Escolar Documentos

Profissional Documentos

Cultura Documentos

Thermally Insulating Packer Fluids

Enviado por

AminDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Thermally Insulating Packer Fluids

Enviado por

AminDireitos autorais:

Formatos disponíveis

Page 1 of 3

Thermally Insulating Packer Fluids

By Weyman Dunaway

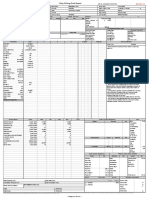

The following graph shows the relative effects of

Deepwater Interest convection and thermal conductivity on the

overall heat transfer coefficient for a

One deepwater project manager recently stated hypothetical deepwater riser using different

that, “Flow assurance and thermal management packer fluids:

are the principle drivers of ultra-deepwater riser

design.” Thermally insulating packer fluids are

aimed directly at flow assurance and thermal Effect of Viscosity and Thermal

management issues, because they provide Conductivity on Heat Transfer Coefficient,

insulating benefit in addition to their traditional U

role of providing hydrostatic head. Several 5.00

operators and engineering firms have expressed

strong interest in thermally insulating packer

fluids as evidenced by the large number of 4.00

technical presentations at the 2002 Offshore

U [=] Btu/hr x ft2 x oF

Technology Conference. 3.00

Several supply and service companies have

2.00

responded to this technical need and customer

Gelled Brine

interest by developing thermally insulating

ThermaFix

packer fluid products. TETRA Technologies, Inc. 1.00

is now marketing its new ThermaFix™ insulating

packer fluid—an advanced, second-generation

0.00

insulating product. This article discusses the 1 10 100 1,000 10,000 100,000

technical requirements for thermally insulating

packer fluids and TETRA® chemists’ development Viscosity [cps]

efforts to meet those requirements.

In this scenario, adding viscosifier to

conventional brine eliminates convection losses

Temperature Retention versus at about 1,200 cps and reduces the overall heat

Heat Transfer Coefficient transfer coefficient by about 30%. Reducing the

thermal conductivity by 70% reduced the heat

Common sense suggests that adding insulation

transfer coefficient by another 30%. Therefore,

is more cost effective than buying a bigger

convection and conduction effects are equally

heater. The same is true for insulating pipes;

important for an insulating packer fluid.

you may still need a heater, but the heater can

be smaller and less complex if you insulate first.

Therefore, a primary consideration for insulating Measuring Thermal Properties

packer fluids is their insulation value.

One approach to developing a better insulating

Some vendors have expressed the insulating packer fluid is to measure properties such as

value of their products in terms of temperature thermal conductivity and specific heat. However,

retention. Because it ignores surface area, time, TETRA has found that commercial Thermal

and energy flux, temperature retention is an Conductivity Laboratories can report results that

inadequate method of quantifying insulation differ from published values by as much as 50%.

value. A more useful method of quantifying Therefore, care must be taken to select a lab

insulating value is the overall heat transfer that gets results similar to published values for

coefficient, U, and U has the dimensions of: known materials in the range of interest.

U [=] Btu/ft2 x oF x hr The onset of convection is a very low shear

phenomenon. Most of the insulating packer

fluids are non-Newtonian gels, so it is important

Convection versus Thermal to measure the viscosity at very low shear rates.

Conductivity TETRA measures very low shear viscosity of

insulating packer fluids at 0.09 sec-1 (0.05 rpm);

The three modes of heat transfer are that is one revolution every 20 minutes.

conduction, convection and radiation. Radiation

is rarely a factor in oil wells. Calculation of a TETRA recognizes that computer models and

riser’s heat transfer coefficient with conduction property measurements can be instructive;

and convection effects involves a complex set of however, they are no substitute for also

equations that are best performed on a measuring heat transfer coefficients in a realistic

computer simulation program such as OLGA. geometry. Therefore, TETRA has designed and

Page 2 of 3

constructed a 20 foot thermal flow loop to heat transfer. Gelling the brine makes the heat

measure the heat transfer coefficients of packer transfer coefficient both lower and more linear.

fluids in an offshore riser configuration:

The Gel + HGMS curve is particularly interesting

because it represents a mixture of gelled brine

and hollow glass microspheres (HGMS). The

HGMS were tested as a means of lowering the

thermal conductivity of the gelled brine. These

results show that HGMS is beneficial at lowering

the heat transfer coefficient. However, HGMS is

thermally inferior to ThermaFix.

Cool Down Time

Another key attribute of insulating packer fluids

is Cool Down Time (CDT)—the time required for

the riser to cool down to the hydrate formation

temperature after production has been

interrupted. CDTs depend on the composition of

the produced fluid, the riser geometry, and the

thermal characteristics of the packer fluid. So,

OLGA simulations are also used to estimate

CDT. The following plot shows the effect of

viscosity and thermal conductivity on CDT for

the same hypothetical offshore riser used in the

heat transfer coefficient study:

Effect of Viscosity and Thermal

TETRA’s Thermal Flow Loop Conductivity on Cool Down Time

8.0

TETRA’s thermal flow loop consists of a

production string surrounded by a casing string 7.0

filled with packer fluid. The riser assembly is

surrounded by a jacket containing chilled water. 6.0

Hot fluid is circulated through the production Gelled Brine

Cool Down Hours

5.0

string. Temperature measurements and flow ThermaFix

rates allow the calculation of the measured heat 4.0

transfer coefficient. The following plot shows

typical results from the 20 foot thermal flow 3.0

loop:

2.0

1.0

Experimental Heat Transfer Coefficients

for Packer Fluids 0.0

1 10 100 1,000 10,000 100,000

100.0 Viscosity [cps]

90.0

80.0 Ungelled Brine Gelling the brine increased CDT by about 50%.

70.0 Gelled Brine Reducing the thermal conductivity by 70% and

U = Btu/hr Ft2 oF

60.0 Gel + HGMS viscosifying increased CDT by more than 270%.

ThermaFix

50.0

Air Again, being mindful of the need to actually test

40.0

CDTs, TETRA has designed and constructed a

30.0 cool down tester as shown in the next

20.0 photograph:

10.0

0.0

20.0 70.0 120.0 170.0 220.0

Flow Rate [=] grams/minute

The very non-linear results for ungelled brine

are characteristic of a material that

demonstrates both conductive and convective

Page 3 of 3

The time required to cool these fluids from 150oF

to 60oF was:

Experimental Cool Down Times

(150oF to 60oF)

Fluid Seconds % Computer

Increase Simulation

Brine 210 Basis Basis

Gelled 397 89% 50%

Brine

ThermaFix 807 280% 270%

These experimental results show remarkably

good agreement with the computer simulated

data.

Conclusions

• The key attributes for an effective insulating

packer fluid are heat transfer coefficient and

cool down time.

• Gelling the packer fluid alone has benefits;

but gelling plus lowering the thermal

TETRA’s cool down tester consists of a jacketed conductivity provides even greater benefits.

glass column fitted with temperature sensors on

each end. The inside of the column is filled with • ThermaFix exceeds the thermal performance

hot packing fluid. Then, chilled water is of gelled brines and gels filled with a proven

circulated through the jacket. A computer logs insulator such as hollow glass microspheres.

the temperatures inside the packer fluid and

averages the two RTDs. Typical results are

shown in the following plot:

Experimental Cool Down Times of

Packer Fluids

180

Brine

160

Gelled Brine

140 ThermaFix

TETRA Technologies, Inc.

Temperature (F)

120

100

Corporate Headquarters

25025 Interstate 45 North

80

The Woodlands, Texas 77380

60 281.364.2264

40

National Sales

20

713.980.5230

0

0 200 400 600 800 1000 1200 1400 1600

sales@tetratec.com

Time (seconds)

Weyman Dunaway is currently Technology Center Manager of Engineering and Special Projects

for TETRA Technologies, Inc. He graduated BsChE from the Georgia Institute of Technology in

1977.

Copyright © 2003 TETRA Technologies, Inc. All rights reserved.

ThermaFix is a trademark of and TETRA is a registered trademark of TETRA Technologies, Inc.

Você também pode gostar

- NeoFlo 1-58 Datasheet PDFDocumento4 páginasNeoFlo 1-58 Datasheet PDFSteven MarinoffAinda não há avaliações

- The Use and Misuse of Centrifuges PDFDocumento4 páginasThe Use and Misuse of Centrifuges PDFChandrasekar Srinivas MohanAinda não há avaliações

- Drilling Problems Mitigation in Geothermal Environtment, Case Studies of Stuck Pipe and Lost Circulation (W.a. Nugroho, 2017)Documento11 páginasDrilling Problems Mitigation in Geothermal Environtment, Case Studies of Stuck Pipe and Lost Circulation (W.a. Nugroho, 2017)Daniel TobingAinda não há avaliações

- From Mud To Cement PDFDocumento15 páginasFrom Mud To Cement PDFFabian MontoyaAinda não há avaliações

- Envirotherm NTDocumento6 páginasEnvirotherm NTErlgabAinda não há avaliações

- Reverse-Circulation Cementing and Foamed Latex Cement Enable Drilling in Lost - Circulation ZonesDocumento5 páginasReverse-Circulation Cementing and Foamed Latex Cement Enable Drilling in Lost - Circulation ZonesRMolina65Ainda não há avaliações

- Safe ThermDocumento6 páginasSafe ThermLoganBohannonAinda não há avaliações

- SPE-116364-Entrance Pressure of Oil Based Mud Into Shale Effect of Shale, WaterDocumento19 páginasSPE-116364-Entrance Pressure of Oil Based Mud Into Shale Effect of Shale, WaterwjawichAinda não há avaliações

- Improved Drilling of Depleted Sands with Cloud-Point GlycolsDocumento3 páginasImproved Drilling of Depleted Sands with Cloud-Point GlycolsJulie SpencerAinda não há avaliações

- Geothermal Drilling Fluid PresentationDocumento35 páginasGeothermal Drilling Fluid PresentationWillianAinda não há avaliações

- SPE 68504 Jet Drilling Tool: Cost-Effective Lateral Drilling Technology For Enhanced Oil RecoveryDocumento9 páginasSPE 68504 Jet Drilling Tool: Cost-Effective Lateral Drilling Technology For Enhanced Oil RecoveryAnonymous VNu3ODGavAinda não há avaliações

- Cementing Design OptimizationDocumento5 páginasCementing Design OptimizationnkhamidyAinda não há avaliações

- Clay Nanoparticles Modifed Drilling Fluids For Drilling of Deep Hydrocarcbon Wells PDFDocumento7 páginasClay Nanoparticles Modifed Drilling Fluids For Drilling of Deep Hydrocarcbon Wells PDFJuliana BuelvasAinda não há avaliações

- Acid Retarder TDSDocumento1 páginaAcid Retarder TDSAmbrish KamdarAinda não há avaliações

- Chapter 14 - Drilling Fluids For ERD, Horizontal WellsDocumento14 páginasChapter 14 - Drilling Fluids For ERD, Horizontal WellsAbbas AlkhudafiAinda não há avaliações

- Bore MaxDocumento2 páginasBore Maxibjsa7586Ainda não há avaliações

- Air Compressors 1170cfm T4Documento2 páginasAir Compressors 1170cfm T4death666darkAinda não há avaliações

- Chapter II - Geothermal Project Development: Phases and ExpertiseDocumento2 páginasChapter II - Geothermal Project Development: Phases and ExpertiseMr Burns100% (1)

- Spe 135704 MS PDFDocumento9 páginasSpe 135704 MS PDFKd FaAinda não há avaliações

- Drilling Fluid TreatmentDocumento9 páginasDrilling Fluid TreatmentKasper JensenAinda não há avaliações

- CFS Technology DevelopmentDocumento23 páginasCFS Technology DevelopmentHangga Guna DharmaAinda não há avaliações

- Drilling Fluid Rheology: "N" and "K" ApplicationsDocumento6 páginasDrilling Fluid Rheology: "N" and "K" ApplicationsAnonymous T32l1RAinda não há avaliações

- Pilot Test: ScientificDocumento12 páginasPilot Test: ScientificHomam MohammadAinda não há avaliações

- Drilling Fluid Rheology ExplainedDocumento22 páginasDrilling Fluid Rheology ExplainedLazharAinda não há avaliações

- Turbochem BrochureDocumento8 páginasTurbochem BrochureSameer KhanAinda não há avaliações

- Well Description: Lead Slurry 999 2276 10 550 Tail Slurry 212 1038 550 650Documento8 páginasWell Description: Lead Slurry 999 2276 10 550 Tail Slurry 212 1038 550 650Nitin GandhareAinda não há avaliações

- Manzalai-07 Daily Mud Report (10!7!20)Documento1 páginaManzalai-07 Daily Mud Report (10!7!20)Sharjeel AhmedAinda não há avaliações

- MAX LOCK Lost Circulation Material SLSH PDFDocumento2 páginasMAX LOCK Lost Circulation Material SLSH PDFmehranAinda não há avaliações

- 2 SPE 58793 OptibridgeDocumento8 páginas2 SPE 58793 OptibridgePT100% (1)

- 13-Bit Selection & Operating ConditionsDocumento116 páginas13-Bit Selection & Operating ConditionsMehdi SoltaniAinda não há avaliações

- Oil Well Cement Slurry Design Analysis and Test For ConsistencyDocumento16 páginasOil Well Cement Slurry Design Analysis and Test For Consistencylitu janardhananAinda não há avaliações

- Mud Engineers HandbookDocumento29 páginasMud Engineers HandbookWasif KarimAinda não há avaliações

- Drilling Fluids: Islamic Azad University Science and Research Branch Drilling DepartmentDocumento26 páginasDrilling Fluids: Islamic Azad University Science and Research Branch Drilling Departmentali nahiAinda não há avaliações

- Geothermal Drilling: A Baseline Study of Nonproductive Time Related To Lost CirculationDocumento13 páginasGeothermal Drilling: A Baseline Study of Nonproductive Time Related To Lost CirculationForloradAinda não há avaliações

- Polymer Support FluidDocumento2 páginasPolymer Support FluidhamsarajshettyAinda não há avaliações

- Right Angle Set Cement - "RAS"Documento1 páginaRight Angle Set Cement - "RAS"alizareiforoush100% (1)

- Drill String 1 DISDocumento1 páginaDrill String 1 DISpiies85Ainda não há avaliações

- Ruspetro PI 413 P41 05 EOWDocumento15 páginasRuspetro PI 413 P41 05 EOWOleg MalkovAinda não há avaliações

- 2 Spe 96798 HPWBM - HodderDocumento12 páginas2 Spe 96798 HPWBM - HodderPT100% (1)

- 1 Completion Fluids: Clear-Fluid SystemsDocumento23 páginas1 Completion Fluids: Clear-Fluid SystemsYongki SuharyaAinda não há avaliações

- SILDRIL System Engineering GuidelinesDocumento7 páginasSILDRIL System Engineering GuidelinesAhmer AkhlaqueAinda não há avaliações

- Rheological Models For Drilling FluidDocumento16 páginasRheological Models For Drilling FluidModesty Ekeh100% (1)

- Drilling Fluid Services On Offshore Wells: Georgiy GagloyevDocumento24 páginasDrilling Fluid Services On Offshore Wells: Georgiy GagloyevKevin RossAinda não há avaliações

- 03 - Skin Factor and Wellbore StorageDocumento39 páginas03 - Skin Factor and Wellbore Storageاحمد محمد عليAinda não há avaliações

- Bentonite Clay-Acid Activation Studies: K. Suresh, R. Samant, S.K. Jatty and H. BambhaniaDocumento5 páginasBentonite Clay-Acid Activation Studies: K. Suresh, R. Samant, S.K. Jatty and H. BambhaniaminingnovaAinda não há avaliações

- Drilling Application: Name of Company: Well Name & Number: DateDocumento1 páginaDrilling Application: Name of Company: Well Name & Number: DatescrbdgharaviAinda não há avaliações

- Red Stripe Mud Lightener Technical Data SheetDocumento6 páginasRed Stripe Mud Lightener Technical Data SheetChris SniderAinda não há avaliações

- Manual MiDocumento813 páginasManual MiJuan LorenzoAinda não há avaliações

- Drilling Technology and Costs - Chapter - 6Documento51 páginasDrilling Technology and Costs - Chapter - 6zdq02Ainda não há avaliações

- 5 Effect of High Temp On MudsDocumento8 páginas5 Effect of High Temp On Mudsgplese0Ainda não há avaliações

- DDR N°02 - Sydnw1 - Enf57 - 24122019Documento3 páginasDDR N°02 - Sydnw1 - Enf57 - 24122019Kenaouia Bahaa100% (1)

- Performance Evaluation of HP WBM Drillin PDFDocumento105 páginasPerformance Evaluation of HP WBM Drillin PDFÃndÿ RøõnęÿAinda não há avaliações

- Study On Rice Husk As Lost Circulation MaterialDocumento52 páginasStudy On Rice Husk As Lost Circulation MaterialMuhammad Nursalam100% (1)

- Bariod Completion FluidsDocumento26 páginasBariod Completion FluidsAniekan SabastineAinda não há avaliações

- Acid-Tunneling Technique Shows Success in Stimulating Carbonate ReservoirsDocumento3 páginasAcid-Tunneling Technique Shows Success in Stimulating Carbonate ReservoirsFisher YohannesAinda não há avaliações

- BaraBlend 665BaraLock 666russiaDocumento2 páginasBaraBlend 665BaraLock 666russiaArun Raj LatchumananAinda não há avaliações

- Extended Leak Off TestDocumento2 páginasExtended Leak Off TestPrasanti Plaban Dash100% (1)

- Use of Nanomaterials in Cementing ApplicationsDocumento0 páginaUse of Nanomaterials in Cementing ApplicationsMobeen MurtazaAinda não há avaliações

- Fundamentals and Applications of Bionic Drilling FluidsNo EverandFundamentals and Applications of Bionic Drilling FluidsAinda não há avaliações

- BOAST-VHS Simulator ManualDocumento89 páginasBOAST-VHS Simulator ManualAminAinda não há avaliações

- IPA15 SE 025 Epoxy - Resin WSODocumento10 páginasIPA15 SE 025 Epoxy - Resin WSOAminAinda não há avaliações

- Asphaltene Deposition in Carbonate Rocks: Experimental Investigation and Numerical SimulationDocumento14 páginasAsphaltene Deposition in Carbonate Rocks: Experimental Investigation and Numerical SimulationAminAinda não há avaliações

- Artificial Lift MethodsDocumento239 páginasArtificial Lift MethodsEbenezer Amoah-Kyei100% (2)

- 1-S2.0-S1875510016305492-Main @oildocDocumento12 páginas1-S2.0-S1875510016305492-Main @oildocAminAinda não há avaliações

- Permana 2015Documento20 páginasPermana 2015AminAinda não há avaliações

- Artificial LiftDocumento61 páginasArtificial LiftAminAinda não há avaliações

- Checks Before Water Shut Off JobDocumento1 páginaChecks Before Water Shut Off JobAminAinda não há avaliações

- Basic Artificial LiftDocumento9 páginasBasic Artificial LiftlabrujisAinda não há avaliações

- Water Shut OffDocumento10 páginasWater Shut OffAminAinda não há avaliações

- Integrated Analysis of Choke PerformanceDocumento25 páginasIntegrated Analysis of Choke PerformanceAminAinda não há avaliações

- WSO Procedure-Cemment SlurryDocumento3 páginasWSO Procedure-Cemment SlurryAminAinda não há avaliações

- Asphaltene Deposition in Carbonate Rocks: Experimental Investigation and Numerical SimulationDocumento14 páginasAsphaltene Deposition in Carbonate Rocks: Experimental Investigation and Numerical SimulationAminAinda não há avaliações

- Coiled Tubing Cement Squeeze ChallengesDocumento7 páginasCoiled Tubing Cement Squeeze ChallengesAminAinda não há avaliações

- Case Study 01Documento14 páginasCase Study 01AminAinda não há avaliações

- BOAST-VHS Simulator ManualDocumento89 páginasBOAST-VHS Simulator ManualAminAinda não há avaliações

- CT CMT Squeezing ProcedureDocumento10 páginasCT CMT Squeezing ProcedureAminAinda não há avaliações

- Introduction to CMG's Modelling WorkflowsDocumento55 páginasIntroduction to CMG's Modelling Workflowsstbernardj100% (1)

- BucklingDocumento10 páginasBucklingAminAinda não há avaliações

- Introduction to CMG's Modelling WorkflowsDocumento55 páginasIntroduction to CMG's Modelling Workflowsstbernardj100% (1)

- Wang 2001Documento16 páginasWang 2001AminAinda não há avaliações

- CMG Asphaltin SimulationDocumento9 páginasCMG Asphaltin SimulationAminAinda não há avaliações

- Kinetics of Methanol Synthesis From Carbon Dioxide Hydrogenation Over Copper Zinc Oxide CatalystsDocumento13 páginasKinetics of Methanol Synthesis From Carbon Dioxide Hydrogenation Over Copper Zinc Oxide CatalystsAminAinda não há avaliações

- Chemical Engineering Journal: SciencedirectDocumento11 páginasChemical Engineering Journal: SciencedirectAminAinda não há avaliações

- Applied Catalysis B: Environmental: Matej Hu S, Venkata D.B.C. Dasireddy, Neja Strah Stefan Ci C, Bla Z LikozarDocumento12 páginasApplied Catalysis B: Environmental: Matej Hu S, Venkata D.B.C. Dasireddy, Neja Strah Stefan Ci C, Bla Z LikozarAminAinda não há avaliações

- How Oxide Carriers Control The Catalytic Functionality of The Cu-Zno System in The Hydrogenation of Co To MethanolDocumento8 páginasHow Oxide Carriers Control The Catalytic Functionality of The Cu-Zno System in The Hydrogenation of Co To MethanolAminAinda não há avaliações

- Investigating The Propagation of The Colloidal DisDocumento18 páginasInvestigating The Propagation of The Colloidal DisAminAinda não há avaliações

- Accepted Manuscript: ApsuscDocumento30 páginasAccepted Manuscript: ApsuscAminAinda não há avaliações

- Fundumentals of DrillingDocumento147 páginasFundumentals of DrillingAmin100% (2)

- z5040758 FAHAD Lowsalinitywaterflooding FINALDocumento28 páginasz5040758 FAHAD Lowsalinitywaterflooding FINALAminAinda não há avaliações

- Vapour Absorption Refrigeration System and Vapour Compression Refrigeration SystemDocumento9 páginasVapour Absorption Refrigeration System and Vapour Compression Refrigeration Systemsandip singhAinda não há avaliações

- Buderus G115 Oil Fired Hot Water Boiler BrochureDocumento4 páginasBuderus G115 Oil Fired Hot Water Boiler Brochuree-ComfortUSAAinda não há avaliações

- Estimating Design Parameters in Propane Refrigerant Systems - Pumps & SystemsDocumento6 páginasEstimating Design Parameters in Propane Refrigerant Systems - Pumps & Systemsm.shehreyar.khanAinda não há avaliações

- CBSE Chemistry Question Bank 2023Documento496 páginasCBSE Chemistry Question Bank 2023NafeesAinda não há avaliações

- Basics of InfraredDocumento58 páginasBasics of InfraredConstantyn_FrederikAinda não há avaliações

- BAC Product and Application HandbookDocumento513 páginasBAC Product and Application HandbookyasserismailAinda não há avaliações

- Steam TableDocumento24 páginasSteam TableHyein KimAinda não há avaliações

- Lab Report Materials Thermodynamics: Hee's Law: Determine The EnthalpyDocumento8 páginasLab Report Materials Thermodynamics: Hee's Law: Determine The EnthalpyfatinzalilaAinda não há avaliações

- IC100 - Compact Controller for Single Circuit Systems Up to 2 CompressorsDocumento3 páginasIC100 - Compact Controller for Single Circuit Systems Up to 2 CompressorsBishoy MekhaelAinda não há avaliações

- Volumetric Properties of Pure Fluids: Chapter 3 Smith and Van NessDocumento60 páginasVolumetric Properties of Pure Fluids: Chapter 3 Smith and Van NessKush PatelAinda não há avaliações

- Prediction of Reaction Enthalpy and Adiabatic Temperature RiseDocumento20 páginasPrediction of Reaction Enthalpy and Adiabatic Temperature RisetpchoAinda não há avaliações

- Convective Mass Transfer GuideDocumento30 páginasConvective Mass Transfer GuideBeatriceAinda não há avaliações

- CCI BGA and Heat Pipe SinksDocumento3 páginasCCI BGA and Heat Pipe SinkscivicbladeAinda não há avaliações

- Ibrahim Dincer, Tahir Abdul Hussain Ratlamwala Auth. Integrated Absorption Refrigeration Systems Comparative Energy and Exergy Analyses PDFDocumento280 páginasIbrahim Dincer, Tahir Abdul Hussain Ratlamwala Auth. Integrated Absorption Refrigeration Systems Comparative Energy and Exergy Analyses PDFahaddi58100% (1)

- Chapter 18Documento4 páginasChapter 18Marco LuigiAinda não há avaliações

- Charles LawDocumento22 páginasCharles LawLervy Shane Navares IndabAinda não há avaliações

- BE Applied Electronics and InstrumentationDocumento104 páginasBE Applied Electronics and InstrumentationEr Paramjit SinghAinda não há avaliações

- Neutral Thermal Environment (NTE) Temperature Guidelines: 0-6hrs 72-96hrsDocumento1 páginaNeutral Thermal Environment (NTE) Temperature Guidelines: 0-6hrs 72-96hrsYulia Mufidah100% (1)

- Rotary Dryer DesignDocumento43 páginasRotary Dryer DesignsasitharAinda não há avaliações

- ACTIVITY: Interpreting Representations - Heat Pump CycleDocumento5 páginasACTIVITY: Interpreting Representations - Heat Pump CycleAngelica Calamba CalicaAinda não há avaliações

- ME F414 Fuel Cell Science and Technology: Tribeni - Roy@pilani - Bits-Pilani - Ac.inDocumento26 páginasME F414 Fuel Cell Science and Technology: Tribeni - Roy@pilani - Bits-Pilani - Ac.inArpanAinda não há avaliações

- Butt CrackDocumento33 páginasButt CrackElgen CabanagAinda não há avaliações

- Explaining Hess' Law by Finding The Heat of ReactionDocumento9 páginasExplaining Hess' Law by Finding The Heat of ReactionFanilo RazafindralamboAinda não há avaliações

- NIT Rourkela 5th Sem Mechanical Engineering Student Project ListDocumento2 páginasNIT Rourkela 5th Sem Mechanical Engineering Student Project ListSHIVANANDA DALEIAinda não há avaliações

- Heat & Thermodynamics Complete SankalpDocumento58 páginasHeat & Thermodynamics Complete SankalpASHOK KUMAR RANAAinda não há avaliações

- Module 3 PDFDocumento27 páginasModule 3 PDFkaushal shivaprakashAinda não há avaliações

- BIOELECTROMAGNETICS Current Concepts The Mechanisms of The Biological Effect of Extremely High Power PulsesDocumento441 páginasBIOELECTROMAGNETICS Current Concepts The Mechanisms of The Biological Effect of Extremely High Power Pulsesscribbedulle0% (1)

- Calorific Value of Fuel Using Junker S Gas CalorimeterDocumento12 páginasCalorific Value of Fuel Using Junker S Gas Calorimeterjishnu100% (1)

- 103 Top Heat Transfer Question and Answers PDFDocumento11 páginas103 Top Heat Transfer Question and Answers PDFbenny narrido67% (6)