Escolar Documentos

Profissional Documentos

Cultura Documentos

Sugarcane Compute

Enviado por

Jun Burias PadillaDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Sugarcane Compute

Enviado por

Jun Burias PadillaDireitos autorais:

Formatos disponíveis

SASTA Laboratory Manual p 1/12

CHAPTER 3

Calculations

1. General

Quantitative measurements of the products entering and leaving the factory are required

for the purpose of factory control, whilst those relating to cane, mixe d juice, final bagasse

and where applicable press water mud, are also required for cane payment.

2. Rules for rounding off

Wherever a decimal place to be discarded is represented by a number less than five, the

preceding digit (that is the last to be recorded) shall remain as it stands; but where the

number to be discarded is greater than five, one shall be added to the preceding digit.

Where the number to be discarded is exactly five, the preceding digit shall be unaltered if

it is an even number, but if it is an odd number one shall be added to it.

3. Cane payment requirements

3.1 Mill balance and direct analysis of cane

In the South African Sugar Industry cane is analysed in parallel at every factory by two

methods:

(a) the mill balance which entails the determination of Brix, pol and fibre from the

analysis of mixed juice and final bagasse and where applicable, diffuser press water

muds and recycled clarifier muds, and

(b) the direct analysis of individual cane consignments for Brix, pol and fibre content.

These methods are independent of one another except that the final bagasse mass

determination in the mill balance does depend on the quantity of fibre in cane as

determined by Direct Analysis of Cane (DAC).

- See section 4 for standard methods of calculation.

3.2 Distribution of mill balance tonnages

The mill balance tonnages of pol, Brix and fibre are normally determined for a weekly

period at a mill and the respective weekly tonnages are then distributed among the

individual cane suppliers pro rata to their individual cane consignment tonnages of pol,

Brix and fibre as determined by DAC. Distribution periods are set in terms of clause 142

of the Sugar Industry Agreement, 2000.

3.3 Factors for pol, Brix and fibre

The distribution of the mill balance tonnage is effected by determining a factor for the

week, which in the case of pol is determined as follows:

total tons pol for all cane by mill balance for week

Factor (pol) =

total tons pol for all cane by DAC for the week

Revised July 2005 Chapter 3: Calculations

SASTA Laboratory Manual p 2/12

The individual cane consi gnment tonnages of DAC pol are then multiplied by the

factor to give the adjusted pol tonnages for each consignment; similarly for brix and

fibre.

3.4 Conversion of adjusted pol tonnages to sucrose tonnages

Composite samples of mixed juice are collected over the week at each factory. These

weekly samples are stored and transported under freeze preservation to the Sugar Milling

Research Institute (SMRI) where they are analysed for pol and for sucrose by gas

chromatography and the pol/sucrose ratio so determined is applied to the corresponding

pol tonnage in mixed juice as determined at the mill, to convert it to sucrose (see 4.1.18).

All individual consignment adjusted pol tonnages are converted to sucrose tonnages by

correcting for the change from pol to sucrose in mixed juice.

3.5 Calculation of recoverable value % cane

Having determined individual consignment tonnages of sucrose, brix and fibre as shown

above, the corresponding consignment percentages are readily calculated. For calculating

recoverable value % cane, the sucrose % cane, non -sucrose % cane and fibre % cane are

required and non-sucrose % cane is calculated as follows:

non-sucrose % cane = Brix % cane – sucrose % cane

Recoverable value % cane is then calculated according to 4.2.35 and tons recoverable

value according to 4.2.36.

4. Standard methods of calculation

It is often possible to calculate certain primary data in more than one way. Due to small

errors in the different primary data used, very small differences in the results obtained

will be found. Hence it is necessary to standardise methods of calculation as far as

possible. The recommended procedures are listed below but alternatives are sometimes

imperative due to procedural differences in different factories. However for cane payment

purposes the relevant procedures listed below shall apply.

4.1 Masses

4.1.1 Tons Brix in cane by mill balance

tons Brix in mixed juice + tons Brix in bagasse

Where press water clarifier mud is not returned to the mixed juice it is necessary to

include tons Brix in press water mud in the above calculation, and where clarifier mud is

returned to the diffuser, tons Brix must be subtracted in the above calculations.

4.1.2 Tons Brix in cane by DAC

tons cane × DAC Brix % cane

100

4.1.3 Tons pol in cane by mill balance

tons pol in mixed juice + tons pol in bagasse

Where press water clarifier mud is not returned to the mixed juice it is necessary to

include tons pol in press water mud in the above calculation, and where clarifier mud is

returned to the diffuser, tons pol must be subtracted in the above calculations.

Revised July 2005 Chapter 3: Calculations

SASTA Laboratory Manual p 3/12

4.1.4 Tons pol in cane by DAC

tons cane × DAC pol % cane

100

4.1.5 Tons fibre in cane

tons cane × DAC fibre % cane

100

4.1.6 Tons cane per hour

tons cane crushed divided by hours actual milling

4.1.7 Tons fibre per hour

tons fibre in bagasse divided by hours actual milling

4.1.8 Tons Bagasse

Tons fibre in bagasse

× 100

fibre % bagasse

4.1.9 Tons Brix in bagasse

tons bagasse × arithmeticaverage of Brix % bagasse analyses

100

As accurate hourly bagasse mass data are not available, arithmetic averages of the

analyses are used for calculating daily data; daily data are, however, combined on a

weighted basis.

4.1.10 Tons pol in bagasse

tons bagasse × arithmeticaverage of pol % bagasse analyses

100

As accurate hourly bagasse mass data are not available, arithmetic averages of the

analyses are used for calculating daily data; daily data are, however, combined on a

weighted basis.

4.1.11 Tons moisture in bagasse

Tons bagasse × arithmeticaverage of moisture % bagasse analyses

100

As accurate hourly bagasse mass data are not available, arithmetic averages of the

analyses are used for calculating daily data; daily data are, however, combined on a

weighted basis.

4.1.12 Tons fibre in bagasse

tons fibre in cane - tons insoluble solids in mixed juice

Where press water clarifier mud is not returned to the mixed juice it is necessary to

subtract the tons insoluble solids in press water mud in addition to the tons insoluble

solids in mixed juice.

Revised July 2005 Chapter 3: Calculations

SASTA Laboratory Manual p 4/12

4.1.13 Tons insoluble solids in mixed juice

tons mixed juice × insoluble solids % mixed juice

100

4.1.14 Tons uncorrected* Brix in mixed juice

tons mixed juice from scale reading × Brix % mixed juice

100

4.1.15 Tons Brix in mixed juice

tons uncorrected * Brix in mixed juice x (100 - insoluble solids % MJ)

100

4.1.16 Tons uncorrected* pol in mixed juice

tons mixed juice from scale reading × pol % mixed juice

100

4.1.17 Tons pol in mixed juice

tons uncorrected * pol in mixed juice x (100 - insoluble solids % MJ)

100

4.1.18 Tons sucrose in mixed juice

tons pol in mixed juice

pol / sucrose ratio

where the pol/sucrose ratio is the ratio of pol % mixed juice to sucrose % mixed juice as

determined on the composite mixed juice sample by the SMRI laboratory.

4.1.19 Tons Brix in press water mud

tons press water mud × Brix % press water mud

100

4.1.20 Tons pol in press water mud

tons press water mud × pol % press water mud

100

4.1.21 Tons insoluble solids in press water mud

tons press water mud × insoluble solids % press water mud

100

4.1.22 Tons sucrose in cane

tons sucrose in mixed juice + tons pol in bagasse

where clarifier mud is returned to the diffuser, tons sucrose in clarifier mud must be

subtracted from above calculation.

* Uncorrected here refers to insoluble solids and not temperature.

Revised July 2005 Chapter 3: Calculations

SASTA Laboratory Manual p 5/12

4.1.23 Tons cane per ton sugar

tons cane crushed divided by tons sugar made and estimated from that cane

4.1.24 Tons final molasses at 85°Brix

tons final molasses × Brix % final molasses

85

4.1.25 Tons pol in final molasses

tons final molasses × pol % final molasses

100

4.1.26 Tons sucrose in final molasses

tons pol in final molasses

pol / sucrose ratio

where pol/sucrose ratio is the ratio of pol % final molasses to sucrose % final molasses

as determined on the composite final molasses sample by the SMRI laboratory.

4.1.27 Tons undetermined loss of pol

tons pol in cane - tons pol in bagasse - tons pol in filter cake - tons pol in final

molasses - tons pol in sugar

4.1.28 Tons undetermined loss of sucrose

tons sucrose in cane - tons pol in bagasse - tons pol in filter cake - tons sucrose

in final molasses - tons pol in sugar

4.1.29 Tons pol in clarifier mud

tons mud × pol % mud

100

4.1.30 Tons Brix in clarifier mud

tons mud × Brix % mud

100

4.1.31 Adjustment to mill balance for clarifier mud pol and Brix

(i) Adjustment to tons mixed juice

adjusted tons tons mixed tons mud (1 – 0.01

-

mixed juice = juice massed insoluble solids % mud)

(ii) Adjustment to tons pol and Brix in mixed juice

adjusted tons

recorded tons pol – tons pol in mud

pol =

adjusted tons

recorded tons Brix – tons brix in mud

Brix =

Revised July 2005 Chapter 3: Calculations

SASTA Laboratory Manual p 6/12

4.1.32 Final bagasse mass

(i) For total and continuous re-routing of clarifier mud the determination is as follows:

As the insoluble solids leaving the extraction unit in the mixed juice are being

returned via the clarifier mud and then removed via the bagasse be d, the mass of

fibre in bagasse can be taken as being equal to the mass of fibre in cane determined

by DAC. Thus there is no need for the DAC fibre to be corrected for the insoluble

solids in mixed juice when calculating the fibre in final bagasse.

There fore, in the case of clarifier mud being recycled to the diffuser:

tons fibre in cane

tons final bagasse = × 100

fibre % bagasse

(ii) Where re -routing of clarifier mud is partial or intermittent (within a week) the final

bagasse mass determination is as follows:

tons fibre in bagasse

tons final bagasse = × 100

fibre % bagasse

Where

tons fibre in bagasse = tons fibre in cane – tons insoluble solids in

mixed juice + tons insoluble solids in clarifier mud

4.2 Percentages and ratios

4.2.1 Brix % cane

tons Brix in cane

× 100

tons cane

4.2.2 Brix % cane (DAC)

b C+W

Brix % cane = × 100 × − 1.25 × F

100 C

where b ≡ Brix % extract

C ≡ mass of cane sample (g) put into the cold digester bowl

W ≡ mass of water (g) added to the cold digester bowl

F ≡ fibre % cane

Routine procedure is to take 1 000 g cane and 2000 g water and hence the formula

reduces to:

Brix % cane = b × (3 - 0.0125 × F)

The above analysis is normally carried out separately for each consignment of cane. In

determining the average Brix % cane for a period it is ne cessary to weight the individual

analyses according to their respective consignment masses.

4.2.3 Brix % extract (cane)

In the case of manual precision refractometers, the refractometer reading is converted to

Brix percent extract by means of the appropriate tables provided with each refractometer.

Automatic refractometers give a direct read out of Brix % extract.

Revised July 2005 Chapter 3: Calculations

SASTA Laboratory Manual p 7/12

4.2.4 Pol % cane

tons pol in cane

× 100

tons cane

4.2.5 Pol % cane (DAC)

p C+W

pol % cane = × 100 × − 1.25 × F

100 C

where p ≡ pol % extract

C ≡ mass of cane sample (g) put into the cold digester bowl

W ≡ mass of water (g) added to the cold digester bowl

F ≡ fibre % cane

Routine procedure is to take 1 000 g cane and 2 000 g water and hence the formula

reduces to

pol % cane = p × (3 – 0.0125 × F)

The above analysis is normally carried out separately for each consignment of cane. In

determining the average pol % cane for a period it is necessary to weight the individual

analyses according to their respective consignment masses.

4.2.6 Pol % extract (cane)

The pol % extract is obtained from the saccharimeter reading and the Brix value of the

extract. The basic formula for the calculation is as follows:

normal mass × saccharimeter reading

pol % extract =

mass in g of 100 cm 3 of solution

where

(i) normal mass = 26.000 g when the saccharimeter calibrated according to

the International Sugar Scale

(ii) mass in g of 100 cm 3 of solution is equal to 100 × apparent density at

20°C. Values of apparent density at 20°C for corresponding Brix values are

available from Table 3 in the Appendix

In practice the pol is found from the Schmitz’s Table or formula.

4.2.7 Fibre % cane

tons fibre in cane

× 100

tons cane

4.2.8 Fibre % cane (DAC)

100 × C - C × M - (C + W) × b

Fibre % cane =

C × (1 - 0.0125 × b)

where C ≡ mass of cane sample (g) put into the cold digester bowl

M ≡ moisture % cane

W ≡ mass of water (g) added to the cold digester bowl

b ≡ Brix % cane extract

Revised July 2005 Chapter 3: Calculations

SASTA Laboratory Manual p 8/12

When C = 1000 g and W = 2000 g the formula simplifies to

100 - M - 3 × b

fibre % cane =

1 - 0.0125 × b

4.2.9 Moisture % cane (DAC)

(M2 - M 3 )

moisture % cane = × 100

(M2 - M1 )

where M1 ≡ mass of empty oven tray (g)

M2 ≡ mass of tray with original cane sample (g)

M3 ≡ mass of tray with dried sample (g)

4.2.10 Brix % mixed juice

tons Brix in mixed juice

× 100

tons mixed juice

4.2.11 Pol % mixed juice

tons pol in mixed juice

× 100

tons mixed juice

4.2.12 Sucrose % mixed juice

tons pol in mixed juice

× 100

tons mixed juice × pol / sucrose ratio

where the pol/sucrose ratio is the ratio of the pol % mixed juice to sucrose % mixed juice

as determined on the composite mixed juice sample by the SMRI laboratory.

4.2.13 Insoluble solids % mixed juice

(M 3 - M1 )

insoluble solids % mixed juice = × 100

(M 2 - M1 )

where M1 ≡ mass of beakers, filter paper and filter aid prior to addition

of mixed juice (g)

M2 ≡ M1 + mass of mixed juice sample (g)

M3 ≡ M1 + mass of insoluble solids in mixed juice sample (g)

4.2.14 Brix % bagasse

b B+W

Brix % bagasse = × 100 × − 1.25 × F

100 B

where b ≡ Brix % bagasse extract

B ≡ mass of bagasse sample (g) put into the cold digester bowl

W ≡ mass of water (g) added to the bagasse sample in the cold

digester bowl

F ≡ fibre % bagasse

In the case of final bagasse the quantities of bagasse and water taken are as follows:

B = 350 g

Revised July 2005 Chapter 3: Calculations

SASTA Laboratory Manual p 9/12

W = 2541 g

Therefore the above formula reduces to:

Brix % bagasse = b × (8.26 – 0.0125 × F)

For routine purposes Brix % final bagasse is calculated with sufficient accuracy using the

formula:

Brix % bagasse = 7.7 × Brix % extract

Final bagasse samples are taken and analysed once per hour. As an accurate hourly

bagasse mass is not readily available, arithmetic averages of the analyses are used for

calculating daily data. Daily data are combined on a weighted basis.

4.2.15 Brix % extract (bagasse)

As for 4.2.3.

4.2.16 Pol % bagasse

p B+W

pol % bagasse = × 100 × − 1.25 × F

100 B

where p ≡ pol % bagasse extract

B ≡ mass of bagasse sample (g) put into the cold digester bowl

W ≡ mass of water (g) added to the bagasse sample in the cold

digester bowl

F ≡ fibre % bagasse

In the case of final bagasse the quantities of bagasse and water taken (350 g and 2541 g

respectively) are such as to give a solution very close to half normal. Thus when using a

200 mm saccharimeter tube, the saccharimeter reading multiplied by 2 gives the pol %

bagasse directly.

Final bagasse samples are taken and analysed once per hour. As an accurate hourly

bagasse mass is not readily available arithmetic averages of the analyses are used for

calculating daily data. Daily data are combined on a weighted basis.

4.2.17 Pol % extract (final bagasse)

The pol % extract is obtained from the saccharimeter reading and the Brix value of the

extract using the following formula:

normal mass × saccharimeter reading

mass in g of 100 cm 3 of solution

where

(i) normal mass 26.000 g for saccharimeters calibrated according to the

International Sugar Scale

(ii) mass in g of 100 cm 3 of solution is equal to 100 × apparent density at

20°C. Values of apparent density at 20°C for corresponding Brix values are

available from Table 3 in the Appendix

Bagasse extract concentrations usually fall outside the range covered by Schmitz’s Table

hence the Table cannot be applied in these instances.

Revised July 2005 Chapter 3: Calculations

SASTA Laboratory Manual p 10/12

4.2.18 Fibre % bagasse

100 × B - B × M - (B + W) × b

(a) fibre % bagasse =

B × (1 - 0.0125 × b)

where B ≡ mass of bagasse (g) put into the cold digester bowl

M ≡ moisture % bagasse

W ≡ mass of water (g) added to the cold digester bowl

b ≡ Brix % bagasse extract

In the case of final bagasse with B = 350 g and W = 2541 g the formula simplifies to:

100 - M - 8.26 × b

fibre % bagasse =

1 - 0.0125 × b

(b) daily fibre % bagasse = 100 arithmetic average of moisture % bagasse analyses

- arithmetic average of Brix % bagasse analyses

tons fibre in bagasse for the week

(c) weekly fibre % bagasse = × 100

tons bagasse for the week

where tons fibre in bagasse for the week are calculated as shown in 4.1.12

4.2.19 Moisture % bagasse

(M 2 - M 3 )

moisture % bagasse = × 100

(M 2 - M1 )

where M1 ≡ mass of the empty tray (g)

M2 ≡ mass of the tray with original bagasse sample (g)

M3 ≡ mass of the tray with dried sample (g)

Final bagasse samples are taken and analysed once per hour. As an accurate hourly

bagasse mass is not readily available, arithmetic averages of the analyses are used for

calculating daily data. Daily data are combined on a weighted basis.

4.2.20 Brix % press water mud

The press water mud is assumed to have the same pu rity as the press water. Brix %

press water mud is calculated as follows:

pol % press water mud

× 100

purity of press water

4.2.21 Pol % press water mud

The sample is prepared as a normal solution and therefore the pol result is obtained

directly from the saccharimeter reading.

4.2.22 Insoluble solids % press water mud

The calculation is carried out in the same manner as in 4.2.13.

4.2.23 Brix % press water

The result is obtained in the same manner as in 4.2.3.

Revised July 2005 Chapter 3: Calculations

SASTA Laboratory Manual p 11/12

4.2.24 Pol % press water

The result is obtained in the same manner as in 4.2.6.

4.2.25 Pol factor

tons pol in cane by mill balance

× 100

tons DAC pol in cane

4.2.26 Brix factor

tons Brix in cane by mill balance

× 100

tons DAC Brix in cane

4.2.27 Mixed juice pol/sucrose ratio

pol % mixed juice (SMRI laboratory analysis)

sucrose % mixed juice (SMRI laboratory analysis)

4.2.28 Bagasse % cane

tons bagasse

× 100

tons cane

4.2.29 Imbibition % cane

tons imbibition

× 100

tons cane

4.2.30 Imbibition % fibre

tons imbibition

× 100

tons fibre in bagasse

4.2.31 Mixed juice % cane

tons mixed juice (from scale reading)

× 100

tons cane

4.2.32 Purity of cane juice

pol % extract

× 100

Brix % extract

4.2.33 Reducing sugars/pol ratio

reducing sugars % product

× 100

pol % product

4.2.34 Reducing sugars/ash ratio

reducing sugars % product

× 100

ash % product

Revised July 2005 Chapter 3: Calculations

SASTA Laboratory Manual p 12/12

4.2.35 Recoverable value % cane (RV % cane)

(i) RV = S - dN - cF

where S ≡ sucrose % cane

N ≡ non-sucrose % cane

F ≡ fibre % cane

d ≡ the relative value of sucrose which each unit of non -sucrose

diverts from sugar production to molasses.

C ≡ the loss of sucrose from sugar production per unit of fibre

(ii) Calculation of the d factor

The factor d represents the quantity of sucrose lost to molasses per unit of non-sucrose,

but with a credit for the value of the molasses recovered per unit of non-sucrose, and is

calculated as follows:

m × Pm

d = 1 − × b

Rs/es × b × Ps

where m ≡ industry average molasses yield per unit of N delivered

Pm ≡ industry average realisation per ton of molasses as

calculated by SASA

Rs/es ≡ industry average unit recovery of saleable sugar (S) from the

estimated sugar (ES). See item (iv) for calculation of ES

Ps ≡ industry average realisation per ton of saleable sugar as

calculated by SASA

tons non - sucrose in molasses and sugar tons sucrose in molasses

b= ×

tons non - sucrose in cane tons non - sucrose in molasses

(iii) Calculation of the c factor

tons sucrose in bagasse

c=

tons fibre in cane

(iv) The factors m, b, c and Rs/es used in the above formulae are rolling three season

weighted averages determined for the immediately preceding three seasons.

In the case of Rs/es the ES delivered is determined as follows:

ES = S – bN – cF

Where S, N and F are the industry average sucrose %, non-sucrose % and fibre % cane

for the season concerned and the factors b and c are again rolling three seasons weighted

averages calculated as above.

(v) Pm and Ps will at the start of the season be the SASA pre-season estimates with

adjustments made each month by SASA on basis of the latest available data with

final adjustment at the end of the season to actual data for the season.

4.2.36 Tons recoverable value (RV) in a cane consignment

Tons cane × RV % cane

100

Revised July 2005 Chapter 3: Calculations

Você também pode gostar

- Blowdown Economizer CalculationDocumento2 páginasBlowdown Economizer CalculationSajjad AhmedAinda não há avaliações

- Cogenerations of Energy From Sugar Factory BagasseDocumento8 páginasCogenerations of Energy From Sugar Factory BagasseTade GaromaAinda não há avaliações

- 21Documento29 páginas21Remington SalayaAinda não há avaliações

- Glaxo Vol IDocumento164 páginasGlaxo Vol IPrakash WarrierAinda não há avaliações

- Heat Rate of Thermal Power PlantDocumento15 páginasHeat Rate of Thermal Power Plantsameer betal100% (1)

- 1996 - Misplon - Pinhole Grate Conversions ofDocumento4 páginas1996 - Misplon - Pinhole Grate Conversions ofmchoi23Ainda não há avaliações

- Tank EductorDocumento3 páginasTank Eductorkonainglincho001Ainda não há avaliações

- Design of Boiler Forced Draft FanDocumento5 páginasDesign of Boiler Forced Draft FanAu TagolimotAinda não há avaliações

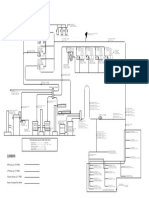

- Ign Schematic Block Diagram of Sugar ProcessingDocumento1 páginaIgn Schematic Block Diagram of Sugar ProcessingTung Bui ThanhAinda não há avaliações

- Roller Grate 5Documento9 páginasRoller Grate 5barrosojmsAinda não há avaliações

- h (V) (m) M (T) /η 45 (0.7734) (20) 1800 (298) /0.8Documento9 páginash (V) (m) M (T) /η 45 (0.7734) (20) 1800 (298) /0.8RajashekarBheemaAinda não há avaliações

- SRI Jigger Tubes System: Design, Installation and Commissioning ManualDocumento16 páginasSRI Jigger Tubes System: Design, Installation and Commissioning ManualSebastiánSaltarenAinda não há avaliações

- Sulphur MelterDocumento9 páginasSulphur MelterabderrahimnAinda não há avaliações

- Biomass (Rice Straw) Fired BoilerDocumento9 páginasBiomass (Rice Straw) Fired BoilerSnehashis MaityAinda não há avaliações

- Boiler CalculationDocumento4 páginasBoiler Calculationmohsin husen BargirAinda não há avaliações

- AccumulatorsDocumento11 páginasAccumulatorsRufus D SAinda não há avaliações

- DraughtDocumento33 páginasDraughtNipun SabharwalAinda não há avaliações

- Vacuum System ParametersDocumento7 páginasVacuum System ParametersOmar Ahmed ElkhalilAinda não há avaliações

- Cryogenic CoolingDocumento17 páginasCryogenic CoolingmaheshwaranAinda não há avaliações

- Pump Manual - Single Plunger AmbicaDocumento24 páginasPump Manual - Single Plunger AmbicaHimTex /JaswinderAinda não há avaliações

- Aeroduct Program (Duct Sizing) : Characteristics and Functions of The ProgramDocumento4 páginasAeroduct Program (Duct Sizing) : Characteristics and Functions of The ProgramAshraf KamalAinda não há avaliações

- Efficiency Calculations of BagasseDocumento4 páginasEfficiency Calculations of BagasseOmar Ahmed ElkhalilAinda não há avaliações

- SRI Jigger Steam ManualDocumento23 páginasSRI Jigger Steam ManualzalabiAinda não há avaliações

- Steam Balance Layout (TPH) ModelDocumento1 páginaSteam Balance Layout (TPH) ModelRemington SalayaAinda não há avaliações

- Mechanical Vapour Recompression System For The Evaporation of Water From Salt Containing Solution: BackgroundDocumento2 páginasMechanical Vapour Recompression System For The Evaporation of Water From Salt Containing Solution: BackgroundjokishAinda não há avaliações

- Verification of Capacity of Secondary Air Fan For Bagasse Fired BoilerDocumento2 páginasVerification of Capacity of Secondary Air Fan For Bagasse Fired BoilerAu TagolimotAinda não há avaliações

- Diagrams PDFDocumento15 páginasDiagrams PDFAhmed M. Abdel HamedAinda não há avaliações

- Request Letter: Sub:Requesting Experience Certificate For Applying BOE ExamDocumento3 páginasRequest Letter: Sub:Requesting Experience Certificate For Applying BOE ExammaheshAinda não há avaliações

- Chapter 3Documento48 páginasChapter 3Jeevanandam ShanmugasundaramAinda não há avaliações

- FD Fan Sizing CalculationDocumento3 páginasFD Fan Sizing CalculationkumarananyarupeshAinda não há avaliações

- Boiler Blow Down: Workshop On Efficient Operation & Maintenance of BoilersDocumento3 páginasBoiler Blow Down: Workshop On Efficient Operation & Maintenance of Boilerskcp1986Ainda não há avaliações

- Liquid - Liquid Heater (Condensate or Duplex Juice Heater) CalculationDocumento8 páginasLiquid - Liquid Heater (Condensate or Duplex Juice Heater) CalculationYounas SardarAinda não há avaliações

- Phosphate Hideout PDFDocumento4 páginasPhosphate Hideout PDFAHMAD DZAKYAinda não há avaliações

- Co-Injection of Coal and Gas in Blast Furnaces Are There Hidden BenefitsDocumento19 páginasCo-Injection of Coal and Gas in Blast Furnaces Are There Hidden Benefitsqun niuAinda não há avaliações

- Che 2Documento25 páginasChe 2Jaynie Lee VillaranAinda não há avaliações

- JBC Common Boiler FormulasDocumento12 páginasJBC Common Boiler Formulasnesrine10Ainda não há avaliações

- Draft of Boiler Efficiency CalculationsDocumento8 páginasDraft of Boiler Efficiency CalculationsMohsin MajeedAinda não há avaliações

- Lurgi PSI Evaporator PaperDocumento13 páginasLurgi PSI Evaporator PaperMariAle Droz CastroAinda não há avaliações

- Nrs 1-50 GestraDocumento28 páginasNrs 1-50 Gestramike tsakirisAinda não há avaliações

- Report FY 2017-18Documento20 páginasReport FY 2017-18Tarachand PatidarAinda não há avaliações

- Balistic SeperatorDocumento36 páginasBalistic SeperatorAhmetAinda não há avaliações

- Brauer 1981Documento41 páginasBrauer 1981rodgerAinda não há avaliações

- Boiler Afbc PDFDocumento101 páginasBoiler Afbc PDFdika wahyuAinda não há avaliações

- Trials of A New Stirrer-Less Juice Sulphiter at Experimental Sugar FactoryDocumento4 páginasTrials of A New Stirrer-Less Juice Sulphiter at Experimental Sugar FactoryInternational Journal of Innovative Science and Research TechnologyAinda não há avaliações

- Capacity - Calculation 8000 TCDDocumento4 páginasCapacity - Calculation 8000 TCDYadav Shweta0% (1)

- FlocculationDocumento13 páginasFlocculationTimto1984Ainda não há avaliações

- Lower and Higher Heating ValuesDocumento1 páginaLower and Higher Heating ValuesPierangelo CarozzaAinda não há avaliações

- MP305 PDFDocumento40 páginasMP305 PDFrichardstormAinda não há avaliações

- 1a.calibration of OrificemeterDocumento7 páginas1a.calibration of OrificemeterArjun P PAinda não há avaliações

- Centrifugal Pumps NPSHDocumento6 páginasCentrifugal Pumps NPSHSubrata MukherjeeAinda não há avaliações

- The Calorific Value of A Fuel Is TheDocumento4 páginasThe Calorific Value of A Fuel Is TheRana PrathapAinda não há avaliações

- Chlorine: International Thermodynamic Tables of the Fluid StateNo EverandChlorine: International Thermodynamic Tables of the Fluid StateAinda não há avaliações

- Boiler Types and ClassificationsDocumento26 páginasBoiler Types and ClassificationshardikAinda não há avaliações

- Training ReportPDF PDFDocumento42 páginasTraining ReportPDF PDFAman RajAinda não há avaliações

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNo EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasAinda não há avaliações

- Sugar Factory DefinitionDocumento8 páginasSugar Factory Definitiontsrinivasan5083100% (1)

- Definitions of TermsDocumento9 páginasDefinitions of Termsapi-3740268Ainda não há avaliações

- 1972 - Guthrie - Sugar Factory Material BalanceDocumento6 páginas1972 - Guthrie - Sugar Factory Material BalanceNaeemSiddiquiAinda não há avaliações

- Brix CurveDocumento4 páginasBrix CurveKemoy Johnson100% (8)

- Analytical Methods For Use in The Control Laboritories of Raw Sugar FactoriesDocumento181 páginasAnalytical Methods For Use in The Control Laboritories of Raw Sugar FactoriesAtul BansalAinda não há avaliações

- Chlorpyrifos Technical Fact SheetDocumento18 páginasChlorpyrifos Technical Fact SheetJun Burias PadillaAinda não há avaliações

- Sugar Cane Mini Mill PDFDocumento4 páginasSugar Cane Mini Mill PDFJun Burias PadillaAinda não há avaliações

- PD 1067 Amended IRRDocumento27 páginasPD 1067 Amended IRRMer CeeAinda não há avaliações

- Aeroponic - Hydroponic Growth ModuleDocumento88 páginasAeroponic - Hydroponic Growth ModuleJun Burias PadillaAinda não há avaliações

- Soluciones Prácticas para El Ingeniero Químico, PDFDocumento409 páginasSoluciones Prácticas para El Ingeniero Químico, PDFDavid LunaAinda não há avaliações

- Irac 2018Documento26 páginasIrac 2018Jun Burias PadillaAinda não há avaliações

- Philippine Labor Laws Employers Must KnowDocumento11 páginasPhilippine Labor Laws Employers Must Knowmanol_salaAinda não há avaliações

- Sugar Cane Mills Control PDFDocumento25 páginasSugar Cane Mills Control PDFJun Burias PadillaAinda não há avaliações

- Soil Sampling: Bulletin 704 (Revised)Documento8 páginasSoil Sampling: Bulletin 704 (Revised)Jun Burias PadillaAinda não há avaliações

- Compilation of Question and Answers On Workers BenefitsDocumento17 páginasCompilation of Question and Answers On Workers Benefitsapi-199238915Ainda não há avaliações

- Tr-Sugarcane Production NC IIDocumento145 páginasTr-Sugarcane Production NC IIJun Burias PadillaAinda não há avaliações

- Coconut OilDocumento18 páginasCoconut OilJun Burias PadillaAinda não há avaliações

- BASF TechBulletin Zampro Overview MedResDocumento1 páginaBASF TechBulletin Zampro Overview MedResJun Burias PadillaAinda não há avaliações

- Handbook of PhotosynthesisDocumento883 páginasHandbook of PhotosynthesisJun Burias PadillaAinda não há avaliações

- Sinh Li Thuc VatDocumento83 páginasSinh Li Thuc VatNguyễn HiếuAinda não há avaliações

- Techno-Economic Analysis of Biofuel Production From Macroalgae (Seaweed)Documento10 páginasTechno-Economic Analysis of Biofuel Production From Macroalgae (Seaweed)Jun Burias PadillaAinda não há avaliações

- Biofuels Data Technical ReportDocumento49 páginasBiofuels Data Technical ReportJun Burias PadillaAinda não há avaliações

- Core Sampling Recommended ProceduresDocumento16 páginasCore Sampling Recommended ProceduresAgus Wahyu SetiawanAinda não há avaliações

- The Determination of Sugar Cane Quality in Louisiana by The CoreDocumento185 páginasThe Determination of Sugar Cane Quality in Louisiana by The CoreJun Burias PadillaAinda não há avaliações

- ИнкотермDocumento1 páginaИнкотермbuugiiAinda não há avaliações

- Gods Dream by Bo SanchezDocumento28 páginasGods Dream by Bo SanchezPauline Joanne Arceo100% (1)

- VBA Book PDFDocumento121 páginasVBA Book PDFAriadiKetutAinda não há avaliações

- Sulfuric Acid Hand Book PDFDocumento36 páginasSulfuric Acid Hand Book PDFJob Warit100% (2)

- PhosphorusDocumento4 páginasPhosphorusJun Burias Padilla100% (1)

- 3 Mass Balance Agro1 PDFDocumento28 páginas3 Mass Balance Agro1 PDFLiam LagartoAinda não há avaliações

- 2013 CruisAir PricebookDocumento109 páginas2013 CruisAir Pricebooknwmarineair2869Ainda não há avaliações

- Wire¤t Rating PDFDocumento2 páginasWire¤t Rating PDFVIKRAM DESAIAinda não há avaliações

- Error CodesDocumento3 páginasError CodesJumansyah JumansyahAinda não há avaliações

- 2, 3, and 4 Wire RTDs - What Is The Difference - PDFDocumento2 páginas2, 3, and 4 Wire RTDs - What Is The Difference - PDFKelly chatingAinda não há avaliações

- 5000m3 LPG Tank FarmDocumento2 páginas5000m3 LPG Tank FarmLpgTankFarmAinda não há avaliações

- Hairpin Heat ExchangersDocumento9 páginasHairpin Heat ExchangersrajachemAinda não há avaliações

- Atuadores Rotativos Eletromecanicos Com Drive Integrado Serie Tritex - 2Documento60 páginasAtuadores Rotativos Eletromecanicos Com Drive Integrado Serie Tritex - 2Alex SouzaAinda não há avaliações

- Ramgarh Gas Thermal Power Plant PPT PresentationDocumento31 páginasRamgarh Gas Thermal Power Plant PPT Presentationswai singh100% (1)

- Hyd TrainingDocumento72 páginasHyd TrainingJuned Hamid KhanAinda não há avaliações

- SPE-164820-MS - Probabilistic and Deterministic Methods Applicability in Unconventional ReservoirsDocumento12 páginasSPE-164820-MS - Probabilistic and Deterministic Methods Applicability in Unconventional ReservoirsRayner Susanto100% (1)

- Tianjin Eco-City Showcasing Sino-Singapore Planning and Development EffortsDocumento2 páginasTianjin Eco-City Showcasing Sino-Singapore Planning and Development EffortsR. Mega MahmudiaAinda não há avaliações

- Kawasaki Gas Turbine PDFDocumento45 páginasKawasaki Gas Turbine PDF13421301508100% (1)

- Ptfe HandbookDocumento38 páginasPtfe Handbookparthihce100% (1)

- Jayson PostlabDocumento9 páginasJayson PostlabJeric CestinaAinda não há avaliações

- Hydrogen Handbook - Middle EastDocumento54 páginasHydrogen Handbook - Middle Eastbfaalh23Ainda não há avaliações

- 1.1. Daftar Spek. Peralatan RigDocumento61 páginas1.1. Daftar Spek. Peralatan RigLavayrter100% (1)

- CH 14Documento28 páginasCH 14Mushini Nagabhushan100% (1)

- Final Gasket FileDocumento48 páginasFinal Gasket FileRajarshi ChakrabortyAinda não há avaliações

- Enviroment Project On Rain Water HarvestingDocumento17 páginasEnviroment Project On Rain Water HarvestingShaikh ShoebAinda não há avaliações

- User Manual: Where Sun Shined Power Always OnDocumento20 páginasUser Manual: Where Sun Shined Power Always OnАнатолий ЯновскийAinda não há avaliações

- XZ400 (14X) Owners ManualDocumento18 páginasXZ400 (14X) Owners ManualRohan SimonAinda não há avaliações

- Harmony Control Relays - RM35TF30Documento7 páginasHarmony Control Relays - RM35TF30معين عزامAinda não há avaliações

- Lhotser Optimization Research of Grading Ring For 330 KV Power Transmission Line PDFDocumento6 páginasLhotser Optimization Research of Grading Ring For 330 KV Power Transmission Line PDFRagavanAinda não há avaliações

- Earthing Transformers For Power SystemsDocumento11 páginasEarthing Transformers For Power Systemsanoopk222100% (1)

- Centrifugal Compressor Surge and Speed ControlDocumento13 páginasCentrifugal Compressor Surge and Speed ControlDaniel Puello RodeloAinda não há avaliações

- Cooper MEDC Datasheet DB10Documento2 páginasCooper MEDC Datasheet DB10bestbest07Ainda não há avaliações

- Ig-100 Calculation SheetDocumento1 páginaIg-100 Calculation SheetNA PauleAinda não há avaliações

- Q1 - LESSON 5 Student's NameDocumento3 páginasQ1 - LESSON 5 Student's NameNGUYỄN THẾ VIỆT QUANGAinda não há avaliações

- TurbomachineryDocumento64 páginasTurbomachineryStefan Arichta100% (1)