Escolar Documentos

Profissional Documentos

Cultura Documentos

Circular Weld

Enviado por

ALPHYL BALASABASTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Circular Weld

Enviado por

ALPHYL BALASABASDireitos autorais:

Formatos disponíveis

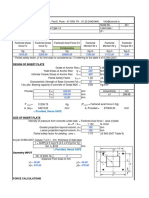

Weld Design For CHS

Design Parameter

Fx = 0.0 kN Maximum Shear Force at X Axis

Fz = 83.13 kN Maximum Shear Force at Z Axis

Fy = 0.0 kN Maximum Shear Force at Y Axis

Mx = 0.00 kNm Mx , Max. Torsional Moment

Mz = 0.00 kNm Mz , Max. Flexural Moment

Weld = Fillet Weld Type of Weld

E = E42 Weld Electrode ( BS 639 ) B.S. Table 10

Grade = S275 Steel Grade ( BS 4360 )

pw = 220 N/mm2 Design strength of fillet weld B.S. Table 37

Lw = 88 mm Diameter of Weld

ww = 0 mm Width of weld for rectangular shape weld

tw = 5 mm Thickness of Fillet Weld

Lt = ∏ * Lw

= 276.4608 mm

4.2 Torsional Shearing Stress of Weld

ΣMo = 0

xw = 44 mm Location of weld Centroid At X Axis

zw = 44 mm Location of weld Centroid At Z Axis

Ix = ∏(Lw /2 )3

= 301029 mm3 Moment of Inertia of Weld at X Axis

Iz = ∏(Lw /2 )3

= 301029 mm3 Moment of Inertia of Weld at Z Axis

Flexural Shearing Stress of Weld

fy1 = Mx* ( zw)

Ix

= 0.00 N/mm

fy2 = Mz* ( xw)

Iy

= 0.00 N/mm

fy' = fz1 + fz2

= 0.00 N/mm Total Flexural Stress at Weld

4.4 Minimum Weld Thickness Requirement

FR = [ (fy' )2 + ( Fx / Lt 2 + Fy/Lt 2+ Fz/Lt2) ]0.50

= 300.69 N/mm Maximum Shearing Stress at Most Stressed

tmin = FR

0.707 * ( 1mm ) * pw

= 1.933 mm Minimum Thickness of Weld required

Since tmin < tw therefore the weld Connection is ADEQUATE

Weld Design For RHS

Design Parameter

Fx = 20.0 kN Maximum Shear Force at X Axis

Fz = 50 kN Maximum Shear Force at Z Axis

Fy = 20.0 kN Maximum Shear Force at Y Axis

Mx = 0.00 kNm Mx , Max. Torsional Moment

Mz = 45.00 kNm Mz , Max. Flexural Moment

Weld = Fillet Weld Type of Weld

E = E42 Weld Electrode ( BS 639 ) B.S. Table 10

Grade = S275 Steel Grade ( BS 4360 )

pw = 220 N/mm2 Design strength of fillet weld B.S. Table 37

Lw = 250 mm Length of Weld

ww = 150 mm Width of weld for rectangular shape weld

tw = 6 mm Thickness of Fillet Weld

Lt = 2* Lw + 2 * ww

= 800 mm Total Length of Weld

4.2 Torsional Shearing Stress of Weld

ΣMo =

xw = 75 mm Location of weld Centroid At X Axis

zw = 125 mm Location of weld Centroid At Z Axis

Ix = Lw2 ( 3ww + Lw )

= 6 Moment of Inertia of Weld at X Axis

7291667 mm 3

Iz = ww ( 3Lw + ww )

2

= 6 Moment of Inertia of Weld at Z Axis

3375000 mm3

Flexural Shearing Stress of Weld

fy1 = Mz* ( zw)

Ix

= 771.43 N/mm

fy2 = Mx* ( xw)

Iz

= 0.00 N/mm

fy' = fz1 + fz2

= 771.43 N/mm Total Flexural Stress at Weld

4.4 Minimum Weld Thickness Requirement

FR = [ (fy' )2 + ( Fx / Lt 2 + Fy/Lt 2+ Fz/Lt2) ]0.50

= 883.93 N/mm Maximum Shearing Stress at Most Stressed

tmin = FR

0.707 * ( 1mm ) * pw

= 5.683 mm Minimum Thickness of Weld required

Since tmin < tw therefore the weld Connection is ADEQUATE

Weld Design For RHS

Design Parameter

Fx = 0.0 kN Maximum Shear Force at X Axis

Fz = 1.243 kN Maximum Shear Force at Z Axis

Fy = 0.0 kN Maximum Shear Force at Y Axis

Mx = 0.00 kNm Mx , Max. Torsional Moment

Mz = 45.00 kNm Mz , Max. Flexural Moment

Weld = Fillet Weld Type of Weld

E = E42 Weld Electrode ( BS 639 ) B.S. Table 10

Grade = S275 Steel Grade ( BS 4360 )

pw = 220 N/mm2 Design strength of fillet weld B.S. Table 37

Lw = 250 mm Length of Weld

ww = 150 mm Width of weld for rectangular shape weld

tw = 6 mm Thickness of Fillet Weld

Lt = Lw + 2 * ww

= 550 mm Total Length of Weld

4.2 Torsional Shearing Stress of Weld

ΣMo =

xw = 125 mm Location of weld Centroid At X Axis

zw = 125 mm Location of weld Centroid At Z Axis

Ix = ∏(Lw /2 )3

= 6902095 mm3 Moment of Inertia of Weld at X Axis

Iz = ∏(Lw /2 )3

= 6902095 mm3 Moment of Inertia of Weld at Z Axis

Flexural Shearing Stress of Weld

fy1 = Mx* ( zw)

Ix

= 0.00 N/mm

fy2 = Mz* ( xw)

Iy

= 814.97 N/mm

fy' = fz1 + fz2

= 814.97 N/mm Total Flexural Stress at Weld

4.4 Minimum Weld Thickness Requirement

FR = [ (fy' )2 + ( Fx / Lt 2 + Fy/Lt 2+ Fz/Lt2) ]0.50

= 817.23 N/mm Maximum Shearing Stress at Most Stressed

tmin = FR

0.707 * ( 1mm ) * pw

= 5.254 mm Minimum Thickness of Weld required

Since tmin < tw therefore the weld Connection is ADEQUATE

Você também pode gostar

- Spliced ColumnsDocumento5 páginasSpliced ColumnsALPHYL BALASABASAinda não há avaliações

- Licensed DateDocumento1 páginaLicensed DateALPHYL BALASABASAinda não há avaliações

- Bolted Connection ToolDocumento28 páginasBolted Connection ToolALPHYL BALASABASAinda não há avaliações

- Mill BuildingDocumento135 páginasMill BuildingKaraline MarcesAinda não há avaliações

- Anchorage of Steel Building Components To ConcreteDocumento7 páginasAnchorage of Steel Building Components To ConcreteEn HenAinda não há avaliações

- 1 Input Data: Profis Anchor 2.7.2Documento6 páginas1 Input Data: Profis Anchor 2.7.2ALPHYL BALASABASAinda não há avaliações

- 27 Bolt Group PulloutDocumento14 páginas27 Bolt Group PulloutALPHYL BALASABASAinda não há avaliações

- Moment ConnectionDocumento5 páginasMoment ConnectionALPHYL BALASABASAinda não há avaliações

- Moment ConnectionDocumento5 páginasMoment ConnectionALPHYL BALASABASAinda não há avaliações

- 27 Bolt Group PulloutDocumento14 páginas27 Bolt Group PulloutALPHYL BALASABASAinda não há avaliações

- Moment ConnectionDocumento5 páginasMoment ConnectionALPHYL BALASABASAinda não há avaliações

- Steel Staircase DesignDocumento6 páginasSteel Staircase DesignMario FeghaliAinda não há avaliações

- Anchorage of Steel Building Components To ConcreteDocumento7 páginasAnchorage of Steel Building Components To ConcreteEn HenAinda não há avaliações

- Anchor Bolt BiAxialDocumento10 páginasAnchor Bolt BiAxialALPHYL BALASABASAinda não há avaliações

- False Form WKDocumento12 páginasFalse Form WKRonald Cario SeguinAinda não há avaliações

- Steel Erection Checklist: DrawingsDocumento2 páginasSteel Erection Checklist: DrawingsALPHYL BALASABASAinda não há avaliações

- EPD Bratsberg TeglDocumento10 páginasEPD Bratsberg TeglALPHYL BALASABASAinda não há avaliações

- How To Calculate UAE Gratuity Pay - GulfNewsDocumento3 páginasHow To Calculate UAE Gratuity Pay - GulfNewsALPHYL BALASABASAinda não há avaliações

- Design Structural Steel Design and Construction PDFDocumento59 páginasDesign Structural Steel Design and Construction PDFdkaviti100% (2)

- Connections I V2 1 0 A 1Documento49 páginasConnections I V2 1 0 A 1ALPHYL BALASABASAinda não há avaliações

- RD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryDocumento25 páginasRD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryHanuman Sharma83% (6)

- End Plate Moment Connections Per AISC 9th Edition (ASD)Documento27 páginasEnd Plate Moment Connections Per AISC 9th Edition (ASD)cengizAinda não há avaliações

- Adel Mohamed Dubai Municipality 2Documento43 páginasAdel Mohamed Dubai Municipality 2ALPHYL BALASABAS100% (2)

- Structural Computation AnalysisDocumento9 páginasStructural Computation AnalysisALPHYL BALASABASAinda não há avaliações

- ConnectionsDocumento77 páginasConnectionsAlphyl BalasabasAinda não há avaliações

- Hook Design Check Calc Sheet SGDDocumento17 páginasHook Design Check Calc Sheet SGDALPHYL BALASABASAinda não há avaliações

- 2 0 Insert Plate Calculations Type 14 PDFDocumento4 páginas2 0 Insert Plate Calculations Type 14 PDFALPHYL BALASABASAinda não há avaliações

- Beam Column Connection To BS5950 PDFDocumento6 páginasBeam Column Connection To BS5950 PDFALPHYL BALASABASAinda não há avaliações

- Circular Tube End Plate Calculation PDFDocumento4 páginasCircular Tube End Plate Calculation PDFALPHYL BALASABASAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- Shiva Prasad Ext. 7571: (Shivap (At) Phy - Iitb.ac - inDocumento38 páginasShiva Prasad Ext. 7571: (Shivap (At) Phy - Iitb.ac - inTavishi SinghAinda não há avaliações

- Horizontal CurveDocumento2 páginasHorizontal CurveAmar DanialAinda não há avaliações

- Pressure Transient AnalysisDocumento52 páginasPressure Transient Analysisrmm99rmm99Ainda não há avaliações

- SolutionDocumento9 páginasSolutionSriniwas JhaAinda não há avaliações

- Physics VocabularyDocumento4 páginasPhysics Vocabularyapi-309597212Ainda não há avaliações

- Cold Thermogenesis 1 - Theory To Practice BeginsDocumento32 páginasCold Thermogenesis 1 - Theory To Practice BeginsCătălinStoicescuAinda não há avaliações

- A Manual For The: TH Omas R. Duls KiDocumento16 páginasA Manual For The: TH Omas R. Duls KiKanchanAinda não há avaliações

- 503 Pds Stopaq Wrappingband CZHT v4 (En)Documento2 páginas503 Pds Stopaq Wrappingband CZHT v4 (En)EngTamerAinda não há avaliações

- Cutting and Spreading, Use of AutomationDocumento30 páginasCutting and Spreading, Use of AutomationAditi33% (3)

- Ijert Ijert: Design and Flow Through CFD Analysis of Enclosed ImpellerDocumento8 páginasIjert Ijert: Design and Flow Through CFD Analysis of Enclosed ImpellerguganesannnAinda não há avaliações

- 931 2006 Robert Bosch Placement Paper 1 PDFDocumento4 páginas931 2006 Robert Bosch Placement Paper 1 PDFPaul JosephAinda não há avaliações

- Hooke's LawDocumento5 páginasHooke's LawVikash Kumar SinghAinda não há avaliações

- Stevia Poster 2007r2Documento1 páginaStevia Poster 2007r2Mukul SriAinda não há avaliações

- Synthesis of FlavanoneDocumento5 páginasSynthesis of FlavanonefikarisvitaAinda não há avaliações

- Optimization of Gear Reduction Unit Through Ray DiagramDocumento7 páginasOptimization of Gear Reduction Unit Through Ray Diagramأحمد دعبس100% (1)

- Astronomy For AstrologyDocumento7 páginasAstronomy For AstrologyVaradarajanAinda não há avaliações

- Is.1893 Codebook PDFDocumento25 páginasIs.1893 Codebook PDFArbaz HussainAinda não há avaliações

- Design of Multi Storied Building ReportDocumento19 páginasDesign of Multi Storied Building ReportKevin HuangAinda não há avaliações

- Optics and Modern Physics PDFDocumento95 páginasOptics and Modern Physics PDFRishi GargAinda não há avaliações

- Experiment # 1 Bernoulli Principle The Venturi MeterDocumento6 páginasExperiment # 1 Bernoulli Principle The Venturi MeterSharoni PavadhayAinda não há avaliações

- CFD Approach To Firearms Sound Suppressor Design PDFDocumento13 páginasCFD Approach To Firearms Sound Suppressor Design PDFGabriel AlbornozAinda não há avaliações

- ++ Drift-Velocity Closure Relationships For Slug Two-Phase High-Viscosity Oil Flow in PipesDocumento9 páginas++ Drift-Velocity Closure Relationships For Slug Two-Phase High-Viscosity Oil Flow in PipesAnonymous H9n5g3aaCEAinda não há avaliações

- Insolation Exam TC Ver3Documento10 páginasInsolation Exam TC Ver3api-263090057Ainda não há avaliações

- We Will Be Denied Libra Cryptocurrency As Our DNA Is Mapped That Is The Beast System Anthony PatchDocumento9 páginasWe Will Be Denied Libra Cryptocurrency As Our DNA Is Mapped That Is The Beast System Anthony PatchAshish RajeAinda não há avaliações

- OSF Paper PDFDocumento16 páginasOSF Paper PDF111111Ainda não há avaliações

- 020 Cadmium AcetateDocumento6 páginas020 Cadmium Acetateeng20072007Ainda não há avaliações

- Actions Induced by Cranes and MachineryDocumento52 páginasActions Induced by Cranes and MachineryVladislavs Pozņaks0% (1)

- Measurement TerminologyDocumento3 páginasMeasurement TerminologyAbishaAinda não há avaliações

- Error Analysis TutorialDocumento13 páginasError Analysis TutorialmakayaboAinda não há avaliações