Escolar Documentos

Profissional Documentos

Cultura Documentos

Levantamiento Topografico

Enviado por

anon_365119658Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Levantamiento Topografico

Enviado por

anon_365119658Direitos autorais:

Formatos disponíveis

Fecha:

No:

Revisiones:

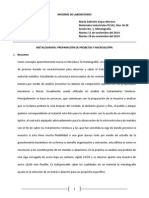

Detail 645 920

Ground floor 2.020

M 1:30 540

120

460

+/-0

500

65 N/cm2

200 266 400

400

156 400

1.135

1.630

NOTAS :

1.475

1.466

1.345

1.066

910

600

Copia definitiva

400 266 200 600

910

1.345

1.066

400 156

2.260

400

500

+/-0

900 5.440

510

5.350

620 2.400 620

810 3.884

3.884

3.884

1.640

265

235 665 515 665 280 5 5.200

235 400 410 770 410 400 1.900

2.625 1.900

Fecha:

No:

Revisiones:

7.500

R

V3

new level of existing

prefabricated pi-plate

to - 120 mm for rails, hole for rails - 120 mm

additional concrete layer at site with 20 mm steelplates - 100 mm

(see detail)

hole for rails - 120 mm 2.455

with 20 mm steelplates - 100 mm EDR

(see detail)

4

500 5.170 500

NOTAS :

- 120 mm 2.147

pi-plate

EDR

1.565

17.400

two existing plates

A D NOTA: LOS NIVELES FUERON MARCADAS CONREFERENCIA AL

660

3.135

BANCO DE NIVEL MARCADO EN COLUMNA DE EJE 6.

Mittelpunkt Presse ARISA 1

5

hole 5.170 x 1.000 mm

as oil drip, depth - 40 mm,

center press ARISA 1

500 500

pi-plate

1.355 17 1.565

1.000

with steel grid

h = 40 mm, anti - slip

wheels

2.270

33

33

17

Copia definitiva

7.500

B E

metal plate

17 8.960 26 after assembly

pi-plate

pi-plate

1.355

pi-plate

- 120 mm machine

two new plates

two new plates

21 8.960 22

reference column R/6

2.735

2.735

pi-plate

holes for rails

25

25

for ARISA 1

7.750

13 8.960 30

3.928

EDR

2.482

pi-plate

pi-plate

3.912

pi-plate

1.355

1.355

EDR

metal plate

- 120 mm 6.980 EDR

645 920

2.308

after assembly 21 8.960

5.820

C F

30

30

30

30

machine F3

+2.262,00

900

50 2.163 319 305 depth -400mm

8.400 53

EDR depth -950mm depth -100mm EJE 06 SERA EL EJE MAESTRO DE TRAZO EN SU

C

624

C

+/-0

6

327

500

2

3.007

65 N/cm

2.760

2.760

INTERSECCION CON EL EJE CENTRAL DEL PIT

center decoiler

400

156 400

F1

1.630

2.107

load on each Axis 6 intersection with Axis R will be the master layout point

1.466

1.345

steel plate: F3

1.066

static 125,00 tons

910

600

5.520

5.520

dynamic 23,75 tons F6

existing hole

existing hole

depth -500mm

11.870

11.847

F3

EDR

EDR

400 266 200 600

F3

910

1.345

1.066

1.660

400 156

1.100 1.100

2.260

2.262

2.760

2.760

400

2.050

65 N/cm2

500

+/-0

5.870

65 N/cm2 depth -400mm +/-0 65 N/cm2

C

900 5.440 900

+/-0

7.935

EDR

8.400 45

7.942

7.500

EDR

5.200

853 1.257

5.350

30

30

30

30

G J 620 2.400 620

holes for rails

810

F5

pi-plate

pi-plate

3.884

3.884

1.730

1.730

3 plates supplied

7.260

and leveled by

3.884

- 120 mm

two new plates

two new plates

the contractor

F4

1.640

30 8.960 13

3.490

3.490

pi-plate

30

30

F4

21 8.960 22

pi-plate

pi-plate

pi-plate

1.730

1.730

H K

623

500 500

wheels

2.270

1.000

5

324

30 8.960 13

pi-plate

25

25

32

32

311 312 depth -100mm

2.189

EDR

existing plate

new plates with 120 mm

948

new plates with 120 mm

pi-plate

1.560

1.560

additional concrete layer at site I L 2.500 additional concrete layer at site

EDR

5.570 265

wheels

15

235 665 515 665 280 5 5.200

15

235 400 410 770 410 400 1.900

hole 5.170 x 1.000 mm 500 2.585 2.585 500

6.670 2.625 1.900

as oil drip, depth - 40 mm,

with steel grid 500 5.170 500

holes for rails hole for rails - 120 mm

h = 40 mm, anti - slip 250 250

8.503 with 20 mm steelplates - 100 mm

7.500

pit (see detail)

Proyeccion de Mezannine h= +4.50

hole for rails - 120 mm 9.003

4.755

with 20 mm steelplates - 100 mm EDR load per wheel 17,5 tons

(see detail) total load table 70 tons

new level of existing

prefabricated pi-plate

to - 120 mm for rails,

additional concrete layer at site

2.523

EDR

4

2.207

EDR

Você também pode gostar

- Practica 8 de Metalmecanica - Ensayo de ImpactoDocumento19 páginasPractica 8 de Metalmecanica - Ensayo de ImpactoGabriel CaballeroAinda não há avaliações

- Clasificación de Los ElectrodosDocumento8 páginasClasificación de Los ElectrodosJeysson Condori CcamaAinda não há avaliações

- Definicion Del AceroDocumento11 páginasDefinicion Del AceroErikaAndreinaAinda não há avaliações

- Catalogo Gral CIMETDocumento48 páginasCatalogo Gral CIMETMarcelo Aldao100% (2)

- FESTO-Cilindro Doble efecto-DSNU ES-LGDocumento19 páginasFESTO-Cilindro Doble efecto-DSNU ES-LGAndrea FloresAinda não há avaliações

- Inforgrama TruDocumento6 páginasInforgrama TruLuisAinda não há avaliações

- AISI 304 - 304L Acero InoxidableDocumento5 páginasAISI 304 - 304L Acero InoxidableMiguel Eduardo RivadeneiraAinda não há avaliações

- FT Ficha TecnicaDocumento7 páginasFT Ficha TecnicaalexisAinda não há avaliações

- Rodamientos Autoalineables y SoportesDocumento10 páginasRodamientos Autoalineables y Soporteslixmen rojasAinda não há avaliações

- Dibujo y CadDocumento13 páginasDibujo y CadJose AndresAinda não há avaliações

- Curriculum Vitae - RAMOS LULICHACDocumento17 páginasCurriculum Vitae - RAMOS LULICHACFrank Vargas RAinda não há avaliações

- Tabla Periódica Actual 123Documento6 páginasTabla Periódica Actual 123cristianAinda não há avaliações

- TEORICA T2 2019 - 11 Moldeo de MetalesDocumento63 páginasTEORICA T2 2019 - 11 Moldeo de MetalesValentin CurciAinda não há avaliações

- Precios Unitarios Voz y Datos PDFDocumento1.126 páginasPrecios Unitarios Voz y Datos PDFChuy Davila100% (1)

- Presupuesto de Caseta Obra Civil PDFDocumento1 páginaPresupuesto de Caseta Obra Civil PDFMarlon SingAinda não há avaliações

- Informe de Laboratorio 1, MetalografíaDocumento6 páginasInforme de Laboratorio 1, MetalografíagabrielavayasAinda não há avaliações

- INFORME No. 1922 Inspeccion NDT A Rodillos Ejes Area Calderas Fabrica Ingenio Manulieta 2018Documento6 páginasINFORME No. 1922 Inspeccion NDT A Rodillos Ejes Area Calderas Fabrica Ingenio Manulieta 2018mauriciomejia7Ainda não há avaliações

- RRRDocumento13 páginasRRRGonzalo SalazarAinda não há avaliações

- BOLARDOSDocumento22 páginasBOLARDOSCesar Carranza VejaranoAinda não há avaliações

- CorrosionDocumento17 páginasCorrosionViviana Contreras CzAinda não há avaliações

- Basicos Morteros 2018Documento23 páginasBasicos Morteros 2018aldahirAinda não há avaliações

- Características de Los Modelos y Procesos de FundiciónDocumento4 páginasCaracterísticas de Los Modelos y Procesos de FundiciónTania Altamirano RomeroAinda não há avaliações

- Alto Horno y Horno BOFDocumento19 páginasAlto Horno y Horno BOFDavidHG12100% (1)

- DM1 T2. ProblemasDocumento5 páginasDM1 T2. ProblemasVicente Pascual NavarroAinda não há avaliações

- Relacion de Materiales de Escritorio UgmDocumento62 páginasRelacion de Materiales de Escritorio UgmGlover C. Mamani CariAinda não há avaliações

- Muelles y Balancines PDFDocumento2 páginasMuelles y Balancines PDFingrid padilla chigualaAinda não há avaliações

- Apunte 8 AmalgamaDocumento8 páginasApunte 8 AmalgamaPame Araneda GonzalezAinda não há avaliações

- Acero InoxidableDocumento61 páginasAcero Inoxidableortodoncia 2018100% (1)

- CamWorks Turn TutoDocumento316 páginasCamWorks Turn TutoJavierAinda não há avaliações

- Candado Bloqueo Dieléctrico 74-40 KD Colores ABUSDocumento4 páginasCandado Bloqueo Dieléctrico 74-40 KD Colores ABUSscofiel1Ainda não há avaliações