Escolar Documentos

Profissional Documentos

Cultura Documentos

Timber vs. PFRP

Enviado por

THERMAX007Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Timber vs. PFRP

Enviado por

THERMAX007Direitos autorais:

Formatos disponíveis

Timber Cooling Tower Vs.

Pultruded FRP Cooling Tower

Pultruded FRP cooling tower offers many advantages over timber cooling tower. A small compari-

son between the two is enough to highlight the difference between the two.

Criteria Timber Cooling Tower FRP Pultruded Cooling Tower

Commercial Timber presently available FRP is composite material having re-

is generally imported and is of species markable strength and other proper-

of low grade timber. It is from trees ties

Quality that are less than 10 years old. The

grain size has not fully matured as a

result of which the structural strength

is weak.

Though initial cost a little bit low, main- Though slightly expensive, mainte-

tenance is very expensive and fre- nance is very less and thus recovers

Cost of in-

quent. Water treatment for wood re- the extra cost. Downtime less

stallation

quired. These factors make it expen-

and running

sive in long run. Downtime for mainte-

nance is more

Operation More operation and maintenance re- Less operation and maintenance re-

and mainte- quirement for good running quired

nance

Maximum length of single structural FRP sections are made by pultrusion

member presently available is up to 10 machines. Therefore required long

Lengths of ft. Consequently, numbers of joints are sections are available.

Members more. This leads to weakening of the

structure and vibration over a period

of time.

Wood contains cellulose and edible FRP made of fiberglass and resins be-

organic materials hence susceptible for ing neutral material, is not susceptible

growth of Algae/Fungi which causes for growth of Algae/Fungi. Algae can-

Decay due to

decay in wood. It is difficult to control not attach easily with the surface,

Algae/Fungi

these fungi even with the best of the hence less slime.

preservative treatments once they are

established within the wood.

Chlorine used to reduce the slime There is no impact of acid/chlorine on

(Algae/Fungi) problem is responsible FRP

for corrosion and attacks lignin (natural structure. Special FRP materials can

wood adhesive) at ambient tempera- be used for corrosion resistance as

Decay due to

ture thereby reducing the service life per chemicals in the water.

Water qual-

of cooling towers. Acid used to control

ity

pH in water causes decay of wood else

alkaline media decays lignin. Other cor-

rosive media cause more decay and

there is no option for resistance.

Timber Cooling Tower Vs. Pultruded FRP Cooling Tower (contd.)

Criteria Timber Cooling Tower FRP Pultruded Cooling Tower

Alternate dry Alternate dry and wet condition Not applicable for FRP as it is non

and wet and sunlight is ideal for slime hygroscopic.

condition (algae/fungi) development. Such

alternate wet and dry condition

cause tension in wood member.

Hence full shut down is not possi-

ble. Water has to flow even in

standby cell to avoid drying of

members. Plenum or other areas

suffer due to this

Installation Installation is prone to defects as it As FRP is easy to design, fabricate

depends on quality of timber fabri- and installation is easy and re-

cation. It is time consuming and quires less time. Project manage-

usually requires more skilled tech- ment used effectively

nicians. Project management be-

comes difficult

Repair and Replace- Repair and replacement cost is very Replacement is not required as

ment high due to decay of structural there is no such decay.

members.

Material Availability Good quality wood used for timber FRP is easily available. Certification

cooling tower is not readily avail- of quality available. Quality ban be

able in India and has to be im- easily checked.

ported. Inferior quality timber im-

ported. Generally no certification

of quality available.

Life and disposal 5 years (with present wood qual- 20 Years, recycling processes avail-

ity), treated wood is environmen- able.

tally unsafe

Environmental Impact Vast cutting of wood is causing en- No adverse impact on environ-

vironmental disaster. Getting envi- ment.

ronmental clearance not easy

Você também pode gostar

- Tank Heating DiscussionsDocumento26 páginasTank Heating DiscussionsTHERMAX007Ainda não há avaliações

- Sonic Soot BlowerDocumento10 páginasSonic Soot BlowerTHERMAX007Ainda não há avaliações

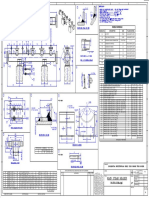

- Main Steam Header: FIG - NO.XII/ 93 (A) OF IBRDocumento1 páginaMain Steam Header: FIG - NO.XII/ 93 (A) OF IBRTHERMAX007Ainda não há avaliações

- Vam OutlookDocumento5 páginasVam OutlookTHERMAX007Ainda não há avaliações

- Vam OutlookDocumento5 páginasVam OutlookTHERMAX007Ainda não há avaliações

- OILON BURNER CATALOG - Group 4 200-700Documento32 páginasOILON BURNER CATALOG - Group 4 200-700THERMAX007Ainda não há avaliações

- Refinery of Palm OilDocumento14 páginasRefinery of Palm OilEvantono Balin Christianto100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Living and Non-Living Things: Choose The Correct AnswerDocumento5 páginasLiving and Non-Living Things: Choose The Correct Answervandana gautamAinda não há avaliações

- As 5013.15-2006 Food Microbiology Microbiology of Food and Animal Feeding Stuffs - Horizontal Method For TheDocumento8 páginasAs 5013.15-2006 Food Microbiology Microbiology of Food and Animal Feeding Stuffs - Horizontal Method For TheSAI Global - APACAinda não há avaliações

- Oil of Sandalwood: (Volatile Oil) By-Shubhi SaxenaDocumento14 páginasOil of Sandalwood: (Volatile Oil) By-Shubhi SaxenaPalakAinda não há avaliações

- Madame Bovary - Gustave FlaubertDocumento166 páginasMadame Bovary - Gustave FlaubertKatherine YeAinda não há avaliações

- Botanical Garden Shah AlamDocumento130 páginasBotanical Garden Shah AlamMuhammad NazmiAinda não há avaliações

- Deforestation in IndiaDocumento46 páginasDeforestation in IndiaSanjib PoddarAinda não há avaliações

- Cce WL W Series W30 Brochure 06-09-2009Documento6 páginasCce WL W Series W30 Brochure 06-09-2009ltovar01Ainda não há avaliações

- Orchids - Their Structure, History & Culture - (1886) - Castle, LewisDocumento136 páginasOrchids - Their Structure, History & Culture - (1886) - Castle, LewisfelinabrancaAinda não há avaliações

- Loi 1312Documento2 páginasLoi 1312Rafael GuillermoAinda não há avaliações

- Vocabulary Workshop Level GDocumento1 páginaVocabulary Workshop Level GShehab El-Menshawy33% (3)

- MONOCOTSDocumento1 páginaMONOCOTSAunieyAinda não há avaliações

- Sustainable Land Management PDFDocumento240 páginasSustainable Land Management PDFmastawalAinda não há avaliações

- Wood Awards Ireland 2016 Finalists Brochure154746572Documento33 páginasWood Awards Ireland 2016 Finalists Brochure154746572JelicaAinda não há avaliações

- Darren Pillsburry - Peter and The VampiresDocumento249 páginasDarren Pillsburry - Peter and The VampiresDaniela StanAinda não há avaliações

- CE ProfileDocumento162 páginasCE ProfileRizwan MirzaAinda não há avaliações

- Grading Experiment BiologyDocumento3 páginasGrading Experiment BiologyAnaRosuAinda não há avaliações

- Harvesting of CoconutDocumento10 páginasHarvesting of CoconutEsaHandayaniAinda não há avaliações

- Budawangia No. 23 Feb.14Documento7 páginasBudawangia No. 23 Feb.14pigott_peterAinda não há avaliações

- TAUNGYADocumento2 páginasTAUNGYAayokunleajigbonAinda não há avaliações

- A Demonstration Jamaican Bamboo GreenhouseDocumento29 páginasA Demonstration Jamaican Bamboo GreenhouseJamie LongAinda não há avaliações

- "Performance Management System at JKPM": A Summer Internship Project OnDocumento53 páginas"Performance Management System at JKPM": A Summer Internship Project OnAntaryami SahuAinda não há avaliações

- Agroforestry: Presentation by G.AISHWARYA (BSC, (AGRI) ) 1 YearDocumento23 páginasAgroforestry: Presentation by G.AISHWARYA (BSC, (AGRI) ) 1 Yearvignesh waran100% (1)

- TeriDocumento4 páginasTeriSamson SeiduAinda não há avaliações

- Ramirez Vs Director of LandsDocumento6 páginasRamirez Vs Director of LandsFhel Jun D. MaghuyopAinda não há avaliações

- Trees of DelhiDocumento3 páginasTrees of DelhiChandan GuptaAinda não há avaliações

- Proclamation No. 2146Documento75 páginasProclamation No. 2146clandestine2684Ainda não há avaliações

- Basic Concepts of Vastu For Town PlanningDocumento6 páginasBasic Concepts of Vastu For Town PlanningPrajitha Jinachandran T KAinda não há avaliações

- DISTRIBUTION OF GUAIACYL AND SYRINGYL LLGNLNS IN JAPANESE BEECH (FAGUS CRENATA) : VARIATION WITHIN AN ANNUAL RINGDocumento8 páginasDISTRIBUTION OF GUAIACYL AND SYRINGYL LLGNLNS IN JAPANESE BEECH (FAGUS CRENATA) : VARIATION WITHIN AN ANNUAL RINGAditya ShrivastavaAinda não há avaliações

- 05 Republic vs. MambulaoDocumento7 páginas05 Republic vs. MambulaoKris Dela CruzAinda não há avaliações

- DAO96-40 (IRR of RA 7940) Pursuant to PD No. 705, as amended, and E.O. No. 192 dated 10 June 1987, and in consonance with the sustainable development thrust of the Government, a Log Control and Monitoring System in the DENR is hereby adopted and the following guidelines are hereby issued for the information of all concerned.Documento726 páginasDAO96-40 (IRR of RA 7940) Pursuant to PD No. 705, as amended, and E.O. No. 192 dated 10 June 1987, and in consonance with the sustainable development thrust of the Government, a Log Control and Monitoring System in the DENR is hereby adopted and the following guidelines are hereby issued for the information of all concerned.Mditsa1991100% (4)