Escolar Documentos

Profissional Documentos

Cultura Documentos

Lab Report

Enviado por

botakmbg6035Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Lab Report

Enviado por

botakmbg6035Direitos autorais:

Formatos disponíveis

1.

0 ABSTRACT

The purpose of venture scrubber is used for air pollution control systems. It is a gas cleaning

devices that utilizes liquid in order to collect particles in the form of droplets. Other than that,

this equipment is very effective to remove submicron particles that give effect to human

health as well as environment. The objectives of this experiment is to study the theoretical

relationship between pressure drop that across throat (DPT02) and pressure drop that across

venture chamber (DPT01) with a constant air flow rate. In this experiment, the values of

velocity that have been used is 4, 6, 8, 10 and 12 m/s with 5 litre per minutes (LPM) of air

flow rates. The measurement of DPT01, DPT02 and blower speed was taken for every 2

minutes. On top of that, the values of velocity was calculated which to convert from Pascal to

inch H2O which also known as DPT03. Based on the experiment, the values of DPT01 and

DPT02 was obtained which for DPT01 was 0.6, 1.3, 2.4, 4.0 and 6.0 inch H2O while for

DPT02 was 0.3, 0.5, 1.0, 1.8 and 2.7 inch H2O. The results showed that the values for both

pressure drop was increased when the velocity increased.

2.0 INTRODUCTION

The venturi scrubber is one of air pollution control innovation collectively alluded as

wet scrubber. The term wet scrubber portrays an assortment of gadgets that expel poisons

from a heater vent gas or from other gas streams. In a wet scrubber, the contaminated gas

stream is brought into contact with the scouring fluid, by showering it with the fluid, by

driving it through a pool of fluid, or by a few other contact strategies, so as to evacuate the

pollutants. The plan of damp scrubbers or any discuss contamination control gadget depends

on the mechanical handle conditions and the nature of the discuss poisons included. Inlet gas

characteristics and tidy properties (in the event that particles are displayed) are of essential

significance. Scrubbers can be outlined to gather particulate matter and/or vaporous poisons.

The flexibility of wet scrubbers permit them to be built in numerous configurations, all

planned to supply great contact between the fluid and contaminated gas stream.

Wet scrubbers evacuate tidy particles by capturing them in fluid beads. The beads are

at that point collected, the fluid dissolving or retaining the toxin gasses. Any beads that are in

the scrubber channel gas must be isolated from the outlet gas stream by implies of another

gadget alluded to as a fog eliminator or entrainment separator (these terms are conversely).

Moreover, the resultant cleaning fluid must be treated earlier to any extreme release or being

reused in the plant. A wet scrubber's capacity to gather little particles is regularly

straightforwardly corresponding to the control input into the scrubber. Moo vitality gadgets

such as spray towers are utilized to gat,her particles bigger than 5 micrometers. To get tall

effectiveness evacuation of 1 micrometer (or less) particles, for the most part, requires tall

vitality gadgets such as venturi scrubbers or increased gadgets such as condensation

CEV 452 (unit operations laboratory): Venturi Scrubber

scrubbers. Moreover, an appropriately outlined and worked entrainment separator or mist

eliminator is vital.

Wet scrubbers that expel vaporous toxins are alluded to as safeguards. Great gas-to-

liquid contact is fundamental to get tall expulsion efficiencies in safeguards. A number of wet

scrubber plans are utilized to expel vaporous poisons, with the stuffed tower and the plate

tower being the most common. If the gas stream contains both molecule matter and gasses,

damp scrubbers are by and large the as it were single discuss contamination control gadget

that can evacuate both poisons. Wet scrubbers can accomplish tall evacuation efficiencies for

either particles or gasses and, in a few occurrences, can accomplish a tall evacuation

proficiency for both poisons in the same framework. Be that as it may, in numerous cases, the

finest working conditions for particles collection are the poorest for gas removal.

In common, getting tall simultaneous gas and particulate removal efficiencies requires

that one of them be effectively collected (i.e., that the gasses are exceptionally dissolvable in

the fluid or that the particles are large and promptly captured) or by the utilize of a cleaning

reagent such as lime or sodium hydroxide.

3.0 OBJECTIVES

To study the theoretical relationship between pressure drop across throat (DPT02) and

pressure drop across venture chamber (DPT01) with air flowrate.

4.0 THEORY

One of the fundamental sorts of the wet scrubber is venturi scrubber. For the most part,

venturi scrubber quickens the contaminated gas stream to progress atomization and contact

between the gas and cleaning fluid. It can successfully evacuate both vaporous and particulate

contaminant, of the molecule estimate extending from 0.5 to 5.0 µm. Hence, it is

exceptionally compelling in expulsion submicron particulates related with exhaust and

smokes.

Venturi scrubber is partitioned into 3 areas, which is converging area, throat, and a

diverging segment. In particulate outflow control, the contaminated gas stream is encouraged

to the focalizing area. The gas is drive to quicken when it streams thru the throat area, as the

channel contracts and its region diminishes (complying Bernoulli equation). In the venturi

throat, both speed and turbulence gas increments. A cleaning fluid shower is infused into the

throat.

CEV 452 (unit operations laboratory): Venturi Scrubber

The cleaning fluid is at that point atomized, shaping little particles or fine beads, by

the tall gas speed and turbulence. The fluid beads shaped collide with particulates in the gas

stream and their interaction is increased.The channel stream exits through the separating area,

where the blends decelerate and lull. Assist impacts and intelligent cause beads to

agglomerate. The particulates with scouring fluid will be isolated by entrainment, which

ordinarily is cleared out to drop to the foot. For afterward expulsion, while the clean gas

stream is coordinated upwards through the cyclonic separator to be discharged into the

environment.

Venturi effect will occur inside the venturi scrubber. When the flow of liquid or gas

flow in the certain velocity into the constrict entrance, the flow will increase but the pressure

will decrease. This is known as the Bernouli’s Principles. The Bernouli’s Principle says that

when a fluid speeds up, its pressure goes down. So at the initial entrance the pressure is

higher compared to the pressure at the venturi throat. This can be presented as Bernouli’s

Equation.

CEV 452 (unit operations laboratory): Venturi Scrubber

𝐴2 2(𝑃1 − 𝑃2 )

𝑉1 = √

𝐴

𝑝[1 − (𝐴2 )2 ]

1

Where A2 = 0.000452 m2 P1 – P2 = DP03 (Pa)

A1 = 0.001810 m2 𝜌 = 1.2 kg /m3

The gas speed in venturi throat for a given pressure drop is related to the volume of

gas passing through the throat, the density of the gas, the amount of fluid in contact with the

gas and a steady which rectifies for the hydraulic losses of the specific throat or restriction.

5.0 PROCEDURE

General start up procedure

a. All the valves was closed except valves 5 and 7.

b. Filled water tank with clean water by connecting a hose to inlet valves 6.

c. Connected another hose to drain valves of water tank for draining purpose.

d. Connected air supply onto pressure regulator.

e. Switched on the main power supply and control panel.

Experimental procedure

a. Switched on the blower.

b. The speed regulator was adjusted to 4 m/s and opened valve 3.

c. Switched on the water pump (P1).

d. Valves 3 and 4 was adjusted until water flow meter FT1 showed 5LPM.

e. The value of DPT01, DPT02 and blower speed was recorded. The step a until e was

repeated by changed the value of velocity for 6.8.10,12 m/s within two minutes time

intervals.

Shut down procedure

a. The venturi scrubber was cleaned using spray nozzle.

b. Lower down the spray nozzle to desired level

c. The valves 2, 4, 5, 7 and 11 was opened.

d. The flow rate was adjusted to clean the venturi scrubber.

e. Switched off the pump and blower.

f. Switched off the main power supply and control panel.

CEV 452 (unit operations laboratory): Venturi Scrubber

6.0 APPARATUS

DPT02 (inch

H2O)

DPT02 (inch

H2O)

Pressure

regulator

DPT01 (inch

H2O)

Throat

PT01 (bar)

FT01 (LPM) Sump tank

Speed

regulator Venturi

scrubber

Water pump

Separation

chamber

Filter

Figure xx: SOLTEQ Venturi Scrubber System (Model: AP 02)

CEV 452 (unit operations laboratory): Venturi Scrubber

Table xx: Description of the diagram

Names Description

Control Panel To manipulate the pressure drop which

DPT03 by adjusting the speed regulator and

to measure the value for DPT01, DPT02

and blower speed.

Water Pump To pump the liquids or gases for the further

process.

Sump Tank As a tank to fill in the water where it is use

to separate the particulates.

Flow transmitter To measure the flow rate of liquid that has

been move through the pipe.

Air Blower Use to deliver air in low pressure but large

volume.

Separation chamber To separate the liquid and gas particulate

Venturi Scrubber The function is to separate the fine

particulate matter.

CEV 452 (unit operations laboratory): Venturi Scrubber

7.0 RESULTS

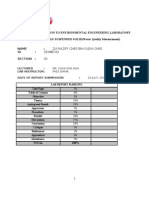

Table XX: Raw data

Velocity, V DPT01 (inch DPT02 (inch DPT03 DPT03 (inch Blower speed

(m/s) H2O) H2O) (pa) H2O) (rpm)

4 0.6 0.3 144.3401 0.6 1113

6 1.3 0.5 324.7650 1.3 1510

8 2.4 1.0 577.3600 2.3 2016

10 4.0 1.8 1299.1251 3.6 2636

12 6.0 2.7 1299.0601 5.2 3248

Where,

DPT01 is at the venturi chamber

DPT02 is at the throat

DPT03 is the blower speed

V is the velocity of the flow rate

CEV 452 (unit operations laboratory): Venturi Scrubber

8.0 SAMPLE CALCULATION

To calculate pressure drop, ∆𝑃:

a. Derivation

2∆𝑃

𝑉=√

𝐴1

𝜌〔(𝐴2) ² − 1〕

2∆𝑃

𝑉² =

𝐴1

𝜌〔(𝐴2) ² − 1〕

𝐴1

2∆𝑃 = 𝑉²𝜌〔( ) ² − 1〕

𝐴2

𝐴1

𝜌〔(𝐴2) ² − 1〕

∆𝑃 =

2

b. For velocity, V=4m/s

Data given;

𝐴1 = 0.001810 𝑚2

𝐴2 = 0.000452 𝑚2

𝜌 = 1.2𝑘𝑔 𝑚3

0.001810𝑚

(4𝑚/𝑠)²𝑥1.2𝑘𝑔/𝑚³〔( ²) ² − 1〕

∆𝑃 = 0.000452𝑚²

2

∆𝑃 =144.3401 pa

c. Conversion unit from pa to inch H20

0.004015 𝑖𝑛𝑐ℎ 𝐻₂0

∆𝑃 = 144.3401𝑝𝑎 ×

𝑝𝑎

CEV 452 (unit operations laboratory): Venturi Scrubber

9.0 DISCUSSION

10.0 CONCLUSION

CEV 452 (unit operations laboratory): Venturi Scrubber

11.0 RECOMMENDATION

a. During the adjustment of the blower speed, make sure the speed regulator is

stabilized and maintain at the desired value within 5minutes so that the data

reading will be accurate.

b. To maintain the flow meter FT101, switch on the water pump by adjusting

gate valves 3 and bypass valves.

c. Make sure all the tubes is connected properly before start the experiment

especially during start up. This is very important because as a precaution

which to avoid from leaking and entire residue can be collected inside of the

tank after finish the experiment.

d. Check the systematic error of the meter reading of pressure drop which

labelled as DPT before run the experiment. It is can minimized the error of the

data collected.

CEV 452 (unit operations laboratory): Venturi Scrubber

12.0 REFERENCES

Pence, M. (2012). Handbook of Air Pollution Control System and Device. Delhi: University

Publications. Retrieved on March 20 from ile.zums.ac.ir/ebook/351-Handbook of Air

Pollution Control Systems and Devices-Margeret Pence-8132337603-University Pu.pdf

Goel, P., Moharana, A., & Nayak, A. K. (2010.). Experimental study of pressure drop in self-

priming and submerged venturi scrubber, 14–17. Retrieved on March 20 from

http://www.sar-net.eu/sites/default/files/ERMSAR_2017/309%20Paper%20-

%20Experimental-study-of-pressure-drop-in-self-priming-venturi-scrubber.pdf

Brady, J. D and L. K. Legatski. In P. N. Cheremisinoff and R. A. Young (Eds.). (1977).

Venturi scrubbers. In M. Dekker, Air Pollution Control and Design Handbook.Part 2 (pp. 76-

80). New York. Retrieved on March 20 from

https://www.scribd.com/document/73970236/Design-Evaluation-of-Particulate-Wet-

Scrubbing-Systems

McIlvaine Company, I. (1974). The Wet Scrubber Handbook. Northbrook. McIlvaine

Company. Retrieved on March 20 from http://www.worldcat.org/title/mcilvaine-scrubber-

manual-a-continually-updated-loose-leaf-guide-reference-directory-and-handbook-of-the-

practical-information-and-recommendations-about-wet-scrubbers-needed-by-purchasers-

consultants-government-officials-researchers-and-suppliers/oclc/4959830

CEV 452 (unit operations laboratory): Venturi Scrubber

13.0 APPENDICES

CEV 452 (unit operations laboratory): Venturi Scrubber

Você também pode gostar

- Dust CollectorDocumento24 páginasDust Collectorafroz ahmedAinda não há avaliações

- Daily MealDocumento6 páginasDaily Mealbotakmbg6035Ainda não há avaliações

- Handbook For Oleochemical in IndustriesDocumento2 páginasHandbook For Oleochemical in Industriesbotakmbg6035Ainda não há avaliações

- Jar TestDocumento2 páginasJar TestTengku Mohd KhairiAinda não há avaliações

- Nebosh Idip Ib3 PDFDocumento67 páginasNebosh Idip Ib3 PDFfrancis0% (1)

- CHE244 Project GuidelinesDocumento5 páginasCHE244 Project GuidelinesEiman UzmiAinda não há avaliações

- Exp.6-Jar TestDocumento9 páginasExp.6-Jar Testمحمد أمير لقمانAinda não há avaliações

- Wet Scrubber Lesson01Documento45 páginasWet Scrubber Lesson01fzhou80% (5)

- Jar TestDocumento16 páginasJar Testikhwan100% (1)

- CycloneDocumento15 páginasCycloneTheyvan T-van0% (2)

- Brochure Blast Furnace Technology enDocumento30 páginasBrochure Blast Furnace Technology enShubhamAinda não há avaliações

- Unit 6 Final PPT Control of PartiDocumento43 páginasUnit 6 Final PPT Control of PartiVikasPodipireddiAinda não há avaliações

- Group 4 Lab 1 Fluid Lab ReportDocumento31 páginasGroup 4 Lab 1 Fluid Lab ReportHarizx SaufixAinda não há avaliações

- Industrial Odor ControlDocumento30 páginasIndustrial Odor ControlArindam BhowmickAinda não há avaliações

- Spray ChamberDocumento12 páginasSpray Chamberkang1995100% (1)

- CHE246 - Technical Lab Report On Rotary PDFDocumento5 páginasCHE246 - Technical Lab Report On Rotary PDFanujaAinda não há avaliações

- Venturi ScrubbersDocumento47 páginasVenturi ScrubbersAnoop SharmaAinda não há avaliações

- Unit 4 - The Chemistry of The Environment: Learning ObjectivesDocumento8 páginasUnit 4 - The Chemistry of The Environment: Learning ObjectivesNiña Viaña BinayAinda não há avaliações

- Vacuum TheoryDocumento79 páginasVacuum TheoryrusyadAinda não há avaliações

- Chapter 8Documento50 páginasChapter 8Amirul Izan100% (1)

- Gas Cleaning PlantDocumento24 páginasGas Cleaning PlantPrabir Kumar PatiAinda não há avaliações

- Manuscript Lab CPE622Documento11 páginasManuscript Lab CPE622zaimfaridAinda não há avaliações

- Lab Report Aspen Hysis UiTMDocumento12 páginasLab Report Aspen Hysis UiTMAhmad SiddiqAinda não há avaliações

- Scrubbing SystemsDocumento68 páginasScrubbing SystemsDr. Akepati Sivarami Reddy100% (15)

- Fully Report Vs-Group 5Documento25 páginasFully Report Vs-Group 5Faradilah Binti Ajma'inAinda não há avaliações

- E Sampler Discussion 1Documento2 páginasE Sampler Discussion 1IzzahAinda não há avaliações

- Experiment # 2: DO, EC, Turbidity and PH MeasurementsDocumento15 páginasExperiment # 2: DO, EC, Turbidity and PH MeasurementsAbo SmraAinda não há avaliações

- Exp 7 Spray ChamberDocumento8 páginasExp 7 Spray ChamberKinosraj Kumaran100% (1)

- Experiment 4Documento11 páginasExperiment 4mirza farhanAinda não há avaliações

- Lab Manual Gas Pressure Process ControlDocumento10 páginasLab Manual Gas Pressure Process ControlAziemah AulanAinda não há avaliações

- FST559 Exam 1 Question Feb Aug21Documento4 páginasFST559 Exam 1 Question Feb Aug21fatin umairahAinda não há avaliações

- PCR Lab - Experiment 4 Ambient Air Quality ManagementDocumento14 páginasPCR Lab - Experiment 4 Ambient Air Quality ManagementJasmine Kang100% (1)

- CPE501 - Lab Simulink Control Loop Syste PDFDocumento27 páginasCPE501 - Lab Simulink Control Loop Syste PDFJose Heli Vallejos CoronadoAinda não há avaliações

- 03 Short Path DistillationDocumento8 páginas03 Short Path Distillationanis_tehah100% (1)

- Assignment PressureDocumento6 páginasAssignment PressureNadia RefaiAinda não há avaliações

- CPE680 Ethics EssayDocumento2 páginasCPE680 Ethics EssayAeyrul KhairulAinda não há avaliações

- Assignment 1 Che522Documento14 páginasAssignment 1 Che522EreenAinda não há avaliações

- (Project Eco) Latest Semifull Half Without Part RogerDocumento35 páginas(Project Eco) Latest Semifull Half Without Part RogerRoger FernandezAinda não há avaliações

- Student 4 Mini Project (Reaction Engineering)Documento7 páginasStudent 4 Mini Project (Reaction Engineering)Muhammad KasyfiAinda não há avaliações

- Jar TestDocumento6 páginasJar Testaoi_chiepAinda não há avaliações

- Lab 4 BODtestDocumento7 páginasLab 4 BODtestcindyn_46100% (2)

- Air Particle 11Documento7 páginasAir Particle 11Hanz HanzAinda não há avaliações

- CPB 20104 Mass Transfer 2 UniKL MICET Experiment 2: Tray Dryer Full Lab ReportDocumento9 páginasCPB 20104 Mass Transfer 2 UniKL MICET Experiment 2: Tray Dryer Full Lab ReportSiti Hajar MohamedAinda não há avaliações

- CES513 - Lesson Plan (ODL)Documento5 páginasCES513 - Lesson Plan (ODL)Athirah DinataAinda não há avaliações

- MiniProject Stage 1 - Process Dynamic & ControlDocumento4 páginasMiniProject Stage 1 - Process Dynamic & ControlFarihah EyfaAinda não há avaliações

- Conclusion BodDocumento1 páginaConclusion BodKhairul FitryAinda não há avaliações

- EXPERIMENT 2 Suspended SolidDocumento7 páginasEXPERIMENT 2 Suspended SolidMuhammad Faiz Zafuan Idrus67% (3)

- Assignment 1 PDFDocumento1 páginaAssignment 1 PDFRoydia SimanAinda não há avaliações

- (Finalized) Assignment Modelling CPE 603Documento48 páginas(Finalized) Assignment Modelling CPE 603Muhammad AshmanAinda não há avaliações

- Research Framework Siti Nur Farhanis Dialysate EffluentDocumento2 páginasResearch Framework Siti Nur Farhanis Dialysate EffluentChannis ExoAinda não há avaliações

- Lab Report Air ParticleDocumento2 páginasLab Report Air ParticleMohamad Zahir RazakAinda não há avaliações

- Aisyah's Group EH2204E Full ReportDocumento38 páginasAisyah's Group EH2204E Full ReportNadiah YusofAinda não há avaliações

- Excercise - Part 3Documento3 páginasExcercise - Part 3Kai Faha LukumAinda não há avaliações

- Health, Safety and Environment (Hse) CGE653 Assignment: Fire and Explosion PO5, CO2, C4Documento4 páginasHealth, Safety and Environment (Hse) CGE653 Assignment: Fire and Explosion PO5, CO2, C4LouisAinda não há avaliações

- EXP 3 Packed Absorption Column Raschig RingDocumento14 páginasEXP 3 Packed Absorption Column Raschig RingHaiqal AzizAinda não há avaliações

- CHE61403 - Safety in Process Plant Design: SolutionDocumento5 páginasCHE61403 - Safety in Process Plant Design: SolutionPorkkodi SugumaranAinda não há avaliações

- Pre-Lab PM10 Sampling in FoodCourtDocumento8 páginasPre-Lab PM10 Sampling in FoodCourtAjlaa RahimAinda não há avaliações

- INTRODUCTION Spray ChamberDocumento5 páginasINTRODUCTION Spray Chamberhilm0% (1)

- Evt 531Documento8 páginasEvt 531Yul100% (1)

- Experiment 1 Ester SapnificationDocumento14 páginasExperiment 1 Ester SapnificationTajTaj100% (1)

- Experiment Bag FilterDocumento14 páginasExperiment Bag FilterMuhammad Adzfar100% (2)

- Refrigeration Unit (DONE)Documento33 páginasRefrigeration Unit (DONE)Eimint Mansor Applez100% (1)

- Jar Test Lab ReportDocumento7 páginasJar Test Lab ReportTeCkMunAinda não há avaliações

- Mixed Liquor Volatile Suspended SolidsDocumento4 páginasMixed Liquor Volatile Suspended Solidscva50% (2)

- Lab 4Documento18 páginasLab 4Amir Al-AimanAinda não há avaliações

- CPB 30103 Biochemical Engineering UniKL MICET Experiment 4: Determination of Bacterial Loads Viable Cell Counts Full Lab ReportDocumento12 páginasCPB 30103 Biochemical Engineering UniKL MICET Experiment 4: Determination of Bacterial Loads Viable Cell Counts Full Lab ReportSiti Hajar Mohamed100% (2)

- G2-Lab3 (S1)Documento18 páginasG2-Lab3 (S1)bndrprdnaAinda não há avaliações

- CHM260 Experiment 5Documento16 páginasCHM260 Experiment 5Muhammad Azri HaziqAinda não há avaliações

- CSTR Design For Propylene Glycol Chemical ProductionDocumento13 páginasCSTR Design For Propylene Glycol Chemical ProductionMeilani Kusuma WatiAinda não há avaliações

- Air Scrubber ReportDocumento10 páginasAir Scrubber ReportAzrol Azmir LongAinda não há avaliações

- Basics of VacuumDocumento7 páginasBasics of Vacuumsanthosh_yash1Ainda não há avaliações

- Fluid Dynamics Student ManualDocumento70 páginasFluid Dynamics Student ManualJayachandran SivagurunathanAinda não há avaliações

- Tutorial 1Documento2 páginasTutorial 1botakmbg6035Ainda não há avaliações

- CEV654-Lecture 4d - Fire Hazards PDFDocumento38 páginasCEV654-Lecture 4d - Fire Hazards PDFbotakmbg6035Ainda não há avaliações

- CEV633 - ASGN 1 - Mar2018 - QuestionDocumento2 páginasCEV633 - ASGN 1 - Mar2018 - Questionbotakmbg6035Ainda não há avaliações

- CEV654-Lecture 8 - Emergency Response PlanningDocumento25 páginasCEV654-Lecture 8 - Emergency Response PlanningSolehah OmarAinda não há avaliações

- Lab ReportDocumento20 páginasLab Reportbotakmbg6035100% (1)

- Assignment 1 (Part A and Part B)Documento8 páginasAssignment 1 (Part A and Part B)botakmbg6035Ainda não há avaliações

- Acknowledgement: TH THDocumento53 páginasAcknowledgement: TH THbotakmbg6035Ainda não há avaliações

- Assignment 3 (Case Study)Documento5 páginasAssignment 3 (Case Study)botakmbg60350% (1)

- DiscussionDocumento2 páginasDiscussionbotakmbg6035Ainda não há avaliações

- CEV 420 Basic Environmental SciencesDocumento2 páginasCEV 420 Basic Environmental Sciencesbotakmbg6035Ainda não há avaliações

- Jabatan Alam Sekitar Pulau PinangDocumento18 páginasJabatan Alam Sekitar Pulau Pinangbotakmbg6035Ainda não há avaliações

- Global Warming and Greenhouse EffectDocumento2 páginasGlobal Warming and Greenhouse Effectbotakmbg6035Ainda não há avaliações

- Group No.: Date of Meeting Summary of Progress Dateline Person in ChargeDocumento1 páginaGroup No.: Date of Meeting Summary of Progress Dateline Person in Chargebotakmbg6035Ainda não há avaliações

- Course Outline 239Documento4 páginasCourse Outline 239botakmbg6035Ainda não há avaliações

- Proposal: Community Program For Cev631 (Leadership and Professional Ethics For Engineers)Documento5 páginasProposal: Community Program For Cev631 (Leadership and Professional Ethics For Engineers)botakmbg6035Ainda não há avaliações

- CHE321 Lesson PlanDocumento6 páginasCHE321 Lesson Planbotakmbg6035Ainda não há avaliações

- CHE 321 Tutorial - Week 5&6 QuestionDocumento1 páginaCHE 321 Tutorial - Week 5&6 Questionbotakmbg6035Ainda não há avaliações

- 135CHE135 - ASGN1 - GroupC3 - Port WentworthDocumento11 páginas135CHE135 - ASGN1 - GroupC3 - Port Wentworthbotakmbg6035Ainda não há avaliações

- Separation ProcessDocumento18 páginasSeparation ProcessSafyan ManzoorAinda não há avaliações

- Argumentative EssayDocumento2 páginasArgumentative Essaybotakmbg6035Ainda não há avaliações

- Front PageDocumento1 páginaFront Pagebotakmbg6035Ainda não há avaliações

- Pre-Feasibility Report Centralized Biomedical Waste Treatment Facility in KeralaDocumento25 páginasPre-Feasibility Report Centralized Biomedical Waste Treatment Facility in KeralaVashudev BohraAinda não há avaliações

- Approaches To Incinerator Selection and DesignDocumento83 páginasApproaches To Incinerator Selection and DesignAbu Izzan Al BunyAinda não há avaliações

- Moisture RemovalDocumento9 páginasMoisture RemovalRafi AkbarAinda não há avaliações

- Effect of Cylindrical Turbulators On The Mixing PRDocumento6 páginasEffect of Cylindrical Turbulators On The Mixing PRAshirbad SahuAinda não há avaliações

- Flue Gas DesulfurizationDocumento4 páginasFlue Gas DesulfurizationPiyush AgarwalAinda não há avaliações

- Cyclones and Inertial SeparatorsDocumento36 páginasCyclones and Inertial SeparatorsShashank SrivastavaAinda não há avaliações

- Air-Pollution Control - Assessing The OptionsDocumento9 páginasAir-Pollution Control - Assessing The OptionsAlexAinda não há avaliações

- Absorbers: About AbsorptionDocumento18 páginasAbsorbers: About AbsorptionLorraineAinda não há avaliações

- Lab ReportDocumento12 páginasLab Reportbotakmbg6035Ainda não há avaliações

- Blasch FCCU Wear PresentationDocumento33 páginasBlasch FCCU Wear PresentationKhaled BOUALIAinda não há avaliações

- Waste Management Study of FoundriesDocumento64 páginasWaste Management Study of FoundriesSumit GusainAinda não há avaliações

- Venturi Gas Scrubber WorkingDocumento3 páginasVenturi Gas Scrubber WorkingDonAinda não há avaliações

- Wet Scrubbing of Acidic Gases: Robert J. Chironna Schutte & KoertingDocumento4 páginasWet Scrubbing of Acidic Gases: Robert J. Chironna Schutte & Koertingnikhaarj100% (1)

- SIEC-Bag FilterDocumento13 páginasSIEC-Bag FilterMahendra RathoreAinda não há avaliações

- Air Scrubber ReportDocumento10 páginasAir Scrubber ReportAzrol Azmir LongAinda não há avaliações

- Chapter 5-Slides PDFDocumento92 páginasChapter 5-Slides PDFMonaElabbassiAinda não há avaliações

- IGNTU Econtent 674613883400 B.SC EnvironmentalSciences 2 PallaviDas EnvironmentalPollutionandHumanHealth 2Documento136 páginasIGNTU Econtent 674613883400 B.SC EnvironmentalSciences 2 PallaviDas EnvironmentalPollutionandHumanHealth 2Neeraj Raushan KanthAinda não há avaliações

- 5 VsDocumento4 páginas5 VsAdhitomoWirawanAinda não há avaliações

- Air Filtration Technology A Comprehensive ReviewDocumento6 páginasAir Filtration Technology A Comprehensive Reviewharold ngAinda não há avaliações

- The Evolution of Blast Furnace Gas Cleaning TechnologiesDocumento8 páginasThe Evolution of Blast Furnace Gas Cleaning TechnologiesJJAinda não há avaliações