Escolar Documentos

Profissional Documentos

Cultura Documentos

Choosing API 650 and API 620 Tanks PDF

Enviado por

rajachemTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Choosing API 650 and API 620 Tanks PDF

Enviado por

rajachemDireitos autorais:

Formatos disponíveis

Choosing Between API 620...

Page 1

419-826-4816

Choosing Between API 620 and 650 for

Your Storage Tank

Posted by Ken Brakefield

Topics: Swanton Welding, Custom Fabrication

Tweet Share 0 Like 0 Share

The American

Petroleum Industry

(API) has established

https://blog.swantonweld.co... 1/29/2018 9:36:59 AM

Choosing Between API 620... Page 2

standards for the

design, fabrication

and construction of

welded steel storage

tanks for storing oil.

The most popular

tanks available on the

market today are the

620 and 650 models,

but which is right for you? The answer depends on what you require out of the

product.API 620 regulates the design and manufacture of large steel low-

pressure storage tanks, usually larger than 300 feet in diameter. By contrast,

API Standard 650 is typically used for carbon, stainless steel and aluminium

tanks located in terminals, refineries, pipelines and other process facilities. Both

have different pressure and temperature parameters as well. Your choice of

model will depend on you and/or your client’s particular needs.

Actual Standards

If you require the complete API Standard 620, 10th Edition, February 2002, click

here. For the complete API Standard 650, 10th Edition, March 2007, click here.

API 620

The design configuration of API 620 requires that you have an elevated or flat

bottom on which to store it. The tank has a single, vertical, centered axis of

revolution with a minimum material thickness of 3/16 inch. Other attributes of

API 620 include:

• It is constructed from carbon steel, austenitic stainless steel and nickel

alloys (low temperature only).

• A Welding Certification is stipulated by American Society of Mechanical

Engineers (ASME), Section 10.

• There is a required inspection, no third party.

• The inspection cost is the cost of the non-destructive inspection (NDE)

Benefits of API 620 are:

1. It is used for products which have high internal pressure such as liquefied

natural gas (LNG) and cryogenic tanks.

https://blog.swantonweld.co... 1/29/2018 9:36:59 AM

Choosing Between API 620... Page 3

2. It can store contents at a higher pressure (maximum 15 pounds per

square inch (PSI) of gas or vapor storage) and lower temperature (-325

degrees F to 250 degrees F) than API 650.

3. It can store any liquid.

API 650

API 650 sets minimum

requirements for the design,

material, construction, and

testing for aboveground, open

and closed-top, cylindrical steel

storage tanks in different

capacities and sizes, roughly

equating to the pressure of the

atmosphere (not greater than the

weight of the roof plates). If

additional requirements are met,

higher internal pressures are allowed. API 650 only covers tanks that support

the whole bottom evenly and tanks in non-refrigerated service that have a

maximum design temperature of 200 degrees F. It requires that you have a

minimum material thickness of 3/16 inch. Other attributes of API 650 are:

• It is constructed from carbon steel, austenitic duplex stainless steel, and

aluminium

• A Welding Certification is stipulated by American Society of Mechanical

Engineers (ASME), Section 10.

• There is a required inspection, no third party.

• The inspection cost is the cost of the NDE.

Benefits of API 650 include:

1. It can store oil, gas, chemical, water and biofuel for some of the most

common tanks in the oil industry.

2. It can store contents at a lower pressure (maximum of 2 ½ PSI) but at

much higher temperature (-40 degrees F to 500 degrees F) than the

standards of API 620.

3. It can be any tank size.

https://blog.swantonweld.co... 1/29/2018 9:36:59 AM

Choosing Between API 620... Page 4

Hopefully, this article provides some clarification for those of you in the metal

fabrication industry regarding the key differences between API Standards 620

and 650 for storage tanks. To quickly summarize, API 620 can store contents at

a lower temperature and higher pressure whereas API 650 permits a lower

amount of pressure at a higher temperature. Given that, and knowing your

specific pressure and temperature requirements, you can see that choosing

your standard carefully is critical. If you need help, contact the experts at

Swanton Welding today.

Topics: Swanton Welding, Custom Fabrication

First Name*

Last Name

Email*

Website

Comment*

https://blog.swantonweld.co... 1/29/2018 9:36:59 AM

Choosing Between API 620... Page 5

Subscribe to follow-up comments for this post

Type the text

Privacy & Terms

Submit Comment

Subscribe to Email Updates

Email*

Subscribe

Recent Posts

• Differences in Stitch Welding Versus Seam Welding

• Welding Carbon Steel to Stainless Steel

• Project Spotlight: Truck Dump Platform Project

• Reducing Costs Without Cutting Corners In Structural Steel Fabrication

• The Science Behind Painting

• Employee Spotlight: Kody Kessler

• Quality Control: Know Your Steel

• Your Essential Guide to Fabricated Storage Tanks

• Employee Spotlight: Toby Curtis

https://blog.swantonweld.co... 1/29/2018 9:36:59 AM

Choosing Between API 620... Page 6

• The Coal Mining Industry Relies on Steel Fabricators

Posts by Topic

• Steel (40)

• Structural Steel Fabrication (39)

• Swanton Welding (38)

• Custom Fabrication (32)

• Custom Metal Fabrication (25)

see all

Services

Custom Metal Fabrication

Structural Steel Fabrication

Custom Welding

Heavy Fabrication

Steel Processing

Rolling & Forming

Painting and Blasting

CNC Machining

Company Information

https://blog.swantonweld.co... 1/29/2018 9:36:59 AM

Choosing Between API 620... Page 7

Custom Fabrication

History

Leadership

Careers

Locations

Privacy Policy

Sitemap

Contact Us

407 Zeiter Way

Swanton, OH 43558

Phone: 419-826-4816

Email: info@swantonweld.com

Connect With Us

Copyright © 2017 Swanton Welding & Machining, all rights reserved. | Privacy Policy

https://blog.swantonweld.co... 1/29/2018 9:36:59 AM

Você também pode gostar

- 7.2.24 - Breather ValvesDocumento28 páginas7.2.24 - Breather Valvessav33Ainda não há avaliações

- Pig Receiver Data Sheet 91303 - 8 InchDocumento4 páginasPig Receiver Data Sheet 91303 - 8 InchSinaAinda não há avaliações

- IR HL Heatless DryerDocumento1 páginaIR HL Heatless DryerYing Kei ChanAinda não há avaliações

- Sampling Systems StandardDocumento54 páginasSampling Systems StandardLuis Carlos CabreraAinda não há avaliações

- Oisd STD 118Documento1 páginaOisd STD 118KusnadiAinda não há avaliações

- CPMA Ch. 20.3 Measurement of Multiphase Flow Working GroupDocumento1 páginaCPMA Ch. 20.3 Measurement of Multiphase Flow Working GroupeduardoAinda não há avaliações

- STD 111Documento25 páginasSTD 111Sanjay Patel0% (1)

- Flare System: Types, Segregation, Tips, Purge System and MoreDocumento23 páginasFlare System: Types, Segregation, Tips, Purge System and Morerutuja100% (1)

- Quick Opening ClosuresDocumento4 páginasQuick Opening ClosuresJuan CarvajalAinda não há avaliações

- PSV Load Calculation For Gas Expantion Fire Case PDFDocumento2 páginasPSV Load Calculation For Gas Expantion Fire Case PDFAnonymous V5UYBUMaAinda não há avaliações

- GoyalDocumento3 páginasGoyalVan LeAinda não há avaliações

- Dimensionamiento de Un Aeroenfriador de GasDocumento14 páginasDimensionamiento de Un Aeroenfriador de GasHernan Coba100% (1)

- Kg-Tower ManualDocumento5 páginasKg-Tower ManualJohnny50% (2)

- Reciprocating Pumps - NDPDDocumento2 páginasReciprocating Pumps - NDPDDhanny MiharjaAinda não há avaliações

- HMB Latest Stream ReporterDocumento20 páginasHMB Latest Stream ReporterConnor SailorAinda não há avaliações

- HAT Horiz Vessel VolDocumento1 páginaHAT Horiz Vessel VolAnonymous JWI6rqtAinda não há avaliações

- 1.1.4 NGL Fractionation Train - 3Documento20 páginas1.1.4 NGL Fractionation Train - 3Julio Adolfo López PortocarreroAinda não há avaliações

- Danfoss SFVLDocumento8 páginasDanfoss SFVLTorres Ivan100% (1)

- 10 1016@j Jngse 2016 01 016Documento37 páginas10 1016@j Jngse 2016 01 016saiful bahriAinda não há avaliações

- User's GuideDocumento30 páginasUser's GuideAnonymous Wd2KONAinda não há avaliações

- Mechanical Data Sheet V-001 PDFDocumento3 páginasMechanical Data Sheet V-001 PDFdharwin ap100% (1)

- Manual Flare Sim ExproDocumento69 páginasManual Flare Sim ExproJuan Pablo AlonsoAinda não há avaliações

- 4 SPE-77495-Increasing Separation Capacity With New and Proven TechnologiesDocumento6 páginas4 SPE-77495-Increasing Separation Capacity With New and Proven TechnologiesDavid VMAinda não há avaliações

- Solubility of Calcium Carbonate in WaterDocumento2 páginasSolubility of Calcium Carbonate in WaterKEHALI AbdelheqAinda não há avaliações

- Ball Valve SpecDocumento35 páginasBall Valve SpecsandystaysAinda não há avaliações

- C:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchDocumento1 páginaC:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchFadhila Ahmad AnindriaAinda não há avaliações

- E 106Documento1 páginaE 106Bith SMGAinda não há avaliações

- VGS Vane Separators Are Recommended ForDocumento1 páginaVGS Vane Separators Are Recommended ForSanthu PeelaAinda não há avaliações

- KO DrumDocumento3 páginasKO DrumArynda Dimas SadewoAinda não há avaliações

- 4528.07.R380.02 ShellDocumento26 páginas4528.07.R380.02 ShellAnil B YadavAinda não há avaliações

- Sulsim IntegrationDocumento23 páginasSulsim IntegrationSergio Lazarte MercadoAinda não há avaliações

- Typical Fouling FactorsDocumento3 páginasTypical Fouling FactorsmahadevAinda não há avaliações

- Inspection & Test Plan For Storage Tanks Work: ITP NO.:-9560/SITE/QAC/022/ITP-13Documento6 páginasInspection & Test Plan For Storage Tanks Work: ITP NO.:-9560/SITE/QAC/022/ITP-13Shubham ShuklaAinda não há avaliações

- Flare Gas Recovery PDFDocumento13 páginasFlare Gas Recovery PDFSadad MohamadAinda não há avaliações

- Different Between Nm3Documento11 páginasDifferent Between Nm3Iskandar Zulkarnain HasibuanAinda não há avaliações

- Vent Tip Info Sheet SDocumento1 páginaVent Tip Info Sheet SabsahkahAinda não há avaliações

- Ludwigs's Applied Process Design For Chemical and Petrochemical Plants, Agitación, 4ta Ed. Vol. 1Documento79 páginasLudwigs's Applied Process Design For Chemical and Petrochemical Plants, Agitación, 4ta Ed. Vol. 1Luis Joel Ramos RamosAinda não há avaliações

- 1.0 J1415 QF200-2 PSA DatasheetDocumento2 páginas1.0 J1415 QF200-2 PSA DatasheetCarlos MagAinda não há avaliações

- Aaharya Technologies Aspen Hysys Training ProgramDocumento2 páginasAaharya Technologies Aspen Hysys Training Programpavanchem61Ainda não há avaliações

- Liquid Monopropellant CombustionDocumento4 páginasLiquid Monopropellant Combustionherdi sutanto adigunaAinda não há avaliações

- Pressurized Glycol Dehy SystemsDocumento11 páginasPressurized Glycol Dehy SystemsJagan BoseAinda não há avaliações

- Hydrocyclone Process Simulation Using Aspen HYSYSDocumento8 páginasHydrocyclone Process Simulation Using Aspen HYSYSmadhav287Ainda não há avaliações

- Aspen Exchanger Design and Rating Shell & Tube V9: Tema SheetDocumento7 páginasAspen Exchanger Design and Rating Shell & Tube V9: Tema SheetTuấn VũAinda não há avaliações

- KG Tower Loadings V1.1Documento13 páginasKG Tower Loadings V1.1Lee Koon PengAinda não há avaliações

- Chemical & Process Technology - Two-Third (2 - 3) Rule or Ten-Thirteen (10 - 13) RuleDocumento3 páginasChemical & Process Technology - Two-Third (2 - 3) Rule or Ten-Thirteen (10 - 13) RuleomeshchemAinda não há avaliações

- Excel Unit Op TutorialDocumento11 páginasExcel Unit Op TutorialEleazar RodriguezAinda não há avaliações

- ETL Pressure Relief Valves Datasheet PDFDocumento6 páginasETL Pressure Relief Valves Datasheet PDFNanasaheb PatilAinda não há avaliações

- Att2 Baretti InternalsDocumento36 páginasAtt2 Baretti InternalsAli MetinAinda não há avaliações

- EDO-PPP-ME-GNR-INT-XXX-013-107-108-Rev-A-AMMONIA STORAGE TANK DESIGN PDFDocumento33 páginasEDO-PPP-ME-GNR-INT-XXX-013-107-108-Rev-A-AMMONIA STORAGE TANK DESIGN PDFErol DAĞ100% (1)

- Steam Condensate Pot Sizing PDFDocumento1 páginaSteam Condensate Pot Sizing PDFjittshong8072Ainda não há avaliações

- Design Practices - SVsDocumento12 páginasDesign Practices - SVsagarwalashwin32Ainda não há avaliações

- The Weby's: PSV Selection For BeginnerDocumento15 páginasThe Weby's: PSV Selection For BeginnerShanmuga MuthukumarAinda não há avaliações

- 17-ApGreid - Pump Sizing Rev.2Documento14 páginas17-ApGreid - Pump Sizing Rev.2Dhanny MiharjaAinda não há avaliações

- Design Study of Floating Roof TanksDocumento2 páginasDesign Study of Floating Roof TanksSrikrishnan KrishAinda não há avaliações

- New Microsoft Word DocumentDocumento56 páginasNew Microsoft Word DocumentshabeekmAinda não há avaliações

- Shahjalal University of Science and Technology, SylhetDocumento3 páginasShahjalal University of Science and Technology, SylhetSourav SutradharAinda não há avaliações

- API 620 Vs API 650Documento2 páginasAPI 620 Vs API 650Dymac IndiaAinda não há avaliações

- Difference Between API 650 and API 620 Tanks API 650 Vs API 620 With PDFDocumento5 páginasDifference Between API 650 and API 620 Tanks API 650 Vs API 620 With PDFBogdan ChivulescuAinda não há avaliações

- H010ARDocumento22 páginasH010ARMohammed ChaabateAinda não há avaliações

- Spot Welding Interview Success: An Introduction to Spot WeldingNo EverandSpot Welding Interview Success: An Introduction to Spot WeldingAinda não há avaliações

- Karthik Updated ResumeDocumento2 páginasKarthik Updated ResumerajachemAinda não há avaliações

- TF-08 Therminol 66Documento8 páginasTF-08 Therminol 66rajachemAinda não há avaliações

- Field Experience With The Blasch VectorWall Reaction Furnace Checkerwall PTQ Q1 2014Documento7 páginasField Experience With The Blasch VectorWall Reaction Furnace Checkerwall PTQ Q1 2014rajachemAinda não há avaliações

- Kast O Lite 97 L - DatasheetDocumento1 páginaKast O Lite 97 L - DatasheetrajachemAinda não há avaliações

- Preliminary Feasibility Study Co2 Carrier Ship Based Ccs Unmanned Offshore FacilityDocumento112 páginasPreliminary Feasibility Study Co2 Carrier Ship Based Ccs Unmanned Offshore FacilityrajachemAinda não há avaliações

- Steam HXDocumento1 páginaSteam HXrajachemAinda não há avaliações

- Hysys V8.0 Tutorial - Part 1 PDFDocumento109 páginasHysys V8.0 Tutorial - Part 1 PDFrajachem100% (1)

- CO2 Recovery Plant To Urea Production in Abu Dhabi: Back To Projects DatabaseDocumento2 páginasCO2 Recovery Plant To Urea Production in Abu Dhabi: Back To Projects DatabaserajachemAinda não há avaliações

- Fuel Oil AdditivesDocumento2 páginasFuel Oil AdditivesrajachemAinda não há avaliações

- Choosing API 650 and API 620 TanksDocumento7 páginasChoosing API 650 and API 620 TanksrajachemAinda não há avaliações

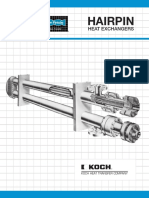

- Hairpin Heat ExchangersDocumento9 páginasHairpin Heat ExchangersrajachemAinda não há avaliações

- ASTM Grades For Insulating Fire BrickDocumento2 páginasASTM Grades For Insulating Fire BrickrajachemAinda não há avaliações

- Ιδιότητες Therminol- Με ΕξισωσειςDocumento5 páginasΙδιότητες Therminol- Με ΕξισωσειςaelalexAinda não há avaliações

- 110-Nb1 Anton Marco Fantolini SaipemDocumento21 páginas110-Nb1 Anton Marco Fantolini SaipemrajachemAinda não há avaliações

- Project No. 16279S Project Name Bapco - JVTST: Calculation of Emissivity of Process GasDocumento11 páginasProject No. 16279S Project Name Bapco - JVTST: Calculation of Emissivity of Process GasrajachemAinda não há avaliações

- Corrosion Testing of Metals - Is It Needed?: Presented atDocumento21 páginasCorrosion Testing of Metals - Is It Needed?: Presented atandrea assanelliAinda não há avaliações

- Supplementary Cementitious Materials - LiteratureDocumento68 páginasSupplementary Cementitious Materials - LiteraturealulatekAinda não há avaliações

- Price List: Revision - BDocumento16 páginasPrice List: Revision - Banilrawat1987Ainda não há avaliações

- ASTM A106 Seamless Carbon Steel PipeDocumento2 páginasASTM A106 Seamless Carbon Steel PipeCarlosAinda não há avaliações

- Introduction To Mud Plaster and Mud MortarDocumento10 páginasIntroduction To Mud Plaster and Mud MortarHridhya mpAinda não há avaliações

- Press Tool TechnologyDocumento4 páginasPress Tool TechnologyErzan FauzanAinda não há avaliações

- BS 5352-1981 PDFDocumento22 páginasBS 5352-1981 PDF윤규섭Ainda não há avaliações

- KVT Tappex en 05-2015 Web-CatalogDocumento32 páginasKVT Tappex en 05-2015 Web-CatalogWK SinnAinda não há avaliações

- Heroes WardDocumento10 páginasHeroes WardmmabeeAinda não há avaliações

- Chapter8-Design of Masonry Walls For Gravity LoadsDocumento34 páginasChapter8-Design of Masonry Walls For Gravity Loadsreadcc.nepalAinda não há avaliações

- Performance of Slurry Infiltrated Fibrous Concrete Sifcon With Silica FumeDocumento13 páginasPerformance of Slurry Infiltrated Fibrous Concrete Sifcon With Silica FumeMOHAN KUMARAinda não há avaliações

- Corrosion Protection Engineers IndiaDocumento2 páginasCorrosion Protection Engineers IndiaCorrosion FactoryAinda não há avaliações

- Casquillo Roscados para Metales Kobsert-En-1000Documento16 páginasCasquillo Roscados para Metales Kobsert-En-1000WANKEL25Ainda não há avaliações

- TECE2Documento8 páginasTECE2ahmedAinda não há avaliações

- Datasheet For Gate Valves: ProjectDocumento3 páginasDatasheet For Gate Valves: ProjectbecpavanAinda não há avaliações

- DPWH Cost Estimation Manual For Low Rise BuildingsDocumento288 páginasDPWH Cost Estimation Manual For Low Rise Buildingsg200290% (127)

- Excavation SupportDocumento15 páginasExcavation Supportcraig bureyAinda não há avaliações

- StudentDocumento7 páginasStudentKartik AryanAinda não há avaliações

- 21 L0 Is 2101 Piping Material Specification 06 9Documento1 página21 L0 Is 2101 Piping Material Specification 06 9karthiAinda não há avaliações

- Project ManagementDocumento99 páginasProject ManagementVIJAY BHILWADEAinda não há avaliações

- Mix Proportioning of Bituminous Concrete Grade-1: SL - No Test Test Method Spec. Requireme NT Test Results RemarksDocumento6 páginasMix Proportioning of Bituminous Concrete Grade-1: SL - No Test Test Method Spec. Requireme NT Test Results RemarksAbhay kumar SinghAinda não há avaliações

- IC72 Panel Spec Data 1100367 PDFDocumento3 páginasIC72 Panel Spec Data 1100367 PDFNiral PanchalAinda não há avaliações

- (NTU) Flowmeter CatalogDocumento25 páginas(NTU) Flowmeter Catalogtesya konelaAinda não há avaliações

- Floors, Walls and Windows: Cleaning For HealthDocumento30 páginasFloors, Walls and Windows: Cleaning For HealthMALOU ELEVERAAinda não há avaliações

- Haldia Petrochemicals LTD LLDPEDocumento6 páginasHaldia Petrochemicals LTD LLDPEsenthilkumar santhanamAinda não há avaliações

- Pipe Schedule Table PDFDocumento16 páginasPipe Schedule Table PDFAlaa edine SmaaliAinda não há avaliações

- EMT Burn Data SheetDocumento2 páginasEMT Burn Data SheetAhmad Salah100% (2)

- Tairilac Abs Resin: Formosa Chemicals & Fibre CorporationDocumento1 páginaTairilac Abs Resin: Formosa Chemicals & Fibre CorporationRodrigo LoraAinda não há avaliações

- BECE BDT Past Questions 2016Documento9 páginasBECE BDT Past Questions 2016Anonymous lnC6IDg67% (3)

- Letter For Feild Compressive Strength Test 1Documento2 páginasLetter For Feild Compressive Strength Test 1Pja Shantha100% (1)