Escolar Documentos

Profissional Documentos

Cultura Documentos

Living Quarter Layout

Enviado por

Phornlert WanaDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Living Quarter Layout

Enviado por

Phornlert WanaDireitos autorais:

Formatos disponíveis

Living Quarter Layout

INTRODUCTION

This presentation provides general criteria for designing living quarters. Although the

emphasis is on living quarters for offshore platforms, some of the concepts discussed

are equally valid for living quarters at other remote locations. Design Considerations

subject contains a broad overview of design considerations that must be taken into

account before a detailed quarters design can be developed. To some extent, these

considerations may affect quarters layout and the location of the quarters within the

facility.

In the Layout Selection subject some guidelines are presented for initially selecting

an overall quarters size and making an approximate allocation of plan area among

the different areas within the quarters. Included in this subject are items to be

considered when laying out individual rooms. Example room layouts are presented in

the last subject.

Living Quarter Layout Page 1 of 69

DESIGN CONSIDERATIONS

General

Quarters buildings are designed to house people comfortably and safely, regardless

of the surrounding environment. However, the variety of environments, number and

type of personnel, and function of the quarters leads to many different designs.

Design problems presented by the Middle East are different from those encountered

in Alaska. A building in the North Sea, where work-shifts are longer than in the Gulf

of Mexico, requires different considerations. A building designed for Africa may need

to reflect cultural differences. Quarters that house drilling personnel may have

different requirements than quarters that house production personnel (i.e., a change

room). Quarters may be multipurpose and may, for example, contain generator

packages or may incorporate a helicopter pad.

Design considerations include weight, span, location, supporting structures,

materials, loads, and methods of installation. Each choice should be weighed in

relation to the functions of the building and the overall cost. Materials may use steel

frame and skin or steel frame and gauge metal siding; still other buildings may be

built completely of wood and fiberglass. Quarters present interesting and different

structural problems in that not only do dead, live, and wind loads need to be

considered as in any static structure, but the quarters must be transported and may

be dropped. Some typical loading conditions for quarters buildings are presented in

Table 1.

Table 1: Structural Loading for Quarters Buildings

A. Live Loads

2 2

Area (kg/m ) (lb/ft )

Bedroom Floors 290 60

Shop Floor 975-1460 200-300

Roof (1) 290-490 60-100

Common Area 490 100

Stairs 610 125

Heliport Special Special

B. Dead Loads: (including concentrated loads)

Actual

C. Wind Loads:

Wind loads depend on location, but they are based on the formula, P = 0.0625 V 2 C s C h (metric), or P

= 0.0256 V 2 C s C h (customary), where P is the wind generated pressure in kg/m 2 (lb/ft 2 ), V is

velocity in m/s (mph), C s is a shape factor, and C h is a height above water factor.

Living Quarter Layout Page 2 of 69

Wind Velocity Wind Load P Wind Load P

C s and Ch = 1 * C s = 1 and C h = 1.1 **

2 2 2 2

(m/sec) (mph) (kg/m ) (lb/ft ) (kg/m ) (lb/ft )

45 100 125.0 25.6 137.7 28.2

56 125 195.3 40.0 214.8 44.0

67 150 281.2 57.6 309.5 63.4

78 175 871.0 178.4 420.9 86.2

90 200 500.0 103.4 549.8 112.6

* When the surface is flat and height is less than 15 m (50 ft) above the water.

** Building surface is flat and height is 15 m (50 ft) to 30 m (100 ft) above the water.

C h increases 10 percent each 15 m (50 ft) in height.

D. Other

Loads

Impact 100 percent increase

Padeyes Lift load each padeye

Combination -Static Dead + Live + Wind

-Lift Dead x Impact

Seismic Check location conditions

Handrails 90 kg (200 lbs) applied to the rail at any point in any direction

Quarters are much different from the normal architectural structures such as schools

and houses. Quarters design resembles ship-building, where space and fit are a

problem. Air conditioning ducts, pressure and gravity pipes, as well as electrical

conduit/wiring, all compete for limited space. Window locations may well be

determined by furniture location, especially in bedrooms. Redesign of an entire floor

might be required because sufficient space was not allowed for the specified washers

and dryers. Equipment must be moved through passageways, and turns must be

able to accommodate the furnishings.

Machinery and fixtures must get in and fit together. The quarters must function; it

must be safe, long lasting, and please a multitude of people.

Kitchen design is something of a specialty. The best and most interested source is

the caterer who might be using the facility. The layout of the work floor of a kitchen

is very important. See Appendix for examples. Workers and material should travel

minimum distances, proceeding in a logical sequence with a minimum of criss-

crossing and backtracking. Delays in storage of materials, in processing, and in

Living Quarter Layout Page 3 of 69

serving should be reduced to a minimum. Garbage and trash disposal facilities are

required for all functions. A functional Flow Diagram is shown in Figure 1 (Function

flow diagram of a commercial kitchen).

Figure 1

Materials and Construction

Quarters buildings are most commonly made of steel. A quarters building using steel

plate exterior is shown in Figure 2 (New quarters building with structural wall plate).

Walls seldom carry a vertical load.

Living Quarter Layout Page 4 of 69

Figure 2

A wall must bear wind loads (see Table 1) and act as diagonal bracing in the

quarters frame. Wall plates may be flat or crimped and are normally 4.8 mm (3/16

in) thick.

The section modulus of crimped plate may be substituted for angle or channel

stiffeners with flat plate. Crimped plate is generally considered more attractive due

to its texture. However, the exterior wall is thickened and may therefore introduce a

space problem. Not all manufacturers can crimp plate, and few can handle plate over

3 m (10 ft) in width. Thus, available plate width may be a consideration in selecting

floor-to-floor heights.

Light gauge siding, shown in Figure 3 (Exterior of quarters with light gauge metal

siding.), is not as tough or durable as plate.

Living Quarter Layout Page 5 of 69

Figure 3

It is easier to replace and lighter. However, the use of such siding makes it difficult

to pressurize the building. In an area where high wind loads are present, the

structure needed to transmit those loads from a light skin to the frame may increase

in cost due to additional diagonal bracing. This may make the light gauge alternative

uneconomical.

Most fiberglass buildings are small, temporary buildings. Some manufactured

buildings are larger, multi-floored, and capable of receiving helicopters. Fiberglass

buildings generally require more maintenance, must be watched for internal rotting

of wood structures, and are more susceptible to physical damage. Therefore, steel

plate construction is generally preferred.

The geometry of shape affects cost. A square building uses less wall material to

contain the same square footage of floor area as a rectangular building.

Buildings are usually lifted during installation, as shown in Figure 4 (Newly

constructed quarters building being moved by crane).

Living Quarter Layout Page 6 of 69

Figure 4

A top lift is preferred since lifting from the skid requires the use of a spreader bar. A

well-designed roof or heliport will absorb the horizontal forces exerted by slings

during lift. For larger buildings where padeyes are farther apart, the need for

diagonal bracing should be investigated.

Padeyes are generally the most critical aspect of the structural design. Rooftop eyes

must accommodate the sling angle. The smaller the angle the more the horizontal

load that is introduced into the roof. Therefore, the angle should be 45 degrees or

greater from the horizontal, with 60 degrees being preferred. A very heavy pin must

be inserted in the sling and padeye, and sufficient space must be allowed. Unless the

building has a centrally positioned center of gravity, the load will not be equal on all

slings. The sling length can sometimes be adjusted with shackles to level the load.

However, an additional safety factor must be included for the effect of the eccentric

load.

Drains in the padeye wells should be provided. The padeyes should be spaced to

balance the lift load. However, the lift columns must carry the major downwind loads

to the platform and must be located appropriately. Small adjustments may be

necessary to miss windows and doors.

Structural floors may be wood, steel plate, or poured concrete. Wood was more

common in the past than it is today. If wood is selected for floors, consider sandwich

panels for span and strength. A structural semi-lightweight concrete floor is cheaper

and faster to place than steel, allows the sloping of floors to drain, and does not "oil

can" (develop an uneven appearance). The disadvantage is that the concrete floor is

73 kg/m2 (15 lbs/ft2) heavier than 6.3 mm (1/4 in plate).

Heliports can be raised or incorporated as the roof. Heliports without air gaps are

more susceptible to turbulence and should therefore be larger. The Federal Aviation

Administration publishes a design guide for heliports. The API RP 2L on planning,

design, and construction of heliports.

Living Quarter Layout Page 7 of 69

Most companies have written specifications for welding and welding inspection.

Certain environments and locations such as extreme cold climates may call for more

sophisticated procedures. All exposed steel joints should be seal welded to prevent

corrosion. Small tight spaces that cannot be properly sandblasted and coated should

be completely enclosed.

Walkways, stairs, and handrails, both internal and external, should be given close

attention. These fixtures are closely related to personnel evacuation routes and

contribute to the overall safety of the quarters. Handrails should be designed for

loads as shown in Table 1.

Figure 5 (Exterior handrail detail)

Figure 5

and Figure 6 (Example handrail and grating detail) show examples of external and

internal handrail details.

Living Quarter Layout Page 8 of 69

Figure 6

The maximum angle for stairs should be less than 45 degrees from the horizontal.

Treads should be non-skid design and large enough not to present a trip hazard in an

emergency. A typical exterior stairway design is shown in Figure 7 (Exterior

stairway).

Living Quarter Layout Page 9 of 69

Figure 7

Some guidelines for stairway arrangements are presented in Figure 8A and Figure 8B

(Recommended stairway arrangements).

Living Quarter Layout Page 10 of 69

Figure 8A

Figure 8B

Living Quarter Layout Page 11 of 69

Sandblasting and Coatings

Coating

The coating system is the chief protection of a building in a harsh environment. Blasting and

recoating of buildings or structures on location is an extremely expensive procedure. Therefore,

the quality of the original job is of the utmost importance. Normally a coating system similar to

that used to protect the other structures will be chosen. Interior painting in a quarters building,

while limited, should be of good quality and easy to clean. The full coating system should be

applied to the steel before windows and aluminum doors are installed, if possible.

Galvanizing protects steel in some of the more exposed locations such as exterior

grating and handrails. Galvanized surfaces may be painted for extra protection or

aesthetics, but painting is an additional expense. Handrails should be checked after

galvanizing for drips and sharp edges. Imperfections should be buffed off.

Sandblasting

Sandblasting provides the anchor pattern to hold the paint to the surface to be protected. The key

to a proper paint job is a good surface preparation. There are three common grades of

sandblasting specified by standards set by the Structural Steel Painting Council. The least

effective preparation is "sweep" blasting, then "commercial" blast, with the best preparation being

"white" blast. "White" blasting is usually required for all exposed surfaces.

Exterior Openings

In the offshore environment an architectural window is not sufficient. The usual

marine window is 0.6 m by 0.9 m (2 ft by 3 ft). Aluminum is the most commonly

selected material. Windows may be fixed or operable. Where the building is

pressurized, consider fixed windows. Where the building has a controlled interior

environment, windows are seldom opened. Windows must be considered in designing

heating, ventilation, and air-conditioning systems

The selection of glazing should consider safety, solar transmission, and

replaceability. Wire reinforced glass, shatterproof glass, tinted and reflective glasses,

double glass, and vacuum drawn insulated glass are available. It is recommended

that, regardless of the type of glass chosen, it should be at least 6 mm (1/4 in) thick.

Screens on operating windows are optional, but some sort of shade should be

provided inside. Complete black-out shades are normally used in sleeping areas, with

venetian blinds being used in other areas. Opaque glass may be called for in certain

locations. Aluminum windows must be insulated from the steel to control electrolysis.

Hardware for the windows is generally furnished by the window manufacturers.

Exterior doors are usually of hollow metal steel or aluminum. Aluminum is preferred

except where fire ratings are required. Steel doors and frames should be galvanized

before coating, and all doors should be insulated. Small vision panels should be

provided. Codes may restrict these to 64,500 mm2 (100 in2). Fire rated and labeled

Living Quarter Layout Page 12 of 69

doors may be called for in some locations. See subject NFPA 80 for fire ratings. Steel

doors should be coated with the same coating system as the building. Explosion-

proof windows and doors are sometimes required in special circumstances.

Exterior openings should be caulked with top quality silicon sealant and water-tested

under a firehose to duplicate wind-driven rains in storm conditions.

Some door hardware guides are:

• A minimum of three hinges on normal size doors.

• Doors using closures should have ball bearing hinges.

• All exterior doors should use closures with a back check to prevent the wind from

slamming the door open. As an added protection, a chain stop may be used.

• Thresholds and weather stripping are needed to seal the openings.

• All exterior doors should swing out and have panic bars.

• Screen doors are not recommended.

• Fire rated doors should guard stairways.

• Fire rated doors require special hardware.

• Care should be taken that the door swing does not impair personnel evacuation routes.

Interior Finishes

General

Interior Finishes should be chosen for safety, durability, comfort, and aesthetics.

Partitions

Metal studs are normally used. These are usually 20 gauge galvanized and

perforated in 92 mm (3 5/8 in) and 143 mm (5 5/8 in) widths. Gypsum board back-

up is then applied. By using 16 mm (5/8 in) fire coded sheetrock on both sides of the

stud, a one-hour fire protection rating can be achieved. A typical partition is shown in

Figure 9 (Typical interior partition).

Plywood may also be used as a back-up, but it does not have the same fire rating.

Living Quarter Layout Page 13 of 69

Figure 9

Some treated lumbers and plywoods are fire retardant, but their specifications must

be checked closely, especially with regard to humidity. Treatments designed for

exterior use (high humidity) contain formaldehyde, which may pose a smoke risk to

the occupants in the event of fire. The treatment for interior usage has humidity

limitations. Exceeding these limitations may cause leaching of the treatment, which

may cause damage to any metal it contacts. Care should be exercised to assure that

proper application of the interior products is made.

Finishes are a matter of choice. Glasweld, a brand of cementitious board is probably

the most popular. It is fireproof, waterproof, cleanable, and durable. Some

companies prefer prefinished wood paneling, others plastic laminate or heavy-duty

wall coverings. Several patented partition systems allow for the removal of panels for

access to the inside of the wall. A number of Coast Guard approved partition

materials also are available. These form a "ship system," and they are used mostly

on mobile rigs. Figure 10 (Double wall panel construction) shows an example of

double wall panel construction.

Living Quarter Layout Page 14 of 69

Figure 10

Ceramic tile is popular in showers and baths. Other options are covered in the

mechanical section.

Floor Coverings

Floor coverings fall under two major classifications: hard and soft. There are a

number of types of grouts used between the tiles after they are in place. An epoxy

grout is best for galleys and other locations of hard use and frequent cleaning. Hard

floors include ceramic tile, quarry tile, and terrazzo. Ceramic and quarry tile floor can

be "thin set" (glued down), or "mud set" (seated on a bed of sand and cement

grout). Mud set is preferred because it allows for sloping to drains. Generally, it is a

good idea to use hard floors in wet areas such as kitchens and bathrooms and to use

soft tiles in other areas.

Soft floors are the various resilient tiles such as vinyl and reinforced vinyl, sheet

goods, carpets, and several poured finishes.

Sheet goods have fewer seams than tiles and are preferred. Carpets may be used if

a little more luxury is desired.

Living Quarter Layout Page 15 of 69

Base Trim

The base trim, the strip at the bottom of the wall, is designed to protect the wall

during mopping and floor cleaning. 100 mm (4 in) high extruded aluminum base is

popular in quarters. A vinyl base may be used with vinyl floors but may tend to come

unglued. Against wood paneling, a wood base may be used and ceramic or quarry

may be used to match the floor.

Ceilings

Ceilings, or "overheads" as they are called on ships, should be selected for fire

protection, lack of smoke development, sound attenuation, cleanability, and access

to the attic spaces. The priority is dictated by the use of the particular spaces.

Kitchens and baths need a hard, scrubbable surface easily removed for cleaning.

Sleeping and public areas need more sound absorption. No ceiling should ever be

inflammable. An unfaced fiberglass batt over the ceiling helps with sound control.

The great majority of ceilings are suspended in a grid of steel, aluminum, or

aluminum capped steel. An acoustic ceiling is shown in Figure 11 (Acoustic ceiling

w/recessed fluorescent light fixture).

Figure 11

Some ceilings carry a fire rating. In normal buildings, the grid is hung with a 9 gauge

wire, in accordance with a recognized industry standard. However, quarters buildings

are constructed to be transported and lifted, and may be dropped. Extra caution,

therefore, must be taken with a ceiling. Light fixtures must be securely attached to

the structure surface, not the ceiling. Rods at all four corners are preferred for this

purpose. If a building is dropped or landed hard, the fixtures could bring down the

ceiling.

Living Quarter Layout Page 16 of 69

Millwork and Furnishings

Interior Doors

Interior doors may be wood or hollow metal steel. Wooden doors may be solid core

or hollow core. Solid wood doors are preferred over hollow core. See Table 2 for

example door widths.

Table 2: Example Door Widths

Service Width (Metric) Width

(Customary)

Exit 910 mm 3 ft 0 in

Bedroom 810 mm 2 ft 8 in

Private Bath 610 mm 2 ft 0 in

Gang Bath 910 mm 3 ft 0 in

Galley 910 mm 3 ft 0 in

Cabinets

Cabinets must be heavy-duty and durable and mounted on a structural surface. The

design should reflect the function, and as much storage space as is practical should

be provided. Kitchen cabinets and shelving in larger quarters should be stainless

steel. Wood cabinets should be of solid plywood and not those generally chosen for

residential use. Wood cabinets clad in a laminated plastic are preferred over painted

wood surfaces in quarters buildings.

Accessories

Choose brass or stainless steel with a heavy duty finish. Attach the fixtures to the

wall with screws because factory attachments do not stand up. Provide an ash

receptacle at each exterior door unless smoking is prohibited. There should be

adequate coat hooks throughout the building. Except in a private bath, towel bars

are seldom used. Towel hooks are Preferred Near Shower Stalls.

Furnishings

Furnishings are a matter of individual choice provided they are functional and heavy-

duty. Adequate shelf space and file drawers should be provided for all documentation

required to operate the facility properly. Bunks need to be large and comfortable.

Provide as much private locker space as is possible. Bunks and lockers should be

securely attached to the wall. Provide adequate bunk lights and bunk shelves at each

bed space. Bunk curtains are a good idea. They block the light from a bunk light if

one person wants to read and the other wants to sleep. Figure 12 (4-man bedroom

with bunk beds) shows bunks installed in a four-man bedroom.

Living Quarter Layout Page 17 of 69

Figure 12

Consideration should be given to including lockers, a desk with a chair, and a waste

basket in each bedroom. More luxurious spaces including lounge chairs and

televisions may be provided. Areas provided for reading, TV watching, card playing,

pool, or even workouts are furnished according to their use. More elaborate and

comfortable quarters may be required in those areas where work shifts are extended

or where the isolation of the location allows few diversions.

Food Service

The food service should be sized according to the number of people eating rather

than the number sleeping. The following items are normally required:

• Range (heavy duty commercial grade)

• Hood over range and fryer

• Mixer

• Refrigerator, reach-in or walk-in

• Freezer, reach-in or walk-in (storage for maximum complement for normal restocking

period)

• Coffee urn

• Toaster

• Milk and/or drink dispenser

• Dishwasher (heavy duty commercial grade)

• Three-compartment sink

• Disposal

• Serving tables

Living Quarter Layout Page 18 of 69

• Pantry storage

In some parts of the world cultural and religious dietary considerations may dictate

two separate kitchens. Storage capacity for frozen food and dry storage depends on

the number of personnel and frequency of supply. A typical galley is shown in

Figure 13 (Galley.

Figure 13

Far door is to pantry. Note halon fire suppressor in hood.).

Thermal Insulation

Fiberglass thermal insulation such as that shown in Figure 14 (Fiberglass insulation

installed in exterior wall) is most commonly used in walls and roofs.

Living Quarter Layout Page 19 of 69

Figure 14

Proper installation is essential for achieving effective results. Fiberglass batting is

better than blown fiberglass, since it is difficult to obtain uniform distribution with

blown fiberglass. There are a number of spray-on types, but these may suffer from

adhesion problems. Some sprays act as fire retardants as well but are not equivalent

to fire coatings.

Floors are more difficult to insulate. A concrete deck requires less insulation than a

steel deck. One approach is to install a fiberglass board on pins welded to the

underside of the floor. Another is to use spray-on insulation. Cost/benefit ratios

should be discussed with a specialist.

Adhesion may be a problem with spray-on insulation applied to the underside of floor

structures with smooth coating systems. Tapes are available to measure adhesion

and should be used to assure a quality job. Most spray insulation, whether applied

vertically or horizontally, requires a layer of wire reinforcing for thicker applications.

Check the manufacturer's literature for exterior use under offshore conditions.

Noise and Vibration

Vibrations and sound can be transmitted to the quarters from other equipment in the

facility. This can be minimized by assuring that the quarters building is not located

adjacent to noisy equipment and is structurally supported to minimize vibrations.

Vibrations can be particularly troublesome if offshore quarters are located on a

cantilever that has inadequate stiffness. In severe cases, it may be necessary to

install sound enclosures or vibration dampeners to isolate the offending equipment.

Excessive noise may significantly affect comfort. The use of acoustical tiles and

carpets helps to deaden sound. It may be necessary to provide sound-attenuating

walls in mechanical equipment rooms or to install sound-attenuating enclosures

around the equipment itself to keep sound from spreading to other areas of the

building.

Living Quarter Layout Page 20 of 69

In choosing a quarters layout, care should be exercised to separate the areas that

tend to be noisy (e.g., mess areas, recreation rooms, change rooms) from

bedrooms. Turns in corridors and stairways help to dampen the transmission of

sound from one area to another.

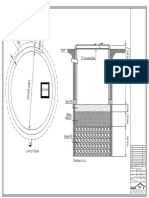

In some offshore quarters designs the heliport is located on the roof of the quarters.

Helicopter traffic can be a source of both noise and vibration. While the duration of

the nuisance may be short (only during take-off and landing) and will not affect

those who are awake, it can be very disturbing to those who are asleep. An effective

way to minimize the disturbance to sleepers is to elevate the helideck 2.5 to 3.0 m

(8 to 10 ft) above the roof of the quarters and to isolate its structural support from

the skid of the building, as shown in Figure 15 (Quarters building with elevated

helideck being placed on barge).

Figure 15

The air gap thus created becomes an effective insulator.

Mechanical

In buildings, the term "mechanical" refers to plumbing, heating, ventilation, and air

conditioning equipment. Figure 16 (Underside view of quarters building showing

structure, plumbing, and electrical components) shows the underside view of a

quarters and its plumbing and electrical components.

Living Quarter Layout Page 21 of 69

Figure 16

The water supply may be split between potable and salt water. Potable water is

piped to showers, lavatories, drinking fountains, and sinks. Piping is usually copper

for potable water, both hot and cold. Plastics can be used as well. If plastic is used

on the hot water system, the temperature specifications should be checked. Salt

water may be used to flush toilets and urinals. Plastic piping is usually used for salt

water.

Consideration should be given to the use of a continuous hot water circulating

system to provide instant (i.e., in 3 to 5 seconds) hot water at each fixture. This

eliminates the need to allow water to flow for a while to reach temperature, thereby

saving water. In a continuous circulating system, there is heat loss from the piping,

but the reduction of water usage may be a more important consideration.

Fresh water may be supplied by a public utility and transported to location by ships,

or else it may be made on-site by a vacuum distillation or reverse osmosis water

maker. It is a good idea to filter either the entire potable system or the fixtures

supplying water for internal consumption. Treatment for bacteria is required.

Fresh water systems are normally designed for 375 to 475 l (100 to 125 gal) of

water per person per day. The amount of storage required for potable water depends

on the source of potable water. Many small platforms in the Gulf of Mexico get their

water from supply boats. Depending on the supply boat schedule, five to ten days of

storage may be provided. If water makers are installed to desalinate seawater,

storage should be sufficient to supply normal need if the unit must be repaired. On

large platforms, two or more water makers can be installed to minimize the need for

potable water storage. On large platforms in the North Sea where weather conditions

may preclude shipments of potable water, it is common to install stand-by water

makers as well as 7 to 14 days of storage. The design of the watermakers is beyond

the scope of this tutorial.

Wastewater piping is usually plastic, with special high temperature pipe used for a

distance of about 1.5 m (5 ft) from the dishwasher. Dishwashers normally use 82°C

(180°F) water. Cast iron, steel, and copper are sometimes used, but not with salt

Living Quarter Layout Page 22 of 69

water. Clean-outs should be installed at the back end of each drain run and every 50

ft on long runs. It is not unusual to see two separate waste systems, one for water

carrying human waste ("black water"), and another for drain water from sinks and

showers ("grey water"). Often, the discharge limitations require treatment of black

water in a marine sanitation device, while such treatment is not required for grey

water. Nevertheless, both systems should be brought to one location so they can be

tied together if treatment of both systems is likely to become required.

The hot water system should be insulated to minimize heat loss. The cold water

systems should be insulated to prevent condensation if run in the ceilings. Exposed

water piping (both hot and cold) must be insulated for freeze protection if there is

that possibility.

Toilets and urinals are usually made of vitreous china. Sinks can be any material

from cast iron to stainless steel. Figure 17 (Porcelain sinks installed in gang shower)

Figure 17

and Figure 18 (Stainless steel sinks) show examples of porcelain and stainless steel.

Living Quarter Layout Page 23 of 69

Figure 18

Individual shower stalls, such as those shown in Figure 19 (Integrated fiberglass

shower stalls), are normally fiberglass, tile, or stainless steel.

Figure 19

Tile is desirable for individual showers as it is stiffer and more durable than

fiberglass, and it costs less than stainless steel. Group showers are usually ceramic

tile. Showerheads are usually sized for 9.5 l (2.5 gal) per minute flow.

Except for private or semi-private baths, usually one toilet is provided for each eight

people, one lavatory for each four, and one shower for each eight. Consideration

should be given to provide one drinking fountain per floor.

Living Quarter Layout Page 24 of 69

Normally, the galley has a three-compartment sink deep enough for large pots. It is

also a good idea to provide a slop sink per floor on all but the smallest quarters for

cleanup.

Hot water heaters are usually electric with high recovery capacity to provide

adequate hot water. The heater should be sized considering peak usage rates. Total

capacity calculated on daily use will be inadequate for the one hour peak usage at

shift change. For safety reasons, gas is not widely used for heating water or cooking

in offshore quarters.

It is not unusual to locate the hot water heaters on the roof of quarters. Check

valves should be provided for the supply side of each heater to prevent a loss of

pressure from draining the heater. The electrical submersion elements will burn out if

draining occurs.

There are two basic types of Western toilets (also called water closets), tank type

and flush valve type. Either type uses about 1.3 l (3.5 gal) per flush. The flush valve

type takes about 7 kg (15 lbs) of pressure to operate properly. Thus an operating

pressure of at least 9 kg (20 lbs) must be maintained at the highest level of the

building. Since storage vessels most likely will be at a lower level, a pump system

will probably be required. Flush valves require water that is free of debris that can

catch in the valve and hold it open. Urinals are usually flushed and equipped with

flush valves. Toilets are normally in a compartment and urinals are protected by

screens. Porcelain or stainless steel is best for these toilet compartments and

screens. In the Middle East and part of Africa, an Eastern type of toilet may be used

by native personnel.

Heating and Air Conditioning

Heating, ventilation, and air conditioning systems (HVAC), are critical to offshore

facilities. In extreme conditions, such as the Middle East, redundancy is a necessity.

When deciding on the HVAC system to use, consider the maximum duty needed.

Normal extremes are cooling from 35°C (95°F), 100 percent humidity to 21°C

(70°F), 50 percent humidity and heating from -1°C (30°F), 100 percent humidity to

24°C (75°F), 50 percent humidity, for offshore Gulf of Mexico environments.

There are two basic types of air conditioning used in most buildings: direct expansion

(usually a split system) and chilled water. Figure 20 (Schematic arrangement of a

chilled water system)

Living Quarter Layout Page 25 of 69

Figure 20

and Figure 21 (Schematic arrangement of a direct expansion system) schematically

illustrate the two systems.

Figure 21

Living Quarter Layout Page 26 of 69

Chilled water systems are generally found in the larger quarters. The advantage of a

chilled water system is that, through the use of individual fan/coil units in each area,

the temperature can be individually controlled. One room may even be air

conditioned while another is being heated. Individual fans/coils also relieve the need

for return air systems. Return air systems can help spread fire and smoke

throughout a quarters. A more complete description of the different systems and

how they are sized is contained in the presentation on Heating Ventilation and Air

Conditioning.

It is generally a good idea to design a zoned system, one for each floor. Sometimes

a system will have all bedrooms on one zone and all common areas on another. The

air supply flow of a central system is often more important to a well functioning

system than the refrigeration side. Attention to the duct design is essential. Since

humidity is the major key to sensible cooling, it may be a good idea to dry the air by

sub-cooling and then to reheat the air to a comfortable temperature.

One method used to conserve conditioned air is the use of air locks such as the one

shown in Figure 22 (Partial layout with air lock).

Figure 22

An air lock is formed by a second exit door set in a corridor four ft or so behind the

door to the outside. If both doors are not open at the same time, the volume of

Living Quarter Layout Page 27 of 69

escaping air is significantly reduced. Air locks are widely used in the Middle East and

in arctic climates.

Ventilation

Because of the odors generated in the building from cooking, bath use, and from

normal human occupancy, there must be an induction of fresh air. A certain amount

of fresh air enters through doors or open windows, but some must be brought in with

the air conditioning system. This fresh air is not to be confused with pressurization.

The kitchen is the largest generator of heat and odor. A hood over the range and

fryer is a necessity, but an exhaust hood also pulls out sizable amounts of

conditioned air. Some hood designs use a supply fan as well as an exhaust fan. The

two fans are balanced so that about 80 percent of the volume of the extracted air is

supplied back to the hood by the intake fan. This short-circuits the air over the

cooking surfaces and extracts odor and moisture without pulling too much air from

the building. Such a hood is known as an "energy saver" hood and is very cost

efficient.

Baths should have positive exhaust, and each bath should be independently ducted

to the exterior. Most guidelines call for a ventilation capacity of 1.4 m 3 (50 ft 3 ) of

air per minute per toilet. The method of supplying air to the room from the air

conditioning system and allowing for an equal amount of air to escape through fixed

vents does not work well. Air from an odor-generating area must not be allowed to

enter the return air flow because this causes odors to be distributed throughout the

building. Exhaust systems should not be combined. It is too easy for odors from one

area to escape to another.

Pressurization

While a well-designed air conditioning system provides a minor amount of positive

pressure in a tight building, certain locations may require an interior pressure

sufficient to insure that contaminated or potentially explosive air cannot enter the

building even through open windows and doors. To achieve this pressure, a separate

pressurizing system consisting of intake fans, pressure relief vents, and a duct from

the fans to a location of non-contaminated air for intake will be required. If this

pressurizing air is to be conditioned, there will be a requirement for extra heating

and cooling capacity. If, however, the need of such positive pressure is on an

emergency basis only, there is little benefit in spending the money necessary to treat

this extra air.

The standard requirements for a positive pressure air system are that it should (1)

be capable of maintaining a pressure of at least 25 Pa (0.1 in of water) in the area to

be pressurized with all openings closed and that it should (2) be capable of providing

a minimum outward velocity of 0.3 m/sec (60 ft/min) through all openings. All doors

and windows capable of being opened should be considered as open, and an

allowance for other openings should be included. Air lock/exterior doors should be

automatically closing to minimize air losses. The pressurizing ability of the air

conditioning system may be included in the calculations.

Living Quarter Layout Page 28 of 69

Power and Lighting

Power and lighting is a term used to denote the quarters building's electrical system

-consisting of such items as wiring, switches, transformers, fixtures, and receptacles

-providing light and electrical power for the occupants' use. Normal and emergency

lighting are included in the lighting. In addition to the general power system noted

above, there may also be an auxiliary power system for telephones, smoke

detectors, gas detectors, emergency communications, and other such important

items.

Light fixtures for normal lighting indoors are mainly the recessed fluorescent type.

Limited use of incandescent fixtures for bed lamps and other needs is common.

Fixtures for outdoor lighting on stairs and perimeter walkways should be similar to

the type used in the facility. Usually the majority of the external fixtures are high

intensity discharge (HID) fixtures. HID fixtures include those using mercury vapor

and sodium vapor lamps. Sodium vapor fixtures are usually more expensive than

mercury fixtures, but they are more efficient in electricity usage. At locations where

power cost is low and where many fixtures are required due to equipment

shadowing, mercury vapor fixtures are often preferred because of their low initial

cost, lower replacement lamp cost, and better color rendition.

The low profile of fluorescent fixtures often dictates their use in areas of low

headroom. A relatively short life, low efficiency, and susceptibility to vibration

exclude incandescent lamps from serious consideration for most applications. In

areas free from vibration and easily accessible for maintenance, such as

entranceways, incandescent fixtures may be acceptable.

Emergency lighting fixtures are often incandescent types. They should provide

sufficient light for personnel evacuation. Normally, 11 lumens/m 2, or one footcandle

(FC), at the floor level of all exit and interior stairs is considered to be sufficient.

Emergency lights could be powered from individual battery packs that are

automatically charged by the normal electrical system. They can also be powered by

a separate emergency power system that receives its power from a central

uninterruptible power supply (UPS).

Minimum design lighting intensities should be specified for the different rooms or

areas. Some examples of design intensities are as shown in Table 3. Design

voltages and cycles should be specified in accordance with local standards.

Table 3: Approximate Lighting Intensities in Different Rooms

Room (lumen/m 2

) Illumination (FC) *

Bedrooms 375 35

Kitchen 540 50

Dry Storage 215 20

Mess Hall 375 35

Living Quarter Layout Page 29 of 69

Laundry 540 50

Recreation/Lounge 430 40

Video 430 40

Medical Clinic 1075 100

Toilet/Change Rooms 325 30

Corridors 270 25

Interior Stairs 270 25

Exterior Stairs and 110 10

Walkways

Janitor's Closets 160 15

Roof Equipment Areas 55 5

* Taken at 760 mm (30 in) above floor level or at working level

Fixtures in baths and galleys should be vapor tight. Special fixtures are used in

showers.

Electrical systems provide power for heat and air conditioning, fans, and kitchen

equipment. They also provide power to convenience outlets (base outlets) and any

dedicated outlets that may be required for clocks, televisions, drinking fountains, or

special tools.

Normally a duplex outlet is provided on each wall of each room and spaced

approximately every 6 m (20 ft) along the walls. An outlet is also provided at each

bunk and over each lavatory for shaving. All outlets are usually ground fault

interceptors, especially in the lavatory/shower areas. An outlet should be provided in

the vicinity of equipment for trouble lighting or power tools. Outlets on the exterior

of the building must be water-tight and may need to be explosion-proof.

Circuiting should be laid out with an eye to failure. A whole area should not go dark

because of a single circuit outage. The outlets and lights in a room should be on

different circuits. The lights should be split on two circuits in large rooms. Circuits

should be limited to 1,600 full load watts for 110 v systems. It is a good idea to have

a separate distributing panel for each floor.

Circuit characteristics vary in different parts of the world, but most quarters are

operated on platform generated electricity. The proper size and type of service must

be provided for all equipment items. A three-phase air conditioner will not work on

single-phase wiring. The same thing is true for a 220 v hot water heater connected

to a 440 v supply.

Service must be designed by a qualified electrical engineer. All circuits must be

grounded and polarity continuous. Some areas may require explosion-proofing.

Living Quarter Layout Page 30 of 69

Fire Detection and Protection Equipment

Required fire detection and protection equipment is normally specified by local codes.

As a minimum, all onshore quarters should have an adequate number of fire and

smoke detectors that can trigger an alarm loud enough to be heard in each bedroom.

In addition, hand held extinguishers should be located in the mess hall/kitchen area,

hallways, mechanical, and equipment areas. Offshore, consideration should be given

to installing gas detectors to warn of the presence of hydrocarbons.

Fire detection equipment is used to detect the start of a fire or those conditions in

which a fire could begin. Examples of detection equipment include heat detectors,

smoke detectors, and gas detectors. Some of these are shown in Figure 23

(Examples of detection equipment (courtesy of Pyrotronics, Cedar Knolls, NJ)).

Figure 23

These systems normally trigger alarms and can be made to initiate certain

emergency shutdown systems and extinguishing systems. On larger quarters

buildings, the triggering of these detectors can be made to close off the HVAC

dampers to prevent fire, smoke, or gas from spreading to other areas of the building

through the HVAC system.

Living Quarter Layout Page 31 of 69

Heat detectors are chosen by temperature rating and fluctuations. They are

commercially available in 57°C (135°F) and 93°C (200°F) settings both in "rate of

rise" and fixed temperature modes. Gas detectors generally monitor the presence of

natural gas and trigger alarms at 20 percent lower explosive limit (LEL) and

shutdowns at 60 percent LEL. Smoke detectors may be ionization or infrared type

detectors.

Fire fighting systems consist of hand extinguishers, automatic sprinkler systems, and

fire suppression systems such as Halon and dry chemical. Hand extinguishers should

be wall-mounted in accessible locations throughout the building. Extinguishers

should be located near the exterior exits and points of possible combustion such as

the kitchen and mechanical rooms. There are several types of hand extinguishers,

which can be specified: (1) dry chemical, (2) carbon dioxide, and (3)

monoammonium phosphate, depending on the type of fire anticipated. The all-

around ABC extinguisher is readily serviceable and can be used on any of the three

classified fires.

The following guidelines should be considered for ABC extinguishers:

Space Quantity and Location

Corridors One 4.5 kg (10 lb) extinguisher in each main corridor spaced at 45 m (150 ft) intervals

and at each exit.

Sleeping Areas One 1.1 kg ( 2 1/2 lb) extinguisher for each bunk room.

2 2

Service Areas One 4.5 kg (10 lb) extinguisher for each room or for each 230 m (2,500 ft ).

Galley See Service Areas. Include a fire suppression system in the hood over the range and

fryer.

Other Heliports require special consideration. Also place extinguishers in outside walks and

at machinery.

Automatic sprinkler systems can be either permanently pressured (wet pipe) or pressured on

actuation (dry pipe). Potable water does not have to be used. Offshore, seawater is normally

used in sprinkler systems, but a means for flushing with potable water is normally provided to

keep the system clean of sediment and rust.

Firewalls are sometimes used to protect internal stairwells and other critical exit

paths. They may also be used to contain equipment fires within mechanical

equipment rooms. Use of fire walls in certain rooms dictates the use of ceiling

systems of similar fire rating to prevent fires from spreading to other levels.

NFPA 80 (National Fire Protection Association) subject under Living

Quarters contains fire-rating information for standard types of construction. Higher

ratings can be achieved by using steel and/or coating with a commercially available

fire retardant product, which usually must be applied by factory authorized personnel

to maintain the warranty. The fire walls can be separate standing walls or walls of

the building, as shown in Figure 24 (Fire wall integrated into side of quarters.

Living Quarter Layout Page 32 of 69

Figure 24

(Steel plate, no openings)). All fire ratings are based on actual testing of the

partitions installed as nearly as possible to actual situations for the tests. The testing

is done by recognized organizations such as Underwriters Laboratories or Factory

Mutual.

Openings of any type should be avoided in a fire wall. Plumbing vents and ventilation

outlets can usually be arranged to penetrate other walls. If it is necessary that a

window or door be installed in a fire wall, then that opening must be rated or

protected. That is, if a fire rated window or door and frame is not used, an

automatically closing fire shutter must be installed over the opening.

Modular Construction

Quarters are sometimes composed of a number of separate truck-transportable

modules. Most often these modules are rectangular in shape with doors on the ends.

Separate modules are available for bedroom/bathroom, kitchen/galley, office,

recreational rooms, and any combination. Modules can be laid side by side on the

deck and/or stacked one above the other to provide any amount or desired

accommodation of floor space. Communication between modules is through external

walkways and stairs.

Modular construction is particularly well suited for small or temporary quarters. Often

these are standard models that can be leased or purchased and may even be

Living Quarter Layout Page 33 of 69

stocked for immediate delivery. The repetitive nature of their construction minimizes

cost, and their size and weight allows for easy transportation to the platform. Often

the platform crane can be used to install or remove the modules.

A main drawback is that the modules' narrow width does not allow for large common

areas. It is also difficult to arrange standard modules so that it is possible to go from

one to the other without going outside. A variation of separate module construction

involves laying out the quarters so that it can be constructed on the platform by

installing "building blocks" of prefabricated modules one next to each other, with

openings in the walls for passageways and larger common areas. Using this

approach, any layout is possible. The building blocks concept has the disadvantage

that it requires more offshore hookup time and additional structural cost. In addition,

there is a potential for leaks to develop where the building blocks are joined.

Examples of modules and building blocks are provided in the Example Layouts

Subject.

Living Quarter Layout Page 34 of 69

LAYOUT SELECTION

There are seven basic pieces of information required for a quarters layout:

• Number of people the building will accommodate

• Anticipated accommodations makeup according to sex or (in some parts of the world)

religion and race

• Required space per accommodation

• Amount of deck space to be allotted to the quarters building

• Level and height restrictions, if any

• Any hazards in the area

• Structural makeup and load-carrying capacity of the structure on which the building will

set

Laying out a quarters building is an iterative process. First, an overall requirement

for floor area must be determined. From this, several alternatives of length, width,

and number of stories can be chosen consistent with the platform space available.

Table 1 can be used to help in the overall size determination, taking into account

local environmental and cultural conditions.

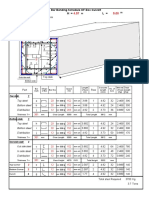

Table 1: Preliminary Sizing

Gulf of Mexico

Range Average North Sea

Example

2 2 2 2 2 2

(m ) (ft ) (m (ft ) (m (ft )

) )

Bedrooms and bathrooms, 3.7- 40-80 6.0 65 7.4 80

per bed 7.4

Kitchen/Food Storage, per bed 0.9- 10-20 1.4 15 1.4 15

1.8

Dining, per bed 0.9- 10-15 0.9 10 1.2 13

1.4

Office, Lounge and Recreation, 2.8- 30-80 5.6 60 6.5 70

per bed 7.4

TOTAL 8.4- 90-200 13.9 150 16.5 178

18.6

Sizing requirements, including change/shower rooms, number of persons per bedroom, etc., vary in the North Sea, depending on the

regulatory agent. Consult the Norwegian Petroleum Directorate for Norwegian areas; Offshore Supplies Office for U.K. areas.

The geometry of the building has some significance. A square 3 m X 3 m (10 ft x 10

ft) building contains 9 m2 (100 ft 2) with 12 linear m (40 linear ft) of walls, but a 15

m X 0.6 m (50 ft x 2 ft) building (to make the point) also contains 9 m2 (100 ft2) of

area but has 31.2 linear m (104 linear ft) of wall. The cost of wall is economically

significant; therefore, the closer to a square a design is, the more economical the

building becomes.

Living Quarter Layout Page 35 of 69

When reasonable combinations of length, width, and number of stories are chosen,

some preliminary space allocation should be made to assure that the different areas

identified in Table 1 could be separated from each other. Of particular concern is to

attempt to separate bedrooms from noisy common areas. Achieving this goal may

require adjustments in overall floor space required.

The next step is to lay out the different areas in more detail within the confines of

the "box" determined in the first step. Table 2 can be used to help in this effort.

Important decisions include determining the number of people to be accommodated

in each bedroom and the arrangements for bathrooms. For example, a Gulf of Mexico

quarters may have private rooms for the foremen, while other company personnel

are housed two per room. The contract and catering personnel may be

accommodated four to a room. Although not recommended, some bedrooms have

been designed to sleep six or more persons. The one-man room may have a private

bathroom, and the two-man rooms may share a bathroom with adjacent two-man

rooms. The four-man and larger rooms may have one large common bathroom on

the same floor level. Another quarters may have only one-or two-man rooms, with

each room sharing a bathroom with the adjacent bedroom. Where both women and

men must be accommodated, it may be necessary to provide two sets of common

bathrooms or to physically separate the rooms that share bathrooms from those that

share a common bathroom.

Table 2: Area Allocations

Gulf of Mexico Norwegian North Sea

*

Range Average Minimum Areas

2 2 2 2 2 2

(m (ft (m (ft (m ) (ft )

) ) ) )

1 Man bedroom 10.0- 108- 9.3 100 6.0 65

11.7 126

2 Man bedroom 6.7- 72- 9.3 100 12.0 130

12.1 130

4 Man bedroom 8.3- 89- 13.9 150 Not Not

17.7 190 Allowed Allowed

6 Man bedroom 18.6 200 Not Not

Allowed Allowed

Private Bath 3.3- 36- 3.9 42 3.7 Est'd 40 Est'd

4.5 48

Common Bath 1.1- 12- 1.6 17 3.7 Est'd 40 Est'd

2.0 22

Change Rooms 0.7 8 0.9 10

Kitchen, m 2

/person and ft 2

/person 0.6- 6-21 1.4 15 Undefined Undefined

1.9

Living Quarter Layout Page 36 of 69

Dining, m 2

/person and ft 2

/person 0.7- 7-32 1.9 20 1.2 13

3.0

2 2

Rec. Room, m /person and ft 8.3- 8-17 1.1 12 1.1 12

/person 12.4

1 Man Office 7.6- 89- 10.2 110 Undefined Undefined

18.5 133

2 Man Office 0.1- 82- 13.1 141 Undefined Undefined

0.3 199

2 2

Food Storage, m /person and ft 1-3 0.2 2 0.2-0.3 2-3 Est'd

/person Est'd

Other Storage 0- 0-6 0.3 3 0.2-0.3 2-3 Est'd

0.6 Est'd

2 2

Corridors & Stairs, m /person and ft 1.0- 11- 2.9 31 Undefined Undefined

/person 5.2 56

(1.2 m, or 4 ft, minimum width)

2

Laundry, Utilities, Common, m /person 0.6- 6-23 1.1 12 Undefined Undefined

and ft 2 /person 2.1

* Requirements for undefined areas are not given on an area per person basis, but are clearly specified otherwise.

Sometimes it is desirable to separate the sleeping quarters into different classes of

accommodations. A distinction may be made between sleeping accommodations for

employees and those for contractors. This goal is normally accomplished by grouping

the larger bedrooms in one area or floor of the quarters.

Another important decision is determining the number of kitchens and dining rooms

required. In most locations only one kitchen and one dining room is required.

However, certain religions such as Islam, Hinduism, and Judaism have dietary

restrictions. If the quarters are designed to accommodate people of a religion that

has dietary restrictions as well as one that does not, it may be necessary to have

separate kitchens and dining rooms. Alternately, all personnel may have to observe

dietary conditions that satisfy all religions present.

The number and size of special purpose rooms such as offices, recreation rooms,

auditoriums, and clinics must be considered in the layout. In Moslem countries it

may be necessary to provide a prayer room. The areas allocated for each room type

should be somewhat larger than required for that room type, to allow for corridors,

entrances, and wall thickness.

Practical considerations, such as locating all bedrooms on one level, grouping office

space together, etc., may require that either the initial allocation to each room type

be adjusted slightly or the preliminary quarters dimensions be changed. It may be

desirable at this stage to try several different layout concepts with varying length to

width ratios to see which one results in a more nearly optimum layout from the

standpoint of lowest cost (usually this means smallest area) while still meeting the

layout and preliminary sizing objectives.

Living Quarter Layout Page 37 of 69

The following are some concepts to consider in making a layout. It may not be

desirable or economically feasible to incorporate all these in a particular layout.

1. Isolate bedrooms on floors by themselves to reduce the noise level in these rooms.

2. Place the food storage areas near a door leading to a crane laydown area.

3. Place the HVAC units on the roof to save deck space, reduce energy losses, and allow

onshore commissioning.

4. Check that equipment and machinery can be removed for servicing from any mechanical

equipment rooms and that furnishings and other equipment can be moved in and out.

5. In mild climate areas, place external walkways at each level on the ocean sides to

promote human relaxation.

6. While the quarters must be as compact as possible, providing enough space for proper

function, especially in the kitchen and common areas.

7. Use extra spaces for storage. Do not waste space.

In laying out the quarters it is absolutely necessary to provide two escape routes

from every location in the quarters. For offshore facilities the layout of the quarters

relative to potential locations of fires within the facility must be considered. It is not

sufficient to provide two routes from the building if both lead to a common path for

abandoning the platform. Where possible, each escape path should be independent

of others and should lead to a different final location of platform abandonment (e.g.,

boat landing, survival craft, etc.). It may be necessary to provide fire walls to shield

personnel from radiation from a potential fire location.

The final layout must be checked to assure there is room for furnishings. It is always

a good idea to leave extra space in the preliminary layout stage. There is always

need for extra space. Walls have thickness, and they consume floor space. They may

be thicker than normal because of piping such as vents at each toilet or because of

flush-mounted electrical panels. If these things are not considered during preliminary

planning, they can cause the designers serious problems during final planning. Even

the swing of a door can be a problem in the final design.

The Appendices provide example layouts of the individual room types. However, the

designer is limited only by safety considerations, available deck space, and the need

to provide sufficient space for the furnishings. Architectural reference books such as

Architectural Graphic Standards contain detailed dimensions of individual items of

furniture and other fixtures. Some of the more common dimensions are shown in

Table 3.

Table 3a (SI Units): Common Furnishings and Fixture Dimensions

Bunk 91 cm x 213 cm

Locker 46 cm x 46 cm

Writing Desk (for bunk 76 cm x 61 cm

room)

Molded Plastic Chair 51 cm x 56 cm

Office Desk 152 cm x 56 cm

Swivel Chair 69 cm x 71 cm

Living Quarter Layout Page 38 of 69

Sofa (3 person) 229 cm W x 81 cm D

Lounge Chair 76 cm x 76 cm

Range 152 cm x 76 cm plus 33 cm oven door

Fryer 38 cm x 81 in

Serving Table (3 112 cm x 61 cm plus shelves and slides

compartments)

Serving Table (5 183 cm x 61 cm plus shelves and slides

compartments)

Refrigerator (reach-in 22 168 cm x 84 cm plus 61 cm for door

e.f.)

Freezer (reach-in 22 e.f.) 168 cm x 84 cm plus 61 cm for door

Dining Table 61 cm per chair with least dimension, 76

cm

Dishwasher under counter 61 cm x 64 cm plus 48 cm for door

Washing Machine (regular) 65 cm W x 76 cm from wall

Dryer (regular) 71 cm W x 76 cm from wall

Washer/Extractor 91 cm x 122 cm

(commercial)

Dryer/Extractor 91 cm x 122 cm

(commercial)

NOTE: Allow 122 cm in front of washer and dryer equipment for door-swing

and operator.

Showers 91 cm x 91 cm preferred, can go 76 cm x 76

cm

Toilet Compartment 81 cm minimum, 86 cm preferred wide and

137 cm minimum, 145 cm preferred deep

Lavatory top 64 cm deep with lavatories at 61 cm o.c.

based on 46 cm wide fixtures

3 Compartment Sink 145 cm x 56 cm

Ice Cube Maker (61 kg/day) 76 cm x 74 cm

Ice Cube Maker (113 112 cm x 74 cm

kg/day)

Standard Walk-in Refrigerator Start at 183 cm x 183 cm and increase in 30

or Freezer cm increments, both ways

Living Quarter Layout Page 39 of 69

Table 3b (Oilfield Units): Common Furnishings and Fixture Dimensions

Bunk 3 ft x 7 ft

Locker 18 in x 18 in

Writing Desk (for bunk room) 30 in x 24 in

Molded Plastic Chair 20 in x 22 in

Office Desk 60 in x 30 in

Swivel Chair 27 in W x 28 in D

Sofa (3 person) 90 in W x 32 in D

Lounge Chair 30 in x 30 in

Range 60 in x 30 in plus 13 in oven door

Fryer 15 in x 32 in

Serving Table (3 44 in x 24 in plus shelves and slides

compartments)

Serving Table (5 72 in x 24 in plus shelves and slides

compartments)

Refrigerator (reach-in 22 e.f.) 66 in x 33 in plus 24 in for door

Freezer (reach-in 22 e.f.) 66 in x 33 in plus 24 in for door

Dining Table 2 ft per chair with least dimension, 30

in

Dishwasher under counter 24 in x 25 in plus 19 in for door

Washing Machine (regular) 25 1/2 in W x 30 in from wall

Dryer (regular) 28 in W x 30 in from wall

Washer/Extractor (commercial) 36 in x 48 in

Dryer/Extractor (commercial) 36 in x 48 in

NOTE: Allow 48 in. in front of washer and dryer equipment for door-swing and

operator.

Living Quarter Layout Page 40 of 69

Showers 36 in x 36 in preferred, can go 30 in x 30

in

Toilet Compartment 32 in miminum, 34 in preferred wide x 54

in minimum, 57 in preferred deep

Lavatory top 25 in deep with lavatories at 24 in o.c.

based on 18 in wide fixtures

3 Compartment Sink 57 in x 22 in

Ice Cube Maker (135 lbs/day) 30 in x 29 in

Ice Cube Maker (250 lbs/day) 44 in x 29 in

Standard Walk-in Refrigerator or Start at 6 ft x 6 ft and increase in one

Freezer foot increments, both ways

Living Quarter Layout Page 41 of 69

LIST OF APPLICABLE CODES

AAMA Architectural Aluminum Manufacturers Association

ACI American Concrete Institute

AIA American Institute of Architects

AISC American Institute of Steel Construction

AMCA Air Movement and Control Association

ANSI American National Standards Institute

APA American Plywood Association

API American Petroleum Institute

ARI American Refrigeration Institute

ASHRAE American Society of Heating, Refrigeration and Air Conditioning

Engineers

ASTM American Society of Testing Materials

AWS American Welding Society

DOE, UK U.K. Department of Energy, Offshore Supplies Office

DHI Door and Hardware Institute

DNV Det Norske Veritas

FAA Federal Aviation Administration

IES Illumination Engineers Society

ILO International Labor Organization

MMS U.S. Department of Interior Minerals Management Service, OCS

Orders

NASFCA National Automatic Sprinkler and Fire Control Association

NBS National Bureau of Standards

NEC National Electric Code

NEMA National Electric Manufacturers Association

NFPA National Fire Protection Association

NPD Norwegian Petroleum Directorate

NSPC National Standard Plumbing Code

OSHA Occupational Safety & Health Administration

SMACNA Sheet Metal & Air Conditioning Contractors National Association

SOLAS International Convention for the Safety of Life at Sea

Living Quarter Layout Page 42 of 69

SSPC Steel Structures Painting Counsel

TCA Tile Council of America

UL Underwriters Laboratories

USCG United States Coast Guard

Living Quarter Layout Page 43 of 69

NFPA 80 (NATIONAL FIRE PROTECTION ASSOCIATION)

Doors

Maximum Size

Class Single Double Glass Allowance Special Rating

Hardware

A 1.22 m x 3.05 2.44 m x 3.05 None Yes 3 hrs

m m

(4 ft x 10 ft) (8 ft x 10 ft)

B 645 cm2 (100 in2) Yes 1 1/2

Wireglass hrs

C 8361 cm2 (1296 in2) Yes 3/4 hrs

D None Yes 1 1/2

hrs

E 8361 cm2 (1296 in2) Yes 3/4 hrs

Class A Openings: In walls separating buildings or dividing a single building into fire areas.

Class B Openings*: In enclosures of vertical communication through buildings such as entrances to

stairs.

1) Made of approved non-combustible material.

2) Prevents flame from passing through it for 30 minutes if subjected to a

standard test.

Class C Openings: In corridor and room partitions.

Class D Openings*: In exterior walls that are subject to severe fires from outside the building and

smoke for 60 minutes, if subjected to a standard fire test.

Class E Openings: Inexterior walls subject to moderate or light fire exposure.

* Most commonly required ratings in offshore quarters buildings.

Class ALO: 1) Is Class A.

2) Is insulated with approved insulation, panels or covering.

3) If subjected to the standard fire test for 60 minutes has an average

temperature rise on the unexposed side of the insulated surface of less than

121°C (250 °F) above the temperature before the test and a rise of less than

162.8 °C (325 °F) at any point on the unexposed surface including joints.

Partitions

1 hour Metal stud with 15.9 mm (5/8 in) thick fire code sheet rock each side.

2 hour Metal stud with 2 layers of fire code sheet rock each side with staggered

Living Quarter Layout Page 44 of 69

joints.

Ceilings

See manufacturers' specifications.

Exterior Walls

U.S. Coast Guard requirements for walls, ceilings, and floors for marine applications:

Class A: 1) Is made of steel or other equivalent material and

2) Prevents the passage of flame.

Class C: Made of approved non-combustible material.

Applied Fire Coatings and Covers

See manufacturer's specifications.

A "Standard Fire Test" is described as one in which the sample is exposed in a test

furnace to a series of temperature relationships approximately as follows:

At the end of: 5 minutes 37.8 °C (100 °F)

10 minutes 704 °C (1300 °F)

30 minutes 843 °C (1550 °F)

60 minutes 927 °C (1700 °F)

Living Quarter Layout Page 45 of 69

GUIDELINES FOR QUARTERS AREAS

Bedrooms

1. Beds -Provide a steel or wood single bed with mattress, bed lamp, lockable drawer(s),

and curtain for each person accommodated. Use a two-tier system and include a

bookshelf.

2. Lockers -Provide individual lockers with drawer(s) for each person accommodated, with

adequate space to hang clothes.

3. Desks -Provide at least one desk with chair, waste basket and ashtray per bedroom.

4. Miscellaneous -Some rooms may contain mirrors, window curtains, sofa, chairs, table,

bookcase, television, refrigerator, etc.

Kitchen

1. Refrigerators -Size is normally set based on restocking requirements. Approximate

required volume ranges from 0.042 to 0.057 m3 (1.5 to 2 ft3) per person accommodated

in the Gulf of Mexico to 0.071 to 0.085 m3 (2.5 to 3.0 ft3) in the North Sea. Walk-in rather

than reach-in type becomes feasible for larger quarters.

2. Freezers -Same requirements as for refrigerators.

3. Range -Normally marine quality and freestanding with an exhaust hood equipped with a

dry chemical extinguisher system. The range may be equipped with an underhood fryer.

4. Oven -Can be microwave type or large marine quality electric deck oven or preferably,

both.

5. Dishwasher -Should be electrical marine quality with a booster heater to raise water to

82°C (180°F).

6. Garbage Disposal -Size can range from 370 to 1490 W (1/2 to 2 HP).

7. Trash Compactor -Should be electric marine quality with at least a one-year supply of

plastic containers.

8. Tables -Tables are normally stainless steel and can include steam serving table, food

preparation table, dish table, baker's table, utility serving table, and cold pan unit with pie

shelves.

9. Dispensers -Dispensing machines for ice, milk, iced tea, juice, ice cream, coffee, and ice

water may be required.

10. Misc. Appliances -Appliances may include a meat slicer, vegetable peeler, food mixer,

toaster, electric can opener, meat tenderizer, steam cooker, deep fat fryer, and char-

broiler.

11. Cooking Utensils -Cooking utensils may include pots and pans with rack, mixing spoons,

sifters, measuring cups, meat saws, cleavers, rolling pins, spatulas, and mixing bowls.

12. Cabinets -Cabinets are normally stainless steel, overhead and base type.

13. Sinks -Sinks are normally stainless steel marine quality with three compartments all 356

mm (14 in) deep.

14. Hand lavatory.

Living Quarter Layout Page 46 of 69

Dry Storage

The dry storage room should be sized based on re-stocking requirements. Dry

storage areas are normally fully shelved with approximately six heavy duty shelves

from floor to ceiling.

Mess Hall

1. Dining Tables -Dining tables are normally laminated plastic, with sufficient chairs to seat

at least half the number of people being accommodated.

2. Eating Utensils -Settings for approximately twice the number of people being

accommodated are normally required. A setting should include knife, fork, spoon, iced

tea spoon, dinner plate, saucer, salad bowl, soup bowl, cereal bowl, coffee cup, 10 ounce

glass. Serving trays are normally provided for about the total number of people being

accommodated.

3. Tray Slide -Usually a four bar stainless steel tray slide along the entire length of serving

tables is specified.

4. Coat and Hat Rack -Consideration should be given to providing a rack to accommodate

hard hats for total number of people who can be seated.

Laundry and Janitorial Closets

1. Clothes Washers -automatic, multi-cycle, commercial quality washing machines with total

capacity of about one pound per person are normally provided.

2. Clothes Dryers -Clothes dryers are normally vertically stackable and of commercial

quality, with a total capacity equal to that provided by the clothes washers.

3. Ironing Boards -Can be standard size collapsible with steam-type industrial irons and

spare covers and pads.

4. Folding Tables -Folding tables are normally commercial, marine quality with laminated

plastic tops.

5. Cabinets and Shelves -As much overhead capacity of cabinets and shelves should be

provided as can fit in the space allocated.

6. Sinks -Stainless steel sinks with hot and cold water service are normally provided.

Recreation/Lounge/Video

In the video room, seating for about one-third the total number of people being

accommodated is normally provided. Furnishings for recreation areas are arbitrary

and can include the following as examples:

1. Pool tables -With 1 in thick slate top and ten cues, racks, balls, chalk, and cue repair kit.

2. Sofa And Lounge Chairs.

3. Ping Pong Tables -Folding, with extra nets and paddle sets.

4. Stereo Console -Similar to home units.

5. Televisions -635 mm (25 in) or larger color screen.

6. Video Cassette Recorders/Players -Specify tape format (e.g., VHS)

7. Dart boards -Include darts.

8. Games -Chess, Checkers, etc., with game tables and chairs.

Living Quarter Layout Page 47 of 69

9. Sofas -with lamp tables and lamps.

10. Exercise Machines -Could include universal-type floor-mounted machines, pull-up bars

and free weights.

11. Bookshelves.

Medical Clinic

For small quarters buildings the medical area may consist of a first aid cabinet only.

All quarters should have as a minimum a first aid kit, splints, and a burn kit.

Following are examples of items that may be contained in the medical wards of

larger buildings:

1. Pharmaceutical Cabinets -Stainless steel, lockable.

2. Sink -Stainless steel with eyewash fountain

3. Hospital Beds -Stainless steel with fully adjustable mattress position.

4. Desk -With chair, file cabinet, bookcase, lamp, and trash can.

5. Refrigerator -Undercounter type with four cubic ft capacity.

6. Examination Table - With cushion top and stool.

7. Miscellaneous -including clinical instruments, medical supplies, shelves, sterilizers,

weighing machine, and stretchers.

8. Separate Bathroom

Bathrooms/Common Toilet Rooms/Change Rooms

1. Toilets -Number of toilets will vary depending on number of bathrooms adjoining

bedrooms. In general, there should be one toilet for every five to eight people being

accommodated. In certain geographical locations, flush-mounted eastern-style toilets will

have to be provided in place of some of the western-style units.

2. Urinals -Urinals are usually provided in the common toilet areas. The number varies from

the same number of toilets provided in the common areas to twice that number.

3. Shower Stalls -The number of stalls varies for the same reason as does the number of

toilets. In general, provide one stall with door or curtain for every six to ten people being

accommodated.

4. Wash Basins -Provide about the same number of wash basins, each with mirrors and

soap dispenser, as toilets.

5. Miscellaneous -Provide towel racks, toilet paper dispensers, paper towel dispensers,

lockers, benches, etc.

Corridors

The amount of furnishings in corridors is minimal and usually consists of recessed

wall-mounted electric drinking fountains, recessed fire-hose fire extinguisher

cabinets, ash receptacles at each door to exterior, and bulletin board.

Offices

Desk, swivel chairs, side chairs, wastebaskets, file cabinets, hanging file, tables,

bulletin board, and chalk board.

Living Quarter Layout Page 48 of 69

EXAMPLE LAYOUTS

In this section several examples are provided for quarters layouts. These are not

intended as recommendations, but are merely included to show the large variety of

options possible.