Escolar Documentos

Profissional Documentos

Cultura Documentos

Alekov Aleksandr 3

Enviado por

vahidDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Alekov Aleksandr 3

Enviado por

vahidDireitos autorais:

Formatos disponíveis

13

2.2.4. LNG LOADING PROCESS

Because of LNG cargo characteristics, the technology of loading process is

very complex and sophisticated. LNG is usually classified as a flammable

and high-explosive cargo. That is why there are strict rules that determine

the whole procedure for conduction of loading operations. The first step of

the loading process is to inspect the service-condition ability of the fire-

prevention system, emergency valve closing system, pipelines of onboard

cargo handling system air-tightness, mechanical equipment of onboard

cargo-handling system, measurement and control equipment, ventilation

systems of pump and machine rooms, gas leakage warning and alarm

systems, and the alarm system of the tanks filing limit level. After

completing this technical commission, a check-list has to be made. Then,

cargo tanks must be inertized in order to prevent chemical reaction

between the remains of previous cargo and LNG. The loading itself starts

from the connection of onboard cargo pipe lines with terminal pipelines by

so-called loading arms. Due to the low transportation temperature of LNG (-

162 c), the onboard cargo system should be precooled because otherwise

rapid temperature change that will happen after the start of loading process

can negatively affect the connections of pipelines and pipelines themselves.

After the start of loading process, the loading speed has to be increased

gradually in order to make the temperatures of cargo and pipe-line system

equal and to prevent formation of air bound in the system. Throughout the

loading process, the temperature and pressure in cargo tanks should be

monitored. In case of increase, their characteristics must be corrected by

using special pressure pumps and vessel cooling equipment. The lowering

of loading speed must also be done gradually in order to provide the

maximum load without risks of accidents. Usually, the message about the

end of loading process is sent at least 30 minutes earlier. After stopping

loading process, the loading arms and pipelines of the ship’s cargo systems

must be cleaned from the cargo residues. After that, it is affordable to

disconnect loading arms and finish the loading process. ( McGuire & White,

1986, p. 89).

14

2.3. RISKS OF LNG TRANSPORTATION

As it was mentioned before, the LNG is a flammable and explosive cargo.

In other words, LNG can be classified as a hazardous cargo. Generally,

hazardous cargoes provide a range of specific risks. (Batarliene, 2010, pp.

98-99). The most important of them are described below.

Human factor risks

LNG tankers are equipped with complex loading and cargo monitoring

systems. Most of these systems are operated by humans. Crew members

are responsible for the cargo condition monitoring and controlling and

equipment maintenance. That is why crew members’ neglectful attitude to

the duties can provoke serious accidents. (Berg, 2013, p. 344).

Technical risks

As it was mentioned, LNG is a dangerous cargo. Because of its

transportation characteristics, it must be transported and handled by using

specific facilities. These facilities are made to withstand temperature

overloads from cargo. Due to the requirements they have to meet, their

structure is extremely complex which makes it hard to maintain and control

their operable condition. For example, the hulls of vessels are gradually

deteriorating and lose their hermiticity. It can provoke two main crisis

scenarios. First of them is the complete demolition of the vessel caused by

cold LNG leakage which misshapes the vessel’s structure. In this case, the

vessel may sink and become a cause of an environmental accident.

Another scenario seems to be even worse, especially if it takes place when

LNG is being transported by truck near the public places. If the inner hull is

damaged and the outer hull remains intact, the temperature of the cargo

may rapidly increase. As a result of this, the cargo can detonate because of

the surge overpressure inside the tank. (Dodge, 2014). Another example of

hazardous situation caused be technical malfunction is the breakdown of a

spark catcher on the vessel. Considering the fact that evaporations of

natural gas are flammable and explosive, the situation can have

unpredictable consequences. The most important problem here is that it is

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

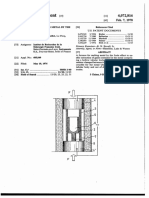

- Us20170291826a1 1Documento2 páginasUs20170291826a1 1vahidAinda não há avaliações

- US4072814Documento6 páginasUS4072814vahidAinda não há avaliações

- Us20170291826a1 4Documento2 páginasUs20170291826a1 4vahidAinda não há avaliações

- Orsi 2005Documento10 páginasOrsi 2005vahidAinda não há avaliações

- Us20170291826a1 2Documento2 páginasUs20170291826a1 2vahidAinda não há avaliações

- Inso نﺎﻣزﺎﺳ ﻲﻠﻣ ناﺮﻳا دراﺪﻧﺎﺘﺳا: ناﺮﻳا ﻲﻠﻣ دراﺪﻧﺎﺘﺳا 14607 14607 لوا پﺎﭼ 1st. EditionDocumento8 páginasInso نﺎﻣزﺎﺳ ﻲﻠﻣ ناﺮﻳا دراﺪﻧﺎﺘﺳا: ناﺮﻳا ﻲﻠﻣ دراﺪﻧﺎﺘﺳا 14607 14607 لوا پﺎﭼ 1st. EditionvahidAinda não há avaliações

- Table 3.1 Heater Specification of Plastic Extrusion SystemDocumento2 páginasTable 3.1 Heater Specification of Plastic Extrusion SystemvahidAinda não há avaliações

- Us5834394 2Documento2 páginasUs5834394 2vahidAinda não há avaliações

- Us5834394 5Documento2 páginasUs5834394 5vahidAinda não há avaliações

- Sure. in The Ideal Case This A Diabatic Process IsDocumento2 páginasSure. in The Ideal Case This A Diabatic Process IsvahidAinda não há avaliações

- Us5834394 1Documento2 páginasUs5834394 1vahidAinda não há avaliações

- 10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JH - 4Documento2 páginas10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JH - 4vahidAinda não há avaliações

- Us5834394 3Documento2 páginasUs5834394 3vahidAinda não há avaliações

- Cacl2 Concntrating - 1 PDFDocumento2 páginasCacl2 Concntrating - 1 PDFvahidAinda não há avaliações

- 10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JH - 6Documento2 páginas10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JH - 6vahidAinda não há avaliações

- 08 - Chapter 3Documento2 páginas08 - Chapter 3vahidAinda não há avaliações

- 08 - Chapter 3 - 5 PDFDocumento2 páginas08 - Chapter 3 - 5 PDFvahidAinda não há avaliações

- Equipment Description: 4.1 CasingDocumento2 páginasEquipment Description: 4.1 CasingvahidAinda não há avaliações

- 4.1.2 Steel Casing - LQ DesignDocumento2 páginas4.1.2 Steel Casing - LQ DesignvahidAinda não há avaliações

- H2so4 3 48x72x59 DDFLHDocumento8 páginasH2so4 3 48x72x59 DDFLHvahidAinda não há avaliações

- 10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JH - 7Documento2 páginas10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JH - 7vahidAinda não há avaliações

- 10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JH - 8Documento2 páginas10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JH - 8vahidAinda não há avaliações

- 10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JH - 5Documento2 páginas10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JH - 5vahidAinda não há avaliações

- Cassava Master PlanDocumento9 páginasCassava Master PlanendosporaAinda não há avaliações

- 10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JH - 5 PDFDocumento2 páginas10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JH - 5 PDFvahidAinda não há avaliações

- 10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JH - 2Documento2 páginas10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JH - 2vahidAinda não há avaliações

- 10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JH - 3Documento2 páginas10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JH - 3vahidAinda não há avaliações

- Methylated Mesoporous SnsiDocumento2 páginasMethylated Mesoporous SnsivahidAinda não há avaliações

- 10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JH - 1Documento2 páginas10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JH - 1vahidAinda não há avaliações

- 10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JHDocumento26 páginas10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JHvahidAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Research Paper On Plate Heat Exchanger PDFDocumento8 páginasResearch Paper On Plate Heat Exchanger PDFc9s9h7r7100% (1)

- A6Documento67 páginasA6Ashraff AudiAinda não há avaliações

- Fastcap 22 630v PDFDocumento1 páginaFastcap 22 630v PDFDarrenAinda não há avaliações

- Chapter 3 Hydro Thermal SchedulingDocumento65 páginasChapter 3 Hydro Thermal Schedulingbik_mesiloveAinda não há avaliações

- Anern Integrated Solar Garden Light-201604Documento1 páginaAnern Integrated Solar Garden Light-201604Godofredo VillenaAinda não há avaliações

- Managerial Communication - (MC) - SEM I-GTUDocumento93 páginasManagerial Communication - (MC) - SEM I-GTUkeyurAinda não há avaliações

- B. Tech. Electrical and Electronics EngineeringDocumento105 páginasB. Tech. Electrical and Electronics EngineeringKarthik NagarajanAinda não há avaliações

- Links Deep WebDocumento2 páginasLinks Deep WebArnoldTorresAinda não há avaliações

- Press Working OperationsDocumento23 páginasPress Working OperationsKanagaraj Ganesan100% (1)

- Serie: Guía RápidaDocumento12 páginasSerie: Guía RápidalumapueAinda não há avaliações

- Manual ArchicadDocumento67 páginasManual ArchicadkhajaimadAinda não há avaliações

- Cansat2017 5235 CDR v02Documento185 páginasCansat2017 5235 CDR v02tom2susanAinda não há avaliações

- Cabezas de Rotulas-RotulasDocumento64 páginasCabezas de Rotulas-RotulasFRANCISCO100% (1)

- Renderoc RsxtraDocumento4 páginasRenderoc RsxtraBalasubramanian AnanthAinda não há avaliações

- Plasma TV SMPS TroubleshoutingDocumento5 páginasPlasma TV SMPS TroubleshoutingmindjokerAinda não há avaliações

- Materi 1 - Analisis SinyalDocumento17 páginasMateri 1 - Analisis SinyalUsmanAinda não há avaliações

- Appendix 1: Lesson Plan (Template)Documento4 páginasAppendix 1: Lesson Plan (Template)Anonymous X7u8sMAinda não há avaliações

- Ingrid Olderock La Mujer de Los Perros by Nancy GuzmnDocumento14 páginasIngrid Olderock La Mujer de Los Perros by Nancy GuzmnYuki Hotaru0% (3)

- Predictive Analytics in Warranty ClaimsDocumento6 páginasPredictive Analytics in Warranty ClaimsRaj SharmaAinda não há avaliações

- 08 - Relief System Adequacy - A Step Towards SAFER Operations - Deepak - IngeneroDocumento40 páginas08 - Relief System Adequacy - A Step Towards SAFER Operations - Deepak - IngeneroCalAinda não há avaliações

- 46 50Documento1 página46 50isturmanAinda não há avaliações

- Linear ProgrammingDocumento6 páginasLinear ProgrammingabeerAinda não há avaliações

- Osisense ManualDocumento2 páginasOsisense ManualLki SelfAinda não há avaliações

- Acornejo Southmayd ProfileDocumento11 páginasAcornejo Southmayd Profileapi-242543114Ainda não há avaliações

- Time Impact Analysis by BrewerConsultingDocumento3 páginasTime Impact Analysis by BrewerConsultingAAKAinda não há avaliações

- Acer Computers Aspire 9300 Aspire 9300 Aspire 7000 Service Guide Ae6e07aDocumento143 páginasAcer Computers Aspire 9300 Aspire 9300 Aspire 7000 Service Guide Ae6e07acvotechnicalsAinda não há avaliações

- Factors Affecting Beam StrengthDocumento2 páginasFactors Affecting Beam StrengthkalpanaadhiAinda não há avaliações

- Thesis FYPDocumento50 páginasThesis FYPEyka ZulaikaAinda não há avaliações

- Work OverDocumento3 páginasWork OverDaniil GhilescuAinda não há avaliações

- Concrete Pumping Cop 2005 PDFDocumento27 páginasConcrete Pumping Cop 2005 PDFShoaib HassanAinda não há avaliações