Escolar Documentos

Profissional Documentos

Cultura Documentos

FastMIG - Service Manual

Enviado por

MetCESDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

FastMIG - Service Manual

Enviado por

MetCESDireitos autorais:

Formatos disponíveis

Service manual

v. 1.0

FastMig

KM 300 KMS 300

KM 400 KMS 400

KM 500 KMS 500

MF 29

MF 33

MSF 53

MSF 55

MSF 57

Downloaded from www.Manualslib.com manuals search engine

Table of contents

Technical data

Fastmig KM / MF............................................................................. 3

FastMig KMS / MFS........................................................................ 4

Fastmig KMS / MVU........................................................................ 5

Main circuit diagram

KM.................................................................................................... 6-7

MF.................................................................................................... 8

KMS................................................................................................. 9

MSF................................................................................................. 10

KM / MVU........................................................................................ 11

KMS / MVU..................................................................................... 12

Block diagram.................................................................................................... 13

Main circuit card Z001 KM / KMS

Operating diagram........................................................................... 14

Operation principle.......................................................................... 15

Connectors...................................................................................... 16

Operational measurings.................................................................. 17

Capacitor card Z002

Operating diagram.......................................................................... 18

Connectors..................................................................................... 18

Secondary rectifier card Z003

Operating diagram.......................................................................... 19

Connectors..................................................................................... 19

Operational measurings................................................................. 19

Control card A001

Operating diagram.......................................................................... 20

Connectors..................................................................................... 21-22

Operation of the LEDs on control card........................................... 22

Motor control card A002

Operating diagram.......................................................................... 23

Connectors..................................................................................... 24

ID-chip card A002 (MSF)

Connectors..................................................................................... 25

Panel card P001

Operating diagram.......................................................................... 26

Connectors..................................................................................... 26

Error codes........................................................................................................ 27

Setup menu....................................................................................................... 28

Wire feed speed calibration / KM.................................................................... 29-30

Structure

KM / KMS....................................................................................... 31-32

MF.................................................................................................. 33

MFS................................................................................................ 34

IGBT testing....................................................................................................... 35

IGBT replacing................................................................................................... 36

2

Downloaded from www.Manualslib.com manuals search engine

Technical data

FastMig KM / MF

Downloaded from www.Manualslib.com manuals search engine

Technical data

FastMig KMS / MSF

Downloaded from www.Manualslib.com manuals search engine

Technical data

FastMig KMS / MVU

Downloaded from www.Manualslib.com manuals search engine

Main circuit diagram

L001 Z002 Z001 T001 Z003

Choke Capasitor card Main circuit Main transformer Secondary card

card

R001 S001 PTC PTC PTC L001 RC001

Varistors Main switch Secondary choke RC-protection

G003

Diode bridge

T002 M001 A001 F001 H001 / 002 A002 P001

Aux. transformer Cooling fan Control card Fuse 6,3 A Leds Control card Panel card

KM-power sources (A002) also contain circuitry that is needed for wire feeding motor driving and reading of the

potentiometer of the simple wire feeder (MF or other).

6

Downloaded from www.Manualslib.com manuals search engine

Main circuit diagram KM

Downloaded from www.Manualslib.com manuals search engine

Main circuit diagram MF

Downloaded from www.Manualslib.com manuals search engine

Main circuit diagram KMS

Downloaded from www.Manualslib.com manuals search engine

Main circuit diagram MSF

10

Downloaded from www.Manualslib.com manuals search engine

Main circuit diagram KM / MVU

11

Downloaded from www.Manualslib.com manuals search engine

Main circuit diagram KMS / MVU

12

Downloaded from www.Manualslib.com manuals search engine

Block diagram

Control card A001 Main circuit card Z001

•Microcontroller

•PWM circuit •EMI filtering

•Secondary voltage measurement •Three phase rectifier (V6)

•Secondary current measurement •Switching-ON transient suppression

•IGBT driver •Power Stage

•Auxiliary device connection •Current transformer (T1)

•Auxiliary power supply

•Machine size jumpers(J1, J2)

•Primary current limit jumpers(J3, J4, J5)

•Operational jumpers

•LED’s

•Water cooler connection

Control card A002 Capasitor card Z002

•WF-motor control

•Connection to the panel card P001 •Energy storage

•Remote controller connection •Discharging

•MIG gun connection

•Solenoid valve connection

•Fuse

Panel card P001 Secondary card Z003

•Main micro controller •Rectifying

•User interface (buttons, •Snubber

potentiometers, displays, LED’s) •Protection against HF

•Connection to the A002

13

Downloaded from www.Manualslib.com manuals search engine

Main circuit card Z001 KM / KMS

DC-link (+)

IGBT gates

From main

switch

Main transformer

primary coil

DC-link (-)

Operating diagram

- EMI filtering

- Three phase rectifier (V6)

- Switching-ON transient suppression

- Power Stage

- Current transformer (T1)

14

Downloaded from www.Manualslib.com manuals search engine

Main circuit card Z001

Operation principle

Approx.. + 570 V

G1 G2

G5

UG1 UG2

L1

UT1

UG5 UL1

G3 G4

UG3 UG4

UG1

t

UG2

t

UG3

t

UG4

t

UT1

UG5

t

UL1

t

When IGBT-transistors G1 and G4 conduct, there is a positive voltage UT1 in main transformer T1 primary

and when IGBT-transistors G2 and G3 conduct there is a negative voltage UT1 in main transformer primary.

Power is adjusted by changing the IGBT timings (PWM)

15

Downloaded from www.Manualslib.com manuals search engine

Main circuit card Z001

Connectors

X19 X21

X15

X14

X11

X6 X10

X37 X13

X12

X36 X9

X8

X7

X20

X17 X18

X40

X16 X41

X29

X3

X2

X4 X1 X5

Z001 connectors / signals Z001 connectors / signals

X1 Main switch X16 Primary choke

X2 Main switch X17 Primary choke

X3 Main switch X18 DC-link voltage (+)

X4 Chassis ground X19 DC-link voltage (+)

X5 Chassis ground X20 DC-link voltage (-)

X6 Main transformer X21 DC-link voltage (-)

X7 Main transformer X29 Chassis ground

X8 IGBT gates and emitters X36 Current transformer secondary

X9 IGBT gates and emitters X37 Current transformer secondary

X10 IGBT gates and emitters X40 Auxiliary transformer

X11 IGBT gates and emitters X41 Auxiliary transformer

X12 IGBT gates and emitters

X13 IGBT gates and emitters

X14 IGBT gates and emitters

X15 IGBT gates and emitters

16

Downloaded from www.Manualslib.com manuals search engine

Main circuit card Z001

Operational measurings

A. B.

Main transformer T001 primary voltage, IGBT-gate pulses, set values 50 A/16,5 V

set values 50 A/16,5 V

17

Downloaded from www.Manualslib.com manuals search engine

Capacitor card Z002

Operating diagram

X3 X1

- Energy storage

- Discharging

X4 X2

Connectors

Z002 connectors / signals

X1 DC +

X2 DC +

X3 DC -

X4 DC -

18

Downloaded from www.Manualslib.com manuals search engine

Secondary rectifier card Z003

Operating diagram

X5 X6 X7 X8

Z003

X1 X2 X3 X4

X5-X8 X1-X4

- Rectifying

- Snubber

- Protection against HF

Connectors

Z003 connectors / signals

X1 Main transformer

X2 Main transformer

X3 Main transformer

X4 Main transformer

X5 Secondary choke

X6 Secondary choke

X7 Secondary choke

X8 Secondary choke

Operational mesurings

C X003, machine (-) pole

X5 X6 X7 X8

Z003

X1 X2 X3 X4

C.

Voltage after secondary rectifier card Z003,

set values 50 A/16,5 V 19

Downloaded from www.Manualslib.com manuals search engine

Control card A001

X5 X6 X7 X9 H7

X2

F1 X17

F2 H8

H4 X15

X14

X4 X13

X16

H2

H10

X1

H9

H1

X3 X11

X8 X10

Operating diagram

- Microcontroller

- PWM circuit

- Secondary voltage measurement

- Secondary current measurement

- IGBT driver

- Auxiliary device connection

- Auxiliary power supply

- Machine size jumpers (J1, J2)

- Primary current limit jumpers (J3, J4, J5)

- Operational jumpers

- LED’s

- Water cooler connection

20

Downloaded from www.Manualslib.com manuals search engine

Control card A001

Connectors

A001 / X1 A001 / X9 / KM

X1 DC-link voltage (+) X9/1 System bus DATA

X9/2 System bus DATA B

X9/3 GND

A001 / X2

X9/4 + 50 V

X2/1 20V auxiliary voltage~

X9/6 -

X2/2 20V auxiliary voltage ground

X9/7 -

X2/3 20V auxiliary voltage~ X9/8 -

X9/9 -

A001 / X3 X9/10 Connection A002 X1/4

X3/1 IGBT emitter X9/11 -

X3/3 IGBT emitter

X3/4 IGBT gate

X3/6 IGBT gate A001 / X9 / KMS

X9/1 System bus DATA B (X005)

X9/2 System bus DATA B (X006)

A001 / X4 X9/3 +50V (X005)

X4/1 IGBT emitter X9/4 +50V (X006)

X4/3 IGBT emitter X9/6 +5V (X005)

X4/4 IGBT gate X9/7 +5V (X006)

X4/6 IGBT gate X9/8 Analog DATA (X005)

X9/9 Analog DATA (X006)

A001 / X5 X9/10 GND (X006)

X5/1 Fan (-) (M002) X9/11 GND (X005)

X5/2 Fan (+) (M002)

A001 / X10

A001 / X6 X10/1 Shunt (+)

X6/1 Fan (-) (M001) X10/2 -

X6/2 Fan (+) (M001) X10/3 Secondary voltage (+)

X10/4 -

X10/5 Machine size jumper J1

A001 / X7 X10/6 Machine size jumper J2

X7 Production programming bus X10/7 Shunt (-)

X10/8 TxD0 (possible future use)

X10/9 RxD0 (possible future use)

A001 / X8 X10/10 GND

X8/1 Current transformer ~ X10/11 GND(Machine size jumper J1)

X8/3 Primary current limit jumper (J3) X10/12 GND(Machine size jumper J2)

X8/4 Primary current limit jumper (J4)

X8/5 Primary current limit jumper (J5)

X8/6 GND A001 / X11

X8/7 Current transformer ~ - Not connected

X8/9 GND (Primary current limit jumper J3) J6 Forced programming mode

X8/10 GND (Primary current limit jumper J4) J7 For future purposes

X8/11 GND (Primary current limit jumper J5) J8 For future purposes

X8/12 GND J9 For future purposes

21

Downloaded from www.Manualslib.com manuals search engine

Control card A001

Connectors

A001 / X13 A001 / X16

X13/1 PTC, Rg 101 (Z001) X16/7 H002 + (yellow led)

X13/2 PTC, Rg 101 (Z001) X16/8 H002 -

X16/9 H001 + (green led)

A001 / X14 X16/10 H001 -

X14/1 PTC, Rt 101 (T001)

X14/2 PTC, Rt 101 (T001) A001 / X17

X17/1 +24V

A001 / X15 X17/2 CLU_fault

X15/1 PTC, Rg 201 (Z003) X17/3 GND

X15/2 PTC, Rg 201 (Z003) X17/4 CLU_AD_CH1

X17/5 CLU_AD_CH2

X17/6 ON/OFF

Operation of the LEDs on control card

A001 / LEDS

H1 IGBT gate pulses

H2 IGBT gate pulses

H3 IGBT gate pulses

H4 IGBT gate pulses

H5 +15V

H6 +5V

H7 Remote control unit connected

H8 Data communication

H9 Micro controller operation

H10 Micro controller operation

H1-H4: Indicate the existence of the gate pulses.

H5, H6: Indicate that auxiliary voltages exist (+5V and +15V). If these Leds are not lit when the power source is

switched on, first thing to do is check if control card fuses are OK.

H7, H8: Indicate operation of the auxliary device connection. LED H8 indicates that there is data

communication taking place through the system bus when it is lit. LED H7 indicates that remote control unit is

connected when it is lit.

H9, H10: Indicate state of the microcontroller. In normal situation both leds should be lit.

22

Downloaded from www.Manualslib.com manuals search engine

Motor control card A002

X4

X3 X1 X2

Operating diagram

- WF-motor control

- Connection to the panel card P001

- Remote controller connection

- MIG gun connection

- Solenoid valve connection

- Fuse

- ID-Chip connection (MSF)

23

Downloaded from www.Manualslib.com manuals search engine

Motor control card A002 (A001 = MSF)

Connectors

A002 / X1 / KM

X1/1 Connection to A001, X9/4

X1/4 Connection to A001, X9/10

A001 / X1 / MSF

X1/1 Bus +50V

X1/3 Tacho +5V

X1/4 Bus GND

X1/5 Tacho GND

X1/6 Tacho Signal

A002/A001 / X2

X2 Connection to panel card

A002 / X4 / MF

X4/2 Start

X4/3 Motor+

X4/4 U-measurement

X4/6 Pot +5V

X4/8 Connection A001 X9/2

X4/11 WF-pot

X4/12 Valve

X4/14 GND

X4/15 Motor -

A001 / X4 / MSF

X4/1 Pot GND

X4/2 Start 2

X4/3 Motor +

X4/4 Pot 2

X4/5 Start 1

X4/6 Pot +5V

X4/7 ID Bus 2

X4/8 Bus Data

X4/9 General I/O

X4/10 Valve -

X4/11 Pot 1

X4/12 Valve +

X4/13 ID Bus 1

X4/14 GND

X4/15 Motor -

24

Downloaded from www.Manualslib.com manuals search engine

ID chip card A002 (MSF)

A002

ID-chip card

Connectors

A002

TP1 ID Bus 1 (connection to A001)

TP2 ID Bus 2 (connection to A001)

25

Downloaded from www.Manualslib.com manuals search engine

Panel card P001 / KM

Operating diagram

- Main micro controller

- User interface (buttons, potentiometers,

displays, LED’s)

- Connection to the A002

Connectors

P001 / X2

X2 Connection to A002

26

Downloaded from www.Manualslib.com manuals search engine

Error codes

Power source 1 ..... 50

MIG Logic 51 ….. 100

Curve Access 101 ….. 130

Robot Interface 131 ….. 150

MIG / TIG Unit 151 ….. 200

User interface 201 ….. 250

Others 0 ….. 999

Err 2: Power source undervoltage ( new start up )

Err 3: Power source overvoltage ( new start up )

Err 4: Power source is overheated

Err 5: Water unit alarm

Err 11: Two units have the same address in the system bus

Err 12: Data error on communication (2)

Err 13: Member of a wrong FastMIG family connected

Err 14: Data communication problem between power source and auxiliary unit

Err 15: Power source program / updating method problem

Err 21: Power source´s control card +5 V aux. Voltage too low

Err 22: Power source´s control card +15 V aux. Voltage too low

Err 23: Temporarily power source overvoltage

Err 31: Power source calibration error. Welding only possible with default values.

Err 54: No data communication from power source. Perhaps faulty cable/connector.

Err 55: Welding forbidden (congiguration / system bus reserved)

Err 61: The water unit is not found. Cooling unit may be OFF.

Err 153: Overheating of liquid-cooled gun

Err 154: Wire feed motor overcurrent. Perhaps the wire liner is blocked or gun cable too curvy.

Err 155: Wire feed motor overload. Motor´s current is too close to the limit.

Err 161: Warning of the wire feed unit overheating

Err 162: Overloading of the wire feed motor

Err 171: Configuration of the equipment can not be found. Gun start wires cross-connected.

Err 172: Wrong configuration code has been supplied

Err 173: Operation is not activated with right configuration code

Err 184: Control cable not connected or faulty.

Err 185: Machine program update error. Wrong program or updating method.

Err 201: Usage of PMT-gun prevented

Err 221: Data error of the panel (1)

Err 222: Data error of the panel (2)

Err 223: Data error of the panel (3)

Err 224: Data error of the panel (4)

Err 225: Program updating problem.

Err 241: EEPROM is faulty

Err 251: DLI data communication error(another unit in the bus is using same code=conflict)

Err 252: DLI data error (2)

Err 254: DLI data communication error(connection to other units has been interrupted(maybe bad connectors or cable

damages)

Err 255: DLI data communication error(program update problem, maybe a wrong program version etc)

Err 999: Unidentified error (systembus has sent an error message not identified by the panel)

27

Downloaded from www.Manualslib.com manuals search engine

Setup menu

MF 29 / 33

FastMig Basic (MF) SETUP menu

SF 51, 52, 53, 54

Normal MIG

1-MIG

FR-MIG

All MIG

processes

MMA

FastMig Synergic (MSF) setup menu

28

Downloaded from www.Manualslib.com manuals search engine

Wire feed speed calibration / KM

• In factory set Wfs is adjusted in the range of 4...100 without any unit

• LED light and feed roll symbol tells that the parameter to be set is Wfs

• After Wfs Calibration m/min unit is displayed

• Drive filler wire through the MIG gun and contact tip

• Enter to User Setup Menu by pressing SETUP button ( appr 5 s )

• Select the Calibration menu ( CAL ) with left side potentiometer

• Select "Enter" ( Ent ) with right side potentiometer

• Approve your selection by pressing briefly REMOTE / LOCAL key

• Select 'm/min' as calibration value of the quantity with right side potentiometer

• Approve selection by pressing briefly REMOTE / LOCAL key

• Set first Calibration point (e.g. 2.0 m/min ) with left side potentiometer

1. Press MIG gun trigger and let the wire run until it stops automatically

2. Measure the length of feeded wire with the accuracy of 1 cm

3. Enter wire length to the panel display ( cm ) with right side potentiometer

4. Approve your selection by pressing briefly REMOTE / LOCAL button

• Set second Calibration point (e.g. 18.0 m/min )

• Repeat steps 1 - 4 with left side potentiometer

• Message "Suc cES" in the display inform that calibration has ended successfully

• After Calibration panel returns to the operation mode

29

Downloaded from www.Manualslib.com manuals search engine

Wire feed speed calibration

If wire feeding speed is not correct (too slow or too fast), motor

control card A002 must be calibrated by following instruction:

• Set ‘MIN’ and ‘MAX’ -trimmers to middle position.

• Set ‘IR-comp’ -trimmer to clock vice maximum.

• Set wire feeding speed to maximum from the panel (Basic: 100, Synergic: 25,0

m/min). Adjust ‘MAX’ –trimmer until wire feeding speed is same than value adjusted

from the panel.

• Set wire feeding speed to minimum from the panel (Basic: 4, Synergic: 1,0

m/min). Adjust ‘MIN’ –trimmer until wire feeding speed is same than value adjusted

from the panel.

• Check/adjust minimum and maximum again until both are OK.

• If adjustment range is too small, decrease IR -compensation and adjust minimum

and maximum again.

R87 IR R24

max. comp min

30

Downloaded from www.Manualslib.com manuals search engine

Structure

KM / KMS

Mains connector

and

varistors

Z001

Main circuit board

S001

Main

Z002 switch

DC-link

R001

Capasitor board

Shunt

resistor

P001

Panel card

A002 (KM)

Wire feed

control card

A001

Control card

Water cooler

Power

connector

31

Downloaded from www.Manualslib.com manuals search engine

Structure

KM / KMS

T002

Auxiliary L001

transformer Choke

L002

Secondary Z003

choke Secondary

rectifier diodes

Capacitors and

varistors

32

Downloaded from www.Manualslib.com manuals search engine

Structure

MF 29 / 33

Dura Torque wire feeding mechanism Axle for wire reel coop

Control cable connector

& wiring

Welding gun

connection

Solenoid valve

Welding current connector

Dura Torque wire feeding mechanism

& copper bar

33

Downloaded from www.Manualslib.com manuals search engine

Structure

MSF 53 / 55 / 57

A001

Motor control

card

A002

ID-chip

card

34

Downloaded from www.Manualslib.com manuals search engine

IGBT testing

C1/3 C1 E2

B1/4 X15

X14

G3

X14/G3

X12 X11/

G1 X6 X10/G4

X15

X13

E3

X13

E1 C2E1/1

X6 X12/G1

B2/6

X10 X7 X9

X8/G2

G4

X8 X7

G2

X11

E4

X9

E2

E2/2

C1/3

X14

G3

B1/4 X12

G C E

G1

X15

E3

X13

E1

X6 C2E1/1

C2E1/1

X7

E2/2

B2/6

X10

C1/3

G4

B2/6 X8

B1/4

G2

X11

IGBT-TESTER

TR 1

E4

OFF

CONTROL

X9

E2

ON

TR 2

E2/2

35

Downloaded from www.Manualslib.com manuals search engine

IGBT replacing

Mounting the IGBT to the heat sink

The tools and premises used in this work must be clean and free of dirt and dust. Even very

small particles (0,050mm) between the surfaces may increase the gap between heatsink and

module, causing overheating ans possible damage.

Heat transfer compound is to be spread in even layer of approximately 0,1 mm onto the module

base. Then the module should be immediately mounted on the heatsink, in order to minimize

the possibility of dirt getting between the components.

Firts, all the M5 type screws are tightened 0,5...2 NM. After a few minutes the module can be

tightened into the torque of 3 NM.

36

Downloaded from www.Manualslib.com manuals search engine

Você também pode gostar

- Despiese Carroceria Nissan Almera Classic B10Documento78 páginasDespiese Carroceria Nissan Almera Classic B10lambjabibiAinda não há avaliações

- Kirisun PT260-Service-ManualDocumento29 páginasKirisun PT260-Service-ManualRobertinoAinda não há avaliações

- Goulds Pumps Jet Pump Repair PartsDocumento12 páginasGoulds Pumps Jet Pump Repair PartsMarissa Bryce50% (2)

- Schema Generator Curent Kipor KDE180XWDocumento1 páginaSchema Generator Curent Kipor KDE180XWGeneratoare de Curent ElectricAinda não há avaliações

- Panasonic CS-W7DKR CS-W9DKR CS-W7DKR Series Service Manual Repair GuideDocumento92 páginasPanasonic CS-W7DKR CS-W9DKR CS-W7DKR Series Service Manual Repair Guideevangalos100% (1)

- Mitsubishi U100 ManuaDocumento90 páginasMitsubishi U100 Manuapepe1bmAinda não há avaliações

- k9 Classic EdpDocumento2 páginask9 Classic EdpAdi DragutAinda não há avaliações

- bq20z45 Charger Placa Bateria Macbook A1502 PDFDocumento17 páginasbq20z45 Charger Placa Bateria Macbook A1502 PDFFranklim Miranda Dos SantosAinda não há avaliações

- Optoma EP752 - EP761 - EP763 V4.0 EP761 Service Manual PDFDocumento106 páginasOptoma EP752 - EP761 - EP763 V4.0 EP761 Service Manual PDFAlexandre Morgado100% (1)

- Uc 60 GBDocumento2 páginasUc 60 GBDany SalomeAinda não há avaliações

- Tfelc We 0111Documento0 páginaTfelc We 0111miguelx69Ainda não há avaliações

- Automatic Transaxle: SectionDocumento754 páginasAutomatic Transaxle: SectionElias SerranoAinda não há avaliações

- Exhaust System: SectionDocumento11 páginasExhaust System: SectionRafaelCazalesFuentesAinda não há avaliações

- Diagrama hk.t.rt2842p639Documento40 páginasDiagrama hk.t.rt2842p639Miguel Esteban0% (1)

- EV6000 Series Inverter Controller Inside User ManualDocumento96 páginasEV6000 Series Inverter Controller Inside User ManualCarlito MoralesAinda não há avaliações

- Micro Plancha Del Pelo SN8P2722 - V11Documento106 páginasMicro Plancha Del Pelo SN8P2722 - V11Andres AlegriaAinda não há avaliações

- VW Passat B5 1.8T Timing Belt Replacement DIYDocumento26 páginasVW Passat B5 1.8T Timing Belt Replacement DIYaweed100% (1)

- Sony hcd-d590 xb4Documento88 páginasSony hcd-d590 xb4miguel angel jaramilloAinda não há avaliações

- LM U5050Documento55 páginasLM U5050Carlos RodriguezAinda não há avaliações

- Kdfi V1.4: User Manual (English)Documento13 páginasKdfi V1.4: User Manual (English)Dot3xe Nicolas100% (1)

- Technical Service BULLETINDocumento328 páginasTechnical Service BULLETINCarlos E. FuentesAinda não há avaliações

- Assembly Instructions For 1999-2004 WJ Jeep Front Bumper Non-Winch KitDocumento6 páginasAssembly Instructions For 1999-2004 WJ Jeep Front Bumper Non-Winch Kitslawek benekAinda não há avaliações

- Service Manual Rgv7500Documento67 páginasService Manual Rgv7500Dimitri GutiérrezAinda não há avaliações

- Electrical System: GI MADocumento324 páginasElectrical System: GI MADarioAinda não há avaliações

- Eixo Transmissao e Polia Conjunto 84MM (Wynn Marine PN 1588-009-117) PDFDocumento44 páginasEixo Transmissao e Polia Conjunto 84MM (Wynn Marine PN 1588-009-117) PDFAugusto RezendeAinda não há avaliações

- Chrysler JX Stratus Sebring Convertible LHD RHD 1997 Service Manual Ignition SystemDocumento28 páginasChrysler JX Stratus Sebring Convertible LHD RHD 1997 Service Manual Ignition SystemjjrmgAinda não há avaliações

- JVC TD-V662BKDocumento42 páginasJVC TD-V662BKcupitzaAinda não há avaliações

- Grade 10 Automotive Tve q1wk8Documento17 páginasGrade 10 Automotive Tve q1wk8Precious Dorothy Tolentino100% (1)

- Manual de Servicio 185acdcDocumento122 páginasManual de Servicio 185acdcfrebenasi100% (1)

- Wiper Linkage 2023 CatalogDocumento35 páginasWiper Linkage 2023 CatalogAlice DaiAinda não há avaliações

- Fiat Barchetta 55.: EquipmentDocumento24 páginasFiat Barchetta 55.: EquipmentHallex Oliveira100% (1)

- .Archivetempengine - QD32EI Lubrication and Cooling System Workshop ManualDocumento21 páginas.Archivetempengine - QD32EI Lubrication and Cooling System Workshop ManualEduardoGaleanoAinda não há avaliações

- Piaggio X9250Documento75 páginasPiaggio X9250Toni MarasovicAinda não há avaliações

- Cedaspe - BushingDocumento4 páginasCedaspe - BushingWillmar Curillo - G&CAinda não há avaliações

- ECT and A/T Indicator, Engine ControlDocumento19 páginasECT and A/T Indicator, Engine ControlAdin VifaldhiAinda não há avaliações

- Murray Model 30577x8a Rear Engine Riders (2000) Parts ListDocumento14 páginasMurray Model 30577x8a Rear Engine Riders (2000) Parts ListCarl RadleAinda não há avaliações

- Model 4111 Installation Guide: © 2009 Directed Electronics, Vista, CA N4111L 2009-07Documento52 páginasModel 4111 Installation Guide: © 2009 Directed Electronics, Vista, CA N4111L 2009-07Geovani RuizAinda não há avaliações

- A.C Components PDFDocumento368 páginasA.C Components PDFTERO100% (1)

- 03 DR-Z125-03-EngineDocumento60 páginas03 DR-Z125-03-EngineVincent RoyAinda não há avaliações

- Aiwa NSX-MT960 PDFDocumento48 páginasAiwa NSX-MT960 PDFElectroTecno MzaAinda não há avaliações

- Pioneer Lexus Dex-Mg9487zt Dex-Mg9587zt Crt4255Documento148 páginasPioneer Lexus Dex-Mg9487zt Dex-Mg9587zt Crt4255boroda2410Ainda não há avaliações

- Tridonic-Catalogue 2012 2013 enDocumento510 páginasTridonic-Catalogue 2012 2013 enPetru Bumb100% (1)

- WAPU Overhaul BZBDocumento8 páginasWAPU Overhaul BZBNedim ErkocevicAinda não há avaliações

- QDB-2 Instructions For UseDocumento17 páginasQDB-2 Instructions For UseCarlos Castillo100% (1)

- Xpower Blue II Service Manual enDocumento42 páginasXpower Blue II Service Manual enDonald SantanaAinda não há avaliações

- ChigoDocumento104 páginasChigoClaudio Ferreira100% (1)

- Atc Sistema XtrailDocumento164 páginasAtc Sistema XtrailOscarPeredaAinda não há avaliações

- ToyotaDocumento12 páginasToyotaZarate CruzAinda não há avaliações

- MC34 44Documento56 páginasMC34 44Razvan PredaAinda não há avaliações

- E P1 KH2 EJAZai CCVZ G1 KW1600900047Documento35 páginasE P1 KH2 EJAZai CCVZ G1 KW1600900047RosAinda não há avaliações

- Manual Keeway ScooterDocumento15 páginasManual Keeway ScooterJuan G MartinezAinda não há avaliações

- Fisher and Paykel Washing Machine Motors For Electricity GenerationDocumento27 páginasFisher and Paykel Washing Machine Motors For Electricity Generationbuditux100% (1)

- Clarion - PP 3097L A PDFDocumento34 páginasClarion - PP 3097L A PDFspeedyeduAinda não há avaliações

- Infineon IMC100 DataSheet v01 06 enDocumento54 páginasInfineon IMC100 DataSheet v01 06 enHATEM68Ainda não há avaliações

- TMC4671 Datasheet v1.06Documento159 páginasTMC4671 Datasheet v1.06SK P100% (1)

- b5000 6055002 en 0222 DeskDocumento40 páginasb5000 6055002 en 0222 Deskolivier.bigouretAinda não há avaliações

- Minas A5Documento85 páginasMinas A5Daniel Almendarez PazAinda não há avaliações

- DAVICOM Semiconductor, Inc.: 10/100 Mbps Fast Ethernet Physical Layer Single Chip TransceiverDocumento45 páginasDAVICOM Semiconductor, Inc.: 10/100 Mbps Fast Ethernet Physical Layer Single Chip Transceivernguyentienduy1512Ainda não há avaliações

- EMS Vansco - Service Manual SpecificationDocumento85 páginasEMS Vansco - Service Manual SpecificationDaniel Aguirre100% (1)

- Motorola Cablecomm V5.2 Operation and MaintenanceDocumento270 páginasMotorola Cablecomm V5.2 Operation and MaintenancedpnswAinda não há avaliações

- Liftket - ManualDocumento40 páginasLiftket - ManualMetCES100% (1)

- Hitachi Hoist - ManualDocumento156 páginasHitachi Hoist - ManualMetCESAinda não há avaliações

- Chain Hoist Brochure - HlTachiDocumento17 páginasChain Hoist Brochure - HlTachisravan thumojuAinda não há avaliações

- Spare Part List: Liftket Electric Chain HoistDocumento38 páginasSpare Part List: Liftket Electric Chain HoistMetCESAinda não há avaliações

- Radiographic Examination Procedure For Asme CodeDocumento33 páginasRadiographic Examination Procedure For Asme CodeEdAlmAinda não há avaliações

- Feritscope FMP30: Operators ManualDocumento240 páginasFeritscope FMP30: Operators ManualRaja HoneAinda não há avaliações

- ASTM D1000 17 Standard Test Methods For Pressure Sensitive Adhesive Coated Tapes Used For Electrical and Electronic ApplicationsDocumento20 páginasASTM D1000 17 Standard Test Methods For Pressure Sensitive Adhesive Coated Tapes Used For Electrical and Electronic ApplicationsEdisson Casallas100% (1)

- Guide For The Validation ISO 11095Documento92 páginasGuide For The Validation ISO 11095ridzim4638Ainda não há avaliações

- KKK 5 ExpDocumento11 páginasKKK 5 ExpKhairil IkramAinda não há avaliações

- 2.2.40. Near-Infrared SpectrophotometryDocumento5 páginas2.2.40. Near-Infrared SpectrophotometryImad AghilaAinda não há avaliações

- ASTM 4373 - Standard Method For Rapid Determination of Carbonate Contents in SoilsDocumento5 páginasASTM 4373 - Standard Method For Rapid Determination of Carbonate Contents in SoilsGurpreetAinda não há avaliações

- Impedanciometro Aplivox Otowave 102 - MsDocumento29 páginasImpedanciometro Aplivox Otowave 102 - MsAnonymous dGFqrw5vOAinda não há avaliações

- NIST Handbook PDFDocumento426 páginasNIST Handbook PDFFaryalBalochAinda não há avaliações

- DT - M1 - EchoLAB - & - LAP - 0905 - ENGLISHDocumento84 páginasDT - M1 - EchoLAB - & - LAP - 0905 - ENGLISHRaúl AndrésAinda não há avaliações

- Geit-20219 Dmsgoseries enDocumento4 páginasGeit-20219 Dmsgoseries ensolrac4371Ainda não há avaliações

- NASC System Scaffold Master Audit Form Issue 17Documento23 páginasNASC System Scaffold Master Audit Form Issue 17Beste Ardıç ArslanAinda não há avaliações

- HI 2210 HI 2211: Microprocessor-Based pH/mV/°C Bench MetersDocumento15 páginasHI 2210 HI 2211: Microprocessor-Based pH/mV/°C Bench MetersJOSE RIVERAAinda não há avaliações

- Dega Ns Ii LCD: Installation ManualDocumento21 páginasDega Ns Ii LCD: Installation ManualGuy MesikaAinda não há avaliações

- Geoscope Technologies PTE. LTD v. Apple Inc Patent InfringementDocumento91 páginasGeoscope Technologies PTE. LTD v. Apple Inc Patent InfringementJack PurcherAinda não há avaliações

- Crevier-Denoix N Et Al 2013 Comparison of SDFT Loading On Asphalt and Sand in Horses2Documento7 páginasCrevier-Denoix N Et Al 2013 Comparison of SDFT Loading On Asphalt and Sand in Horses2myriamAinda não há avaliações

- KC5 deDocumento66 páginasKC5 degmclellanAinda não há avaliações

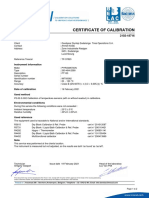

- Certificate of Calibration: Customer InformationDocumento2 páginasCertificate of Calibration: Customer InformationSazzath HossainAinda não há avaliações

- INTECONT® Tersus For Measuring Systems: % Compact Weighing Electronics ForDocumento4 páginasINTECONT® Tersus For Measuring Systems: % Compact Weighing Electronics Forgnazareth_100% (1)

- 690 RA3%2Baire%2Bacondicionado PDFDocumento59 páginas690 RA3%2Baire%2Bacondicionado PDFKaren Vintimilla100% (1)

- 22.MS For HydrotestDocumento9 páginas22.MS For HydrotestASHWANIAinda não há avaliações

- Premier Instruments Service Request Form: CustomerDocumento6 páginasPremier Instruments Service Request Form: CustomerSIVAKUMAR NATARAJANAinda não há avaliações

- Humeral Nail Tech GuideDocumento83 páginasHumeral Nail Tech Guidestv1036Ainda não há avaliações

- Uncertainty of Measurement Calculator Ver3.3 Part1Documento25 páginasUncertainty of Measurement Calculator Ver3.3 Part1MikAinda não há avaliações

- 3D A1000 Dimensioning DatasheetDocumento6 páginas3D A1000 Dimensioning DatasheetdahonoraAinda não há avaliações

- AC Power Transducer User ManualDocumento4 páginasAC Power Transducer User ManualKhaled El-BeheryAinda não há avaliações

- HiAS 743. High Resolution Impulse Analyzing System FEATURES BENEFITSDocumento7 páginasHiAS 743. High Resolution Impulse Analyzing System FEATURES BENEFITSleivajAinda não há avaliações

- Viva Manual de Servicio PDFDocumento142 páginasViva Manual de Servicio PDFLARRYAinda não há avaliações

- Calibr Fluke 1550cDocumento24 páginasCalibr Fluke 1550cHelvécio OliveiraAinda não há avaliações