Escolar Documentos

Profissional Documentos

Cultura Documentos

AlimakSEExTypeLift PDF

Enviado por

Boruida MachineryTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

AlimakSEExTypeLift PDF

Enviado por

Boruida MachineryDireitos autorais:

Formatos disponíveis

1292_en_jan_2011.qxd 11-02-09 10.

58 Sida 1

ALIMAK SE-Ex

Passenger and freight elevators

for hazardous areas

Access anytime, anywhere

1292_en_jan_2011.qxd 11-02-09 10.59 Sida 2

ALIMAK SE-Ex

Passenger and freight elevators

for hazardous areas

Built on experience gained from thousands of installations worldwide, the new Alimak SE-Ex is designed to

deliver on your access requirements for heavy transport needs in hazardous environments.

New design, new flexibility Elevator car

Increased efficiency, productivity and safety are just three Made of extruded anodized saltwater-proof aluminium and

of the benefits delivered by the new Alimak SE-Ex range of hot dipped galvanized steel the Alimak SE-Ex elevator car

freight and passenger elevator solutions from the company maximizes operator comfort without compromising oper-

that pioneered the rack and pinion drive system back in 1962 ating reliability. It also gives the elevator the ability to han-

to safely and efficiently transport people and materials. dle your toughest working environments. The rigid and

The enhanced efficiency delivered by the Alimak SE-Ex strong car door, which is equipped with windows, can be

stems in part from the unique modular design of the cars located on any three sides of the car away from the mast and

that provides a remarkable eighteen different car sizes is mechanically and electrically interlocked to meet all applic-

within the standard range. All elevators are based on a able code requirements. Stainless steel car walls and doors

variety of wall panels made of the characteristic Alimak are also available for extremely aggressive environments.

self locking, aluminium profiles. These wall panels meet The galvanized mast tower gives a slim installation

different elevator needs, and create adaptable floor and profile. Ties are used for attachment of the mast tower to

roof configurations. A more rigid car design is built on a the structure. A cable guiding system keeps the cable

solid car floor and stiffened beams, which supports under tension.

greater load capacity on a single mast. A one, two, three or four-sided enclosure with different

types of doors can be supplied for each of the landings. It

Rack and pinion technology is available in either aluminium or stainless steel.

As with all Alimak elevators, the Alimak SE-Ex is built on

the simple but ingenious rack and pinion principle. Our Powerful drive unit

elevators have their drive motors fitted on top of the car There is a choice of direct-on-line control or frequency

along with the brake and gearbox. The motor drives a controlled electric motors. Each unit has electromechanical

pinion that moves along the rack, which is bolted to the disc brakes and a centrifugal brake. The frequency control

elevator mast tower. This technology enables the elevator drive not only ensures smooth starting and stopping as well

car to climb up and down the mast at controlled speed. as smooth acceleration and deceleration, but also reduces

Neither a machine room or a shaft are required. wear and tear on elevator components such as brakes.

1292_en_jan_2011.qxd 11-02-09 10.59 Sida 3

Easy to operate Safety features

The Alimak SE-Ex is equipped with our well proven ALC-II The Alimak SE-Ex incorporates all the safety features that

control system This system ensures excellent stopping have made Alimak elevators a benchmark for the elevator

accuracy and the ease of use. The ALC-II system can be industry worldwide. The Alimak safety device will engage

provided with a wide range of options such as Auto should the elevator exceed the rated speed, bringing the

return, Auto alarm and Fire and gas alarm. car to a smooth stop. The elevator is normally equipped

with a centrifugal brake, located between the motor and

Remote monitoring the gearbox, that allows passengers to be lowered to the

As an added bonus, Alimak Heks’ online A3 remote moni- landing below in the event of a power failure. The elevator

toring system can be fitted as an accessory. This give the is also fitted with an overload sensing device.

alibity to fully monitor the elevator and trace any faults

instantly. This accessory can speed up corrective diagnos-

tics and minimize downtime.

1292_en_jan_2011.qxd 11-02-09 10.59 Sida 4

ALIMAK SE-Ex

Main benefits • Durable materials: extruded aluminium car wall pan-

• Modular design delivering a wide range of car sizes els with car support frame and mast sections of hot dip

and capacities galvanized steel. All stainless steel electrical cabinets

• Fully compliant with ATEX and EN-13463. Test wit- and landing control boxes. Optional stainless steel cars

nessed by third party • Wide range of optional equipment and functions deliv-

• Two individual elevators can operate on one single ering you the right equipment for each individual task

mast column for greater operational flexibility • Remote Monitoring System – The online A3 remote

• Drive machinery located on the car means no costly control can also be added to monitor elevator opera-

machine room is required tions 24/7 and pro-actively trace faults should they

• Fully collective elevator control system arise to avoid downtime.

TECHNICAL SPECIFICATIONS

FC DOL

Payload capacity 1,200–2,500 kg (2,650 – 5,500 lbs) 450–1,200 kg (1,000 – 2,650 lbs)

Loading classifications (ANSI): Class A, B, (C3) Class A, B, (C3)

Travelling speed 0.5–0.7 m/s (100–140 ft/min) 0.4–0.6 m/s (80–120 ft/min)

Lifting height Up to 80* m (260* ft) Up to 80* m (260* ft)

Motor control Frequency control (FC) Direct-on-line (DOL)

No. of motors 1–3 1–2

Internal car width: 1.30 m – 1.56 m (4’-3 1/4’’ – 5’-1 3/8’’) 0.91 m – 1.30 m (3’ – 4’-3 1/4’)

Internal car length: 2.08 m – 3.12 m (6’-10’’ – 10’-2 3/4’’) 1.30 m – 2.08 m (4’-3 1/4 – 6’-10’’)

Internal car height: 2.17 m and 2.35 m (7’-1 1/2’’ and 7’-8 1/2’’) 2.17 m (7’-1 1/2’’)

Door opening height: 2.01 m and 2.35 m (6’-7 1/4’’ and 7’-8 1/2’’) 2.01 m (6’-7 1/4’’)

Power supply range 380–480 V, 50 or 60 Hz, 3 phase

Type of mast Rectangular (FE) or square (A-50), tubular steel with integrated rack

Length mast section 1.508 m (4’-11 3/8’’)

Regulations ATEX NEC

Protection class Zone 1** or 2 Class 1, Division 2

Gas group I, IIA or IIB Gas group C or D

Temp. class T1–T3 (T4) Temp. class T1–T3 (T4)

Dust – Class 2, Division 2, Dust group F

* Increased lifting height on request. ** Zone 1 up to 1,600 kg payload capacity.

Car door configurations (A, B and C, or any other combination) Type of mast

FE A50

B

C

For other demands or specifications, please consult your Alimak Hek representative.

1292 EN/Feb. 2011

www.alimakhek.com

Alimak Hek AB is ISO 9001 and 14001 certified.

Pictures are illustrative only and do not necessarily show the configuration of products on the market at a given point in time. Products must be used in conformity with safe practice and applicable

statutes, regulations, codes and ordinances. Specifications of products and equipment shown herein are subject to change without notice. Copyright © 2010 Alimak Hek Group AB. All rights reserved.

Alimak Hek, Alimak and Scando are registered trademarks of Alimak Hek Group AB.

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- SA Raxtar TheBeastDocumento4 páginasSA Raxtar TheBeastBoruida MachineryAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- HSMARINE Products at Atb AtcDocumento7 páginasHSMARINE Products at Atb AtcBoruida MachineryAinda não há avaliações

- Hsmarine OffshoreDocumento7 páginasHsmarine OffshoreBoruida MachineryAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- T LiftDocumento4 páginasT LiftBoruida MachineryAinda não há avaliações

- HSMARINE Products AkcDocumento5 páginasHSMARINE Products AkcBoruida MachineryAinda não há avaliações

- HSMARINE Products AkDocumento5 páginasHSMARINE Products AkBoruida MachineryAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hsmarine Tugs and WorkboatsDocumento3 páginasHsmarine Tugs and WorkboatsBoruida MachineryAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Alimak Super Scando FC Manual Elevator Cable PDFDocumento71 páginasAlimak Super Scando FC Manual Elevator Cable PDFBoruida MachineryAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The World's Highest-Climbing Construction Hoist Is Used To Build The World's Tallest StructureDocumento2 páginasThe World's Highest-Climbing Construction Hoist Is Used To Build The World's Tallest StructureBoruida MachineryAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Alimak Industrial Warehouse Lifts: Vertical Access Solutions For Warehousing FacilitiesDocumento4 páginasAlimak Industrial Warehouse Lifts: Vertical Access Solutions For Warehousing FacilitiesBoruida MachineryAinda não há avaliações

- 261 Many Tower Cranes, Self Erecting Cranes and Accessories CatalogueDocumento20 páginas261 Many Tower Cranes, Self Erecting Cranes and Accessories CatalogueBoruida MachineryAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- ALIMAK SCANDO 450 DOL 32ext. 50Hz 1278 EN Oct 2020Documento1 páginaALIMAK SCANDO 450 DOL 32ext. 50Hz 1278 EN Oct 2020Boruida MachineryAinda não há avaliações

- Alimak Install Industrial Elevator Within An Existing Shaft at QNI's Palmer Nickel and Cobalt RefineryDocumento4 páginasAlimak Install Industrial Elevator Within An Existing Shaft at QNI's Palmer Nickel and Cobalt RefineryBoruida MachineryAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Frami Pallet 1.20m and 1.50m: 1997 Models OnwardDocumento5 páginasFrami Pallet 1.20m and 1.50m: 1997 Models OnwardBoruida MachineryAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- ANKA Industrial ElevatorsDocumento1 páginaANKA Industrial ElevatorsBoruida MachineryAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Doka Pallet For Staxo/Aluxo: 1998 Models Onward 2007 Models Onward 2009 Models OnwardDocumento5 páginasDoka Pallet For Staxo/Aluxo: 1998 Models Onward 2007 Models Onward 2009 Models OnwardBoruida MachineryAinda não há avaliações

- Doka Accessory Box: Art. N° 583010000Documento9 páginasDoka Accessory Box: Art. N° 583010000Boruida MachineryAinda não há avaliações

- Shaft Platform: The Cost-Saving System For Forming Inside-ShaftsDocumento2 páginasShaft Platform: The Cost-Saving System For Forming Inside-ShaftsBoruida MachineryAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

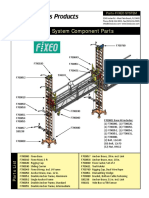

- Parts-Fixeo System ComponentsDocumento1 páginaParts-Fixeo System ComponentsBoruida MachineryAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- FX Cable Suspended Platform LR FADocumento6 páginasFX Cable Suspended Platform LR FABoruida MachineryAinda não há avaliações

- FEM 1.001-1 Object and ScopeDocumento26 páginasFEM 1.001-1 Object and ScopeBoruida MachineryAinda não há avaliações

- CRH Drain Pot LevelDocumento30 páginasCRH Drain Pot LevelBibhash SinghAinda não há avaliações

- RENR1156Documento2 páginasRENR1156Leopoldo Del Campo100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- 3b. Column Base Plate Ce134p Escruz LRFDDocumento17 páginas3b. Column Base Plate Ce134p Escruz LRFDjohn devonAinda não há avaliações

- Datasheet Joint Isolant 4'' #300 PDFDocumento1 páginaDatasheet Joint Isolant 4'' #300 PDFseifAinda não há avaliações

- E46 All-Wheel Drive System Model: E46/16 (330xi/a, 325xi/a, 325xi/a Sport Wagon) - Production Date: 330xi 8/00, 325xi 9/00Documento11 páginasE46 All-Wheel Drive System Model: E46/16 (330xi/a, 325xi/a, 325xi/a Sport Wagon) - Production Date: 330xi 8/00, 325xi 9/00Florin MaguranAinda não há avaliações

- Gear 1st 2nd 3rd 4th 5th Reverse: JJJJC C C C55 5 5Documento4 páginasGear 1st 2nd 3rd 4th 5th Reverse: JJJJC C C C55 5 5todo manualesAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Spare Parts Catalogue: Vibratory Roller CC1200Documento248 páginasSpare Parts Catalogue: Vibratory Roller CC1200Juan Carlos100% (1)

- HDPE Liner WT For CS PipesDocumento2 páginasHDPE Liner WT For CS Pipesmasdarto7032100% (1)

- Ms-Combination enDocumento39 páginasMs-Combination enCarlos VandréAinda não há avaliações

- AFBC-Control Loop Write UpsDocumento12 páginasAFBC-Control Loop Write UpsSaurabh BarangeAinda não há avaliações

- Om - S70 Metric - 11 - 2014Documento30 páginasOm - S70 Metric - 11 - 2014TucumánElectricidadIndustrialAinda não há avaliações

- Ms Productline 2021 n09Documento28 páginasMs Productline 2021 n09Francisco NavasAinda não há avaliações

- Machine Condition Monitoring and Fault DiagnosticsDocumento28 páginasMachine Condition Monitoring and Fault Diagnosticsزيد فؤاد اليافعيAinda não há avaliações

- Abrasion Test PDFDocumento4 páginasAbrasion Test PDFGloria Angelica Mora RomeroAinda não há avaliações

- Rheology of Complex FluidsDocumento130 páginasRheology of Complex FluidsghfdlfAinda não há avaliações

- Ducati Monster 821Documento270 páginasDucati Monster 821Michael NguyenAinda não há avaliações

- APPENDIX 1. Reference Drawing & Equipment LayoutDocumento20 páginasAPPENDIX 1. Reference Drawing & Equipment LayoutrianaAinda não há avaliações

- Iso 4413 2010 en PDFDocumento11 páginasIso 4413 2010 en PDFDiego Lima BarretoAinda não há avaliações

- Is 1893 1984Documento83 páginasIs 1893 1984rcdk2Ainda não há avaliações

- Turolla Hydraulic Gear Pumps Group2 Catalogue en l1016341Documento44 páginasTurolla Hydraulic Gear Pumps Group2 Catalogue en l1016341Opened EyesAinda não há avaliações

- HW07 PDFDocumento117 páginasHW07 PDFAndri OdeAinda não há avaliações

- Starter, Ign & Charging PDFDocumento1 páginaStarter, Ign & Charging PDFIqmalus SyariefAinda não há avaliações

- Fire Protection Design GuidelinesDocumento11 páginasFire Protection Design GuidelinesMarck Gheson InacayAinda não há avaliações

- PLI (Pounds Per Linear Foot)Documento5 páginasPLI (Pounds Per Linear Foot)ccorp00890% (1)

- Teaching Modules For Steel Instruction: Advanced Flexure Design Composite Beam Theory SlidesDocumento27 páginasTeaching Modules For Steel Instruction: Advanced Flexure Design Composite Beam Theory SlideskiranAinda não há avaliações

- Tyco - Test Indikatora ProtokaDocumento4 páginasTyco - Test Indikatora ProtokaMuhidin KozicaAinda não há avaliações

- Everest Full Synthetic Motor OilDocumento1 páginaEverest Full Synthetic Motor OilLa YaungAinda não há avaliações

- MotorDocumento4 páginasMotorAlexandru Manea0% (1)

- ChillerDocumento128 páginasChillerJuan Cascante JiménezAinda não há avaliações

- 01 EJS Metal Technical CatalogDocumento85 páginas01 EJS Metal Technical CatalogGicuAinda não há avaliações