Escolar Documentos

Profissional Documentos

Cultura Documentos

1011-EHV OF Cable (Eng)

Enviado por

Bijaya Kumar MohantyDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

1011-EHV OF Cable (Eng)

Enviado por

Bijaya Kumar MohantyDireitos autorais:

Formatos disponíveis

EHV Oil Filled

Cable & Accessories

Company Profile

Having led the establishment of the nation's power network for the half-century, TAIHAN has led the development of

extra high voltage cables since the 1970s and been recognized for the world class technology in Oil Filled

underground cable. We have continued to develop its technology to 275kV and 400kV Oil Filled cables through

advancement of technology and facilities. In step with the ever increasing power consumption and the expansion of

extra high voltage cable demand, we reinforced the production capacity by equipping the 125 meters high VCV Tower,

to produce high quality extra high voltage Oil Filled cable up to 500kV grade. Furthermore, we produce and supply

quality accessories and joints materials for extra high voltage cables. From raw materials, production process,

testing of products, to network design & installation, we have strictly controlled the quality of products and elevated

ourselves to an extra high voltage cable specialist trusted by the world's major markets.

EHV Oil Filled

Cable & Accessories

Introduction of Oil Filled Cable

Through incessant research and development, the excellent functions of Oil Filled cable have been improved since

1900s. Among the many excellent characteristics, some typical ones can be listed as follows.

1 _ No void within insulation and stable electrically

The insulation oil, whose air bubbles and humidity are sufficiently removed by performing degassing treatment, is

impregnated in insulating paper layer which is fully dried under high vacuum beforehand and kept under high degree

of vacuum, and the cable is made accordingly. Since definitely positive pressure is always kept inside of the finished

cable, there is absolutely no void in the cable insulation.

2 _ Operating potential gradient can be large

Since no deterioration takes place in voids in the insulation by ionization as in the case with the solid-type cable, the

operating potential gradient can be large. Therefore, the insulation thickness can be selected as thinn.

3 _ Expansion and contraction of insulation oil due to temperature change can be compensated by the oil tanks

Expansion and contraction of insulating oil, due to change of load under use or due to change of the external

temperature can be fully compensated by the oil tank installed in a suitable position on the cable route. Therefore,

there can be no void in the insulation.

4 _ Cable self-monitoring

The inside of the cable is always kept at positive oil pressure so that no humidity intrudes from the outside in case

damage occurs in the cable sheath, or in the joint box. Further, in case of the insulating oil leaks, the trouble is

detected earlier as the alarm device actuates and it is possible to repair before occurrence of full-scale trouble in the

cable system.

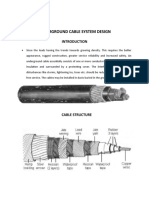

Structure of Oil Filled Cable

Oil Duct

Oil Duct Conductor

Conductor Conductor Shielding Layer

Conductor Shielding Layer Kraft Paper Insulation

Kraft Paper Insulation Insulation Shielding Layer

Insulation Shielding Layer Lead Alloy Sheath

Corrugated Aluminum Sheath Metallic Tape Reinforce Layer

PE or PVC Over-Sheath PE or PVC Over-Sheath

Corrugated Aluminum Sheath Cable Lead Alloy Sheath Cable

Oil Duct

Conductor

Segment Tape

Conductor Screen

Insulation

Insulation Screen

Protective Layer

Metallic Sheath

Anti-corrosion Layer

Serving

PPLP Cable

2 Taihan Electric Wire

EHV Oil Filled

Cable & Accessories

Construction Date

Copper Conductor 66kV ~ 400kV

Single Core Cable

Conductor Approx. Approx. Corrugated AL Sheath Type Lead Sheath Type

Dia.of Dia.of Cu / Kraft (orPPLP) / CAS / PVC [PE] Cu / Kraft (orPPLP) / LEAD / PVC [PE]

Voltage Thick . of

Conductor Insulation Insulation

Nominal Thick .of

Area Shape Shield Shield Metallic Thick . of Overall Dia. Approx

Weight

. Thick .of

Metallic Thick . of Overall Dia. Approx

Weight

.

[mm2] [mm] [mm] sheath Jacket [ton] sheath Jacket [ton]

66 1000 H.C 43.12 7.1 58.32 2.0 4.5 80.84 14.7 - - - -

110 300 H.C 27.02 10.0 48.16 - - - - 2.7 4.0 64.26 11.5

110 400 H.C 33.7 10.2 55.02 - - - - 2.8 3.7 70.76 15.0

132 630 H.C 36.02 10.35 57.7 2.7 4.5 84.4 12.0 - - - -

132 900 H.C 41.61 10.35 63.3 2.5 4.5 88.7 14.9 - - - -

150 800 H.C 39.62 14.22 69.28 - - - - 3.55 4.2 98.12 25.3

154 600 H.C 36.12 11.88 61.06 1.9 6.0 78.3 12.6 - - - -

154 1200 S.H 47.32 12.83 74.26 2.2 4.5 89.1 19.5 - - - -

154 2000 S.H 59.02 12.83 86.0 2.4 4.5 113.1 29.0 - - - -

161 1500 S.H 52.4 13.5 80.6 2.3 4.5 107.1 23.2 - - - -

161 2000 S.H 59.42 13.5 87.52 2.41 4.5 114.46 28.4 - - - -

230 630 H.C 36.96 20.3 78.64 2.7 5.5 109.68 16.8 - - - -

230 1000 S.H 44.76 20.3 86.44 2.7 5.5 117.44 14.9 - - - -

230 2000 S.H 59.06 20.3 100.74 2.7 5.5 131.84 32.8 - - - -

230 2500 S.H 65.86 20.3 107.54 2.8 5.5 139.19 40.3 - - - -

275 500 H.C 33.96 19.9 74.72 2.7 6 105.73 16.5 - - - -

275 1000 S.H 45.06 19.8 85.82 - - - - 3.8 5.0 107.04 31.5

275 1600 S.H 54.06 19.8 94.82 - - - - 4.3 5.0 116.98 41.5

275 2000 S.H 59.26 19.8 99.84 2.7 8 135.25 34.2 - - - -

275 2500 S.H 65.76 19.8 106.92 2.8 4 156.7 40.7 - - - -

345 600 H.C 36.36 22.9 82.96 2.3 6 112.46 18.6 - - - -

345 1200 S.H 48.56 22.9 95.06 2.5 6 125.8 26.6 - - - -

345 2000 S.H 59.86 22.56 106.36 2.7 6 137.7 35.9 - - - -

400 2500 S.H 66.56 25.0 118.52 3.0 5.5 151.5 42.5 - - - -

400 2500 S.H 66.56 25.0 118.52 3.0 6 152.7 44.4 - - - -

※ C.C : Circular Compacted H.C : Hollow Compacted S.H : Segmental Hollow PPLP Cable

Three Core Cable

Conductor Approx. Approx. Corrugated AL Sheath Type Lead Sheath Type

Dia.of Dia.of Cu / Kraft (orPPLP) / CAS / PVC [PE] Cu / Kraft (orPPLP) / LEAD / PVC [PE]

Voltage Thick . of

Conductor Insulation Insulation

Nominal Thick .of

Area Shape Shield Shield Metallic Thick . of Overall Dia. Approx

Weight

. Thick .of

Metallic Thick . of Overall Dia. Approx

Weight

.

[mm2] [mm] [mm] sheath Jacket [ton] sheath Jacket [ton]

69 305 H.C 21.52 6.86 37.18 2.3 3.5 105.3 17.5 - - - -

132 340 C.C 22.72 10.6 45.12 2.6 4.0 125.9 22.8 - - - -

132 400 C.C 24.62 10.6 46.82 2.7 4.0 130.3 25.1 - - - -

150 240 C.C 25.12 14.22 54.78 - - - - 3.55 4.2 80.62 16.0

154 200 H.C 17.52 12.4 43.46 2.5 4.5 112.4 17.4 - - - -

154 250 H.C 19.52 12.0 44.46 2.6 4.5 124.6 19.3 - - - -

154 325 H.C 22.22 12.0 47.16 2.7 4.5 132.0 22.6 - - - -

※ C.C : Circular Compacted H.C : Hollow Compacted

EHV Oil Filled Cable & Accessories 3

EHV Oil Filled

Cable & Accessories

Accessories

Joint & Termination

Straight Through Joint (NJ, IJ)

Straight through Joint is used for jointing cables electrically and hydraulically. This joint has same quality as or

better than cable itself. Insulated joint is almost same as straight through joint and the difference between them

is to put an insulator flange at the center of copper casing. This box is used for jointing cable and at the same

time for insulating metal sheath from the other metal sheath to reduce sheath voltage to safety level.

IJ Reinforced Insulation Layer

Copper Case Epoxy Insulator Anti-Corrosion Layer

Conductor Sleeve

ØD

Nominal Area of Dimension (mm)

Rated Voltage (kV)

Conductor (mm2) L D

Less than 1000 1300 130

110 - 161

1200 ~ 2500 1530 180

220 - 287 Less than 2500 2000 200

330 - 400 Less than 2500 2400 240

Stop Joint (SJ, SIJ)

This joint is used for dividing the oil feeding section in case that route lenght is too long or oil pressure change is

too excessive at static or transient operation. This joint is also used for connecting the cables electrically and at

the same time, separating the oil feeding section of both cables. Insulated stop joint has an epoxy insulator to

divide the metal sheath section.

SJ Insulation Layer

Epoxy Stop Unit

Copper Case Earth Terminal Oil Connector Anti-Corrosion Layer

Conductor Sleeve

ØD

Nominal Area of Dimension (mm)

Rated Voltage (kV)

Conductor (mm2) L D

110 - 161 Less than 2500 2900 250

220 - 287 Less than 2500 3400 350

330 - 400 Less than 2500 4100 350

4 Taihan Electric Wire

Transition Joint (TNJ, TIJ)

This joint is used for connecting the oil filled cable and XLPE cable. On the side of XLPE cable, we have applied

prefabricated type joint to secure the confidence. The stress cone is made of EPDM and in order to maintain the

surface pressure between stress cone and XLPE or epoxy unit, we adopt springs. On the other side, we have used

epoxy bell mouth to control the electric field.

CV SIDE Stress Relief Cone O.F SIDE

Stress Relief Cone Insulation Paper Layer Anti-Corrosion Layer

Connector Epoxy Bell-Mouth

Earth Terminal

ØD

Dimension (mm)

Rated Voltage (kV)

L D

110 - 161 1750 320

220 - 287 1955 320

Outdoor Sealing End

ØD Sealing end is used for sending and taking electric power into or

Connector out of underground cable. This sealing end has stress relief cone

Corona Shield formed of wide width paper and above it, there is a condenser

cone formed of paper and metal foil or a bellmouth made of

epoxy resin to control the electric field. Connector is fastened to

ØE

the cable condutor by compression method and flexible terminal

lug is placed between the conductor and the lead wire to avoid

Porcelain Bushing applying unnecessary external force against the sealing end.

A B

Rated Dimension (mm)

Voltage

(kV) A B C D E

Epoxy Bell-Mouth 110 1480 1725 435 360 315

or Condenser Cone

161 1830 2075 435 360 470

220 2940 3290 500 480 470

Copper Tube

287 3350 3700 500 480 470

Earth Terminal C 400 3975 4250 600 550 510

Oil Connector

Anti-Corrosion Layer

EHV Oil Filled Cable & Accessories 5

EHV Oil Filled

Cable & Accessories

Accessories

Joint & Termination

SF6 Gas Immersed Sealing End

ØA This sealing end is used for terminating the underground cable

Upper Metal for the SF6 gas switchaear. Epoxy bushings are needed to

Connector

insulate between the earth potential parts and the high voltage

parts. The inner construction of this sealing end is similar to that

of an indoor and outdoor sealing end except that this sealing end

Epoxy Bushing E is completely enclosed and immersed in gas to prevent dust from

ØC

collecting and to secure the electric capability, etc.

Insulation Layer

ØB

Epoxy Bell-Mouth

or Condenser Cone Rated Dimension (mm)

Voltage

Fixing Metal (kV) A B C D E

110 - 161 112 220 298 320 757

Earth Terminal

220 - 287 202 4801 559 582 960

Copper Tube 330 - 400 252 540 617 640 1400

Oil Immersed Sealing End

ØF The construction of this sealing end is similar to that of an indoor

and outdoor sealing end except that the sealing end is completely

Corona Shield

enclosed and immersed in oil to prevent dust from collecting,

Connector and the size of Oil Immersed Sealing End is much smaller than

the one of Outdoor Sealing End. This type of sealing end is for

connecting underground cable to transformer.

AB C

Bushing

Rated Dimension (mm)

Voltage

ØG (kV) A B C D E F G H

ØH 110 - 161 990 1170 1260 585 375 340 320 380

Lower Shield 220 - 362 1350 1550 1700 900 420 390 420 550

Flange

Epoxy Insulator

Copper Tube D

Earth Terminal

Oil Connector

6 Taihan Electric Wire

EHV Oil Filled

Cable & Accessories

Certificates

The outstanding quality of TAIHAN EHV Oil Filled cables are verified by internationally accredited certification

institutes.

Type Test List of Extra High Voltage Oil Filled Cable & Accessories

No. Description of Cable & Accessories Institute Date Specification Results of Test BIL (kV)

1 154kV Oil Filled Cable 1C x 600sqmm ( CU) KERI Aug-78 KEPCO Good 750

2 154kV Oil Filled Cable 1C x 1200sqmm ( CU) KERI Jul-97 KEPCO Good 750

3 154kV Oil Filled Cable 1C x 2000sqmm ( CU) KERI Oct-83 KEPCO Good 750

4 154kV Oil Filled Cable 3C x 250sqmm ( CU) KERI Dec-84 POSCO Good 750

5 154kV Oil Filled Cable 3C x 200sqmm ( CU) KERI Dec-84 POSCO Good 750

6 150kV Oil Filled Cable 1C x 1200sqmm (CU) KEMA May-85 IEC 141-1 Good 750

7 150kV Oil Filled Cable 1C x 800sqmm (CU) KEMA May-85 IEC 141-1 Good 750

8 132kV Oil Filled Cable 1C x 800sqmm (CU) KENNEDY & DONKIN Jul-85 IEC 141-1 Good 650

9 154kV Oil Filled Cable 3C x 325sqmm ( CU) KERI Nov-85 POSCO Good 750

10 154kV Oil Filled Cable 1C x 600sqmm ( CU) KERI Aug-86 KEPCO Good 750

11 154kV Oil Filled Cable 1C x 1200sqmm ( CU) KERI Aug-86 KEPCO Good 750

12 154kV Oil Filled Cable 1C x 2000sqmm ( CU) KERI Aug-86 KEPCO Good 750

13 132kV Oil Filled Cable 1C x 960sqmm ( CU) CROWN AGENTS Nov-87 IEC 141-1 Good 650

14 150kV Oil Filled Cable 1C x 600sqmm ( CU) NEW-JEC Dec-88 IEC 141-1 Good 750

15 154kV Oil Filled Cable 1C x 2000sqmm ( CU) KERI Jan-89 KEPCO Good 750

16 150kV Oil Filled Cable 1C x 800sqmm ( CU) NEW-JEC May-89 IEC 141-1 Good 750

17 154kV Oil Filled Cable 1C x 2000sqmm ( CU) KERI May-90 KEPCO Good 750

18 345kV Oil Filled Cable 1C x 2000sqmm ( CU) KERI Oct-89 KEPCO Good 1300

19 345kV Oil Filled Cable 1C x 1600sqmm ( CU) KERI May-90 KEPCO Good 1300

20 345kV Oil Filled Cable 1C x 1400sqmm ( CU) KERI Oct-91 KEPCO Good 1300

21 275kV Oil Filled Cable 1C x 2000sqmm ( CU) KEMA Sep-91 IEC 141-1 Good 1050

22 345kV Oil Filled Cable 1C x 1200sqmm ( CU) KERI Sep-92 KEPCO Good 1300

23 345kV Oil Filled Cable 1C x 2000sqmm ( CU) KERI Aug-92 KEPCO Good 1300

24 150kV Oil Filled Cable 1C x 240sqmm ( CU) PLN Dec-93 IEC 141-1 Good 750

25 345kV Oil Filled Cable 1C x 2000sqmm ( CU) KERI Aug-92 KEPCO Good 1300

26 275kV Oil Filled Cable 1C x 2000sqmm ( CU) KEMA Dec-99 IEC 141-1 Good 1050

27 230kV Oil Filled Cable 1C x 2000sqmm ( CU) SGS/SPPG Mar-05 IEC 60141-1 Good 1050

28 400kV PPLP Oil Filled Cable 1C x 2500sqmm ( CU) TAIHAN Dec-05 IEC 60141-1 Good 1550

29 230kV Oil Filled Cable 1C x 2500sqmm ( CU) SGS/SPPG Feb-06 IEC 60141-1 Good 1050

* KERI : Korea Electrotechnology Research Institute

* KEPCO : Korea Electricity Power Company (The National Power Utility in Korea)

* POSCO : Pohang Steel Corporation

EHV Oil Filled Cable & Accessories 7

Você também pode gostar

- Unir-Cables SubmarinosDocumento14 páginasUnir-Cables SubmarinosManuel NavaAinda não há avaliações

- Fujikura MV Power Cable CatalogueDocumento94 páginasFujikura MV Power Cable Catalogueezpme0% (1)

- Gaon - Cables and Wires - CatalogDocumento18 páginasGaon - Cables and Wires - Catalogphyo7799100% (2)

- 35kv Xlpe Phelps DodgeDocumento2 páginas35kv Xlpe Phelps DodgeCommercial One100% (2)

- 35kv Xlpe Phelps Dodge PDFDocumento2 páginas35kv Xlpe Phelps Dodge PDFRodney LanagAinda não há avaliações

- Tds New 1c Cu 35kvDocumento2 páginasTds New 1c Cu 35kvButch BuciaAinda não há avaliações

- Tds New 1c Cu 25kvDocumento2 páginasTds New 1c Cu 25kvButch BuciaAinda não há avaliações

- MV-90 35 KV 133% I.L. UL Certificate: DescriptionDocumento4 páginasMV-90 35 KV 133% I.L. UL Certificate: Descriptionjhuayre-1Ainda não há avaliações

- Medium Voltage MZDocumento86 páginasMedium Voltage MZsujiAinda não há avaliações

- OCI - MV Power CableDocumento86 páginasOCI - MV Power CableSubhiah CAinda não há avaliações

- Ras Markaz Crude Oil Park: Description of Manufacturing FacilitiesDocumento4 páginasRas Markaz Crude Oil Park: Description of Manufacturing FacilitiesANIL PLAMOOTTILAinda não há avaliações

- Nkt-06086 Katalog HochspannungsgarniturenDocumento20 páginasNkt-06086 Katalog Hochspannungsgarniturenrjk941-1Ainda não há avaliações

- LS EHV Cable System EN 0907 PDFDocumento64 páginasLS EHV Cable System EN 0907 PDFbalwant_negi7520Ainda não há avaliações

- 06 CableDocumento8 páginas06 CableYan MALONGAAinda não há avaliações

- Continuous Vulcanization Cured Rubber - Versus - Mold (Lead) Cured Rubber - for-Extra-Heavy Duty (EHD) Mining Cables JacketsDocumento7 páginasContinuous Vulcanization Cured Rubber - Versus - Mold (Lead) Cured Rubber - for-Extra-Heavy Duty (EHD) Mining Cables JacketsShubham BaderiyaAinda não há avaliações

- Catalogue: Networking Cables CATV Co-Axail Cables CCTV Cables Fire Alarm Cables Data CablesDocumento20 páginasCatalogue: Networking Cables CATV Co-Axail Cables CCTV Cables Fire Alarm Cables Data CablesNoble Firetech Engineers Pvt LtdAinda não há avaliações

- High Voltage (HV) Outdoor Termination OHVT-145C (3A) : UP TO 145 KVDocumento3 páginasHigh Voltage (HV) Outdoor Termination OHVT-145C (3A) : UP TO 145 KVAntonio Gresia100% (1)

- Multicore Armoured Shaped Conductor - XLPE InsulatedDocumento1 páginaMulticore Armoured Shaped Conductor - XLPE InsulatedMohamed InshafAinda não há avaliações

- Underground Cables: Presented by Anikendu MaitraDocumento55 páginasUnderground Cables: Presented by Anikendu MaitraAnikendu MaitraAinda não há avaliações

- UndergroundcablesDocumento31 páginasUndergroundcablesHARIS AHAMMEDAinda não há avaliações

- High Voltage (HV) Outdoor Termination OHVT-145C (2A) : UP TO 145 KVDocumento3 páginasHigh Voltage (HV) Outdoor Termination OHVT-145C (2A) : UP TO 145 KVAntonio GresiaAinda não há avaliações

- MV Cables Catalogue 2022 WebDocumento43 páginasMV Cables Catalogue 2022 WebkanarendranAinda não há avaliações

- Single Conductor 25-35KV Shielded MV-105Documento5 páginasSingle Conductor 25-35KV Shielded MV-105villanueva.texsiAinda não há avaliações

- 44a0111-20-0 44a0111-20-9 44a0111-22-0 44a0111-22-9 44a0111-24-9 44a1121-22-0/9-9 44a0111-18-0 44a0111-26-2Documento6 páginas44a0111-20-0 44a0111-20-9 44a0111-22-0 44a0111-22-9 44a0111-24-9 44a1121-22-0/9-9 44a0111-18-0 44a0111-26-2عبدالغني القباطيAinda não há avaliações

- Fundamentals of Shielded MV Power CableDocumento3 páginasFundamentals of Shielded MV Power CableLedred1Ainda não há avaliações

- Brosur LS-VINA HV - CatalogueDocumento36 páginasBrosur LS-VINA HV - CatalogueDian EkaAinda não há avaliações

- MV Cable Jointing & TerminationDocumento34 páginasMV Cable Jointing & Terminationsinglaamit80% (20)

- Fiber Optic-Supreme PDFDocumento17 páginasFiber Optic-Supreme PDFdHanE anasAinda não há avaliações

- Cable LV 2009Documento95 páginasCable LV 2009Yulian Dea ZollaAinda não há avaliações

- Underground Cable System DesignDocumento25 páginasUnderground Cable System DesignJayvee BustardeAinda não há avaliações

- Jointfill - Cable Jointing Kit - Cast ResinDocumento2 páginasJointfill - Cable Jointing Kit - Cast ResinVenkata ReddyAinda não há avaliações

- Presented By:: Osama NaseemDocumento16 páginasPresented By:: Osama NaseemLloyd Dackz ArenasAinda não há avaliações

- Underground Cables PDFDocumento4 páginasUnderground Cables PDFSukhpal SinghAinda não há avaliações

- Telefonika Katalog MV-105 Short Version 2021 03 18 v2Documento8 páginasTelefonika Katalog MV-105 Short Version 2021 03 18 v2Prabhat RanjanAinda não há avaliações

- NA2XSEBY 3x (35 300) MM 12 20kVDocumento4 páginasNA2XSEBY 3x (35 300) MM 12 20kVKontraktor Panel SceAinda não há avaliações

- Fast Cables LTD.: Manufacturing ProcessDocumento7 páginasFast Cables LTD.: Manufacturing ProcessYaredAinda não há avaliações

- Cable and InsulatorsDocumento43 páginasCable and InsulatorsVarun KumarAinda não há avaliações

- TQJNFV 6 WR 8 Z Xe LTMeubeDocumento28 páginasTQJNFV 6 WR 8 Z Xe LTMeubeJohan MayaAinda não há avaliações

- FLRY11Y CablesDocumento1 páginaFLRY11Y CablesKristaAinda não há avaliações

- SC Fire Resistant Catalogue 2020Documento16 páginasSC Fire Resistant Catalogue 2020Phua Shang YangAinda não há avaliações

- Pipe Wrap Insulation: Technical Data Sheet Product CodeDocumento4 páginasPipe Wrap Insulation: Technical Data Sheet Product CodegemazizAinda não há avaliações

- 132KVC-technical Sep PDFDocumento80 páginas132KVC-technical Sep PDFOnur ÖztürkAinda não há avaliações

- 230 KV E HXLP - Pdic01148Documento2 páginas230 KV E HXLP - Pdic01148José Francisco LozadaAinda não há avaliações

- FLR4G11Y-FL4G11Y CablesDocumento1 páginaFLR4G11Y-FL4G11Y CablesVijay KarthikeyanAinda não há avaliações

- XLPE Power Cable enDocumento10 páginasXLPE Power Cable enYizhar Dwi GogaAinda não há avaliações

- Elastimold Cable Terminations High Voltage Silicone Shrink FitDocumento7 páginasElastimold Cable Terminations High Voltage Silicone Shrink FitCarpe diemAinda não há avaliações

- 501/453/RAC/L: Cable Gland Selection TableDocumento2 páginas501/453/RAC/L: Cable Gland Selection TablesedcAinda não há avaliações

- 1.tki RPL c3 Silb Xi Pemodelan PL RevDocumento51 páginas1.tki RPL c3 Silb Xi Pemodelan PL RevDeni RidwanAinda não há avaliações

- EHV CatalogueDocumento29 páginasEHV Cataloguefigv1975Ainda não há avaliações

- Polycab LDC HDC Composite CatalogueDocumento7 páginasPolycab LDC HDC Composite CatalogueIon VairamuthuAinda não há avaliações

- Medium Voltage Cable-File PDFDocumento66 páginasMedium Voltage Cable-File PDFPrasetiyo HanantoAinda não há avaliações

- Data Sheet YCP EN 0420Documento1 páginaData Sheet YCP EN 0420Fareed KhanAinda não há avaliações

- CablesDocumento36 páginasCablesPrasann KatiyarAinda não há avaliações

- Kabel Katalog Airfield LightingDocumento10 páginasKabel Katalog Airfield LightingHimawan Sigit NugrohoAinda não há avaliações

- CableDocumento24 páginasCableGnanesh GAinda não há avaliações

- Building Cables WiresDocumento88 páginasBuilding Cables WiresReem Ahmed KhalilAinda não há avaliações

- FLALRY CablesDocumento1 páginaFLALRY CablesVijay KarthikeyanAinda não há avaliações

- FLALRY CablesDocumento1 páginaFLALRY CablesKristaAinda não há avaliações

- Electronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionNo EverandElectronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionAinda não há avaliações

- 3.sheath Induced Voltage - 10387-InDDocumento11 páginas3.sheath Induced Voltage - 10387-InDBijaya Kumar Mohanty100% (1)

- 110kv Ehv Cable - GtpsDocumento2 páginas110kv Ehv Cable - GtpsBijaya Kumar MohantyAinda não há avaliações

- Technical Data & Curves For BFP Motor (MDL#BPL-027) - R3 - Cat A Approved DTD 16.03.2011Documento12 páginasTechnical Data & Curves For BFP Motor (MDL#BPL-027) - R3 - Cat A Approved DTD 16.03.2011Bijaya Kumar MohantyAinda não há avaliações

- Minimum Clearance in SubstationDocumento33 páginasMinimum Clearance in SubstationBijaya Kumar MohantyAinda não há avaliações

- Guide To Forms of SeparationDocumento32 páginasGuide To Forms of SeparationBijaya Kumar MohantyAinda não há avaliações

- Nema 250 2008Documento48 páginasNema 250 2008Bijaya Kumar MohantyAinda não há avaliações

- NEMA MG1 2006 Motors and GeneratorsDocumento592 páginasNEMA MG1 2006 Motors and GeneratorsBijaya Kumar Mohanty100% (1)

- Pip Elsgs11 2014Documento6 páginasPip Elsgs11 2014Bijaya Kumar MohantyAinda não há avaliações

- GST002 Rev.1 Full VersionDocumento208 páginasGST002 Rev.1 Full Versiondiegofer1Ainda não há avaliações

- Substation Maintenance - 1Documento35 páginasSubstation Maintenance - 1Semifallen100% (3)

- 3590 - Precision Potentiometer: FeaturesDocumento1 página3590 - Precision Potentiometer: FeaturesAsanka Niroshan SamaranayakeAinda não há avaliações

- CATALOGO EVOLIS 24kvDocumento80 páginasCATALOGO EVOLIS 24kvOgaihtsantosAinda não há avaliações

- 3AP1-FI 245 KVDocumento2 páginas3AP1-FI 245 KVLucas Gabriel CunhaAinda não há avaliações

- 71908Documento4 páginas71908GustavoJanitoAinda não há avaliações

- IEEE Standard Terminology For Power and Distribution TransformersDocumento56 páginasIEEE Standard Terminology For Power and Distribution TransformershoangtinbkAinda não há avaliações

- 220KV CVT 0 2 Metering AccuracyDocumento12 páginas220KV CVT 0 2 Metering AccuracyJAY PARIKHAinda não há avaliações

- Self Powered Relay-CGI14SEnglishDocumento16 páginasSelf Powered Relay-CGI14SEnglishjoydip.dgp2152100% (2)

- IEEE Standard Requirements, Terminology, and Test Code For Bushings For DC ApplicationsDocumento29 páginasIEEE Standard Requirements, Terminology, and Test Code For Bushings For DC ApplicationsCarlos Enrique DíazAinda não há avaliações

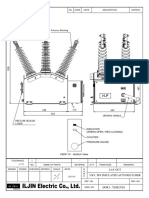

- 33kV 630A Gas Recloser LayoutDocumento6 páginas33kV 630A Gas Recloser LayoutBahaj99Ainda não há avaliações

- VEF-15-09 Catalog DetailsDocumento2 páginasVEF-15-09 Catalog DetailsViswa BhuvanAinda não há avaliações

- Beni-Suef Transformer Erection Plan PDFDocumento23 páginasBeni-Suef Transformer Erection Plan PDFMohamedAinda não há avaliações

- HSN Codes Electrical InsulatorDocumento2 páginasHSN Codes Electrical InsulatorDevAinda não há avaliações

- Flusarc 36: Gas-Insulated SwitchgearDocumento76 páginasFlusarc 36: Gas-Insulated SwitchgearJoey Real CabalidaAinda não há avaliações

- Haryana Vidyut Prasaran Nigam Limited: SPECIFICATION No. HGD/S-67/DGMS-171 (APRIL-2017)Documento37 páginasHaryana Vidyut Prasaran Nigam Limited: SPECIFICATION No. HGD/S-67/DGMS-171 (APRIL-2017)samkarmakar2002Ainda não há avaliações

- Dead-Tank Circuit-Breakers For 72.5 KV Up To 550 KV: Fig. 12: SPS2 / 3AP1 DT 145 KVDocumento7 páginasDead-Tank Circuit-Breakers For 72.5 KV Up To 550 KV: Fig. 12: SPS2 / 3AP1 DT 145 KVMichael DavisAinda não há avaliações

- KVPS RAO - Sub-Station Experience-23Documento20 páginasKVPS RAO - Sub-Station Experience-23Hari HaranAinda não há avaliações

- Anexo C - Nexans-Euromold-MV-Separable-Connectors-and-Bushings - Interface-E PDFDocumento20 páginasAnexo C - Nexans-Euromold-MV-Separable-Connectors-and-Bushings - Interface-E PDFAnonymous zd86j8vVAinda não há avaliações

- 33KV Capacitor Bank PDFDocumento65 páginas33KV Capacitor Bank PDFnilesh100% (1)

- Standard Specification For Transformers For Solar Park Pooling StationDocumento260 páginasStandard Specification For Transformers For Solar Park Pooling Station400KVAinda não há avaliações

- Transformer Diagnostics in The Practical FieldDocumento15 páginasTransformer Diagnostics in The Practical Fieldlbk50Ainda não há avaliações

- DGA Oil SamplingDocumento6 páginasDGA Oil Samplinghino_kaguAinda não há avaliações

- Combined Instrument Transformers Ivokt TMCDocumento8 páginasCombined Instrument Transformers Ivokt TMCRamzan100% (1)

- 14 Samss 531Documento23 páginas14 Samss 531HatemS.MashaGbehAinda não há avaliações

- 220kV GISDocumento20 páginas220kV GISsauravkafle1100% (1)

- CS-C28GFQ Cu-C28gfqDocumento44 páginasCS-C28GFQ Cu-C28gfqPepz Rosauro NavarraAinda não há avaliações

- 200 A Loadbreak Connectors: 25 KV Posi-Break Elbow and CapDocumento19 páginas200 A Loadbreak Connectors: 25 KV Posi-Break Elbow and CapCARHUAMACA PASCUAL mhAinda não há avaliações

- Alstom Otcf Ansi WebDocumento8 páginasAlstom Otcf Ansi WebReji KurianAinda não há avaliações