing 8 Edge tape

2 Double glazing 9 Four-point clamping 11 12

3 Clamping plate bracket

4 Screw 10 Adjusting bolt

5 Permanently elastic 11 Positioning angle, bolted on 13

joint 12 Individual glass support 12 11

6 Setting block bracket

7 Retainer with 13 Silicone gasket, glued in 1

internal thread place

3.1.30

170

Você também pode gostar

- ASTM E1300-16 Standard PracticeDocumento62 páginasASTM E1300-16 Standard PracticeAndres Gonzales100% (6)

- Astm-E-1300 (R09a)Documento61 páginasAstm-E-1300 (R09a)waynectw100% (4)

- Moment Resisting Connections - SteelconstructionDocumento13 páginasMoment Resisting Connections - SteelconstructionAniket Dube100% (2)

- Sec 3 DesignDocumento43 páginasSec 3 DesignAkhilesh Kumar SinghAinda não há avaliações

- CH 7 Simple Beam End Connections-9-13Documento60 páginasCH 7 Simple Beam End Connections-9-13JakesAinda não há avaliações

- Measuring and calculating dimensions for pipes, plates, cylinders and moreDocumento100 páginasMeasuring and calculating dimensions for pipes, plates, cylinders and moreGarcia MaybelleAinda não há avaliações

- Tutorial: Mounting Optical Lens Mir Salek Optomechanics, Fall 2008Documento12 páginasTutorial: Mounting Optical Lens Mir Salek Optomechanics, Fall 2008vasile_andrei24Ainda não há avaliações

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsNo EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsNota: 4 de 5 estrelas4/5 (1)

- North American Glazing GuidelinesDocumento10 páginasNorth American Glazing GuidelinesAyça Bayram OzcanlarAinda não há avaliações

- Power Tube Biasing Operation Manual 15-01-08Documento2 páginasPower Tube Biasing Operation Manual 15-01-08MitchAinda não há avaliações

- Analysis and Design of Structural Sandwich Panels: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo EverandAnalysis and Design of Structural Sandwich Panels: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNota: 5 de 5 estrelas5/5 (1)

- Installing and Commissioning MotorsDocumento4 páginasInstalling and Commissioning MotorsCraig PretoriusAinda não há avaliações

- Cumulative List of Notices to MarinersDocumento2 páginasCumulative List of Notices to MarinersResian Garalde Bisco100% (2)

- Plate Girder DesignDocumento109 páginasPlate Girder Designhasib100% (3)

- Tennis BiomechanicsDocumento14 páginasTennis BiomechanicsΒασίλης Παπατσάς100% (1)

- Engineering Plasticity: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo EverandEngineering Plasticity: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionAinda não há avaliações

- Reinforced Concrete Buildings: Behavior and DesignNo EverandReinforced Concrete Buildings: Behavior and DesignNota: 5 de 5 estrelas5/5 (1)

- Celiac DiseaseDocumento14 páginasCeliac Diseaseapi-355698448100% (1)

- AOAC 2012.11 Vitamin DDocumento3 páginasAOAC 2012.11 Vitamin DPankaj BudhlakotiAinda não há avaliações

- Structural Concrete: Materials; Mix Design; Plain, Reinforced and Prestressed Concrete; Design TablesNo EverandStructural Concrete: Materials; Mix Design; Plain, Reinforced and Prestressed Concrete; Design TablesNota: 3.5 de 5 estrelas3.5/5 (13)

- Joints in Steel Construction - Simple Connections - Part 04 PDFDocumento72 páginasJoints in Steel Construction - Simple Connections - Part 04 PDFkakem61Ainda não há avaliações

- Solid Waste ManagementDocumento26 páginasSolid Waste ManagementPamela MendozaAinda não há avaliações

- Clamping PlateDocumento1 páginaClamping PlateStefan JakovljevicAinda não há avaliações

- Construction details of point fixing glazing systemsDocumento1 páginaConstruction details of point fixing glazing systemsStefan JakovljevicAinda não há avaliações

- Clamp FixingDocumento1 páginaClamp FixingStefan JakovljevicAinda não há avaliações

- DelVal Series 4 TOBV (Imperial)Documento8 páginasDelVal Series 4 TOBV (Imperial)chavasan1Ainda não há avaliações

- Bracing Design GuideDocumento20 páginasBracing Design GuidePhú NguyễnAinda não há avaliações

- Barrel Coupling: TCB / TCB-HDDocumento32 páginasBarrel Coupling: TCB / TCB-HDSherif KhalilAinda não há avaliações

- 257 Part 4Documento15 páginas257 Part 4Silvo ŠtihAinda não há avaliações

- 4 Bar VT Locking Assy GuideDocumento27 páginas4 Bar VT Locking Assy GuidewillayerstAinda não há avaliações

- Guidance Note Attachment of Bearings No. 2.08: ScopeDocumento2 páginasGuidance Note Attachment of Bearings No. 2.08: ScoperohitAinda não há avaliações

- MMBC VI FOR Structural Glazing DraftingDocumento9 páginasMMBC VI FOR Structural Glazing DraftingSamyuktha SureshAinda não há avaliações

- Guidance Note Bracing and Cross Girder Connections No. 2.03: ScopeDocumento5 páginasGuidance Note Bracing and Cross Girder Connections No. 2.03: ScopeRaquel CarmonaAinda não há avaliações

- OchureDocumento13 páginasOchureFabian CampañaAinda não há avaliações

- Guide To Installation of Steel Windows: Sealing The JointDocumento6 páginasGuide To Installation of Steel Windows: Sealing The JointKristoffer Jose AlcantaraAinda não há avaliações

- Design Guide 10: Bolted Moment End Plate Beam Splice Connection, First EditionDocumento1 páginaDesign Guide 10: Bolted Moment End Plate Beam Splice Connection, First EditionAnonymous 0x2pwMCWgjAinda não há avaliações

- Joint at Unsupported EdgeDocumento1 páginaJoint at Unsupported EdgeStefan JakovljevicAinda não há avaliações

- Module 2 (Answered)Documento33 páginasModule 2 (Answered)Roland Paul PrincipeAinda não há avaliações

- Module 2 Answered 1Documento35 páginasModule 2 Answered 1Ralph A. PastranaAinda não há avaliações

- Monitoring Thomas Disc CouplingsDocumento4 páginasMonitoring Thomas Disc CouplingsEdgar CanelasAinda não há avaliações

- B-02 Mechnical Seal For SBPO LubeDocumento8 páginasB-02 Mechnical Seal For SBPO LubeMarvin DuarteAinda não há avaliações

- Design Plate Girders for Buildings & BridgesDocumento109 páginasDesign Plate Girders for Buildings & BridgesFahd Abdul RahmanAinda não há avaliações

- PresentDocumento22 páginasPresentAniqy MarshallAinda não há avaliações

- Skewed CalcsDocumento8 páginasSkewed Calcspost boxAinda não há avaliações

- Joint DetailsDocumento2 páginasJoint Detailsmusibo911Ainda não há avaliações

- 502-02 Vehicle Frame and Body Fixing Base PICKUP JMCDocumento8 páginas502-02 Vehicle Frame and Body Fixing Base PICKUP JMCRusonegroAinda não há avaliações

- Prism: S E I IDocumento11 páginasPrism: S E I IBiswanathMudiAinda não há avaliações

- 5.detailing ProcessDocumento35 páginas5.detailing ProcessMargarita KianidouAinda não há avaliações

- Corner FabricationDocumento8 páginasCorner Fabricationy2kareinAinda não há avaliações

- Broschyr 7 Eng PDFDocumento16 páginasBroschyr 7 Eng PDFNebojša JovanovićAinda não há avaliações

- Trussed Rafter BracingDocumento5 páginasTrussed Rafter BracingZulkhairi Bin MatoriAinda não há avaliações

- Cylinder head bolts with angular tightening techniqueDocumento5 páginasCylinder head bolts with angular tightening techniqueAdrianAinda não há avaliações

- Glass AppendixDocumento7 páginasGlass AppendixGian ClimacoAinda não há avaliações

- Tapping Screws: Ductility Testing ofDocumento2 páginasTapping Screws: Ductility Testing ofRavindra ErabattiAinda não há avaliações

- E 1300-09a - Standard Practice For Determining Load Resistance of Glass in BuildingsDocumento61 páginasE 1300-09a - Standard Practice For Determining Load Resistance of Glass in BuildingsMahmoud OthmanAinda não há avaliações

- Valves Design ImprovementsDocumento5 páginasValves Design ImprovementsXing ChenAinda não há avaliações

- ASTM E 1300-04E1 STD Practice 4determining Load Resistance of Glass in Bldgs1Documento58 páginasASTM E 1300-04E1 STD Practice 4determining Load Resistance of Glass in Bldgs1rozleAinda não há avaliações

- Turn of The Nut For Anchor BoltsDocumento8 páginasTurn of The Nut For Anchor BoltsshannonAinda não há avaliações

- Distortion - Prevention by Pre-Setting, Pre-Bending or Use of RestraintDocumento3 páginasDistortion - Prevention by Pre-Setting, Pre-Bending or Use of RestraintRahul MoottolikandyAinda não há avaliações

- Altra Industrial Motion document analysis of high performance non-lubricated couplingsDocumento4 páginasAltra Industrial Motion document analysis of high performance non-lubricated couplingsAndrea GentileAinda não há avaliações

- Setting BlocksDocumento1 páginaSetting BlocksStefan JakovljevicAinda não há avaliações

- 8ASTM C1249 - Secondary Seal For Sealed Insulating Glass Units ForDocumento12 páginas8ASTM C1249 - Secondary Seal For Sealed Insulating Glass Units ForRajeshAinda não há avaliações

- Installation Instructions: BW Seals Q, QB SeriesDocumento8 páginasInstallation Instructions: BW Seals Q, QB SeriesJoseGarciaRAinda não há avaliações

- Building Integrated Photovoltaics - p089Documento1 páginaBuilding Integrated Photovoltaics - p089arunghandwalAinda não há avaliações

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsNo EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerAinda não há avaliações

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryAinda não há avaliações

- Facades: 8 8 V V V 2 22 V V V 1 11 V V V 4 44 V V V 3 33Documento1 páginaFacades: 8 8 V V V 2 22 V V V 1 11 V V V 4 44 V V V 3 33Stefan JakovljevicAinda não há avaliações

- Modular House Facade DetailsDocumento1 páginaModular House Facade DetailsStefan JakovljevicAinda não há avaliações

- Tsukuba, J 1994 Architects: Naito Architects & Ass., Tokyo Hiroshi Naito, Tatsuo Yoshida º Detail 4/1996Documento1 páginaTsukuba, J 1994 Architects: Naito Architects & Ass., Tokyo Hiroshi Naito, Tatsuo Yoshida º Detail 4/1996Stefan JakovljevicAinda não há avaliações

- Facades: 8 8 V V V 2 22 V V V 1 11 V V V 4 44 V V V 3 33Documento1 páginaFacades: 8 8 V V V 2 22 V V V 1 11 V V V 4 44 V V V 3 33Stefan JakovljevicAinda não há avaliações

- 020Documento1 página020Stefan JakovljevicAinda não há avaliações

- Timber construction systems overviewDocumento1 páginaTimber construction systems overviewStefan JakovljevicAinda não há avaliações

- 022Documento1 página022Stefan JakovljevicAinda não há avaliações

- 022Documento1 página022Stefan JakovljevicAinda não há avaliações

- Adjust brake levers and pedalsDocumento1 páginaAdjust brake levers and pedalsStefan JakovljevicAinda não há avaliações

- 022 PDFDocumento1 página022 PDFStefan JakovljevicAinda não há avaliações

- 1.4 The Social, Cognitive and Experiential: 1.3 The Signi Ficance of Space 11Documento1 página1.4 The Social, Cognitive and Experiential: 1.3 The Signi Ficance of Space 11Stefan JakovljevicAinda não há avaliações

- 020Documento1 página020Stefan JakovljevicAinda não há avaliações

- Residence and Studio Provides Spectacular Views of Gallina CanyonDocumento1 páginaResidence and Studio Provides Spectacular Views of Gallina CanyonStefan JakovljevicAinda não há avaliações

- 36 Claus en Kaan Architecten Crematorium Heimolen Sint-Niklaas, BelgiumDocumento1 página36 Claus en Kaan Architecten Crematorium Heimolen Sint-Niklaas, BelgiumStefan JakovljevicAinda não há avaliações

- 36.01 Site Plan 1:10000Documento1 página36.01 Site Plan 1:10000Stefan JakovljevicAinda não há avaliações

- 05Documento1 página05Stefan JakovljevicAinda não há avaliações

- Shape StackDocumento1 páginaShape StackStefan JakovljevicAinda não há avaliações

- Spandrel PanelDocumento1 páginaSpandrel PanelStefan JakovljevicAinda não há avaliações

- 02Documento1 página02Stefan JakovljevicAinda não há avaliações

- 35 Bennetts Associates Mint Hotel Tower of London City of London, UKDocumento1 página35 Bennetts Associates Mint Hotel Tower of London City of London, UKStefan JakovljevicAinda não há avaliações

- 34 Becker Architekten Hydroelectric Power Station Kempten, GermanyDocumento1 página34 Becker Architekten Hydroelectric Power Station Kempten, GermanyStefan JakovljevicAinda não há avaliações

- 04Documento1 página04Stefan JakovljevicAinda não há avaliações

- 02Documento1 página02Stefan JakovljevicAinda não há avaliações

- Construction details for flat roof junctions with different materialsDocumento1 páginaConstruction details for flat roof junctions with different materialsStefan JakovljevicAinda não há avaliações

- Joint at Unsupported EdgeDocumento1 páginaJoint at Unsupported EdgeStefan JakovljevicAinda não há avaliações

- Profiled GlassDocumento1 páginaProfiled GlassStefan JakovljevicAinda não há avaliações

- Principle Harmony RhythmDocumento16 páginasPrinciple Harmony RhythmRosalinda PanopioAinda não há avaliações

- BiologyDocumento21 páginasBiologyHrituraj banikAinda não há avaliações

- Fatigue Life Prediction of A320-200 Aileron Lever Structure of A Transport AircraftDocumento4 páginasFatigue Life Prediction of A320-200 Aileron Lever Structure of A Transport AircraftMohamed IbrahimAinda não há avaliações

- Tyfo SDocumento2 páginasTyfo SAndi AsAinda não há avaliações

- Very Low Altitude Drag-Free Satellites: R D UpdatesDocumento5 páginasVery Low Altitude Drag-Free Satellites: R D Updatesraa2010Ainda não há avaliações

- Buddhism Beyond ReligionDocumento7 páginasBuddhism Beyond ReligionCarlos A SanchesAinda não há avaliações

- True/False/Not Given Exercise 5: It Rains On The SunDocumento2 páginasTrue/False/Not Given Exercise 5: It Rains On The Sunyuvrajsinh jadejaAinda não há avaliações

- Uji Deteksi Biofilm Dari Isolat Klinik Kateter Urin Bakteri Entercoccus Dibandingkan Dengan Tube MethodDocumento27 páginasUji Deteksi Biofilm Dari Isolat Klinik Kateter Urin Bakteri Entercoccus Dibandingkan Dengan Tube MethodIyannyanAinda não há avaliações

- HS-2172 Vs HS-5500 Test ComparisonDocumento1 páginaHS-2172 Vs HS-5500 Test ComparisonRicardo VillarAinda não há avaliações

- UPSC IFS Botany Syllabus: Paper - IDocumento3 páginasUPSC IFS Botany Syllabus: Paper - IVikram Singh ChauhanAinda não há avaliações

- Personality Types and Character TraitsDocumento5 páginasPersonality Types and Character TraitspensleepeAinda não há avaliações

- Datasheet Optris XI 410Documento2 páginasDatasheet Optris XI 410davidaldamaAinda não há avaliações

- SmartRunway SmartLandingDocumento39 páginasSmartRunway SmartLandingMikeAinda não há avaliações

- EiaDocumento14 páginasEiaRamir FamorcanAinda não há avaliações

- Template EbcrDocumento7 páginasTemplate EbcrNoraAinda não há avaliações

- Coloi Eeml Disease: Original ArticlesDocumento67 páginasColoi Eeml Disease: Original ArticlesLuisAngelPonceTorresAinda não há avaliações

- 4thinternationalconferencetheimportanceofplace Proceedings 2017 PDFDocumento428 páginas4thinternationalconferencetheimportanceofplace Proceedings 2017 PDFnerko86Ainda não há avaliações

- IIT2019 RIT-1-CPM Chemistry TestDocumento15 páginasIIT2019 RIT-1-CPM Chemistry TestPRAKHAR GUPTAAinda não há avaliações

- Khasi Community of MeghalayaDocumento3 páginasKhasi Community of MeghalayaMidhat FatimaAinda não há avaliações

- Physics SyllabusDocumento85 páginasPhysics Syllabusalex demskoyAinda não há avaliações

- Lab Manual Cape Bio Unit 1 2023Documento37 páginasLab Manual Cape Bio Unit 1 2023drug123addict25Ainda não há avaliações

- Grade 11 Holiday Homework Part 1Documento7 páginasGrade 11 Holiday Homework Part 1Jashfa SaboorAinda não há avaliações

- Sanchez 07 Poles and Zeros of Transfer FunctionsDocumento20 páginasSanchez 07 Poles and Zeros of Transfer FunctionsYasmin KayeAinda não há avaliações