Escolar Documentos

Profissional Documentos

Cultura Documentos

Me Reviewer 3

Enviado por

Ariel Dela Cruz0 notas0% acharam este documento útil (0 voto)

12 visualizações20 páginasMechanical engineering reviewer

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoMechanical engineering reviewer

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

12 visualizações20 páginasMe Reviewer 3

Enviado por

Ariel Dela CruzMechanical engineering reviewer

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 20

Qui

Related “o Ma

sion Related @ Ma & Quatiey Control Implemen

2a central mbtng plat

25 than (1) Fifty (S0) seconds

unless miner performance tect prove,

concrete if « shoner time period, How many

2 added to th ca if timing

reaches its maxinum raised positions 7 (1) 10

is (3) i seconds.

™

“Y, Ga the preparation of Base Course vsing lime Stabilization Method, if sluny

ime c employed, whet is the typical siurry ratio 7 ()_1 Tonne line tod

gum cf water (2) Lionne lime to 2 eum. of water (@) {tonne lime to 3

Ana Nat

R ASPHALT

AA. (Li Cutbsck Asphalt (2) Petreleum Asphalt (3) Emmilsified Asphalt

‘2 pitenmous residue of crude olf alfer fis lighter component have been

oh aimospherio & vacuum distilletion The process vary

2 oil production method.

2. Petroicum Asphalis used in pavement construction shall bg homogenous,

fice Siom water & shall not Totin when heated to (AIOE, (465°C

PAs. .

ee

QUE TIONAIRE FOR MATERIALS ENG! NEER:

Lis defined r2 Geminimom moisture content at waich the soll can be

readily malded without breaking or crumbling,

a. Liquid limi: e; Blastie limit

b. Plasticity index dbotha&e

a determining the Fidd Density Test we need to know de folowing:

a.Fidd moisure content ¢.Laboratary compacéan

b,Opdmum moistare content, d. All of che above

Dividing the lord susizins by the spedinen at the suddes holt of the lord

Indicatey pulueer by the nominal cross secdonal area ofthe specimen using

ULM we obtain

as Tensile Suength Aiea Bteength

. Elongation a. Beading

ating (xe ductile properties of

‘This testis one of the methods iu ev

a. Tensile Srengilt 2, Yield Suengih

, Elongation AL Bending Properties

“This item ccnsist of preparing and treating am existing bituminoas or canoe

qeashece surface with bitandaous materialsin accordance with the Plans and

‘Speciliesdous, preparotery to the construction of 2 bituminous sarfase

course.

ne Coat Ai Bituminows Teak Cost

i Coat é. Bizmainous Surface Treatment

a. Bituminees

b, Bieminens Se

This item shall eansist of 6! a Sughe appiicatien ef ‘bitsminaus material

Fellowed bea single spreading of avgrezace(sughe surface ceamenQ in

pecordange with the plans & spedications.

¢, Binmninous Tack Coat

. Bituminous Seal Coat A Bitsminoss Surface Treatment

Pagel

7, Dividing the inaxinwain load the specimen susteins during test by the nominal

cross-sectional ares of the speciiea,

A. Veasiie Strong ¢. Elongation

b. Yield Strength 4, Beading

§, Hupress the increase in lengtts of the gage Length as a percentage af the srignal

gogeleagth.

. Tensile Sireagth A. Bongation

b, Yield So eng a, Bending

9, Whatis ther

every sane

yam testing requirement for steel hars (1) ene somplein

a, 1,900 Bibbgr

b. 2,000 kil

c. 5,000 bilograms

AZ 16,099 kilograms

16, Methad of ratucing fidd samples of aggregates to testing eize can he done byt

a. Mechanical Splitter 2, Miniature Stockpile Samples

b. Quartering f All of the above

tis defined cs the lowest moisince content at which the seil will low upon the

applicadon of'a very smal shearing force and gives n certain measure of the

shearing resistence of a soil when mixed with water.

/

AR siyuid Lint ¢. Plasticity Indes

i a, Shrinkage Limit

s. Flasde Licsit

! responsibility in terins of motesials testing and Quality

she implementation of project.

riginesr gf Project Enginesr

vt, Construction Engineer 4. District Engineer

Poge2

13, Who is responsible for the implementation of Quality Conircl ia the DPWH

Projects?

, Materials Ea gueer 7X Contacter/inpleacuiing Oflice

b, Project Engineer &. Project Inspector

14, A report which is prepared monthly by die Materials Engineer contains the

the number of text couducted based on he approved Quality Control

Progrsi

of the Prejeet.

a. Materials Test Report ¢, Materizis Quality Contral Report

b, Quality Assurance AG Status of Test

<15. In the moisture density rdation test of an Item 240- ASC the MDD & OMC

of materiais is determined by:

/ a. AASHTO 1-150 Methed D A. AASHTO ‘[-99 Methed C

b. AASHTO T-130 Method C d. AASHTO 1.99 Methed D

+HEnd

Page3

pEeAuT

OFFICE OF

os Cui

SOIL

/\. Determine the dry density, ky/m? if the:

‘ Mass of Wet soil = 1.829¢ O/

Vol. micid = 0.000943 m> nice 0

Moisture >ontent = 2.90 % 4

a) 1893 ‘b) 1870 c) 1885 d)1900

/2. Determine the moisture content, % ifthe.

a Container ~ Wet soil = 182.20 g

Container ~ Dry soil = 178.50

Container ** 51.90 g

29 p28 3.0 428

/> Solid panites wit or witout organic constituents which are produced by

of “ocks, sand, yravel and soft mazerials

a)cement — b) soil o) fine aggregates) asphalt

/ 4 ityives certain measure of the shearing resistance ofa soil when mixed with

waler

a) Field Density Test b) Plastic Limit

6) Liquid Limit d) Compaction Test

Control test in embankment construction to ensure adequate compaction

a) Compaction Test b) California Bearing Ratio

c) Moisture Content Determination d) Field Density Test or

Answers’

Ne Qa 3yb 4)e Syd

Prepared by: Submitted by:

Peal eet,

GENOWLVA A. GUERRERO NORMITA $1 NOBLE

| Bagineer TE Engineer 1

CEMENT.

1. What is the % normai consistency if the:

‘Mass of sample = 650 g

Volume 9f water used = 168 mL

1 28.50% — b) 25.85%

2. detern

AB insoluble Residue

¢) Autoclave Expansion

Weight cf sample before ignition = 24.367 _

ye

n

¢) 22.75% — d) 28.10%

ines the inert material present in cement

b) Loss on Ignition

4) Air Comtent

Oxide form from gypsum and it affects the strength and setting time of cement

j Sulfur Trioxide

1 Sodium Oxide

'b) Magnesium Oxide

4) Silicon Dioxide

os 3

Weight cf sample after ignition = 24.347 g e:6

Weight cf sample = 1 g

an l% 2) 3%

5; Materials which contributes lime and magnesi

ai Argillaceous

nb 2a 3a

Prepared by

Bann

GENOyiiVA Al GUERRERO

| Engineer il

2%

the clinker

fCalcareous

) 482.75 MPa

ve “O

b) 475.50 MPa.

(SHA8.S MPa

(AA. The stress developed when external force tends to press or shorten a body

a) Absorption

pyCompressive strength

’p) Moisture content

¢) Load bearing

|S. Part of concrete holiow blocks which connect the two faces

b) Face

pried

Answers!

ye ao 3)4

Prepared by:

GENO AN GUERRERO

7B eur

¢) Cell ) Wall

Submitted by:

NOBMITA

Engineer HT

QUESTIONAIRE

A. SOIL

41, In modified corapaction test, how many blows is required in every layer?

a, 65 blows/layer

b._25 blows'layer

i% blowstlayer

2. What is the Attzrberg Limit Test?

AA. ati lit

b. Liquid limit

©. Plasticity index

+3. 13,050 cum. of embankment is needed to fill the bridge approaches, what are the

mninimum test requirements?

4

Determination 7 2 3 4 |

No. i >

No. of Blows 8 1B 1 28 39

[Moisture loss (gy | 2.17 20 eesee | aeeea 187) 1.46

Weight of Dry 470 3.09 ce a)

Soiltz) _

Moisture | 46.17 43.22 42.21 40.67

content(%) | L

042 Waa 41

5. If liquid limit is 59 and Plastic limit is $1, what is the plasticity index?

a b. 110 e 55

B, CONCRETE

1, Inanarea of 9£() linear meters PCCP, how many core samples are required in

thickness deter nination?

aA

b 9 c 12

2. Inanewly poured PCCP how many days of curing is required to open for traffic?

(without additives)

a. Tdays 14 days c. 28 days

“3, How many set of 3-beam samples will you get in 85 cu.m. of PCCP poured for

the day?

set 023 beam sample

beam sumples

set of 3 beam samples

1

2

3

[A What is the re quired strength of beam samples to fass flexural strength at 14

days%iiegtis? oud-pered lets wills

a. 600 psi b. 630 psi 6650 psi

4 inssampling PCCP, how many blows/layer is required?

a 62 x 63 c. 65

Cc. RSB

1. What is the required tensile strength of RSB using AASHTO M 31 to pass

required specifications?

p483 mpa b. 450 mpa c. 470 mpa

ie a

‘What is the nominal cross section area for 32mm@ RSB? j

a, 820mm E819 mm c. 830 mm

‘What is the maximum average spacing of corrugation of lomm® RSB?

a 11.50mm &. 11.10mm ce. 1S mm

‘What is the required minimum elongation in percent is required for the RSB to

pass the specifications?

a 10% b. 15% cc. 20%

What is the allowable percentage of variation in weight for RSB?

a 5% b. 4% Ee +-0%

). ASPHALT

- Prior to dumping of asphalt pavement into the spreader, what is the minimum

laying temperature?

10’ a 107°C ce. 105°C

+ A day operatio 1 accomplished 450 In.m. half lane of asphalt pavement, Coring

‘est was done te next day, how many density and thickness tests are required

a. Score samp b. 6 core samples ©. 10 core samples

7

Spi iM NE

ioe

ANSWERS:

A. SOIL,

AREY E

sooeo

B. CONCRE

ne wo

soos

vee

ce roe

D. ASPHALT

Re

Bo

vo FERIALS Ty

3. ASPHALT

agus, Occidlental District Eng’. Office

TING EXAM

STIONAIRE

i

i

'

|

1} Athi asphoit sutface treathtent used to Waterproof aud improve the texture of an

asphalt wear ng surface:

|

a) asplialt tack coat: 125 caphal seal coat

6.) asphalt surface treatment i d)none of the above

2.) Ideal composition of bitumtinous aphrogates in the asphalt mix

P hnous aphrog 2

i

6.) 92% ta 98%

4) 93% to 98%

#4) 92% to 25

395 % to 28%

I

dating veepen plaue joint of concrete pavement ?

2.) What asphal: is

a) Rock Asphatt

!

Fe) Lake Asphalt

YF Blown Asphalt {43 Binns

ed Asphalt

118th asphalt mi bavingdivsight 4020 gms & aggregites weighing 2,865.92 g,

ye} ofa ?

Gi %

| J O.0L%

A i

4.) How many samples should betakenifor an ashalt mix for one fal) day operation?

‘one set samples consisting of 3 core sample

sample bul not to exceed 3 core samples

) ene sei of 3 samplds but not [o exceed 6 samples

4) none cf the above |!

5.) Thr objective isto determine a3 ecchomical blend between graded aggregates and

axphait in order to produce a pavement that would meet the required

spectication

4 gobi

by de

¢.) desigr of bituminbus mixe;

d) now ofthe ahovel !

}

of concrete ouixes |

|

|

|

HL CONCRETZ

I i

1) How taag does a vibrator be instrted in

} not to exceed 36 se onus @, 50

"b.) not to exceed 15 seconde dh 59 @

«Faut to exceed Lvecendts

: a) not to exceed 5 seconds d@ 50 o

£4 Conerate shall be thoreughly conselida

! 2 tsmper

5 Yb vibrscor

|

©.) plate compactor |

4) none of the above i

ip

1) Stunsps fi a works ble CCP ithye oe

6)40 to 75mm :

i 6) (tein hh

| ae !

! ©) 4000 Fam : i

7 AY 11640 a “| !

'

Lt Loe a

iy

as p tas i

i 0.) ball penetration test |

7 G) consistency t i

i ) Nowe of the Above

5) Concerta not fa place within

"ie i

4} 40 seconds

6.230 minutes:

i ©.) 20 arinutes

43.90 seconds

wt

foonetete mix?

i

qn to 60 om space interval

nt te GU Gn space interval

50 4 to 60 cee space interval

40 60 cm space interval

td by means of:

d comme cly used to fest on watkaitity af coartete

the iagtedieats wera charged

shall not be used

idental District Engig. Office

4 {WRIALS \_STING EXAM I =

UESTIONAIBE ii j

; |

: i

i

K TY. MISCELLANEOUS | i |

ifi |

1) The proportion mix of mortar fog grontefl grap shall be:

uf ! A.) one part cf cement to J parts of jand

b.} one part cf'coment to 23 parts of sand

*o.) one part wi coment to F pats of ‘waud

4.) ove part a” cement fo d'pants of shod

: XK By Minne diameter ot gobone er stondbd specication squires

a 1 7

: 432700 i

; b)2.0mm i

iit | ©) 2.50 am i

: 4) None ofthe above | |

i, B 1

X +4) How many samples shail be submitted fr fest if 355 pails of flat wall enamet paint is

10 be used in projet? j i 7

j i

i sys i

BF pail i

©) F pails i

iid : 4.) 2 pails ;

po !

4.) Mowe many units of BP is needed tor on coniplete tow af CHE?

2

ays

“88

ey

ayn

i

i

4 ¥f.) What is the eequited size of test specim:

©) 3pes of S0sam x 50 th

~ 8) 3 pes of 611m x 60 mm

©) 3 pes of 70 ata x 7mm

4)3 pes of ROsim x 80 anh,

i

for G. [sheets ?

:

!

!

a i i

Za ta.soil stabilization ethed of théaiment be sweaic subgrade, what is being used?

!

. i a) Lime 1) ¢.) Beitonite

tee | ‘b.) Cement iidj ee trenches and pump out water

jsthe most cmmonanetiad adopttd by DPWH in the determination of density

of soil in place? 1

a) Nuclear Method | * ©.) $and- Cone Method A

b.} Batfoon iype Method | : a. ce of the above

73.) ‘Tos lowest moisnre content ich

diameter vatbout crum lig,

sail can he rolled into threads 1/8” ia

) Plastic | awit u

¢.) Liquid Limit

6.) Group Index

) Atterberg Limits

‘OT. 180 ) method for moisture density

anendied number of bfows per layer?

3) 60 blows «.) TP blows

b) 50 blows a) 2B blows

|

3.3 Howaaany cubse meter ov 4

f that will represent one grading test and ane

plasticity test fer tem 200 o Item 201 {

aj every 7!

by every 0 com

QUESTIONNAIRES I) MATERIALS QUALITY CONTROL .

1. The __ isthe most commonly used method in the design and evaluation of

bituminous concrete mixes

2.) Job mix formula 5.) Marshall Stability ¢.) Design Mix Test 4.) Extraction

Vibrators shall operate at a frequency of 8,300 to 9,690 impulse per minute under ioad at

a paaximSum spacing of __CL_om.

£) 60.em b.) SOc ¢.) 40.om 4) 30cm

The specific gravity cf Sodium Sulfete solution is used in soundness test of aggregates

should be within the rangeof__

a) 1.08410 1.154 9.) 12500 1178 €.) L151 101.174 4.) 1.058 to 1.184

4, The specific gravity of Magnesium Sulfate solution is used in soundness test of

ayyregates should b2 within the range of __¢= .

a.) 1.28010 1.408 b)I 180t0 1.308) 1.174 t0 1.295 d.) 1.195 to 1.318

5. The penetration test is an indication of the A + of asphalt.

2.) Consistency b.) Sofiness ¢.) Hardness 4.) Flash Point

6. Specifications require 1 Quality test for every _.d°__ of asphalt.

a.) 20 cons b.) 200 tons ¢) 50 tons “d.) 40 tons

7. Aggreyate account ‘or 92-95% of the weight of the binsminous mix with asphalt accounts

for $-8% of the weizht of the mix, The exact percentage te be used is determined by the

} Job Mix b.) Design Mix c.) Trial Mix 4.) Job Order

is the ‘ndication that the asphalt mix is overheated.

FAppearano: b.) Blue Smoke c.) Rising Steam d.) Mix slumps in the truck

9, tn checking the ten perature of the mix, the thermometer should be inserted into the mix

atleast

a.) 2 inches b} 6.0 mm ¢.) 4 inches +d.) 6 inches

10, Percent passing locse for coarse aggregate when tested in soft fragments.

AA.)3.50 b.) 0.25, 01 d.) 1.00

11. If slag is used, the density of coarse aggregate is~ .

a.) 30-100 kg/m* b.) 150 kgim® 1120 kgm? 4.) 1400 kg/m?

12, Mass percent loos: for fine aggregate when tested in clay lumps

a)O1 b)925 foyld, 43.5

13. Cement which shal! be transferred to elevated air tight and weather proof bins when

storage ;

44) Bulk Cement 0.) Pozzoland Cement ©.) Portland Cement d.) None of the Above

14, Scales for weighing aggregates and cement shall be accurate within?

~ 2) 0.1% b.) 0.25% FE) 05% 4.) 1.0%

15. In monolithic concrete pavement, the minimum of the conventional concrete as the

surtice course.

a.) 75 min b) 150 mm ©) 100 mm 4.) 50 mm

on to break when mixed with mineral aggregates

©.) Spot Test A) Cement Mixing

16. It determines the resistance of the emu!

77%) Viscosity Test b.) Distillation Test ce

(3%

17 Asphalt cement shill be homogenous, free fiom water, and shali,not foam when heated t0 1.59%

a) 175°C G47 °F) b) 165°C (345°) 6) 145°C 340°F) 185°C (365°F) pa ay

18. irindicates the rate at which the asphalt emulsion will break when mix with aggregate

2.) Pile Load Test of Asphalt 15 Cement Mixing Test of Asphalt

b.) Vane Shear Test of Asphalt 4.) Plat Bearing Test of Asphalt

19. The loss in weight of rock used in gabions when tested t50 sodium sulfate soundness loss

should not exceed

2) 8% b.) 10% % 6) 12%

to a tolerance limit of

f 0.) 23% > . 4) 43.5%

20. Gabions dimensior s are subi

2.) 40.3% b)

1 21. The pour point of concrete joint seller shall be at least lower than the safe

temperature, which is the maximum temperature to which the material may be heated

without exceeding :he permitted flow.

a.) 10°C (i8 °F) b.)10.5°C (20°F) c.) 11°C (20°F) 4.) 12°C (21°F)

Joint scaler, Hot Poured Elastic Type shall not exceed

22. ‘Vhe penetration of

©) 10 4) 120 ‘

90

23,The flow, of water shall be uniform and all water should be in the drum by the end of the

C seconds of the mixing period. -

8) IS seconds

2.) 45 seconds .) 30 seconds .) 20 seconds

minuies ffom the time the ingredients were charged

24. Concrete not placed within _&

into the mixing drum shall not be used

4) 100 minutes 0.) 150 minutes ¢.) 60 minutes.) 90 minutes

ditional water may be added to the

batch and addi 1¢ slump to meet the specified

requirements if pernntied by ce engineers, provided ail shese operations are pertormed

7a.) 45 minutes b.) 15 minutes c.) 30 minutes 6.) 60 minutes

26. A sample from biturninous mix weighs 1000 grams. At extraction, it was found out that

the dry aggregate weighed 950 grams. What is the % of asphalt by weight6 of mix?

a) 4.80% wb.) 5.40% we) 5.00% d.) 5.20%

27. Equipment used in scundaess determination of Portland cement,

2. ilmore Needle (#5 Autoclave Machine

..) Le Chatellier Fiask 4.) Vicat Apparatus

28. The CBR is general.y selected at penetration,

1,30 mm (0.10 ir.) ©) 5.08 mm (0.21 in.)

34 mam (0. Wv it.) d.) 25.4 mm (1.0 in.)

29. if the ratio at 5.08 rrma (0.21 in.) penetration is greater, the test should be

a.) Remove b.) Reported ve) Rena d) Accepied

he ratio at 5.08 mm penetration shall be

sed c.) Remove 4) Retest

30, Ifthe check test gives a similar result, 1

a) Listed eh Adopted or

31.The minimum penetration of the preservative with the surface of the timber pile shall be

a.) 250 mm >.) 100mm co) 150mm A) 200mm

32. The contractor shall submit in writing a job-mix formula for eack mixture supported by

laboratory test data Jong with samples and sources of components and viscosity-

temperature relationships information to the Engineer for testing and approval at least

PF) 3 weeks b.) 2 weeks c) I week d) 4 weeks

he concicte sapplys should be stored in a moist condition at a temperature within the

of 164? Until the time of test

CwiFE — by 18"C to 28°C ec) IS*C to 28"C — d.) 18°C 10 24°C

33.

ajl

34. This is used in soil stabilized road surfaces due to its hygrospic property, that is, it absorb

and retain water.

a.) Sodium Chloride: b¢) Calcium Chieride c.) Magnesium Chloride

d.) Potassium Chioride

35. The mass % wear 0” soil aggregate used in cemeni/iime stabilizations should not be more

than,

a.) 55% b.) 40% ©.) 45% 44.) 50%

36, Unconfined compressive strength test is usually performed on

a.) Sandy soils »,) clayey Soils 2) Organic Soils 4.) Silty Soils

37

39. The cohesion and the interna! friction of soi

40,

Conyolidation testis usually performed en __G&___ samples.

3.) Undisturbed ——_b.) Disturbed C)consolidated —d. botha&b

‘A conerete core sauiple having a maximum height of less thaa__ of its diameter

before capping or f eight less than its diameter after capping shall not be tested.

a) 9OT% b 9% )OI% AI 9%

il is tested by

b.) Direct Shear Test ¢.) Bearing Tesi

4d.) all of the above

in concrete acceptance, cores will be considered adequate if the average strength of the

core is equal to wrat?

2.) 80% of specified strength & if no single core less than 75% of specified strength

90% of specitied strength & iffno single core less than 80% of specified strength

5, 85% of specified strength & if no single core less than 75% of specified strength

4.) 90% of specified strength & if no single core less than 75% of specified strength

. The uniform rate at which the movable head of the CBR machine travels

a)9.09inminute 6.) 0.05 in/minute ©.) 0.15 infminute

4.) 0.06 infminute

Cast in place concrete shall not be post-tensioned until at least and until the

‘compressive sirength has reached the strength specie .

a.) 7 days b.) 20 days %.) 10 days 4.) 14 days

% throughout

Seales for weighi 1g aggregates and cement shall be accurate within

Engineer may deem

the range of use. Scales shall be inspected and sealed as often as

necessary to assiie their continued accuracy

a.) 2.00% 65 0.50% ©.) Loo% d)Lso%

. When cement is placed in Contact with the aggregates, batches muy be rejected unless

mixed within [es “hours of such contract.

a.) 2 hours b.) 2.50 hours ¢.) 0.50 hours d.) 1.5 hours

When mixed at the site or in central mixing plant, the mixing time shall not be less than

“ob _nor more than _70_unless mixer test performance test prove adequate mixing of

the cone. in the shorter time period

a.) 50 seconds nor more than 90 seconds

.) 60 seconds nor more than 120 seconds

c.) 30 seconds nor more than 90 seconds

4.) 90 seconds nor more than 129 seconds

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

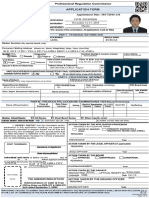

- Application Form NGSE PDFDocumento8 páginasApplication Form NGSE PDFmjfprgcAinda não há avaliações

- Project Title: Location: Subject: Proposed Variation Order No. 1Documento5 páginasProject Title: Location: Subject: Proposed Variation Order No. 1Ariel Dela CruzAinda não há avaliações

- Office of The Vice Chancellor For Planning and DevelopmentDocumento2 páginasOffice of The Vice Chancellor For Planning and DevelopmentAriel Dela CruzAinda não há avaliações

- CISC PVO #1 Blank FormDocumento5 páginasCISC PVO #1 Blank FormAriel Dela CruzAinda não há avaliações

- Project Concerns: Proposed Modular PartitionDocumento5 páginasProject Concerns: Proposed Modular PartitionAriel Dela CruzAinda não há avaliações

- Office of The Vice Chancellor For Planning and DevelopmentDocumento3 páginasOffice of The Vice Chancellor For Planning and DevelopmentAriel Dela CruzAinda não há avaliações

- 2019 12 10 Ce 264 PS 4 TorreDocumento23 páginas2019 12 10 Ce 264 PS 4 TorreAriel Dela CruzAinda não há avaliações

- ACFrOgBVJ4gmGEUbkDmXI2Fd cgxPpERav mRXeXUraJkAW0kzvgAgSOI U1Bmmq2 YT-SmsVmpVL 1EAcXbjdOI3es VEVkEUUHHEOjbF5upb5m0tBtpmMlDQ4y VoDocumento4 páginasACFrOgBVJ4gmGEUbkDmXI2Fd cgxPpERav mRXeXUraJkAW0kzvgAgSOI U1Bmmq2 YT-SmsVmpVL 1EAcXbjdOI3es VEVkEUUHHEOjbF5upb5m0tBtpmMlDQ4y VoAriel Dela CruzAinda não há avaliações

- 5 Fifth Coordination Minutes of MeetingDocumento6 páginas5 Fifth Coordination Minutes of MeetingAriel Dela CruzAinda não há avaliações

- CE 264 Problem Set 1Documento1 páginaCE 264 Problem Set 1Ariel Dela CruzAinda não há avaliações

- Concrete PouringDocumento1 páginaConcrete PouringAriel Dela CruzAinda não há avaliações

- Eccentrically Loaded Rectangular Foundation On Granular SoilDocumento70 páginasEccentrically Loaded Rectangular Foundation On Granular SoilAriel Dela Cruz100% (1)

- Application For Privilege To Study at Reduced FeesDocumento1 páginaApplication For Privilege To Study at Reduced FeesAriel Dela CruzAinda não há avaliações

- Front Elevation Right-Side Elevation: Entrance GateDocumento1 páginaFront Elevation Right-Side Elevation: Entrance GateAriel Dela CruzAinda não há avaliações

- Neltex PPR Product Brochure 2015Documento2 páginasNeltex PPR Product Brochure 2015Ariel Dela CruzAinda não há avaliações

- Revised Lecture by Sir JanggoDocumento43 páginasRevised Lecture by Sir JanggoAriel Dela CruzAinda não há avaliações

- Plastic As A Soil Stabilizer: Shoaib WaniDocumento13 páginasPlastic As A Soil Stabilizer: Shoaib WaniAriel Dela CruzAinda não há avaliações

- Casa Isabel: Site Development PlanDocumento1 páginaCasa Isabel: Site Development PlanAriel Dela CruzAinda não há avaliações

- Appointment Date: 10/17/2016 AM: First-Timer Civil Engineer November 12-13, 2016 ManilaDocumento1 páginaAppointment Date: 10/17/2016 AM: First-Timer Civil Engineer November 12-13, 2016 ManilaAriel Dela CruzAinda não há avaliações