Escolar Documentos

Profissional Documentos

Cultura Documentos

MTK 1023-Material and Consumable

Enviado por

GraceLamTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

MTK 1023-Material and Consumable

Enviado por

GraceLamDireitos autorais:

Formatos disponíveis

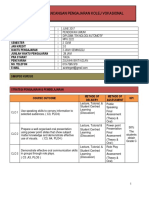

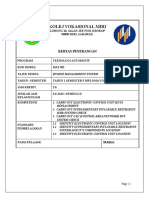

KSKV SVM 2017

MINISTRY OF EDUCATION, MALAYSIA

VOCATIONAL COLLEGE STANDARD CURRICULUM

COURSE INFORMATION

PROGRAMME : WELDING TECHNOLOGY

COURSE NAME : MATERIALS AND CONSUMABLE

COURSE CODE : MTK 1023

YEAR / SEMESTER : 1 SEMESTER 1

CREDIT UNIT : 3.0

CONTACT HOUR : FACE TO FACE : 5.0 HOURS / WEEK

NON FACE TO FACE :

MODULE TYPE : VOCATIONAL

PREREQUISITE : -

CORE REQUISITE : -

MTK 1023 Document Page 1/13

KSKV SVM 2017

COURSE OUTCOMES:

At the end of the course, the students should be able to:-

1. Identify type of materials.

2. Identify and select parent metal for welding.

3. Identify and select welding consumable.

4. Handle welding consumables (identify, segregate, store and bake).

COURSE DESCRIPTION:

This unit identifies the competence required to provide students with a comprehensive technical understanding of the purpose

identifying types of materials and selecting parent metal for welding by referring to mill certificate and client specification. It also required

student to identify and select welding consumables by referring to welding specification and handling welding consumables by storing and

preserving so that the consumables is kept and maintained without losing its chemical and physical properties and according to manufacturer

recommendation.

MTK 1023 Document Page 2/13

KSKV SVM 2017

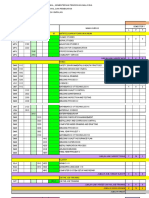

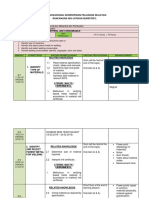

CONTENT AND LEARNING STANDARDS

PROGRAMME : WELDING TECHNOLOGY

COURSE NAME : MATERIALS AND CONSUMABLE

COURSE CODE : MTK 1023

CONTACT HOURS CONTENT

LEARNING STANDARD ASSESSMENT CRITERIA

(TRANING DURATION) STANDARD

20 hours RELATED KNOWLEDGE ASSESSMENT CRITERIA

(4 weeks)

1. IDENTIFY 1.1 Read material 1.1.1 Describe type of materials – ferrous and non-ferrous

Lecture :8 hours TYPE OF specification, charts, metals and its properties.

(2 hours x 4 weeks) MATERIALS tables and manuals. 1.1.2 Define material hardness.

1.1.3 Define chemical composition.

Practical :12 hours 1.1.4 Define tensile stress, yield strength and impact

(3 hours x 4 weeks) strength.

1.1.5 Define material elongation.

1.1.6 Define alloys metal.

1.1.7 Translate material specification, charts, tables and

manuals according to material specification chart.

1.2 Determine type and 1.2.1 Identify material grade in accordance to material

grade of material. specification chart.

1.2.2 Practice safety consciousness, cautious and proper

working etiquette according to Occupational Safety

and Health Act (OSHA).

MTK 1023 Document Page 3/13

KSKV SVM 2017

RELATED SKILLS

1.3 Confirm carbon steel / 1.3.1 Translate material specification, charts, tables and

stainless steel material manuals according to material specification chart.

to relevant WPS. 1.3.2 Describe basic material testing methods for ferrous

and non ferrous materials.

1.3.3 Carry out basic material identification and testing

according to material specification chart.

1.3.4 Identify material grade in accordance to material

specification chart.

ATTITUDE / SAFETY /

ENVIRONMENTAL

1. Meticulous in verifying

based metal material in

accordance to material

mill certificate.

MTK 1023 Document Page 4/13

KSKV SVM 2017

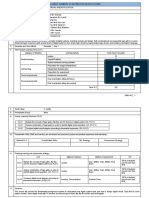

CONTENT AND LEARNING STANDARDS

PROGRAMME : WELDING TECHNOLOGY

COURSE NAME : MATERIALS AND CONSUMABLE

COURSE CODE : MTK 1023

CONTACT HOURS CONTENT

(TRANING DURATION) LEARNING STANDARD ASSESSMENT CRITERIA

STANDARD

25 hours RELATED KNOWLEDGE ASSESSMENT CRITERIA

(5 weeks)

2. IDENTIFY 2.1 Determine size of material 2.1.1 Identify size of material required to meet welding

Lecture :10 hours AND SELECT required. process requirements.

(2 hours x 5 weeks) PARENT

METAL FOR 2.2 Interpret mill certificate. 2.2.1 Define basic metallurgy of materials.

Practical :15 hours WELDING 2.2.2 Interpret material codes in accordance to material

(3 hours x 5 weeks) specification chart.

2.3 Check material as required 2.3.1 Distinguish various types of common materials

by specification. physically.

2.3.2 Identify material against specification.

2.3.3 Carry out simple workshop test on material in

accordance to material specification chart.

2.3.4 Practice safety consciousness, cautious and proper

working etiquette according to Occupational Safety

and Health Act (OSHA).

MTK 1023 Document Page 5/13

KSKV SVM 2017

RELATED SKILLS

2.4 Affirm content of material mill 2.4.1 Interpret material codes in accordance to material

certificate such as: specification chart.

Material standard 2.4.2 Distinguish various types of common materials

Heat number physically.

Chemical composition 2.4.3 Identify material against specification.

Mechanical Properties 2.4.4 Carry out simple workshop test on material in

Material form - plate accordance to material specification chart such as

Material size Thermal conductivity test, appearance test, spark

Physical condition test, file test and fracture toughness test.

2.4.5 Identify size of material required to meet welding

process requirements.

2.4.6 Confirm material physical condition (eg. Dent, rust,

ovality, etc).

ATTITUDE / SAFETY /

ENVIRONMENTAL

1. Meticulous in verifying

based metal material in

accordance to material

mill certificate.

MTK 1023 Document Page 6/13

KSKV SVM 2017

CONTENT AND LEARNING STANDARDS

PROGRAMME : WELDING TECHNOLOGY

COURSE NAME : MATERIALS AND CONSUMABLE

COURSE CODE : MTK 1023

CONTACT HOURS CONTENT

(TRANING DURATION) LEARNING STANDARD ASSESSMENT CRITERIA

STANDARD

20 hours RELATED KNOWLEDGE ASSESSMENT CRITERIA

(4 weeks)

3 IDENTIFY AND 3.1 Identify and choose 3.1.1 Identify welding code for selection of electrode

Lecture :8 hours SELECT electrode required. according to BS/AWS codes and standard.

(2 hours x 4 weeks) WELDING 3.1.2 Determine electrode required for intended welding

CONSUMABLE

Practical :12 hours

(3 hours x 4 weeks) 3.2 Check for welding 3.2.1 Describe electrodes classification according to

electrode specification. British Standard (BS) and American Welding Society

(AWS) / codes and standard.

3.2.2 Interpret specification for selection of electrodes

according to BS/AWS codes and standard.

MTK 1023 Document Page 7/13

KSKV SVM 2017

RELATED SKILLS

3.3 Confirm electrode 3.3.1 Describe electrodes classification according to

specification/ classification British Standard (BS) and American Welding Society

such as: (AWS) / codes and standard.

Core wire 3.3.2 Interpret specification for selection of electrodes

Electrode size according to BS/AWS codes and standard.

Flux coating (basic, 3.3.3 Identify welding code for selection of electrode

rutile and according to BS/AWS codes and standard.

cellulose) 3.3.4 Determine electrode required for intended welding.

ATTITUDE / SAFETY /

ENVIRONMENTAL

1. Cautious practice when

handling hot electrode

from baking oven

MTK 1023 Document Page 8/13

KSKV SVM 2017

CONTENT AND LEARNING STANDARDS

PROGRAMME : WELDING TECHNOLOGY

COURSE NAME : MATERIALS AND CONSUMABLE

COURSE CODE : MTK 1023

CONTACT HOURS CONTENT

(TRANING DURATION) LEARNING STANDARD ASSESSMENT CRITERIA

STANDARD

20 hours RELATED KNOWLEDGE ASSESSMENT CRITERIA

(4 weeks)

4 HANDLE 4.1 Identify manufacturer 4.1.1 Interpret welding consumable according to

Lecture :8 hours WELDING specification. manufacturer specifications.

(2 hours x 4 weeks) CONSUMABLES

(IDENTIFY, 4.2 Classify welding 4.2.1 Follow manufacturer recommendation for handling of

Practical :12 hours SEGREGATE, electrode. electrode.

(3 hours x 4 weeks) STORE AND 4.2.2 Identify classification of consumables in welding field.

BAKE) 4.2.3 Describe method of storage and preservation of

electrode according to manufacturer

recommendation.

4.2.4 Describe segregation of electrode according to

manufacturer recommendation.

4.3.1 Describe electrode drying procedure according to

4.3 Store and preserve manufacturer recommendation.

MTK 1023 Document Page 9/13

KSKV SVM 2017

electrode. 4.3.2 Explain electrode drying oven operation according to

manufacturer specification.

4.3.3 Ensure environmental requirements for storage and

preservation maintenance.

4.3.4 Explain the process of electrode re-drying according

to manufacturer recommendation.

4.3.5 Practice safety consciousness, cautious and proper

working etiquette according to Occupational Safety

and Health Act (OSHA).

PERFORMANCE CRITERIA

APPLIED SKILLS

4.4.1 Follow manufacturer recommendation for handling of

4.4 Carry out electrode electrode.

handling/baking 4.4.2 Identify classification of consumables in welding field.

procedure if required. 4.4.3 Apply method of storage and preservation of

electrode according to manufacturer

recommendation.

4.5.1 Apply segregation of electrode according to

manufacturer recommendation.

4.5 Setting up oven 4.5.2 Apply electrode drying procedure according to

temperature for baking. manufacturer recommendation.

4.6.1 Apply electrode drying oven operation according to

manufacturer specification.

4.6 Setting up temperature 4.6.2 Ensure environmental requirements for storage and

for holding oven. preservation maintenance.

4.6.3 Conduct electrode re-drying according to

manufacturer recommendation.

MTK 1023 Document Page 10/13

KSKV SVM 2017

ATTITUDE / SAFETY /

ENVIRONMENTAL

1. Cautious practice

when handling hot

electrode from baking

oven.

CORE ABILITY

CORE ABILITY

SILA RUJUK LAMPIRAN A : JADUAL PEMETAAN NOSS DAN KSKV

SILA RUJUK LAMPIRAN B : JADUAL PEMETAAN NOSS DAN CORE ABILITY

Tools, Equipment and Materials (TEM)

ITEMS RATIO (TEM : Trainees)

1. Code and standard (AWS D1.1) 1 :1

2. Code and standard (ASME IX) 1 :1

3. Base metal plate 1 :1

4. Base metal pipe 1 :1

5. Welding electrode (2.5mm - 4.0mm) 1 :1

6. Electrode baking oven 1 : 15

7. Electrode holding oven 1 : 15

8. Marking tools and hand tools 1 :1

9. Electrode quiver 1 : 10

MTK 1023 Document Page 11/13

KSKV SVM 2017

ITEMS RATIO (TEM : Trainees)

REFERENCES

1. Sacks & Bohnart,2007,Welding Principles & Practices,3rd edition, 1221, Avenue of the Americas, New York, NY 10020 USA, Mc Graw Hill, ISBN:

978-0077238773

2. James F. Lincoln, Arc Welding Foundation, 2002, The Procedure Handbook of Arc Welding, 14th Edition, 22801 St. Clair Avenue, Cleveland, Ohio,

44117 USA, Lincoln Electric Company, ISBN: 978- 9993897302

3. Robert L. O'Brien, 1997, Jefferson's Welding Encyclopaedia, 18th Edition, 550 N.W. Lejeune Road, Miami, Florida, 33126 USA, American Welding

Society, ISBN: 978-0871715067

4. Joseph W. Giachino, William, Weeks, 1985, Welding Skills & Practices, 6th edition, Western Michigan University, Kalmazoo, Michigan, Chicago,

60637, USA, American Technical Society, ISBN:978-0826930019

5. Griffin, Roden, Briggs, 1985, Pipe Welding Techniques, 4th edition, Albany, New York, 12205 USA, Delmar Publishers, ISBN: 978-0827322486

6. Ivan H. Griffin, Edward M. Roden and Charles W. Briggs, 1984, Basic Arc Welding 4th edition, Albany, New York, 12205 USA, Delmar

Publishers, ISBN: 978-0827321311

7. ASM International, 1983, Metal Reference Book, 2nd edition, Material Park, Ohio, 44073 USA, American Society For Metals, ISBN:978-

0871701565

8. Gower A. Kennedy, 1982, Welding Technology - Student's Manual, 2nd edition, Indianapolis, USA, A Howard W. Sams Book, Bobbs- Merill

Educational Publishing, ISBN:978-0672971099

9. Gower A. Kennedy, 1982, Welding Technology, 2nd edition, Lethbridge Community College, Alberta, New York, USA, Howard W. Sams & Son Inc.,

ISBN: 978-0672979903

MTK 1023 Document Page 12/13

KSKV SVM 2017

REFERENCES

10. Frank R. Schell, 1977, Welding Procedures: Electric Arc, 1st edition, Albany, New York, 12205 USA, Delmar Publishers, ISBN: 978-0827316034

11. Giachino, Weeks, Johnson, 1974, Welding Technology, 2nd edition, Chicago, 60637 USA, American Technical Society, ISBN: 978-0826930637

MTK 1023 Document Page 13/13

Você também pode gostar

- MTK 1032 Mechanical CuttingDocumento17 páginasMTK 1032 Mechanical CuttingMR FIKRIAinda não há avaliações

- KSKV SVM 2017: SMAW 1 Course InformationDocumento20 páginasKSKV SVM 2017: SMAW 1 Course InformationNurun NazirahAinda não há avaliações

- MTK 1023-Material and ConsumableDocumento13 páginasMTK 1023-Material and ConsumableCikgu Azry Azeem PetronessaAinda não há avaliações

- (MTK DVM 1) 01. Struktur DMB Teknologi Kimpalan Sem 1Documento9 páginas(MTK DVM 1) 01. Struktur DMB Teknologi Kimpalan Sem 1Noor Fadlan0% (1)

- Rancangan Pengajaran Kolej VokasionalDocumento22 páginasRancangan Pengajaran Kolej VokasionalAizi ElegantAinda não há avaliações

- Noss Matrix For: Core Abilities (Z-009-3) Level 3: Group No. Group Ability No Abilities M01 M02 M03 M04 M05 M06Documento1 páginaNoss Matrix For: Core Abilities (Z-009-3) Level 3: Group No. Group Ability No Abilities M01 M02 M03 M04 M05 M06Jumrang MendengAinda não há avaliações

- Daftar NOSS Versi 28 Mac 2017Documento353 páginasDaftar NOSS Versi 28 Mac 2017clairons84100% (1)

- 4.syllabus - Deb1143 - Digital Electronic and ApplicationDocumento7 páginas4.syllabus - Deb1143 - Digital Electronic and ApplicationadibAinda não há avaliações

- Introducing Science Daily Lesson PlansDocumento27 páginasIntroducing Science Daily Lesson PlansaldruzzAinda não há avaliações

- K1-Nota Kuliah OSHADocumento8 páginasK1-Nota Kuliah OSHAMuhamad Ismail Mohd JamilAinda não há avaliações

- Mechatronic Course OutlineDocumento8 páginasMechatronic Course OutlineAnonymous V76nXvDAGAinda não há avaliações

- 4.co - DMB 2243 Welding Process 2Documento6 páginas4.co - DMB 2243 Welding Process 2azmi yusofAinda não há avaliações

- Mechanical Engineering Department: Djj3053 - Engineering Mechanics Lab: Velocity and AccelerationDocumento8 páginasMechanical Engineering Department: Djj3053 - Engineering Mechanics Lab: Velocity and AccelerationMuhd AriffAinda não há avaliações

- KUIZ 1 Workshop TechnologyDocumento1 páginaKUIZ 1 Workshop TechnologyMohd Azizee Bin SukorAinda não há avaliações

- K Tugasan (A S)Documento5 páginasK Tugasan (A S)amirul8686100% (2)

- Kebana Engineering SDNDocumento28 páginasKebana Engineering SDNMaruan MuhammadAinda não há avaliações

- Contoh Resume Terbaik 2Documento2 páginasContoh Resume Terbaik 2Mc Den Al BakryAinda não há avaliações

- K5-Nota Kuliah OSHADocumento9 páginasK5-Nota Kuliah OSHAMuhamad Ismail Mohd JamilAinda não há avaliações

- Skop Kerja / Peranan Dan Tanggungjawab CalonDocumento2 páginasSkop Kerja / Peranan Dan Tanggungjawab CalonHaziq Aiman100% (2)

- Course Outline - DEA 2313Documento11 páginasCourse Outline - DEA 2313Roger JohnAinda não há avaliações

- STORDocumento14 páginasSTORMohd KhidirAinda não há avaliações

- Practical Test 1 k4Documento5 páginasPractical Test 1 k4Vicea NurrAinda não há avaliações

- Silibus Sem 1 - Sem 3 A17Documento139 páginasSilibus Sem 1 - Sem 3 A17Hariq Hann0% (1)

- 1.1 Manage Message Effectively: Sue 20021 Workplace EnglishDocumento9 páginas1.1 Manage Message Effectively: Sue 20021 Workplace Englishcora timiAinda não há avaliações

- Soalan SpotDocumento13 páginasSoalan SpotAdnan ShamsudinAinda não há avaliações

- Youth leadership project develops entrepreneur skillsDocumento4 páginasYouth leadership project develops entrepreneur skillsNyss Annyss0% (1)

- Bab 1 - Pengenalan: 1.1 Objektif Latihan IndustriDocumento15 páginasBab 1 - Pengenalan: 1.1 Objektif Latihan Industriamirul rezzaAinda não há avaliações

- c1 - Introduction of Engineering DesignDocumento63 páginasc1 - Introduction of Engineering DesignXCarlZAinda não há avaliações

- Electrical Act and Regulation Course OutlineDocumento4 páginasElectrical Act and Regulation Course Outlinejamil6700% (1)

- Daftar NOSS Version 25 Jun 2014Documento255 páginasDaftar NOSS Version 25 Jun 2014Ahmad ImranAinda não há avaliações

- 5 Types of CMMs Explained: Bridge, Cantilever, Gantry, Horizontal ArmDocumento15 páginas5 Types of CMMs Explained: Bridge, Cantilever, Gantry, Horizontal ArmMOHD KHIDIR RUSTAM BIN ABDUL RAHMAN (KV-KHA5002)Ainda não há avaliações

- JPK/PPT/1002B VTO(2) Skills Evidence ComparisonDocumento2 páginasJPK/PPT/1002B VTO(2) Skills Evidence ComparisonAyin Binti Rashid100% (1)

- 1.co - DMB 2113 Welding Quality Control (Rev.1)Documento6 páginas1.co - DMB 2113 Welding Quality Control (Rev.1)miepakyopAinda não há avaliações

- CONTROL AND INJURY LECTUREDocumento53 páginasCONTROL AND INJURY LECTURENur IffatinAinda não há avaliações

- Kertas Kerja ViDocumento8 páginasKertas Kerja ViFord KatimAinda não há avaliações

- KSKV Etn1013 - Electronic Schematic DrawingDocumento12 páginasKSKV Etn1013 - Electronic Schematic DrawingNur Hafizah RazaliAinda não há avaliações

- Laporan Cqi Eng CommDocumento4 páginasLaporan Cqi Eng CommSuzana Bt SuratmanAinda não há avaliações

- Kertas Penerangan FullDocumento50 páginasKertas Penerangan FullPAUL KENNY TSHONGAinda não há avaliações

- Daftar NOSS Versi 31 Mac 2015Documento268 páginasDaftar NOSS Versi 31 Mac 2015jamil6700% (1)

- Perform basic robot control (40/40Documento5 páginasPerform basic robot control (40/40Walid FarHanAinda não há avaliações

- Reka Bentuk DAN Teknologi Tahun 5 Pertanian Bandar: Let's LearnDocumento17 páginasReka Bentuk DAN Teknologi Tahun 5 Pertanian Bandar: Let's LearnkarlhenzAinda não há avaliações

- TM - Modular Air Chiller (VRA, R410A, R22) - 1401Documento54 páginasTM - Modular Air Chiller (VRA, R410A, R22) - 1401yusuf mohd sallehAinda não há avaliações

- c084b2 PDFDocumento1 páginac084b2 PDFHizirAinda não há avaliações

- RSL Etn 2023Documento3 páginasRSL Etn 2023Masila IsmailAinda não há avaliações

- REPORT MILLING KUMPULAN 1 - Converted - by - AbcdpdfDocumento11 páginasREPORT MILLING KUMPULAN 1 - Converted - by - AbcdpdfShahir Ikram NazriAinda não há avaliações

- Cc206 - IBSDocumento25 páginasCc206 - IBSikazuo800% (1)

- Pelan Mengajar Amali HOUSEKEEPINGDocumento7 páginasPelan Mengajar Amali HOUSEKEEPINGZurr Izaty Zolkepli100% (1)

- Jadual Peratusan Masa C02 6.8Documento6 páginasJadual Peratusan Masa C02 6.8Cucu MaAtok MeseiryAinda não há avaliações

- Direktori Kurikulum SLDN - 2015Documento58 páginasDirektori Kurikulum SLDN - 2015syahrainamirAinda não há avaliações

- 3 - Kertas Tugasan (Wa7)Documento4 páginas3 - Kertas Tugasan (Wa7)amirul8686Ainda não há avaliações

- g452-002!3!2018 Light Vehicle Diagnose ServiceDocumento105 páginasg452-002!3!2018 Light Vehicle Diagnose ServiceMUHAMAD AQIL BIN YAZID100% (1)

- Assignment II Advanced MFGDocumento11 páginasAssignment II Advanced MFGAyu AdiAinda não há avaliações

- Product Function and Specification AnalysisDocumento2 páginasProduct Function and Specification Analysisaffiq100% (5)

- Soalan Ujian HidraulikDocumento9 páginasSoalan Ujian HidraulikDilla AfzanAinda não há avaliações

- MTK 1043 Smaw 1Documento22 páginasMTK 1043 Smaw 1Mohd Dinie HafiqAinda não há avaliações

- KSKV SVM 2017 Thermal Cutting CourseDocumento15 páginasKSKV SVM 2017 Thermal Cutting CourseHanif HalinAinda não há avaliações

- MTK 2022 Thermal CuttingDocumento15 páginasMTK 2022 Thermal CuttingHanif HalinAinda não há avaliações

- MTK 3023 Smaw 3Documento17 páginasMTK 3023 Smaw 3Nor Hafizah AzmianiAinda não há avaliações

- MTK 1012 Safety Practice and ProceduresDocumento18 páginasMTK 1012 Safety Practice and ProceduresHidayat IzharAinda não há avaliações

- MTK 2033 Smaw 2Documento18 páginasMTK 2033 Smaw 2Hanif Halin100% (1)

- f2. Chapter 8 VocaDocumento1 páginaf2. Chapter 8 VocaGraceLamAinda não há avaliações

- EXERCISE 1: Match The Following Pictures With The Correct Jobs Descriptions. (6 Marks)Documento4 páginasEXERCISE 1: Match The Following Pictures With The Correct Jobs Descriptions. (6 Marks)GraceLamAinda não há avaliações

- Remove ExamDocumento3 páginasRemove ExamGraceLamAinda não há avaliações

- Animation Techniques and History for Technical EducationDocumento32 páginasAnimation Techniques and History for Technical EducationGraceLamAinda não há avaliações

- Introduction To Animation Technology: Dr. Norhasyimah Hamzah Faculty of Technical and Vocational Education TechnologyDocumento14 páginasIntroduction To Animation Technology: Dr. Norhasyimah Hamzah Faculty of Technical and Vocational Education TechnologyGraceLamAinda não há avaliações

- Remove ExamDocumento3 páginasRemove ExamGraceLamAinda não há avaliações

- Rock ClimbingDocumento1 páginaRock ClimbingGraceLamAinda não há avaliações

- Spss and TableDocumento15 páginasSpss and TableGraceLamAinda não há avaliações

- Dr. Norhasyimah Hamzah Faculty of Technical and Vocational Education Universiti Tun Hussein Onn MalaysiaDocumento22 páginasDr. Norhasyimah Hamzah Faculty of Technical and Vocational Education Universiti Tun Hussein Onn MalaysiaGraceLamAinda não há avaliações

- Spss and TableDocumento15 páginasSpss and TableGraceLamAinda não há avaliações

- RSL - Modul MTK 1023 Material ConsumableDocumento6 páginasRSL - Modul MTK 1023 Material ConsumableGraceLamAinda não há avaliações

- SWP Saw Abrasive Cut Off AS545Documento2 páginasSWP Saw Abrasive Cut Off AS545GraceLam100% (1)

- Ca2 ZDocumento105 páginasCa2 ZAde RachmanAinda não há avaliações

- RDSO Guidelines - Bs 112 - Planning of Road Over BridgesDocumento9 páginasRDSO Guidelines - Bs 112 - Planning of Road Over BridgesAnkur MundraAinda não há avaliações

- Gauss Lab 01Documento4 páginasGauss Lab 01Diego Giraldo BoteroAinda não há avaliações

- UAE Visa Occupation ListDocumento89 páginasUAE Visa Occupation ListSiddharth JaloriAinda não há avaliações

- Reconfigurable Vivaldi Antenna With Improved Gain For Uwb ApplicationsDocumento5 páginasReconfigurable Vivaldi Antenna With Improved Gain For Uwb ApplicationsSubhanjali MyneniAinda não há avaliações

- 1000100en Image LD DidacticDocumento12 páginas1000100en Image LD DidacticUditha MuthumalaAinda não há avaliações

- Max 223C Pipeline Welding InverterDocumento2 páginasMax 223C Pipeline Welding InvertermtonellyAinda não há avaliações

- 04 - Motion in Two DimensionDocumento3 páginas04 - Motion in Two DimensionMathan KalyanasundaramAinda não há avaliações

- Advanced MICS Platform with 28 ModulationsDocumento4 páginasAdvanced MICS Platform with 28 ModulationsKIRAN SONICSAinda não há avaliações

- PSC Unit 4 PPT - Part 3Documento35 páginasPSC Unit 4 PPT - Part 3Rino VidAinda não há avaliações

- Sap InputDocumento211 páginasSap InputdominscribdAinda não há avaliações

- MiPs View ManualDocumento53 páginasMiPs View ManualClOudyo VirgílioAinda não há avaliações

- Marking Fixture PresentationDocumento31 páginasMarking Fixture PresentationAvinash JejurkarAinda não há avaliações

- Continental Commercial Vehicle Load TablesDocumento6 páginasContinental Commercial Vehicle Load TablesPatricio FAinda não há avaliações

- Adaptive Cruise Control: Current Flow DiagramDocumento5 páginasAdaptive Cruise Control: Current Flow DiagramHany ElsehrawyAinda não há avaliações

- KIOTI tractor manual overviewDocumento150 páginasKIOTI tractor manual overviewNatsumi KawaiAinda não há avaliações

- School Data Management System ReportDocumento122 páginasSchool Data Management System ReportshekharyadawAinda não há avaliações

- N248J ManualDocumento13 páginasN248J ManualChit KhunAinda não há avaliações

- TS1A-13A: Operation and Maintenance ManualDocumento204 páginasTS1A-13A: Operation and Maintenance ManualJavier AponteAinda não há avaliações

- Philips Chassis Lc7-1e La PDFDocumento91 páginasPhilips Chassis Lc7-1e La PDFcomphomeAinda não há avaliações

- Inventory Items DestinyDocumento11 páginasInventory Items DestinyManish NautiyalAinda não há avaliações

- Katalog Menadzer 2013 EnglDocumento119 páginasKatalog Menadzer 2013 EnglMarko MiladinovićAinda não há avaliações

- 2.3 Drawing Operations: Need To See If It Really Works For All Tasks, and If Not Then Get Rid of ItDocumento1 página2.3 Drawing Operations: Need To See If It Really Works For All Tasks, and If Not Then Get Rid of ItTrogo BoAinda não há avaliações

- Intro to Process Control Part 3 by Omar Y IsmaelDocumento25 páginasIntro to Process Control Part 3 by Omar Y IsmaelHATAM TALAL ALIAinda não há avaliações

- Brochure Ef SchoolDocumento2 páginasBrochure Ef SchoolperulapiaAinda não há avaliações

- Experiment Central 2010Documento1.481 páginasExperiment Central 2010D BASU100% (1)

- Acer Aspire 4735z 4736z 4935z 4936z - COMPAL LA-5272P KALG1 - REV 0.1secDocumento46 páginasAcer Aspire 4735z 4736z 4935z 4936z - COMPAL LA-5272P KALG1 - REV 0.1secIhsan Yusoff IhsanAinda não há avaliações

- History Spring08Documento7 páginasHistory Spring08Anonymous 9VcxlFErfAinda não há avaliações

- Ec7 WallapDocumento20 páginasEc7 WallapJack DoverAinda não há avaliações

- Terminal Blocks: KasugaDocumento6 páginasTerminal Blocks: KasugaKs MuraliAinda não há avaliações