Escolar Documentos

Profissional Documentos

Cultura Documentos

Slab Design Spreadsheet (Include Crack Width)

Enviado por

khuanozDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Slab Design Spreadsheet (Include Crack Width)

Enviado por

khuanozDireitos autorais:

Formatos disponíveis

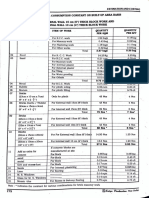

DR Y G TAN JURUTERA PERUNDING SDN. BHD.

5-1, JALAN 2/115A, TAMAN PAGAR RUYONG, JALAN KUCHAI LAMA, 58200 KUALA LUMPUR.

ONE WAY SLAB DESIGN

PROJECT TITLE : Weida

JOB NO : 1479

SLAB: Swimming Pool

1 Slab details

lx = 2.8 m ly = 5.55 m

h = 250 mm ly/lx = 1.98 (NOT OK) main btm (OK)

Fcu = 40 N/mm2 2nd btm (OK)

Fy = 485 N/mm2 deflection (OK)

Dia. = 8 mm main top (OK)

Cover = 40 mm 2nd top (OK)

d= 206 mm shear (o.k)

2 Loading

Dead Load crack width <OK>

S/W = 6 kN/m2 <OK>

Finishes = 22 kN/m2 OK

Total DL = 28 kN/m2 larger than allowed crack width

Imposed Load = 5 kN/m2

Ultimate Load = 47.2 kN/m(per m width)

+Bsx = 0.086 +Bsy = 0.086 ( For value Bsx and Bsy, pls refer to Table 3.12 BS 8110 1997 )

-Bsx = -0.086 -Bsy = -0.086

Short span (bot.), +Msx = 31.82 kNm 31.82413

Short span (top.), -Msx = -31.82 kNm 31.82413

Long span (bot.), +Msy = 31.82 kNm 31.82413

Long span (top.), -Msy = -31.82 kNm 31.82413

3 Design main bottom steel area for +Msx (bending at short span)

K= 0.02 (o.k)

Lever arm, la = 0.98

Z= 195.7

Ast (required) = 385.39 mm2

Ast (min) = 325 mm2

Try bar spacing = 100 c/c dia. steel = 8 mm

Ast (provided) = 502.66 mm2 area = 50.27 mm2

(Deflection o.k) (OK)

PROVIDE T 8 @ 100 c/c MAIN BOTTOM BAR

4 Design distribution bottom steel area for +Msy (bending at long span)

K= 0.02 (o.k)

Lever arm, la = 0.98

Z' = 188.1

Ast (required) = 400.97 mm2

Ast (min) = 325 mm2

Try bar spacing = 100 c/c dia. steel = 8 mm

Ast (provided) = 502.66 mm2 area = 50.27 mm2

(OK)

PROVIDE T 8 @ 100 c/c TRAN BOTTOM BAR

5 Check deflection

Fs = 247.9044

Mod. factor = 1.707096

Span/depth ratio = 20

(L/D) allowable = 34.14

(L/D) actual = 13.59 (OK)

6 Design main top steel area for -Msx (bending at short span)

K= -0.02 (o.k)

Lever arm, la = 0.98

Z= 195.7

Ast (required) = 385.39 mm2

Ast (min) = 325 mm2

Try bar spacing = 100 c/c dia. steel = 8 mm

Ast (provided) = 502.66 mm2 area = 50.27 mm2

(OK)

PROVIDE T 8 @ 100 c/c MAIN TOP BAR

7 Design distribution top steel area for -Msy (bending at long span)

K= -0.02 (o.k)

Lever arm, la = 0.98

Z' = 188.10

Ast (required) = 400.97 mm2

Ast (min) = 325 mm2

Try bar spacing = 100 c/c dia. steel = 8 mm

Ast (provided) = 502.66 mm2 area = 50.27 mm2

(OK)

PROVIDE T 8 @ 100 c/c TRAN TOP BAR

8 Check shear at support

mak. shear coefficients, bsx/bsy 0.63

shear force, V = 83.2608 kN

shear stress, v = 0.40 N/mm2 < 5.00 N/mm2

(o.k)

design shear stress, vc = 0.55 N/mm2

(not require shear reinforcement)

Você também pode gostar

- Professional Engineer GuidelinesDocumento6 páginasProfessional Engineer GuidelinesSandra FerrellAinda não há avaliações

- TM Minutes No. 25Documento3 páginasTM Minutes No. 25khuanozAinda não há avaliações

- S of HousingDocumento17 páginasS of HousingAnonymous 0FIwxrWLaKAinda não há avaliações

- 05 - STD Specs-Building Works - 2016 - EditedDocumento97 páginas05 - STD Specs-Building Works - 2016 - EditedkhuanozAinda não há avaliações

- IEM Professional Interview Guidelines - New Revision Starting 1 Sep 2012Documento17 páginasIEM Professional Interview Guidelines - New Revision Starting 1 Sep 2012Lukeman79100% (1)

- IEM - Route To Become MIEM & PE PDFDocumento75 páginasIEM - Route To Become MIEM & PE PDFkhuanozAinda não há avaliações

- IEM Form of Contact For Civil Engineering Works - 3rd Edition, Jan 2017 - IEM. CE 2011Documento40 páginasIEM Form of Contact For Civil Engineering Works - 3rd Edition, Jan 2017 - IEM. CE 2011khuanoz0% (1)

- Typical Weld Details 1 PDFDocumento1 páginaTypical Weld Details 1 PDFkhuanozAinda não há avaliações

- Uniform Technical Guidelines For Water Reticulation and PlumbingDocumento214 páginasUniform Technical Guidelines For Water Reticulation and PlumbingGan Chin PhangAinda não há avaliações

- SPAN MSIG - Vol.3 - Sewer Network and Pump StationDocumento153 páginasSPAN MSIG - Vol.3 - Sewer Network and Pump StationkhuanozAinda não há avaliações

- Connection DesignDocumento2 páginasConnection DesignkhuanozAinda não há avaliações

- Lot 1906 - Lampiran A - IBS CalculationDocumento12 páginasLot 1906 - Lampiran A - IBS CalculationkhuanozAinda não há avaliações

- Design Parameters BS8110Documento4 páginasDesign Parameters BS8110khuanozAinda não há avaliações

- TNBDocumento2 páginasTNBkhuanozAinda não há avaliações

- The Planning Guidelines For Vibration Limits and Control in The Environment, 2nd Edition, 2007Documento26 páginasThe Planning Guidelines For Vibration Limits and Control in The Environment, 2nd Edition, 2007Phang S. SunAinda não há avaliações

- Draft For Public Comment SPAN TS 21827 Part 1 2013Documento45 páginasDraft For Public Comment SPAN TS 21827 Part 1 2013Jazlan90Ainda não há avaliações

- Draft For Public Comment SPAN TS 21827 Part 1 2013Documento45 páginasDraft For Public Comment SPAN TS 21827 Part 1 2013Jazlan90Ainda não há avaliações

- Specification For Drainage & Infrastructure WorksDocumento33 páginasSpecification For Drainage & Infrastructure WorkskhuanozAinda não há avaliações

- Train The Trainer - FMMD - Well-Being of FW (Apr 10)Documento23 páginasTrain The Trainer - FMMD - Well-Being of FW (Apr 10)khuanozAinda não há avaliações

- Specification For Jack in PileDocumento4 páginasSpecification For Jack in Pilekhuanoz100% (1)

- TNB Compact Substation Requirements 2016 PDFDocumento6 páginasTNB Compact Substation Requirements 2016 PDFkhuanozAinda não há avaliações

- Sample of Earthwork SpecificationDocumento15 páginasSample of Earthwork SpecificationkhuanozAinda não há avaliações

- Installation Guide For GTS NX License: Step 1Documento4 páginasInstallation Guide For GTS NX License: Step 1khuanozAinda não há avaliações

- Design of Water Retaining Structures To ECDocumento44 páginasDesign of Water Retaining Structures To ECVincent Teng100% (4)

- LN 6 Wall LectureDocumento20 páginasLN 6 Wall LecturekhuanozAinda não há avaliações

- TelcosDocumento2 páginasTelcoskhuanozAinda não há avaliações

- Quantity Take OffDocumento26 páginasQuantity Take OffTien Ngo Minh100% (1)

- 4 Shear Strength of Discontinuities PDFDocumento14 páginas4 Shear Strength of Discontinuities PDFAnonymous Re62LKaACAinda não há avaliações

- Internship UTMDocumento1 páginaInternship UTMkhuanozAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- 6ea8a Cis888614800278849Documento148 páginas6ea8a Cis888614800278849ginlemon86Ainda não há avaliações

- Swimming Pool LoadingDocumento4 páginasSwimming Pool LoadingAnn GertrudeAinda não há avaliações

- Ko NstructDocumento15 páginasKo Nstructmark manalangAinda não há avaliações

- 04 Compressive Strength (Mix Design)Documento1 página04 Compressive Strength (Mix Design)jitendraAinda não há avaliações

- Structural Analysis: Influence LinesDocumento31 páginasStructural Analysis: Influence LinesMichael ChangAinda não há avaliações

- Sofistik ManualDocumento129 páginasSofistik ManualPanagiotis Stamatis100% (1)

- Fe Plate 5Documento3 páginasFe Plate 5FeMarie BesanAinda não há avaliações

- Civil Engineering 7000 MCQs - Civil Engineering QuizDocumento26 páginasCivil Engineering 7000 MCQs - Civil Engineering QuizvishalAinda não há avaliações

- A. Design StipulationsDocumento3 páginasA. Design StipulationsAnyam RambabuAinda não há avaliações

- De La Salle University Gokongwei College of Engineering Civil Engineering DepartmentDocumento10 páginasDe La Salle University Gokongwei College of Engineering Civil Engineering DepartmentMiguel CruzAinda não há avaliações

- Hauer-King HouseDocumento18 páginasHauer-King Housepattyleo182Ainda não há avaliações

- Buildings Item Rates 2011-12Documento264 páginasBuildings Item Rates 2011-12sooricivil0% (1)

- Carpentry Works Man-Hour PDFDocumento2 páginasCarpentry Works Man-Hour PDFHenry Tugano50% (2)

- CIVIL 3811 - Lecture Slides - Week 7Documento58 páginasCIVIL 3811 - Lecture Slides - Week 7hadaAinda não há avaliações

- Portal Method Sample Calculation - Google SearchDocumento2 páginasPortal Method Sample Calculation - Google Searchgodofredo dumaliAinda não há avaliações

- Week 3-Design of One Way SlabDocumento4 páginasWeek 3-Design of One Way SlabMAYHAY, ADRIAN PAULAinda não há avaliações

- RRLDocumento1 páginaRRLDaniel VasquezAinda não há avaliações

- MM Exp No 05Documento11 páginasMM Exp No 05saira saghirAinda não há avaliações

- U-Shape Drain (T-25) DU Series: FUJI Precast Concrete SolutionDocumento4 páginasU-Shape Drain (T-25) DU Series: FUJI Precast Concrete SolutionshreyashAinda não há avaliações

- Rheobuild 857: High Range, Water Reducing Superplasticiser For Concretes Containing GGBS and MicrosilicaDocumento2 páginasRheobuild 857: High Range, Water Reducing Superplasticiser For Concretes Containing GGBS and MicrosilicaFrancois-Ainda não há avaliações

- Concrete MixerDocumento10 páginasConcrete MixerRafaqat NiaziAinda não há avaliações

- Analyses On Reinforced Concrete Cross SectionsDocumento31 páginasAnalyses On Reinforced Concrete Cross Sectionsshamsukarim2009Ainda não há avaliações

- RW 3lump Sum Estimation For Prestress LossDocumento2 páginasRW 3lump Sum Estimation For Prestress LossJill ReladorAinda não há avaliações

- Jntuh SA II March-2021 PyqpDocumento2 páginasJntuh SA II March-2021 PyqpPradeepkumarKatgiAinda não há avaliações

- Estimation Book DMDocumento17 páginasEstimation Book DMDanish ShaikhAinda não há avaliações

- Analysis and Design of A Multi-Storey Reinforced Concrete BuildingDocumento40 páginasAnalysis and Design of A Multi-Storey Reinforced Concrete BuildingAbinayaAinda não há avaliações

- 1.2 Basic Principle of PrestressingDocumento25 páginas1.2 Basic Principle of PrestressingDenice CastroAinda não há avaliações

- Micropile-One - System-Many-ApplicationsDocumento16 páginasMicropile-One - System-Many-Applicationsahmed.naeem66Ainda não há avaliações

- Detailed Estimation For Construction of Proposed Building: 27, Navarathinanagar, BPL Complex Karaikudi - 630 001Documento2 páginasDetailed Estimation For Construction of Proposed Building: 27, Navarathinanagar, BPL Complex Karaikudi - 630 001ganesh15Ainda não há avaliações

- Punchlist 50 60th FLRDocumento320 páginasPunchlist 50 60th FLRChristine CafugauanAinda não há avaliações