Escolar Documentos

Profissional Documentos

Cultura Documentos

1166701

Enviado por

gandhiDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

1166701

Enviado por

gandhiDireitos autorais:

Formatos disponíveis

Impact of DMDHEU Resin Treatment on the Mechanical Properties of Poplar

Impact of DMDHEU Resin Treatment on the Mechanical Properties of

Poplar

Tao Jiang1, Hua Gao2, Jianping Sun1, Yanjun Xie3, and Xiurong Li1

1

College of Forestry, Guangxi University, Nanning city, Guangxi province 530005, P.R. China

2

Information engineering college, Guizhou minzu University, Guiyang 550025, P.R. China

3

Key Laboratory of Bio-based Material Science and Technology (Ministry of Education), Northeast Forestry University,

Harbin 150040, P.R. China

Received: 16 March 2014, Accepted: 30 April 2014

Summary

To increase the utilization and the value of poplar, various concentrations of dimethylol dihydroxy ethylene urea

(DMDHEU) were used to impregnate poplar, an important tree specie from the north of China. The resin was fixed

on the timber under certain conditions, after which the weight percent gain (WPG), flexural modulus (MOR),

modulus of elasticity (MOE), impact strength, hardness and compressive strength of the poplar impregnated were

tested and evaluated. The results showed that WPG of poplar is positively associated with the concentrations of

DMDHEU after the resin treatment; when the WPG of poplar was 62.1% and the concentration of resin was 30%,

the concentration of resin shows positive correlation with MOE, the hardness of each section, the compression

strength perpendicular to grain, and the compressive strength parallel to the grain, but demonstrates negative

correlation with MOR and impact strength.

Keywords: DMDHEU; Poplar; Mechanical properties; Bending modulus

1. Introduction In 1987, Nicholas, etc. 2 used DMAHEU resin and wood is that the

DMDHEU resin to improve the hydroxyl group of wood dehydration

Poplar (Populus) is an important dimensional stability of wood; forms hydroxyl ether, followed

fast-growing tree species, which Videlov3, and Ritschkoff4 investigated by a crosslinked compound. The

achieves large-scale cultivation in the preservative properties of the wood crosslinking mechanism is shown in

the north, so that accumulated a huge treated by DMDHEU resin; Xie Y. et Figure 1.

amount of timber resources. However, al.5,6 presented the effects of DMDHEU

the applications range of poplar is resin on the aging properties,

restricted for its loose fiber structure furnishing, gluing properties of wood. 2. Materials and

and relatively poor material quality1. Yasuda etc.7 studied the dimensional methods

This article tries to explore the impact stability, acoustic properties, and

of DMDHEU resin treatment on the modulus of elasticity of the timber

2.1 Test Materials

mechanical properties of poplar. treated by DMDHEU resin. Xie Poplar wood: bought from Harbin timber

Y. et al.8 studied the influence of market, wooden size 1000 mm × 30 mm

Dimethylol dihydroxy ethylene urea DMDHEU resin treatment on tensile × 30 mm, placed in a cool ventilated

(DMDHEU) is a representative properties of wood with MgCl2 as a place until the moisture content is stable

resin of the nitrogen hydroxymethyl catalyst. Zhang B. et al.9-11 mentioned (around 12%), and sawing mechanical

compound. DMDHEU resin has DMDHEU resin modified wood when experiments specimens based on

displaced formaldehyde in cotton he introduced overseas progress of national testing standards for wood

fiber textile industry because of its modification of timber; Xie Y.12 also mechanical properties.

better properties in low formaldehyde referred to the use of DMDHEU resin

emission, and the anti-wrinkle and modified wood when he described DMDHEU resin: provided by

anti-shrink rate of cotton fiber after the the functional improvement of wood. Lanxiang Resin Co., Ltd. in Zhongshan

treatment by DMDHEU resin. The primary reaction process between City, Guangdong Province, with solid

content of about 40%, a density of

about 1.02 g/ml, and infinite dilution

Corresponding Author: Sun Jianping, email: sjp_jpcn@163.com with water. Proportions of the solution

©

Smithers Information Ltd., 2014 herein refer to the mass percent.

Polymers & Polymer Composites, Vol. 22, No. 8, 2014 669

Tao Jiang, Hua Gao, Jianping Sun1, Yanjun Xie, and Xiurong Li

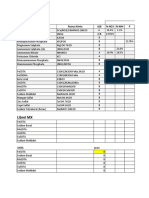

Figure 1. Crosslinking reaction between DMDHEU and hydroxyl groups of wood

MgCl26H2O: white crystals, analytical Where: G0-oven dry weight of sample Figure 2 shows when the wood was

grade, purity of 98%, Tianjin Hengxing before immersion; immersed in the resin solution, under

Chemical Reagent Co., Ltd. pressure from the outside world, the

G1- oven-dry weight of sample resin quickly spread into the internal

after immersion. timber, accumulated in the timber cells

2.2 Test Equipment

chamber and the cell gap, and part of

AG-10T universal mechanical testing the small molecule resin penetrated into

3. Results and

machine (Shimadzu Corporation); the cell wall of the wood. Under the

MV-4 pendulum impact testing

Discussion

action of high temperature and catalyst,

machine (Jinan material testing 3.1 Weight Gain of DMDHEU the resin in cell walls and the hydroxyl

machine factory); Vacuum pressure groups of timber reacted and formed a

Resin Treated Poplar

tank (Harbin Boiler Factory, working crosslinking compound; intermolecular

pressure 2.23 MPa). Weight gain is used to evaluate the condensation might happen to resin

amount of resin immersion. The itself, thereby fixed in the internal

level of weight gain of the treated timber. When the resin concentration is

2.3 Test Methods

wood may affect density, size and high (30%), the viscosity of the solution

The aqueous solutions with a other physical properties. Only is the same, which is not conducive to

concentration of 0, 10%, 20% and when resin treated timber obtains the spread of the resin in the timber. That

30% were prepared by DMDHEU a certain weight gain does the may affect the amount of resin immersed

solutions with solid content of 40%, treatment make sense. Figure 2 is into the cell wall, which account for the

then the catalyst MgCl2 were added to the weight percent grain of poplar reason why it is not obvious that the

the solution with mass ratio at 1.5%. treated with different concentrations increase of WPG treated by resin with

In the vacuum pressure tank, oven-dry of DMDHEU resin. As can be seen the concentration of 30% is small in

and weighed poplar samples were from the figure, with the increasing comparison with that of 20%. Further

immersed in the resin solution, after of the resin concentration (10%, 20%, study is still needed about the changes of

which the specimens were removed 30%), WPG of poplar significantly WPG with even higher concentrations.

when the poplar absorbed solution to increased (27.3%, 56.4%, 62.1%), In addition, when the resin concentration

the saturated state. Wipe the fluid on the when the resin concentration from is 0, i.e. the timber is immersed in an

surface with a towel and air-dried in a 10% to 20%, WPG was significantly aqueous solution, some water-soluble

cool ventilated place, and then drying greater than that from 20% to 30%. extract in the timber is dissolved, which

polymerization at the environment In addition, WPG of untreated timber may be the cause for the slightly lower

temperature of 120 °C, after which slightly reduces. WPG of timber.

the sample is put in a desiccator when

dried. When the sample is cooled to Figure 2. The WPG of DMDHEU treated Poplar wood

room temperature, it is weighed. At that

time the weight gain rate (WPG) can

be calculated according to the Equation

(1). Place the sample in air, and then

test the flexural modulus, the elastic

modulus, impact strength, hardness and

compressive strength of the specimen

when the equilibrium moisture content

of wood is 12%.

WPG = (G1-G0) / G0 × 100% (1)

670 Polymers & Polymer Composites, Vol. 22, No. 8, 2014

Impact of DMDHEU Resin Treatment on the Mechanical Properties of Poplar

3.2 Bending Modulus and toughness is to examine damage As can be seen from Figure 4, treated

Elasticity Modulus of resistance of test materials under with different concentrations of

DMDHEU Resin Treated impact loading. Figure 4 shows the DMDHEU resin, the impact strength

Poplar impact strength of poplar treated with of poplar wood decreased with the

different concentrations of DMDHEU increasing of resin concentration.

Flexural modulus, also known as resin. The impact strength of poplar is

static bending ultimate strength, is the

withstanding ability of wood to lateral

loads. Modulus of elasticity reflects Figure 3. The MOR and MOE of DMDHEU treated Poplar wood

the stiffness or elasticity of wood.

When wood sustains loads, with larger

bending elastic modulus and stiffness

of the wood, the wood is not vulnerable

to warping., otherwise, it is easy to

deform. Figure 3 is bending modulus

and modulus of elasticity of poplar

treated with different concentrations

DMDHEU resin. It can be seen from

Figure 3a that in comparison with

untreated poplar timber, MOR after the

DMDHEU resin treatment decreased

from 81.5 MPa to 62.6 MPa (10%),

67.7 MPa (20%) and 64.93 MPa

(30%), a decrease of 23.2%, 16.9%

and 20.3% respectively. In Figure 3b,

compared with untreated wood, MOE

of DMDHEU resin treated poplar

raised from 6.5 GPa to 7.7 GPa (10%),

9.6 GPa (20%) and 9.0 GPa (30%), an

increase of 18.4%, 46.6% and 38%

respectively.

In Figure 3, after DMDHEU resin

treatment, MOR of poplar showed a

decreasing trend with a rising trend

of MOE, i.e. decreasing elasticity

and increasing rigidity. This may be

due to DMDHEU resins immerse

into the wood cell walls, then the cell

walls inflated, and resins crosslink Figure 4. Impact strength of poplar wood treated with different concentration

with microfibrils in the timber, so that DMDHEU

free movement of the micro-fibrils is

limited, with the results of decreasing

MOR and increasing MOE.

3.3 Impact Strength of

DMDHEU Resin Treated

Poplar

Impact strength, also known as impact

toughness, is the energy absorbed by

sample per unit area while test material

is subject to impact loading resulting

damage in a very short period of time.

The purpose of testing the impact

Polymers & Polymer Composites, Vol. 22, No. 8, 2014 671

Tao Jiang, Hua Gao, Jianping Sun1, Yanjun Xie, and Xiurong Li

20.34 KJ/m, 21.24 KJ/m and 17.2 KJ/m Figure 5. Hardness of three section of poplar treated by DMDHEU with different

while dipping by DMDHEU resin concentration

with concentration of 10%, 20% and

30%, compared with untreated timber

26.33 KJ/m, a decrease of 22.75%,

19.33% and 34.67% respectively.

Decreasing impact strength of test

materials indicates the brittleness is

improved, so that the treated wood

is not suitable for application to the

impact strength higher position. In

previous reports7, decreasing impact

properties of DMDHEU modified

wood have been attributed to the rigid

network structure made by crosslinking

materials were 1406.4 N, 1558.6 N strength. Figure 6 shows compressive

reaction between wood cell wall

and 1407.4N, respectively. Compared strength parallel to grain (cross-section,

components and DMDHEU. When

with 953.0N in untreated material, the Figure 6a and perpendicular to grain

the test materials are subject to the

increase of hardness is 47.6%, 63.5%, (tangential section and radial section,

impact load, because molecules and

and 47.7%; the hardness of radial Figure 6b of poplar treated with

fibers cannot move easily, the impact

section was 1535.7 N, 1637.2 N and different concentrations DMDHEU

strength reduces. In addition, the

1551.9N, respectively. Compared with resin.

presence of magnesium chloride may

untreated material 916.5N, the rise is

cause accelerated hydrolysis of wood,

thus affecting the impact performance 67.6%, 82.6% and 69.3%; the hardness From Figure 6a, it can be seen that

of timber. of cross-sectional was 4371.0 N, compressive strength parallel to grain

4490.4 N and 4452.4N. Compared with of test materials treated by DMDHEU

untreated material 2446.0N, the rise is resin increases with the rise of resin

3.4 Hardness of DMDHEU 78.7 %, 83.6% and 82.0%. concentration. With 10%, 20% and

Resin Treated Poplar 30% resin treatment, the compressive

The hardness of wood is the capability Hardness of the wood is related to strength parallel to grain of test

of timber body resistant to other its species, density, and texture etc. materials is 75.1 MPa, 86.5 MPa and

rigid object. Figure 5 is the three Figure 2 shows the WPG of treated 91.0 MPa. Compared with 47.5 MPa

section hardness of poplar treated wood is at 27.3% ~ 62.1% s. The resin of the untreated wood, the increase is

with DMDHEU resin of different immersed in the cell wall and deposited 57.8%, 81.8% and 91.4%, respectively.

concentrations. in chamber and other locations leads to

the increased density of treated wood. It can be seen from Figure 6b that the

As can be seen from Figure 5, the cross- Treated wood inflates and becomes compressive strength perpendicular to

sectional hardness of the treated wood hard, so that it cannot be compressed grain of test materials increases with the

and untreated wood is much larger than and crushed easily. In cross-section of increasing of the resin concentration;

other two, and there is little difference test wood treated by DMDHEU, the radial compressive strength is higher

between hardness in radial section and cell wall becomes dense (wood density or similar to tangential. After treated

tangential section of untreated wood; increase), and the pressure is consistent by resin with concentration of

treated with different concentrations of with fiber arrangement direction, thus 10%, 20% and 30%, the tangential

DMDHEU resin, hardness in different greater pressure is required, and the compressive strength parallel to

sections of test materials is significantly transverse direction is much larger grain of poplar is 5.2 MPa, 6.0 MPa

bigger than that in untreated wood, and than the longitudinal. and 5.8 MPa, 4.3 MPa, respectively,

the hardness of radial section is slightly compared to untreated materials rose

bigger than tangential section. by 19.8%, 28.3% and 33.2%; the

3.5 Compressive Strength

radial compressive strength parallel to

of DMDHEU Resin Treated

Changing of DMDHEU concentration grain of poplar is 5.7 MPa, 6.0 MPa

does not affect the hardness of Poplar and 6.3 MPa, 4.9 MPa respectively,

the wood. Treated by resin with Compressive strength parallel to grain compared with 16.2%, 22.2% and

concentration of 10%, 20% and 30%, and perpendicular to grain of wood are 28.4% of the untreated timber.

hardness in tangential section of test collectively known as compressive Increasing compressive strength of

672 Polymers & Polymer Composites, Vol. 22, No. 8, 2014

Impact of DMDHEU Resin Treatment on the Mechanical Properties of Poplar

Figure 6. Compression strength parallel and perpendicular to grain of poplar grain and perpendicular to grain

wood treated with DMDHEU solution enhance.

Acknowledgements

Project Sponsored by the Scientific

Research Foundation of Guangxi

University (Grant No.XBZ120677).

The support funding of University

Research Projects of Guangxi (the

method of high-intensity microwave

cell-blasting to improve the permeability

of eucalyptus wood key technology

research) is also acknowledged.

References

1. Jiang T., Northeast Forestry

University PhD thesis, 1 (2012) 13.

2. Nicholas D.D. et al., Dimensional

stabilization of wood with

dimethylol compounds,

International Research Group on

Wood Preservation, IRG/WP/

(1987) p3412.

3. Videlov C.L., Biological

degradation resistance of

pinewood treated with dimethylol

components, International Research

Group on Wood Preservation, IRG/

WP/ (1989) p3528.

4. Ritschkoff A.C. et al., Effect

of some resin treatments on

test materials may be associated with and utilization value of poplar. Effects fungal degradation reactions,

DMDHEU resin impregnated test of DMDHEU resin treatment on the The 30th Annual Meeting of

material. mechanical properties of poplar can International Research Group on

be summarized as follows: Wood Preservation, (Rosenheim,

The resin is deposited on the wood cell Germany) IRG/WP (1999) p99.

lumen, coated on the walls around the 1. As treated by DMDHEU resin, 5. Xie Y. et al., Weathering of wood

microfibrils, and formed physical or weight gain percent of poplar modified with the N-methylol

chemical binding with wood, so that increases with the increasing compound 1, 3-dimethylol-4,

the relative freedom of microfibrils concentration of the resin, weight 5-dihydroxyethylene urea, Polymer

decreases, and rigidity increase, which gain of poplar treated by 30% resin Degradation and Stability, 89

(2005) 189-199.

improves the strength of the cell wall, is 62.1%, the increase in weight

finally the ability resistant to external enhances the density of the poplar; 6. Xie Y. et al., Coating performance

pressures of tested materials enhances. of finishes on wood modified with

2. As treated by DMDHEU resin, an N-methylol compound, Progress

MOR of poplar shows a decreasing in Organic Coatings, 57 (2006)

4. CONCLUSIONS trend, and MOE shows a rising 291-300.

trend, namely, elasticity of poplar 7. Yasuda R. et al., Chemical

Using a treatment of impregnated

decreases and rigidity increases modification of wood by non-

poplar by different concentrations formaldehyde: cross-linking

after treatment;

of DMDHEU resin, the poplar resin reagents:Part1. Improvement of

can enter the cell lumen and cell 3. After DMDHEU resin treatment, dimensional stability and acoustic

walls, and fix on poplar cell wall at impact strength of poplar decreases, properties, Wood Science and

high temperature, improving some namely, brittleness increases; the Technology, 28 (1994) 101-110.

mechanical properties of poplar and, hardness of each section, and the 8. Xie Y. et al., Effect of treatments

in consequence, expanding the scope compressive strength parallel to the with 1, 3-dimethylol-4,

Polymers & Polymer Composites, Vol. 22, No. 8, 2014 673

Tao Jiang, Hua Gao, Jianping Sun1, Yanjun Xie, and Xiurong Li

5-dihydroxy-ethyleneurea 10. Lu W., In order to improve the 12. Xie Y. et al., Wood chemical

(DMDHEU) on the tensile resistance to biological degradation modification: the state of

properties of wood, Holzforschung, and dimensional stability of wood, the art of technologies and

61 (2007) 43-50. the study of adding borax to no commercialization, Scientia silvae

9. Zhang B., Several chemical formaldehyde or low-formaldehyde sinicae, 48 (2012) 154-163.

modification of crosslinking cross-linking agent, Foreign Forest

depends wood weather resistance Product Industries Abstract, 2

and rust resistance, Foreign Forest (2001) 65.

Product Industries Abstract, 1 11. Shao X., The deficiencies of

(1997) 54-55. dimensional stability of crosslinked

wood-plastic composite material,

Foreign Forest Product Industries

Abstract, 1 (1999) 72.

674 Polymers & Polymer Composites, Vol. 22, No. 8, 2014

Você também pode gostar

- 608 155 PDFDocumento10 páginas608 155 PDFgandhiAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- 01 Factsheet TT Testex en v01Documento3 páginas01 Factsheet TT Testex en v01gandhiAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Astm d4442 07direct Moisture Content Measurement of Wood PDFDocumento6 páginasAstm d4442 07direct Moisture Content Measurement of Wood PDFgandhiAinda não há avaliações

- SOP HR HG HB MJ TempCal Moisture Analyzer enDocumento6 páginasSOP HR HG HB MJ TempCal Moisture Analyzer engandhiAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- BV 300 Layer Management Guide: Types of HousingDocumento20 páginasBV 300 Layer Management Guide: Types of HousingBINAY KUMAR YADAV100% (1)

- Student Exploration: Collision Theory: NCVPS Chemistry Fall 2014Documento7 páginasStudent Exploration: Collision Theory: NCVPS Chemistry Fall 2014erwin golovashkin0% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Hdpe SK 6100Documento1 páginaHdpe SK 6100Le Minh TuanAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- 9cbse-ATOMS AND MOLECULES-NOTES-JAN 2023 - UpdatedDocumento4 páginas9cbse-ATOMS AND MOLECULES-NOTES-JAN 2023 - UpdatedTamers artAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- NCERT Exemplar Problems For Solid State Class XIIDocumento16 páginasNCERT Exemplar Problems For Solid State Class XIISuparnaAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Electrolysis 2Documento5 páginasElectrolysis 2trickster jonasAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- AHMSW 8 Fiche de PhaseDocumento12 páginasAHMSW 8 Fiche de PhaseBOUBAKER LOGBIAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- ConcreteDocumento3 páginasConcreteTran DtrungAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Philippines FreshwaterDocumento11 páginasPhilippines FreshwaterBJ Allon Mallari100% (1)

- List 25 Big Refineries in AsiaDocumento4 páginasList 25 Big Refineries in Asiatrantam88Ainda não há avaliações

- Manual Lavadora SecadoraDocumento84 páginasManual Lavadora Secadorakhalid mohamedAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Excel Meracik Nutrisi Bandung 11 Feb 2018Documento30 páginasExcel Meracik Nutrisi Bandung 11 Feb 2018Ariev WahyuAinda não há avaliações

- SK Duggal Construction Materials LectureDocumento19 páginasSK Duggal Construction Materials LectureTaimoor SarfarazAinda não há avaliações

- Gliesse Plant PresentationDocumento20 páginasGliesse Plant PresentationNeel Gliesse PharmaAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Perrys Chemical Engineering Handbook 6th EditionDocumento2 páginasPerrys Chemical Engineering Handbook 6th Editionnabil20% (10)

- Imidazoline-Théorie Ferm1954Documento21 páginasImidazoline-Théorie Ferm1954Belkhadem FatimaAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Grundfosliterature-836 - (PG 10,24-25)Documento226 páginasGrundfosliterature-836 - (PG 10,24-25)anggun100% (1)

- Basic Molecular Biology & Biotechnology Training ManualDocumento23 páginasBasic Molecular Biology & Biotechnology Training Manualsameer420Ainda não há avaliações

- Biogas Production SystemsDocumento22 páginasBiogas Production SystemsEmiliano Rodriguez TellezAinda não há avaliações

- Great DesignomicsDocumento95 páginasGreat DesignomicsChristopher Allen VarsoviaAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- PNSC0021Documento12 páginasPNSC0021romerobernaAinda não há avaliações

- Experiment 08 To Determine Deflection Components of A Semi-Circular Bar Subjected To Diametrical LoadingDocumento7 páginasExperiment 08 To Determine Deflection Components of A Semi-Circular Bar Subjected To Diametrical LoadingKhurram SattarAinda não há avaliações

- Insoluble Ions EssayDocumento2 páginasInsoluble Ions EssayDarshan Meghji100% (1)

- Presentation On Nutmeg Oil For IPB NOV 2022Documento34 páginasPresentation On Nutmeg Oil For IPB NOV 2022KushDaiwikAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Paper Industry Case Study PDFDocumento4 páginasPaper Industry Case Study PDFanitha venkatAinda não há avaliações

- Catalogo Alu MarketDocumento40 páginasCatalogo Alu MarketMiguel Angel Diaz Escobar100% (2)

- M60 Painting/ Clear FinishingDocumento4 páginasM60 Painting/ Clear FinishingPeteAinda não há avaliações

- SPT2021 Butadiene AAMDocumento29 páginasSPT2021 Butadiene AAMTasneem MAinda não há avaliações

- Location Risk Assessment Form-Part A: Basic Information & Hazard ListDocumento3 páginasLocation Risk Assessment Form-Part A: Basic Information & Hazard Listapi-330049796Ainda não há avaliações

- Guidelines For The Establishment of Pharmaceutical Retail BusinessDocumento19 páginasGuidelines For The Establishment of Pharmaceutical Retail BusinessFranc100% (1)