Escolar Documentos

Profissional Documentos

Cultura Documentos

1996 - Wong Sak Hoi Maillard Reaction in Molasses

Enviado por

Raymund GatocTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

1996 - Wong Sak Hoi Maillard Reaction in Molasses

Enviado por

Raymund GatocDireitos autorais:

Formatos disponíveis

MAILLARD REACTION IN MOLASSES STORAGE TANK

IL WONG SAK HOI AND 2JC CHASTEAU DE BALYON

'Mauritius Sugar Industry Research Institute, Reduit, Mauritius

2Flacq UnitedEstates Ltd, Union Flacq, Mauritius

Abstract molasses to a second tank, nor the addition of ice or water

The Maillard reaction was observed in a molasses storage through the air vent, were possible at the time. Nothing much

tank in a Mauritian sugar factory near the end of the 1994 could be done to save the molasses. Trends in brix, sucrose

crushing season. The remedial action taken is detailed and the and reducing sugar contents are shown in Table 2.

economic loss due to the incident is assessed. The mecha-

nisms of the Maillard reaction and measures for its prevention Table 2

are reviewed.

Trends in brix, sucrose and reducing sugar contents in the

Keywords: Froth fermentation, foaming, Maillard reaction, deteriorated molasses

molasses cooling.

Reducing Temperature

Day Date Brix % Sucrose %

sugars % °C

Introduction

With the ad.vent of the continuous C-centrifugal, which 1 28.11.94 86,4 12,7 17,3 63

2 29.11.94 86,2 13,3 17,1 63

enables the cunng of more viscous massecuites than had hith-

3 30.11.94 84,7 13,5 20,8 64

erto been possible by the batch machines either the 09.12.94 84,2 10,2 21,1 69

massecuites are re-heated to a high temperatur~ or steam is

12

used generously to lower the massecuite viscosity, with the

result that the temperature of the final molasses is above

40°C, and may reach 55-60°C. If the hot molasses is not When evolution of the carbon dioxide had subsided, most

cooled before being pumped to the storage tank, a Maillard of the molasses had turned into a dark brown carbonaceous

type reaction may occur in the tank, with catastrophic conse- mass, w~th .only a sIJ.1all proportion remaining in the liquid

quences. state. ThIS liquid portion was analysed and the analytical data

are compared in Table 2 with those of the undeteriorated mo-

Occurrence of the incident lasses obtained just before the occurrence of the incident.

Near the end of the 1994 crushing season, it was noticed on It can be seen that there is a marked decrease in brix, pol,

28 November at Flacq United Estates Ltd (FUEL) sugar fac- sucrose and total sugars, and a gain in reducing sugars. This is

tory that it took longer than usual to fill a 24 ton molasses consistent with the findings of earlier workers (Fromen and

tanker. The molasses was darker in colour than normal, it was Bowland, 1961; Tseng, 1965). As the potassium present in

'froth fermenting' with evolution of carbon dioxide and its the deteriorated molasses was not negligible and had certain

temperature was 63°C. The 7 000 ton capacity mild steel fertiliser value, the molasses was therefore discharged into a

tank, 12 m high and 23 m diameter, was hot and vapour was canal, pH adjusted to 6,8 with milk of lime, and mixed with

coming out of the air vent. The tank was about half full at the river ~ater for surface irrigation of cane. This was a very slow

time the incident was reported. A sample of the molasses was operation as the manhole of the molasses tank was partially

analysed and it was found that the sucrose content was al- blocked by solid carbonaceous mass and it took a fortnight to

ready down from 37,8% to 12,7%, and the reducing sugars up dispose of all the fluid contents of the storage tank.

from 12,93% to 17,3% (Table 1). Neither re-circulation of the The brown solid was found to contain 30,9% moisture and

the analytical data on the dried solid (Table 3) show that it

consists mainly of organic material and can be easily burnt

Table 1 away. Anon (1953) reported that the porous material left after

Comparison of deteriorated with undeteriorated molasses a similar incident in Egypt has a thermal value of 5 336 calo-

ries (1 270 J).

Molasses

Component

Deteriorated Undeteriorated Table 3

Composition of brown carbonaceous mass from deteriorated molasses

Brix % 51,72 83,46

Pol % 1,85 30,40 Loss of ignition % 82,8

Reducing sugars % 15,95 12,93 Solids insoluble in HCI % 0,57

Sucrose % 2,17 37,80 Silica % 0,38

Total sugars % 18,12 50,73 Mixed oxides % 0,94

Carbonated ash % 8,19 10,27 Sodium % 2,00

Calcium % 0,50 1,02 Calcium % 1,82

Magnesium % 0,41 0,43 Magnesium % 0,81

Nitrogen % 0,34 0,64

Phosphorus % 0,08 0,10

Potassium % 3,38 1,27

Sodium % 1,18

When the reaction in the tank had subsided and the tempera-

1,18

ture had dropped, large sections of the molasses tank wall were

Proc S Afr Sug Technol Ass (1996) 70 251

Maillard Reaction in Molasses Storage Tank L Wong Sak Hoi and JC Chasteau de Balyon

cut off to enable a rock breaker to move into the tank to break

the solid mass into small pieces for transportation to the ba-

gasse storage area, where spontaneous combustion took place

before the solid pieces could be used as fuel in the boilers.

The loss of the molasses was estimated at 2,0 M roupies

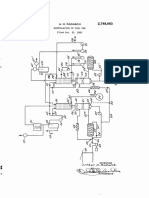

and the cost of the clean-up operation and repairs to the stor- Air inletpipe //"~-----1;- Open-ended

age tank amounted to 1,2 M roupies. (6,3em diameter) branch pipe

(3,8 emdiam)

1 m from

periphery

Discussion

Molasses storage tank

The molasses tank storage conditions at the factory are

summarised in Table 4.

Table 4

Molasses storage conditions at FUEL sugar factory

FIGURE 1: Top view of the air injection system 20 cm abovethe base

of a molasses storage tank

before modification

Tank no 1

Height of tank 12 m Mechanism of Maillard reaction

Diameter of tank 23 m

Back in the 1950s, when incidents of froth fermentation

Type of tank mild steel

Capacity of tank 7000 tons

were reported, it was recognised that the change was chemi-

Method of filling from above cal and not biological as there was an absence of yeast,

Method of emptying from below mould, bacteria or other micro-organisms. It was a spontane-

Temperaturecontrol nil ous exothermic chemical change with evolution of carbon di-

Facilities for re-circulation nil oxide and the formation of volatile acids, mainly acetic. The

Facilities for ventilation two air vents of 15 cm 6 each decomposition is essentially a reaction between amino acids

Facilities for air injection not operational and reducing sugars (Maillard, 1912a, 1912b).

Facilities for inhibitor dosing nil

Average length of storage period 4 weeks maximum Honig (1965) summarised the mechanism of the Maillard

Temperature of molasses entering reaction as follows:

storage ± 60°C 1. Amino acid + hexose amino acid-hexose compound (col-

ourless)

2. Amino acid + amino acid - hexose compound polymerised

A well-designed molasses tank should be equipped with product (I) with dehydration (yellow)

the facilities of re-circulation, for pumping the molasses from

3. Polymerised product (I) undergoes decarboxylation and

one storage tank to another. It should have an air injection

internal combustion

system and, most important of all, adequate ventilation on the

roof top. After the incident, the two air vents have been en- C02 + dehydration product (II) (brown melanoidin)

larged from 15 to 75 cm diameter at FUEL sugar factory. 4. Polymerisation product (II) humic acid + insoluble non-

The retrieval of molasses from the tank should be on a first- sugars (dark reddish- brown).

in, first-out basis so that its storage period would not be un- Ducatillon et al. (1985) reported that, during the froth fer-

duly long. mentation, the pH drop provokes sucrose hydrolysis to reduc-

The design of one of the storage tanks at the molasses ter- ing sugars, which in turn react with amino acids to produce

minal is described below. It is 25 m in diameter, 12 m high, more brown melanoidin and eventually humic acid.

and has a cone roof with four air vents of 40 em diameter each Hucker and Brooks (1942) found that molasses instability

and two manholes of 60 em diameter each. At about 20 em depends on morphological history. Molasses that had been

above the base of the tank there is an air injection system heated produced more gas than that which had not, and in-

whereby air from a compressor unit is led by a 6,3 ern diam- ferred that the higher the temperature the molasses had been

eter pipe to the centre of the tank, where the air is distributed subjected to in the factory process, the lower the critical

into six 3,8 em diameter branch pipes equidistant from each foaming temperature and the greater the foaming on subse-

other. The pipes are open-ended and are situated 1 m from the quent storage.

periphery of the tank wall, as illustrated in Figure 1. The air Newell (1979) studied the factors affecting Maillard reac-

compressor is electrically driven, water-cooled and operating tion occurring in massecuites and molasses, and found effects

at 600 rpm and 100 psi. The temperature of the exit air is of high temperature, high brix and low purity to be signifi-

about 30°C. Compressed air is introduced into each tank for cant.

two hours a day with the objective of breaking through the

upper surface of the molasses to enable the hot gases, if any,

to be carried away into the atmosphere. Preventive measures

Trivett (1953) first claimed that foaming can be controlled After the incident at FUEL sugar factory, molasses after

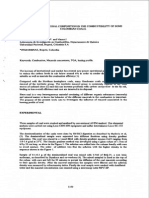

to a certain extent by introduction of compressed air into the curing is cooled in an air cooling tower followed by further

mass of the molasses and Parsons (1958) described an air in- cooling in a crystalliser (Figure 2). Molasses at 60°C is

jection and a calcium hypochlorite dosing system in a tank at pumped to the distributing compartment of the cooling tower

the molasses terminal in the Philippines to control molasses at the rate of 6-7 t/h. It overflows under gravity from one in-

foaming. clined plate to another, and is cooled by air to about 55°C. It

252 Proc S Afr Sug Technol Ass (1996) 70

L Wong Sak Hoi and JC Chasteau de Balyon Maillard Reaction in Molasses Storage Tank

o 0 0 0 0 a 0 0 0 0 Molasses distributing

o a a 0 0 0 0 0 0 0 compartment

Inlet molasses (60°C)

- Cooling tower

I

r--' -.

--1

r-

EXit molasses (45°C)

Water cooled crystalliser

FIGURE 2: Molasses coolingsystemat FUELfactory after modification

then falls into the water-cooled crystalliser, where a further Conclusions

temperature drop to 45°C is achieved. To avoid the Maillard reaction occurring in the storage

Tubular and plate heat exchangers had been used by Julli- tank, the molasses must be cooled to below 40°C. It is there-

enne and Munsamy (1981) for molasses cooling. Broadfoot et fore essential that after the centrifugal station molasses

al. (1990) converted a discarded rotary mud filter to a full should not be heated to lower its viscosity to facilitate pump-

scale scraped rotary drum molasses cooler. The temperature ing. The molasses storage tank should be well equipped with

of the molasses dropped from 60 to 38°C when the cooler facilities for ventilation and re-circulation with an air injec-

operated at a speed of 2,6 rpm, processing 10 t/h molasses tion, and preferably an inhibitor dosing system.

with a molasses film thickness of 1,1 mm on the drum.

Quinan and de Viana (1991) used a plate heat exchanger to

cool molasses from 57 to 37°C with water at 30°C.

Acknowledgements

Antifoam chemicals such as sulphur dioxide, sodium sul-

phite and related compounds have been used in the sugar in- The authors wish to thank the Director of the MSIRI and

dustry, and their inhibitive action on the Maillard reaction the Manager of FUEL sugar factories for permission to pub-

was reported by Trivett (1953). Anet and Igles (1964) showed lish the paper, Mr J Deville, Senior Assistant Director at the

that bisulphite addition compounds are relevant in the inhibi- MSIRI for review of the paper, Mr JC Ng of the Mauritius

tion of browning by sulphur dioxide. Molasses Co Ltd for information on molasses storage tank

design, and the staff in the Sugar Technology Division of the

At MTMD, molasses is now diluted to 83° brix, and cooled

MSIRI for their valued assistance in carrying out the sample

before being sent to the storage tank, which is now equipped

analysis.

with systems of molasses re-circulation, level control and

temperature control. When the molasses temperature exceeds

55°C an alarm is triggered off. A molasses first-in, first-out REFERENCES

system is adopted and a close watch is maintained on the Anet, EFU and Ingles,DL (1964).Mechanism of inhibitionof non-enzymic brown-

amount of steam injected in the centrifugals. ing by sulphite. Chemistry and Industry: 1319.

Proc S Afr Sug TechnolAss (1996) 70 253

Maillard Reaction in Molasses Storage Tank L Wong Sak Hoi and IC Chasteau de Balyon

Anon (1953). Spontaneouscombustionin stored molasses.S Afr SugJ 37(11): 741- Maillard, LC (1912a). Action des acides aminos sur les sucres; formation des

743. melanoidines par role metheique. Compt rend 154: 66.

Broadfoot,R, White, ET, Fitzmaurice,AL and Stendl, RJ (1990). Coolingof molas- Maillard, LC (1912b). Formationd'humus et de combustibles mineraux sans inter-

ses with a scraped rotary drum. ProcAust Soc Sug Cane Technol12: 245-255. ventions de I'oxygene atrnospherique des micro-organismes des hautes

Ducatillon,JP, Deruy, G and Lescure, JP (1985). Utilisationdu dosage des carbon- temperatures ou des fortes pressions. Compt rend 155: 1554.

ates pour la detection de la reaction de Maillard. Sucrerie Francoise: 133-136. Newell,OM (1979). A preliminary investigation into factors affectinggas formation

Fromen,G and Bowland, E (1961). What causes rapid deterioration and destruction in massecuiteand molasses. ProcS Afr Sug Tee/mol Ass 53: 62-65.

of blackstrap molasses. Louisiana SugarJournal 23(10): 28-32. Parsons, MJ (1958). Controlof foaming in molassestank. SugarNews 34: 21-23.

Honig, P (1965). Quantitative aspects of gas formation in final molasses (during Quinan, PB and de Viana, M (1991). Cooling final molasses through a plate heat

boilingof C-strikesand duringstorage, effect of compositionand age of molasses exchanger. ProcAust Soc Sug Cane Technol13: 195-203.

and temperature). Proc int Soc Sug Cane Technol XII: 1741-1749. Trivett, JC (1953). Defrothing of final molasses. Proc int Soc Sug Cane Tee/mol

Hucker, GJ and Brooks, RF (1942). Food Research 7. P 481. VIII: 801-807.

Jullienne, LMSA and Munsamy, S (1981). Assessment of final molasses coolers. Tseng, RH (1965). Rapid deterioration of molasses in storage. Taiwan Sugar XII:

Proc S Afr Sug Technol Ass 55: 83-84. 13·20.

254 Proc S Afr Sug Technol Ass (1996) 70

Você também pode gostar

- Maillard Reaction in Molasses Storage Tank PDFDocumento4 páginasMaillard Reaction in Molasses Storage Tank PDFArthur Yanez100% (2)

- Acid For MicoDocumento2 páginasAcid For MicoJuan Carlos GAinda não há avaliações

- Study of The Reasons For Blocking C S Formation in The Presence of SO and Finding Ways To Overcome BlockagesDocumento10 páginasStudy of The Reasons For Blocking C S Formation in The Presence of SO and Finding Ways To Overcome BlockagesSyed Kazam RazaAinda não há avaliações

- US2687435Documento2 páginasUS2687435Ipalma 3Ainda não há avaliações

- Temperature Influence in Cornstarch Gelatinization For Froth FlotationDocumento5 páginasTemperature Influence in Cornstarch Gelatinization For Froth FlotationRougeeeAinda não há avaliações

- The Prosecc LTDDocumento2 páginasThe Prosecc LTDUV patelAinda não há avaliações

- Transformation Kinetics of Burnt Lime in Freshwater and Sea WaterDocumento28 páginasTransformation Kinetics of Burnt Lime in Freshwater and Sea WaterYang SunmanAinda não há avaliações

- Process Notes: Final ProjectDocumento8 páginasProcess Notes: Final ProjectCluisantony Jayco DizeAinda não há avaliações

- Quench Towers Published Paper PDFDocumento6 páginasQuench Towers Published Paper PDFarmando0212-1Ainda não há avaliações

- ppmp44 257-272Documento16 páginasppmp44 257-272Chemical Ferdi IzzecsonAinda não há avaliações

- procesoMnCO3 PatenteDocumento3 páginasprocesoMnCO3 PatentearnoldmaytaAinda não há avaliações

- 482-Article Text-1475-1-10-20211112 PDFDocumento5 páginas482-Article Text-1475-1-10-20211112 PDFahmad ammarAinda não há avaliações

- US3029298Documento2 páginasUS3029298Muhammad Akbar FahleviAinda não há avaliações

- LeachingDocumento6 páginasLeachingDream CakeAinda não há avaliações

- Patent US2446233Documento3 páginasPatent US2446233Alan ConnorAinda não há avaliações

- Adsorption of Starch, Amylose, Amylopectin and Glucose Monomer and Their Effect On The Flotation of Hematite and QuartzDocumento6 páginasAdsorption of Starch, Amylose, Amylopectin and Glucose Monomer and Their Effect On The Flotation of Hematite and QuartzDiego VeneuAinda não há avaliações

- Combustion Analysis of Coal-Water Slurry Fuel Prepared From Plant Coal and Recovered Coal FinesDocumento7 páginasCombustion Analysis of Coal-Water Slurry Fuel Prepared From Plant Coal and Recovered Coal Finesarsalan322Ainda não há avaliações

- J. Biol. Chem.-1937-Somogyi-741-7Documento8 páginasJ. Biol. Chem.-1937-Somogyi-741-7gibrambo5770Ainda não há avaliações

- 450 Bittern SeparationDocumento5 páginas450 Bittern SeparationJussier VitorianoAinda não há avaliações

- Gabb 1999Documento2 páginasGabb 1999Maysam MohamAinda não há avaliações

- Kin. Mec. of The Carbonation of Ettringite - Fred GlasserDocumento6 páginasKin. Mec. of The Carbonation of Ettringite - Fred GlasserThiagogalvaoclAinda não há avaliações

- Blast Furnace Slag Weathering StudyDocumento8 páginasBlast Furnace Slag Weathering StudyARNALDO BATTAGIN100% (3)

- 1978 - Rouillard - The Crystallization of HighDocumento7 páginas1978 - Rouillard - The Crystallization of Higheal3019Ainda não há avaliações

- The Solubility of Thiourea in Water, Methanol, andDocumento8 páginasThe Solubility of Thiourea in Water, Methanol, andjessicasjs0% (1)

- Mercury in HydrocarbonsDocumento223 páginasMercury in HydrocarbonsBaghdadi AbdelillahAinda não há avaliações

- Hydration of Magnesia in Dolomitic Hydrated Limes and PuttiesDocumento22 páginasHydration of Magnesia in Dolomitic Hydrated Limes and PuttiesDiego AndresAinda não há avaliações

- International Thermodynamic Tables of the Fluid State: Propylene (Propene)No EverandInternational Thermodynamic Tables of the Fluid State: Propylene (Propene)Ainda não há avaliações

- Process For Recovering Lithium From Brine by Salting Out Lithium Sulfate MonohydrateDocumento8 páginasProcess For Recovering Lithium From Brine by Salting Out Lithium Sulfate MonohydrateGabriel ChurioAinda não há avaliações

- 02 Liquid Fuels (Transport, Refining, Quality, Storage)Documento1 página02 Liquid Fuels (Transport, Refining, Quality, Storage)mompou88Ainda não há avaliações

- Fluorite - Saving EnergyDocumento9 páginasFluorite - Saving EnergyrecaiAinda não há avaliações

- Patent US2748063Documento6 páginasPatent US2748063Gökhan Kürşat demirAinda não há avaliações

- 8061-Article Text-39021-1-10-20230530Documento7 páginas8061-Article Text-39021-1-10-20230530Pietro FigueiredoAinda não há avaliações

- Unit 1 Manual 2019Documento18 páginasUnit 1 Manual 2019JozelleAinda não há avaliações

- Libro de FLOTACIÓN-251-300 PDFDocumento50 páginasLibro de FLOTACIÓN-251-300 PDFIsaias Viscarra HuizaAinda não há avaliações

- 1-3 DiketoneDocumento4 páginas1-3 Diketoneshenn0Ainda não há avaliações

- Swelling-Shrinkage Behavior of Natural Expansive Clays B, 2Documento17 páginasSwelling-Shrinkage Behavior of Natural Expansive Clays B, 2Saraswati NoorAinda não há avaliações

- Salty Matters Salty Matters: Calcium Chloride (Cacl) Article 1 of 2: Usage and Brine ChemistryDocumento9 páginasSalty Matters Salty Matters: Calcium Chloride (Cacl) Article 1 of 2: Usage and Brine ChemistryAli KhanAinda não há avaliações

- Effect of Different Salt Solutions On Coal Flotation in The Absence of FrothersDocumento16 páginasEffect of Different Salt Solutions On Coal Flotation in The Absence of FrothersDaniela zapataAinda não há avaliações

- Quantitative Discernments of The Different Calcium Compounds in The Tarfaya Oil Shale (Morocco)Documento11 páginasQuantitative Discernments of The Different Calcium Compounds in The Tarfaya Oil Shale (Morocco)IJAR JOURNALAinda não há avaliações

- EmulsionsDocumento14 páginasEmulsionsام عبدالرحمن الشيخ100% (3)

- High Density Brine-Based Drill-In Fluid Improved RDocumento12 páginasHigh Density Brine-Based Drill-In Fluid Improved RWilson WanAinda não há avaliações

- Compressive and Flexural Strength TestinDocumento16 páginasCompressive and Flexural Strength TestinRani HendrikusAinda não há avaliações

- Research LetterDocumento5 páginasResearch LetterAmeelaDAinda não há avaliações

- Effet Basalte Sur CimentDocumento7 páginasEffet Basalte Sur CimentTarek FennicheAinda não há avaliações

- The Degradation Kinetics of Poly (3-Hydroxybutyrate) Under Non-Aqueous and Aqueous ConditionsDocumento3 páginasThe Degradation Kinetics of Poly (3-Hydroxybutyrate) Under Non-Aqueous and Aqueous ConditionsJUANITA LEALAinda não há avaliações

- Northern This: M M TheDocumento4 páginasNorthern This: M M TheDiego Martínez FernándezAinda não há avaliações

- Tricalcium CaohDocumento3 páginasTricalcium CaohAlin CamarăAinda não há avaliações

- Song 2000Documento5 páginasSong 2000Sajid Mohy Ul DinAinda não há avaliações

- Zodiac Maritime Agencies Ltd. Chemical Operations Manual: Contents - SC 9 MolassesDocumento4 páginasZodiac Maritime Agencies Ltd. Chemical Operations Manual: Contents - SC 9 MolassesRahulPrakashAinda não há avaliações

- SD 14Documento107 páginasSD 14cesar suasacaAinda não há avaliações

- Note On Veratric AcidDocumento2 páginasNote On Veratric AcidpramoglabsAinda não há avaliações

- 1996 Bookmatter DehydrationOfFoodsDocumento14 páginas1996 Bookmatter DehydrationOfFoodsEric Ramos RodriguezAinda não há avaliações

- Contactor Vol - 12 No - 1 (Sulphur Condenser Turndown)Documento2 páginasContactor Vol - 12 No - 1 (Sulphur Condenser Turndown)sepideh asadiAinda não há avaliações

- Precipitation of Magnesium Hydroxide From Brine PDFDocumento7 páginasPrecipitation of Magnesium Hydroxide From Brine PDFHandoko AhmadAinda não há avaliações

- Contradictory Trends For Smart Water Injection Method: Role of PH and Salinity From Sand/Oil/Brine Adhesion MapsDocumento12 páginasContradictory Trends For Smart Water Injection Method: Role of PH and Salinity From Sand/Oil/Brine Adhesion MapsFernanda RuPeAinda não há avaliações

- Sintering of Calcium Phosphate HA 1. Calcination and Particle Growth PDFDocumento13 páginasSintering of Calcium Phosphate HA 1. Calcination and Particle Growth PDFfishvalAinda não há avaliações

- Trapped Gas, Relative Permeability and Residual Oil Saturation of An Oil-Wet SandstoneDocumento15 páginasTrapped Gas, Relative Permeability and Residual Oil Saturation of An Oil-Wet Sandstoneari_si100% (3)

- Key Words: High Sulfur Clinker, Alit C S.: The SummaryDocumento15 páginasKey Words: High Sulfur Clinker, Alit C S.: The Summarymahendra senAinda não há avaliações

- 6.9.2 Pre Treatment Through Neutralisationgypsum Crystallisation For Partial Sulphate Removal 2001Documento20 páginas6.9.2 Pre Treatment Through Neutralisationgypsum Crystallisation For Partial Sulphate Removal 2001samson.idabuAinda não há avaliações

- Analysis of Sugarcane Supply - SRA ReportDocumento72 páginasAnalysis of Sugarcane Supply - SRA ReportRaymund GatocAinda não há avaliações

- Analysis of Sugarcane Juice Quality IndexesDocumento7 páginasAnalysis of Sugarcane Juice Quality IndexesRaymund GatocAinda não há avaliações

- Si-Tec Setup and Commissioning ManualDocumento82 páginasSi-Tec Setup and Commissioning ManualRaymund GatocAinda não há avaliações

- K-Patents Cane Sugar Processing and RefiningDocumento2 páginasK-Patents Cane Sugar Processing and RefiningRaymund GatocAinda não há avaliações

- Drainage Sewerage Piping Work Risk AssessmentsDocumento5 páginasDrainage Sewerage Piping Work Risk Assessmentsboa jean marieAinda não há avaliações

- XMT 350 Vs PDFDocumento36 páginasXMT 350 Vs PDFgerman gualavisiAinda não há avaliações

- Transportation ChecklistDocumento1 páginaTransportation ChecklistHolly Smith100% (1)

- Dating Torrential ProcessesDocumento29 páginasDating Torrential ProcessesJulio Montenegro GambiniAinda não há avaliações

- Silhouette Training NotesDocumento33 páginasSilhouette Training NotesMichael Lester67% (3)

- Catalogue For AutoDocumento22 páginasCatalogue For Autosentimiento azulAinda não há avaliações

- MECH 370 - Modeling, Simulation and Control Systems, Final Examination, 09:00 - 12:00, April 15, 2010 - 1/4Documento4 páginasMECH 370 - Modeling, Simulation and Control Systems, Final Examination, 09:00 - 12:00, April 15, 2010 - 1/4Camila MayorgaAinda não há avaliações

- Operating Systems: Credits: 4 Credits Course Coordinator: V.V.SubrahmanyamDocumento4 páginasOperating Systems: Credits: 4 Credits Course Coordinator: V.V.SubrahmanyamHarendra KumarAinda não há avaliações

- Size Matters: (Type The Document Subtitle)Documento16 páginasSize Matters: (Type The Document Subtitle)SamarthGoelAinda não há avaliações

- Assignment Booklet Me2353 Finite Element Analysis Dec 2013 May 2014Documento85 páginasAssignment Booklet Me2353 Finite Element Analysis Dec 2013 May 2014Ashok Kumar Rajendran100% (9)

- Magnum Dxi13 Engine Torque Settings PDFDocumento67 páginasMagnum Dxi13 Engine Torque Settings PDFbuchniyAinda não há avaliações

- ProxTransSysOpDocumento41 páginasProxTransSysOpNorman MoralesAinda não há avaliações

- Homologos en FiltrosDocumento788 páginasHomologos en FiltrosJohan Gomez100% (1)

- Kroo Subsonic WingDocumento8 páginasKroo Subsonic WingRod ManserAinda não há avaliações

- Feild Inspection of Shell and Tube Heat ExchangersDocumento4 páginasFeild Inspection of Shell and Tube Heat ExchangersMatthew BennettAinda não há avaliações

- AASHTO GeoTechnical Design of PileDocumento5 páginasAASHTO GeoTechnical Design of PiletrannguyenvietAinda não há avaliações

- This Study Resource Was: Laboratory Exercise 2 Preparation of Disturbed Soil Sample For Test ObjectiveDocumento3 páginasThis Study Resource Was: Laboratory Exercise 2 Preparation of Disturbed Soil Sample For Test ObjectiveBienvenida Ycoy MontenegroAinda não há avaliações

- Excel ExercisesDocumento37 páginasExcel ExercisesBERNIELLE DAVE FALDASAinda não há avaliações

- Beam DesignDocumento6 páginasBeam DesignrustamriyadiAinda não há avaliações

- 2 TensionDocumento28 páginas2 TensionRICKY IVANAinda não há avaliações

- Architectural Drawing and Design PHS Syllabus 0910Documento4 páginasArchitectural Drawing and Design PHS Syllabus 0910nourhanAinda não há avaliações

- Mobil DTE 20 Series - Marketing Asset - Display & POS Support Material - Performance ProfileDocumento2 páginasMobil DTE 20 Series - Marketing Asset - Display & POS Support Material - Performance Profilethammarat khruasonkhamAinda não há avaliações

- Test PDFDocumento6 páginasTest PDFDr. L. Bhanuprakash Reddy100% (1)

- MEMS-Based Uncooled Infrared Bolometer Arrays - A ReviewDocumento15 páginasMEMS-Based Uncooled Infrared Bolometer Arrays - A ReviewMarco LicofonteAinda não há avaliações

- Astm D 2699 - 01 - Rdi2otktmdeDocumento49 páginasAstm D 2699 - 01 - Rdi2otktmdeSamuel EduardoAinda não há avaliações

- Critical Care Systems Test Equipment For Repairs and PMS in The USA and CanadaDocumento6 páginasCritical Care Systems Test Equipment For Repairs and PMS in The USA and CanadaMedsystem atAinda não há avaliações

- lfb10 Call PointDocumento1 páginalfb10 Call PointOmar AhmedAinda não há avaliações

- West Beverly Homes-BoqDocumento6 páginasWest Beverly Homes-BoqERICAinda não há avaliações

- Gear Mechanism Used in Wrist WatchesDocumento5 páginasGear Mechanism Used in Wrist WatchesRaja Rv0% (1)

- Memristor Modeling in MATLAB®&SimulinkDocumento6 páginasMemristor Modeling in MATLAB®&Simulinkjoseamh69062247Ainda não há avaliações