Escolar Documentos

Profissional Documentos

Cultura Documentos

Plain Woven Fabric Defect Detection Using GLCM Based Feature Extraction

Enviado por

IJRASETPublicationsTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Plain Woven Fabric Defect Detection Using GLCM Based Feature Extraction

Enviado por

IJRASETPublicationsDireitos autorais:

Formatos disponíveis

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue V, May 2018- Available at www.ijraset.com

Plain Woven Fabric Defect Detection using GLCM

based Feature Extraction

Mrs. S. Sahaya Tamil Selvi1, Dr. G. M. Nasira2

1

Mrs. S. Sahaya Tamil Selvi, Head/Asst. Professor, Department of Computer Science, St. Joseph’s College for women, Tirupur,

India

2

Dr. G. M. Nasira , Head and Professor of Computer Applications, Chikkanna Govt. Arts College, Tirupur , India

Abstract: An accurate fabric defect detection is done in based on extraction of features from Gray level co –occurrence

matrix(GLCM). The process of extracting salient features plays a crucial role in Automatic fabric defect detection. The proposed

system makes a fabric analysis to classify whether the fabric is defect free or defected using several Digital image processing

techniques. This paper presents the application of gray level co-occurrence matrix (GLCM) to extract second order statistical

texture features for classification of various defects in plain woven fabric images. The salient features namely area, entropy,

standard deviation, smoothness, skewness, max intensity, min intensity, mean, standard deviation and energy are calculated

from GLCM. The results show that these texture features have high discrimination accuracy in classification of various defects

in Automatic fabric defect detection where a support vector machine (SVM ) is being used as the classifier.

Keywords: GLCM, Automatic fabric defect detection, texture features, Standard deviation, Entropy, Mean, SVM

I. INTRODUCTION

Producing highest quality goods is highly desirable in the Garment industry. Fabric faults or defects are responsible for nearly 85%

of the defects found by the garment industry [4]. Automatic fabric inspection plays vital role in maintaining the quality of fabric. It

is imperative, therefore, to detect, to identify, and to prevent these defects from reoccurring. The Automatic fabric inspection system

does not suffer the drawbacks of human visual inspection.

The proposed system makes a fabric analysis to classify whether the fabric is defect free or defected using several Digital image

processing techniques. The process is done based on extraction of features from Gray level co –occurrence matrix(GLCM). In this

paper the gray level co-occurrence matrix (GLCM) is used to extract second order statistical texture features for classification of

various defects in plain woven fabric images. The salient features namely area, entropy, standard deviation, smoothness, skewness,

maximum intensity, minimum intensity, mean, standard deviation and energy are calculated from GLCM. The results show that

these texture features have high discrimination accuracy in classification of various defects. Automatic fabric defect detection where

a support vector machine (SVM ) is being used as the classifier. These features are calculated and implemented using MATLAB.

In [1] it has been stated that Feature extraction process reduces the original MRI data set into a set of features . and these feature

vectors are the basic inputs for any classification algorithm . In [2] it has been assessed that Support Vector Machine is a machine

learning algorithm which has the ability to distinguish among different types of patterns fed to it and SVM tries to compute optimal

hyperplanes and maps the points belonging to different categories or classes into distinct spatial regions separated by optimal

hyperplanes. In [11] it has been concluded that in thework the accuracy of 96% is achieved using saliency map characterization

and gray level co-occurrence matrix(GLCM) method is adapted which is very useful in differentiation of Neuro degeneration

diseases with better accuracy. In [5] discusses that Texture analysis aims in finding a unique way of representing the underlying

characteristics of textures and represent them in some simpler but unique form, so that they can be used for robust, accurate

classification and segmentation of objects.

The proposed methodology for feature extraction is described in section II. The result obtained in various stages in the proposed

system is discussed in section III. Finally conclusion is provided in section IV.

II. PROPOSED APPROACH

Most of the defects in fabric occur during weaving. Some of these fabric defects are visible, while others are not. Some of the fabric

defects may be rectified during weaving whereas others are not. Finding the exact location of defects and determining the right type

of defect are also important. The provides a chance to get a warning whenever defect or imperfection occurs during the production

of the fabric which will help taking precautionary measures before the product goes for inspection[3]. In a fabric, defects can

©IJRASET: All Rights are Reserved 874

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue V, May 2018- Available at www.ijraset.com

occur due to: machine faults, yarn problems, poor finishing, excessive stretching, etc. There are a large number of types of fabric

defects available out of which the following are some of the Common Weaving Defects:

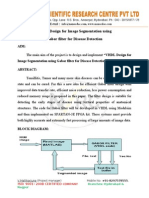

The development of an automated, i.e. computer vision based system for plain woven fabric defect inspection involves several steps

as shown in Fig.2.

Image Image GLCM

Acquisition Preproce Calculation

ssing

Classification Feature Segmentation

by SVM Extraction

Fig. 1 Block diagram of the proposed Automated Fabric defect detection system

A. Image Acquisition

The first stage of any vision system is Image acquisition. There are different types of camera used for this application such as

Digital camera, CCD (Charged Coupled Device) camera, CMOS (Complementary Metal Oxide Semiconductor) camera, etc. The

fabric images database is created using images collected from various fabric producing companies in Tirupur, Tamilnadu, India.

These images are converted to gray scale images and stored as having size of 256x256.

B. Image Preprocessing

Image preprocessing stage consist of collection of techniques that are used to improve the visual appearance of an image or used to

convert the image to a form, which can be better suited for further analysis in the subsequent stages by a human or a

machine[7].Here in the proposed system the noise in the image is removed by applying PSO based median filter[8]. The acquired

image must be converted into gray scale image in order to calculate GLCM matrix.

C. GLCM calculation

The converted Gray image is then used to Graylevel co-occurrence matrix (GLCM). For this calculation, the following method is

being employed to get the GLCM.

The Gray Level Co-ocurrence Matrix (GLCM) method is a used for extracting second order statistical texture features. The

approach can be used in a number of applications [2]. Third and higher order textures consider the relationships among three or

more pixels. A GLCM matrix can be defined to have the number of rows and columns is equal to the number of distinct gray levels

or pixel values in the image. The matrix describes the frequency of one gray level appearing in a specified spatial linear relationship

with another gray level within the area of investigation. Given an image, the GLCM gives the statistical tabulation of how

frequently different combinations of gray levels co-occur in an image or image section [1]. GLCM matrix building is explained with

the example illustrated in fig 2 for four different gray levels. Here one pixel offset is used (a reference pixel and its immediate

neighbor. The top left cell will be filled with the number of times the combination 0,0 occurs, i.e. how many time within the image

area a pixel with grey level 0 (neighbour pixel) falls to the right of another pixel with grey level 0(reference pixel).

D. Segmentation

Image segmentation is typically used to locate objects and boundaries (lines, curves, etc.) in images. The segmentation process

assigns a label to every pixel in an image such that certain visual characteristics are shared by pixels with the same label. Several

methods can be used to segment the defect, i.e., detect the defect on the image, ranging from simple segmentation methods (e.g.,

thresholding) to more advanced methods [9][10]. Here, in this proposed method, Entropy filter combined with morphological

operations is used to segment the fabric images. Various defective type of fabric images after the segmentation stage is shown in the

fig 5.

©IJRASET: All Rights are Reserved 875

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue V, May 2018- Available at www.ijraset.com

Fig. 1 GLCM calculation

E. GLCM based Feature extraction

Feature Extraction is a stage in which various methods can be employed for capturing visual content of images for indexing &

retrieval purpose[5]. The textural features which are extracted in this proposed method are area, entropy, standard deviation,

smoothness, skewness, maximum intensity, minimum intensity, mean, standard deviation and energy are calculated from GLCM.

The formula of various features which are calculated from the GLCM is given in the fig 3.

Fig. 3 Formula for various features calculated from GLCM

The sample MATLAB code to calculate GLCM and the various features is given as follows.

new_defect = graycomatrix(I2,'GrayLimits',[],'Offset',[1 0]);

new_defect(1,1)=0;

mea=mean2(new_defect);

©IJRASET: All Rights are Reserved 876

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue V, May 2018- Available at www.ijraset.com

sa=std(std(new_defect));

% Smoothness

sm_a=1-(1/(1+sa).^2);

%sm_a=1-(1./(1+sa));

% Skewness - 3rd order moment

aa=new_defect(:);

[m, n]=size(aa);

for i=1:m

for j=1:n

sk_a(i,j)=((aa(i,j)-mea)/sa).^3;

end

end

skew_a=mean(sk_a);

e_a=entropy(new_defect);

M=new/sum(new_defect(:));

f_1=M.^2;

ene_a=sum(f_1(:));

I2=double(I2);

MaxIntensity=max(max(I2));

MinIntensity=min(min(I2));

new_nby=[ma_defect mea sa sm_a skew_a e_a ene_a MaxIntensity MinIntensity b]

Fig. 4 The workspace of calculated feature values in MATLAB

©IJRASET: All Rights are Reserved 877

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue V, May 2018- Available at www.ijraset.com

F. Classification

Support vector machines (SVMs) are supervised learning models with associated learning algorithms that analyze data and

recognize patterns, used for classification and regression analysis [2]. This classifier classifies the input image to be one of the

defected type . SVM has the advantage of classifying the defected fabric images with a high degree of accuracy value.

III. RESULT AND DISCUSSION

In this paper ,Grey Level Co-occurrence Matrix (GLCM) and Connected Regions are used for feature extraction. The result of each

process of Automatic fabric defect detection method namely capturing , Preprocessing, Converting to gray scale image and

segmentation is shown in the fig 5 . Each image is segmented and the Grey Level Co-occurrence Matrix (GLCM) is created. From

the GLCM, texture features are calculated and connected regions are used to extract shape features. The sample feature values

which are obtained from the images are shown in fig . 4. The result of classification of fabric image to be one of the defects is

shown in fig 6. and in fig 7. Around 200 fabric images has been used in this work and the accuracy of classification of the fabric

image is 97.4359.

Defects Missed thread Missed thread Greece Ink Tear

Original

images

Filtered

images

Segmented

images

Defected

area

Fig. 5 The resultant images of various stages of Automatic fabric defect detection

©IJRASET: All Rights are Reserved 878

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue V, May 2018- Available at www.ijraset.com

Fig. 6 The result after loading the fabric image into the system from the database

Fig. 7 The result after applying Pre-process and GLCM stages and the result of SVM classifier

IV. CONCLUSIONS

The proposed feature extraction method for the Automatic fabric defect detection is faster and less complex . The accuracy of the

classification is high and the obtained features are authentic. Texture features are extracted using GLCM and shape features are

extracted using connected regions. The shape features are extracted directly from the segmented image. It is the simplest and less

complex method for the calculation of texture and shape features. These features can be used for training the classification algorithm.

The accuracy of classification can be increased by using larger dataset.

REFERENCES

[1] Shijin Kumar P.S and Dharun V. S ,” Extraction of Texture Features using GLCM and shape Features using connected Regions”, International Journal of

Engineering and Technology (IJET), Vol 8 No 6 Dec 2016-Jan 2017

[2] J. Hemraj, Raikwar Himanshu Jain , Amit Baghel , “Calorie Estimation from Fast Food Images Using Support Vector Machine “, International journal on

future revolution in Computer Science & Communication Engineering , ISSN: 2454-4248 Volume: 4 Issue: 4 98- 102 April 2018

[3] Dr.G.M.Nasira and P.Banumathi, , “A Plain Woven Fabric Defect Detection Based on Image Processing and Artificial Neural Networks”, International

Journal of Computer Trends and Technology(IJCTT) volume 6 number 4–Dec 2013 ISSN: 2231-2803 www.internationaljournalssrg.org Page 226

[4] Semiyya E and Jyothi R.L, ”Automatic Fabric Defect Detection using Spatial and Spectral Features”, International Journal of Engineering Research &

Technology (IJERT), ISSN: 2278-0181,Vol. 3 Issue 12, December-2014

[5] R P. Mohanaiah, P. Sathyanarayana and , L. GuruKumar, , “Image Texture Feature Extraction Using GLCM Approach”, International Journal of Scientific

and Research Publications, Volume 3, Issue 5, May 2013 1 ISSN 2250-3153

[6] Namita Aggarwal and R. K. Agrawal, “First and Second Order Statistics Features for Classification of Magnetic Resonance Brain Images”, Journal of Signal

and Information Processing, 2012, 3, 146-153 http://dx.doi.org/10.4236/jsip.2012.32019 Published Online May 2012 (http://www.SciRP.org/journal/jsip)

[7] S.Sahaya Tamil Selvi and Dr.G.M.Nasira, “Noise removal of Fabric images in Automated Fabric Inspection System using Digital Image Processing

Techniques”, International Journal of Applied Engineering Research(IJAER),ISSN:0973-4562,Vol 10 No.69(2015).

[8] S.Sahaya Tamil Selvi, “Particle Swarm Optimization enabled Filtering for Fabric Images in Automated Fabric Inspection System”, IEEE Xplore, INSPEC

Accession Number: 16426564

ell. (2002) IEEEtran homepage on CTAN. [Online]. Available: http://www.ctan.org/tex-archive/macros/latex/contrib/supported/IEEEtran/

[9] R.Gonzales and R. Woods – Digital Image Processing; Prentice Hall of India, 2008.

[10] S.E. Umbough – Computer Vision and Image Processing; Englewood Cliffs, Nj: Prentice- Hall, 1998.

[11] Akhila Reghu and Reby John, “GLCM Based Feature Extraction of Neurodegenerative Disease for Regional Brain Patterns”, International Journal of

Engineering Research and General Science Volume 4, Issue 3, May-June, 2016, ISSN 2091-2730

©IJRASET: All Rights are Reserved 879

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- COMP 4421 - Image ProcessingDocumento56 páginasCOMP 4421 - Image ProcessingLinh TaAinda não há avaliações

- Design and Analysis of Fixed-Segment Carrier at Carbon Thrust BearingDocumento10 páginasDesign and Analysis of Fixed-Segment Carrier at Carbon Thrust BearingIJRASETPublicationsAinda não há avaliações

- Air Conditioning Heat Load Analysis of A CabinDocumento9 páginasAir Conditioning Heat Load Analysis of A CabinIJRASETPublicationsAinda não há avaliações

- Skill Verification System Using Blockchain SkillVioDocumento6 páginasSkill Verification System Using Blockchain SkillVioIJRASETPublicationsAinda não há avaliações

- Real Time Human Body Posture Analysis Using Deep LearningDocumento7 páginasReal Time Human Body Posture Analysis Using Deep LearningIJRASETPublications100% (1)

- 11 V May 2023Documento34 páginas11 V May 2023IJRASETPublicationsAinda não há avaliações

- BIM Data Analysis and Visualization WorkflowDocumento7 páginasBIM Data Analysis and Visualization WorkflowIJRASETPublicationsAinda não há avaliações

- Design and Analysis of Components in Off-Road VehicleDocumento23 páginasDesign and Analysis of Components in Off-Road VehicleIJRASETPublicationsAinda não há avaliações

- IoT-Based Smart Medicine DispenserDocumento8 páginasIoT-Based Smart Medicine DispenserIJRASETPublications100% (1)

- Advanced Wireless Multipurpose Mine Detection RobotDocumento7 páginasAdvanced Wireless Multipurpose Mine Detection RobotIJRASETPublicationsAinda não há avaliações

- Controlled Hand Gestures Using Python and OpenCVDocumento7 páginasControlled Hand Gestures Using Python and OpenCVIJRASETPublicationsAinda não há avaliações

- A Review On Speech Emotion Classification Using Linear Predictive Coding and Neural NetworksDocumento5 páginasA Review On Speech Emotion Classification Using Linear Predictive Coding and Neural NetworksIJRASETPublicationsAinda não há avaliações

- TNP Portal Using Web Development and Machine LearningDocumento9 páginasTNP Portal Using Web Development and Machine LearningIJRASETPublicationsAinda não há avaliações

- Credit Card Fraud Detection Using Machine Learning and BlockchainDocumento9 páginasCredit Card Fraud Detection Using Machine Learning and BlockchainIJRASETPublications100% (1)

- Design and Analysis of Fixed Brake Caliper Using Additive ManufacturingDocumento9 páginasDesign and Analysis of Fixed Brake Caliper Using Additive ManufacturingIJRASETPublicationsAinda não há avaliações

- Low Cost Scada System For Micro IndustryDocumento5 páginasLow Cost Scada System For Micro IndustryIJRASETPublicationsAinda não há avaliações

- CryptoDrive A Decentralized Car Sharing SystemDocumento9 páginasCryptoDrive A Decentralized Car Sharing SystemIJRASETPublications100% (1)

- Real-Time Video Violence Detection Using CNNDocumento7 páginasReal-Time Video Violence Detection Using CNNIJRASETPublicationsAinda não há avaliações

- Comparative in Vivo Study On Quality Analysis On Bisacodyl of Different BrandsDocumento17 páginasComparative in Vivo Study On Quality Analysis On Bisacodyl of Different BrandsIJRASETPublicationsAinda não há avaliações

- A Blockchain and Edge-Computing-Based Secure Framework For Government Tender AllocationDocumento10 páginasA Blockchain and Edge-Computing-Based Secure Framework For Government Tender AllocationIJRASETPublicationsAinda não há avaliações

- Experimental Study of Partial Replacement of Cement by Pozzolanic MaterialsDocumento9 páginasExperimental Study of Partial Replacement of Cement by Pozzolanic MaterialsIJRASETPublicationsAinda não há avaliações

- Literature Review For Study of Characteristics of Traffic FlowDocumento10 páginasLiterature Review For Study of Characteristics of Traffic FlowIJRASETPublicationsAinda não há avaliações

- Skin Lesions Detection Using Deep Learning TechniquesDocumento5 páginasSkin Lesions Detection Using Deep Learning TechniquesIJRASETPublicationsAinda não há avaliações

- Structural Design of Underwater Drone Using Brushless DC MotorDocumento9 páginasStructural Design of Underwater Drone Using Brushless DC MotorIJRASETPublicationsAinda não há avaliações

- An Automatic Driver's Drowsiness Alert SystemDocumento7 páginasAn Automatic Driver's Drowsiness Alert SystemIJRASETPublications100% (1)

- Design and Development of Cost-Effective 3D-PrinterDocumento7 páginasDesign and Development of Cost-Effective 3D-PrinterIJRASETPublicationsAinda não há avaliações

- Application For Road Accident RescueDocumento18 páginasApplication For Road Accident RescueIJRASETPublications100% (1)

- Smart Video Surveillance Using YOLO Algorithm and OpenCVDocumento8 páginasSmart Video Surveillance Using YOLO Algorithm and OpenCVIJRASETPublications100% (1)

- Vehicles Exhaust Smoke Detection and Location TrackingDocumento8 páginasVehicles Exhaust Smoke Detection and Location TrackingIJRASETPublications100% (1)

- Achieving Maximum Power Point Tracking With Partial ShadingDocumento10 páginasAchieving Maximum Power Point Tracking With Partial ShadingIJRASETPublicationsAinda não há avaliações

- Preparation of Herbal Hair DyeDocumento12 páginasPreparation of Herbal Hair DyeIJRASETPublications100% (1)

- DISEASE DETECTION IN VEGETABLES (TOMATO) USING DEEP LEARNINgDocumento38 páginasDISEASE DETECTION IN VEGETABLES (TOMATO) USING DEEP LEARNINgA AAinda não há avaliações

- Easy AlignDocumento5 páginasEasy AlignPaulo CasemiroAinda não há avaliações

- Framework For Network-Level Pavement Condition Assessment Using Remote Sensing Data MiningDocumento32 páginasFramework For Network-Level Pavement Condition Assessment Using Remote Sensing Data MiningStefanos PolitisAinda não há avaliações

- Image Processing SyllabusDocumento1 páginaImage Processing SyllabusSrijan2022 H42Ainda não há avaliações

- Automatic Video Surveillance System For Pedestrian Crossing Using Digital Image ProcessingDocumento7 páginasAutomatic Video Surveillance System For Pedestrian Crossing Using Digital Image ProcessingNeha SinhaAinda não há avaliações

- Choosing the Best Embedded Platform for On-Board UAV Image ProcessingDocumento11 páginasChoosing the Best Embedded Platform for On-Board UAV Image ProcessingImzara AmeaAinda não há avaliações

- 2007 Output Stops RemovedDocumento45 páginas2007 Output Stops RemovedAisyah DzulqaidahAinda não há avaliações

- Car License Plate Recognition With Neural Networks and Fuzzy Log PDFDocumento5 páginasCar License Plate Recognition With Neural Networks and Fuzzy Log PDFestherAinda não há avaliações

- Signature Recognition Using Image Processing ArtificialDocumento104 páginasSignature Recognition Using Image Processing ArtificialNiko Karis GunawanAinda não há avaliações

- Remotesensing 11 00224 v2Documento47 páginasRemotesensing 11 00224 v2Maham TariqAinda não há avaliações

- 1.2 UserManual Vision PDFDocumento126 páginas1.2 UserManual Vision PDFBui Duy HungAinda não há avaliações

- BPJ - Vol - 13 - No - 1 - P - 145-157 (1) (1) - FlowDocumento13 páginasBPJ - Vol - 13 - No - 1 - P - 145-157 (1) (1) - FlowPadmavathy VelayudhamAinda não há avaliações

- Session 2Documento39 páginasSession 2Noorullah ShariffAinda não há avaliações

- VHDL Design For Image Segmentation Using Gabor Filter For Disease DetectionDocumento3 páginasVHDL Design For Image Segmentation Using Gabor Filter For Disease DetectionNsrc Nano ScientifcAinda não há avaliações

- MRI Segmentation Using Dictionary Learning: - Krishna DontarajuDocumento13 páginasMRI Segmentation Using Dictionary Learning: - Krishna DontarajuKrishna KishoreAinda não há avaliações

- Concept Embedding Analysis - A ReviewDocumento47 páginasConcept Embedding Analysis - A ReviewJack LiAinda não há avaliações

- Application of Learning Curves in The Aerospace Industry Handout PDFDocumento34 páginasApplication of Learning Curves in The Aerospace Industry Handout PDFAthanasios ChristogiannisAinda não há avaliações

- Image Processing Final Exam 2014 SOLUTIONDocumento5 páginasImage Processing Final Exam 2014 SOLUTIONsedatAinda não há avaliações

- VisBlb (Systech)Documento56 páginasVisBlb (Systech)DExTERAinda não há avaliações

- Ei13 Abstracts L PDFDocumento150 páginasEi13 Abstracts L PDFLance JohnsonAinda não há avaliações

- Optical Character Recognition Based Speech Synthesis: Project ReportDocumento17 páginasOptical Character Recognition Based Speech Synthesis: Project Reportisoi0% (1)

- Image Analysis and Mathematical Morphology For Civil Engineering MaterialsDocumento19 páginasImage Analysis and Mathematical Morphology For Civil Engineering MaterialsBadri DadiAinda não há avaliações

- Erasenet: End-To-End Text Removal in The WildDocumento16 páginasErasenet: End-To-End Text Removal in The WildThiện Vũ DuyAinda não há avaliações

- Nestle Waters Forecasting Improv Ment SlidesDocumento37 páginasNestle Waters Forecasting Improv Ment Slidesamitwin1983Ainda não há avaliações

- An Intelligent Cloth Quality Analysis and Reduction of Man Power in Image ProcessingDocumento5 páginasAn Intelligent Cloth Quality Analysis and Reduction of Man Power in Image ProcessingInternational Journal of Innovative Science and Research TechnologyAinda não há avaliações

- Detecting Complex Salient Objects via Ultra-Contrast FeaturesDocumento14 páginasDetecting Complex Salient Objects via Ultra-Contrast FeaturesThalapathy VijayAinda não há avaliações

- Mall Customer Segmentation Using Clustering Algorithm: March 2021Documento37 páginasMall Customer Segmentation Using Clustering Algorithm: March 2021Rohith PagadalaAinda não há avaliações

- Análise Microestrutural de Concreto Reciclado Usando Microtomografia de Raios X Ingles LEITE E MONTEIRO - ScienceDirectDocumento11 páginasAnálise Microestrutural de Concreto Reciclado Usando Microtomografia de Raios X Ingles LEITE E MONTEIRO - ScienceDirectCristine RussellAinda não há avaliações

- Texture Analysis Methods - A ReviewDocumento33 páginasTexture Analysis Methods - A ReviewMarcelo QueirozAinda não há avaliações