Escolar Documentos

Profissional Documentos

Cultura Documentos

Telsmith Cone Crusher Components E

Enviado por

m8877223Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Telsmith Cone Crusher Components E

Enviado por

m8877223Direitos autorais:

Formatos disponíveis

Excel Premium Components

Telsmith Cone Crushers

®

S™ MODELS | FC™ MODELS | SBS™ MODELS

Excel Premium Components

Telsmith Cone Crushers

®

S™ MODELS | FC™ MODELS | SBS™ MODELS

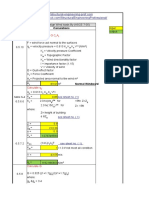

Head & Mainshaft Assembly Lock Nut Cover

Receiving Hopper Shaft Nut Cap

Inner Receiving Hopper Shaft Nut

Burn Ring

Lock Nut

Adjustment Drive Pinion

Lock Cylinder

Adjustment Drive Gear

Support Bowl

Adjustment Drive Gear Box

Thrust Pin

Adjustment Drive Motor

Upper Frame

Concave

Rotary Seal Ring & Counterweight

Mantle

Eccentric

Relief Cylinder

Main Frame Wear Liner

Relief Manifold

Countershaft Box Guard

Relief Valve

Bakelite Seals Countershaft Box

Upper Piston Ring Seal Crusher Sheave

Lower Piston Ring Seal Crusher Sheave Bushing

Upper & Lower Thrust Bearings Countershaft

Adjusting Nut & Lock Washer

Inner & Outer Sleeves

Drive Tang Countershaft Bearing

Slider Plate Bevel Pinion Gear

Adapter Plate Main Drive Gear

Anti-Spin Gear Box Anti-Spin Hydraulic Motor

Excel Premium Components

Telsmith Cone Crushers ®

S™ MODELS | FC™ MODELS | SBS™ MODELS

Excel Bronze Bushings... Simply the Best! Excel Gears and Pinions

Fit, Form, and Function - that’s what we guarantee in every replacement part we deliver. Our Quality

Excel Uses the Straight Tooth

Assurance Department scrutinizes every dimension with exacting tolerances to be sure your bushing is Skew Tooth

perfect in every way, giving your operation an unbelievable value. Less expensive than the OEM, with the Latest Technology

highest quality in the business...sounds too good to be true, doesn’t it? From straight bevel teeth to spiral bevel

teeth, Excel offers direct replacement

gearing that exceeds OEM quality,

Higher Tin

Yields 20%

Higher Tensile Strength starting with the highest quality steel

Higher Strength

forgings. Our gear “gasher” mill at

Tensile Strength

Metallurgical Consistency Yields High-Strength Components

In order to maximize tensile strength, Excel certifies our crusher bronze to the top the beginning of the process and the

end of the CDA specification for tin. Tougher bushings mean less down-time and gear checking center at the end of

fewer replacement cycles. Tin is the most expensive ingredient in the metallurgy of the process help ensure that Excel

crusher bronze alloys. delivers high quality gears and pinions

Tin Content efficiently and consistently.

Spiral Tooth

Uniform Lead Dispersion Coniflex Tooth

Unique Chilling Process Stops Migration

Our foundry utilizes a unique chilling process that assures even dispersion of

lead throughout the casting. Standard foundry molding techniques allow uneven, It’s All About the Contact Pattern

non-directional cooling that can cause lead migration. Even dispersion of lead The contact pattern is the single most important factor

provides consistent lubricity and heat dissipation which increase bushing life and to control when manufacturing crusher gears. Without

reduce unexpected failures. good tooth-to-tooth contact, the load transfer can

Excel’s Chilling

Process

Standard Cooling point-load the tooth face and result in premature or

Process

uneven wear or tooth breakage. Poor contact also

Optimum Concentricity creates excessive noise. The load must be distributed

properly on the tooth face, and Excel rigorously assures

Turning the Simultaneous “4-Axis” Turning Ensures Concentricity this condition is met through contact-testing with

OD & ID

in the

Extensive investment in our equipment, our people, and our process gives our master gears.

Same Excel many unique capabilities, including a special “pinch turning” method in

Operation Incorrect Contact Correct Contact

the machining of our crusher bushings which simultaneously cuts the OD and

ID. Using this technology guarantees absolute concentricity.

Master Gears and Bluing Process

Conventional Casting

with Impurities & Porosities We ensure field performance and wear life when it comes

Porosity-Free/ to gear manufacturing by retaining a high quality set of

Uniform Grain Structure “master gears” to be used in the production process.

Each gear or pinion made is contact-tested against the

Porosities Centrifugal Casting Technique Ensures Alloy Integrity master and must meet the precise specifications of the

Machined Area The purity of our raw materials, coupled with controlled, directional solidification gear’s contact criteria. Simply put, the benefit to our

during the casting process creates a tighter, denser grain structure in our alloys customer is consistency.

while eliminating 99.9% of the gas pockets that produce porosity. The integrity of

Excel’s grain structure ensure strong, long lasting replacement parts.

Porosities Pushed to the ID then

Machined Down

Dedicated to Outstanding

Customer Support

+1.309.347.6155

Toll Free 800.523.9129

sales@ExcelFoundry.com

1 Excel Way | Pekin, Illinois | USA

ExcelFoundry.com

For emergency after-hours support,

call +1.309.202.8300 to speak to

an Excel Professional at any time.

Telsmith® is a mark of Astec Industries Inc. Excel Foundry & Machine is not an authorized repair facility of nor does it have

an affiliation with Astec. These terms are used for identification purposes only and are not intended to indicate affiliation with

or approval by Astec of Excel. All parts are manufactured by, for and warranted by Excel Foundry & Machine and are not

manufactured by, purchased from or warranted by the original equipment manufacturer.

©2017 FLSmidth A/S. All rights reserved. EXPRI138 - REV2

Você também pode gostar

- MVP Chancadora PDFDocumento8 páginasMVP Chancadora PDFTeofilo Paredes Cosme0% (1)

- Sandvik Cone Crusher Components - E PDFDocumento6 páginasSandvik Cone Crusher Components - E PDFoncombroAinda não há avaliações

- Lj-Ts Series Horizontal ScreensDocumento8 páginasLj-Ts Series Horizontal ScreensLuis Vallecillo100% (1)

- 38, 44, 52, 57, 68H and SBS Cone CrushersDocumento4 páginas38, 44, 52, 57, 68H and SBS Cone Crushersjuanandres_martinez100% (2)

- 57SBS PArts CatalogueDocumento68 páginas57SBS PArts CatalogueSergey Slomchinskiy100% (2)

- Parts: Tension Rod and Toggle Plate Assembly: IllustrationDocumento11 páginasParts: Tension Rod and Toggle Plate Assembly: IllustrationAshik Rahaman100% (2)

- Current Revision Approved: Eccentric Assy, 68H/SbsDocumento1 páginaCurrent Revision Approved: Eccentric Assy, 68H/Sbscapslive_001Ainda não há avaliações

- Hydrocone Manual - S223.360.01.en PDFDocumento291 páginasHydrocone Manual - S223.360.01.en PDFLmf Daniel100% (2)

- PE3042 O.M.P. ManualDocumento18 páginasPE3042 O.M.P. Manualgusjav2014c12100% (1)

- H-Series Gyrasphere Parts Catalog: Model 44Documento51 páginasH-Series Gyrasphere Parts Catalog: Model 44emilio garavito100% (1)

- PDFDocumento108 páginasPDFCristian MosqueraAinda não há avaliações

- 2.3 - Td7-B152-E-04Documento17 páginas2.3 - Td7-B152-E-04Julio Suarez Zedano100% (2)

- 4.25 FT STD Cone Crusher Parts ManualDocumento220 páginas4.25 FT STD Cone Crusher Parts ManualricardoAinda não há avaliações

- Parts BookDocumento60 páginasParts Bookjosevelazcoq100% (6)

- Omnicone 937 Parts List-OMNIDocumento2 páginasOmnicone 937 Parts List-OMNIgusjav2014c12Ainda não há avaliações

- MVP380 Cono PartesDocumento64 páginasMVP380 Cono PartesJUAN PABLO ACOSTA100% (1)

- Catalogo de Partes 02 PDFDocumento68 páginasCatalogo de Partes 02 PDFEduardo100% (4)

- Roller Cone Service Manual ExerptsDocumento58 páginasRoller Cone Service Manual ExerptsJoel Olson100% (9)

- 44 SbsDocumento1 página44 SbsCampel SilvaAinda não há avaliações

- HP4 Spear PartsDocumento135 páginasHP4 Spear PartsDmitry Sidlak50% (2)

- TP502 PDFDocumento74 páginasTP502 PDFDaniel Banda Rendón100% (3)

- Omnicone® Cone Crusher Parts ManualDocumento8 páginasOmnicone® Cone Crusher Parts ManualPOWERUPS0% (1)

- Raptor XL900 Cone CrushersDocumento8 páginasRaptor XL900 Cone CrushersLmf DanielAinda não há avaliações

- Gyradisc® Cone Crusher Parts ManualDocumento5 páginasGyradisc® Cone Crusher Parts ManualPOWERUPSAinda não há avaliações

- Extec C12 PDF - 0 - 0Documento21 páginasExtec C12 PDF - 0 - 0gugi100% (1)

- C Series Jaw: Wear Material Sales ManualDocumento69 páginasC Series Jaw: Wear Material Sales Manualespokanhotmail.com100% (2)

- Telsmith 52S Catalogo de Partes GyrasphereDocumento68 páginasTelsmith 52S Catalogo de Partes Gyraspheregusjav2014c1250% (6)

- Boletin Vsi SvedalaDocumento5 páginasBoletin Vsi SvedalaAnonymous 8t0V9S100% (4)

- ASRi20 SPC R223.1355.en-01Documento18 páginasASRi20 SPC R223.1355.en-01bodhy852003100% (2)

- IMalalcaDocumento560 páginasIMalalcalandago100% (9)

- Chancadores de ConosDocumento60 páginasChancadores de Conosvalentina_brune6307100% (8)

- Trituradora CH550-02 - SPC - R 223.1442-01Documento168 páginasTrituradora CH550-02 - SPC - R 223.1442-01AndersonAinda não há avaliações

- Excel Components For Cone and Gyratory Crushers PDFDocumento2 páginasExcel Components For Cone and Gyratory Crushers PDFDanny Joel Espinoza CastañedaAinda não há avaliações

- Terex Crushers (DA) CompressedDocumento24 páginasTerex Crushers (DA) CompressedAnonymous OVhnLp100% (1)

- JM1312-06 WPC R222.307.en-02Documento12 páginasJM1312-06 WPC R222.307.en-02cachitAinda não há avaliações

- Barmac B7150SE S N B7100179Documento147 páginasBarmac B7150SE S N B7100179Javier Jimenez PerezAinda não há avaliações

- Current Revision Approved: Upper Frame, 68SbsDocumento3 páginasCurrent Revision Approved: Upper Frame, 68Sbscapslive_001100% (1)

- CH430-02 WPC R223.1403-01Documento22 páginasCH430-02 WPC R223.1403-01Patricio Tamayo100% (3)

- Telsmith 52S-Catalogo-de-Partes-Gyrasphere PDFDocumento68 páginasTelsmith 52S-Catalogo-de-Partes-Gyrasphere PDFgusjav2014c12Ainda não há avaliações

- CH430 01 02 IMA S223 651 en 02 PDFDocumento33 páginasCH430 01 02 IMA S223 651 en 02 PDFferneyarrieta38100% (2)

- PE2436 O.M.P. ManualDocumento21 páginasPE2436 O.M.P. Manualmario100% (1)

- Crusher Cross-Section (Symons)Documento1 páginaCrusher Cross-Section (Symons)Javier Rivmatam100% (4)

- Current Revision Approved: Base Unit Hydraulics, 68H/SbsDocumento2 páginasCurrent Revision Approved: Base Unit Hydraulics, 68H/Sbscapslive_001Ainda não há avaliações

- Telsmith 52s Catalogo de Partes GyrasphereDocumento68 páginasTelsmith 52s Catalogo de Partes GyrasphereАлександрAinda não há avaliações

- Trio TV85 VSI Parts Manual (SN. 078) PDFDocumento25 páginasTrio TV85 VSI Parts Manual (SN. 078) PDFChancadores Chile100% (1)

- Trio CT 3648 Jaw Crusher Parts (SN. 230)Documento31 páginasTrio CT 3648 Jaw Crusher Parts (SN. 230)gusjav2014c12100% (1)

- Moledor de Impacto VerticalDocumento128 páginasMoledor de Impacto VerticalAdrian Alonso Bustos GonzalezAinda não há avaliações

- MANUAL CONO 11-MAR-15 CRSH-OM-0002ENG - OCT2011 - All APP and APS Models HSI TRIO PDFDocumento52 páginasMANUAL CONO 11-MAR-15 CRSH-OM-0002ENG - OCT2011 - All APP and APS Models HSI TRIO PDFCuello Marin Nayely100% (1)

- Gator PE3242 PartsDocumento8 páginasGator PE3242 PartsAshik Rahaman100% (1)

- Telsmith Cone Sbs PDFDocumento1 páginaTelsmith Cone Sbs PDFoncombro100% (2)

- Cedarapids 1313 & 1316 Horizontal Shaft Impactor ENGLISH MANUALDocumento103 páginasCedarapids 1313 & 1316 Horizontal Shaft Impactor ENGLISH MANUALGheorghe Claudiu50% (2)

- Lokotrack LT300HP S N 77675Documento763 páginasLokotrack LT300HP S N 77675Oscar BermeoAinda não há avaliações

- Hydrocone Sandvik PDFDocumento393 páginasHydrocone Sandvik PDFIsaac TorresAinda não há avaliações

- MP™ Cone Crusher Parts ManualDocumento3 páginasMP™ Cone Crusher Parts ManualPOWERUPS100% (1)

- TP401 PDFDocumento112 páginasTP401 PDFDaniel Tovar Romero50% (2)

- EXCEL High Performance Parts For GP Cone-CrusherDocumento4 páginasEXCEL High Performance Parts For GP Cone-CrusherGires TocheAinda não há avaliações

- EXCEL High Performance Parts For HP-Cone-Crushers - MetsoDocumento7 páginasEXCEL High Performance Parts For HP-Cone-Crushers - MetsoabcAinda não há avaliações

- Jaw Crusher PST1108Documento4 páginasJaw Crusher PST1108Mathew Varghese100% (1)

- 01-STEEER's Extruder Components Brochure - 2009Documento31 páginas01-STEEER's Extruder Components Brochure - 2009Reha YelkenAinda não há avaliações

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsNo EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsNota: 4 de 5 estrelas4/5 (1)

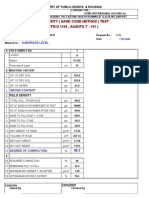

- Field Density (Sand Cone Method) Test (ASTM D 1556, AASHTO T - 191)Documento5 páginasField Density (Sand Cone Method) Test (ASTM D 1556, AASHTO T - 191)m8877223Ainda não há avaliações

- Astm C33Documento11 páginasAstm C33JAVIER NAPOLEON COLINA POZO100% (1)

- 03 2015Documento324 páginas03 2015little_rat_3Ainda não há avaliações

- A 517 A517m PDFDocumento3 páginasA 517 A517m PDFm8877223Ainda não há avaliações

- Metric Practice Guide For Concrete and Concrete AggregatesDocumento1 páginaMetric Practice Guide For Concrete and Concrete AggregatesRogelio I. ClarinAinda não há avaliações

- Elongation Test Bs. 812 Part (1) : Client: Ministry of Public Work and HousingDocumento5 páginasElongation Test Bs. 812 Part (1) : Client: Ministry of Public Work and Housingm8877223Ainda não há avaliações

- Breakaway Sign Posts - PSDocumento3 páginasBreakaway Sign Posts - PSm8877223Ainda não há avaliações

- Astm A 153 PDFDocumento4 páginasAstm A 153 PDFmahmoud hegazy100% (5)

- Al-Haramain - Structural Design - Signs-LayoutDocumento1 páginaAl-Haramain - Structural Design - Signs-Layoutm8877223Ainda não há avaliações

- Standards DWG. - Guard Rail Details PDFDocumento2 páginasStandards DWG. - Guard Rail Details PDFm8877223Ainda não há avaliações

- Signs 24-04-2018Documento52 páginasSigns 24-04-2018m8877223Ainda não há avaliações

- Tipcal Saction-2 - Rev 01Documento1 páginaTipcal Saction-2 - Rev 01m8877223Ainda não há avaliações

- A53 CS Steel Pipe, Welded, Seamless, Black, Galv PDFDocumento21 páginasA53 CS Steel Pipe, Welded, Seamless, Black, Galv PDFguillermoAinda não há avaliações

- GabionDocumento1 páginaGabionm8877223Ainda não há avaliações

- JBC Design of FormworkDocumento4 páginasJBC Design of Formworkm8877223Ainda não há avaliações

- Standards DWG. - Guard Rail DetailsDocumento2 páginasStandards DWG. - Guard Rail Detailsm8877223Ainda não há avaliações

- FHWA-NHI-10-024 Design & Construction of MSE Walls and Reinforced Soil Slopes - Volume IDocumento332 páginasFHWA-NHI-10-024 Design & Construction of MSE Walls and Reinforced Soil Slopes - Volume IKathleen Noonan100% (3)

- Curing ConcreteDocumento10 páginasCuring ConcreteShariq KhanAinda não há avaliações

- Bridge Z3 Section Along Ramp B Base LineDocumento1 páginaBridge Z3 Section Along Ramp B Base Linem8877223Ainda não há avaliações

- FHWA-NHI-10-024 Design & Construction of MSE Walls and Reinforced Soil Slopes - Volume IDocumento332 páginasFHWA-NHI-10-024 Design & Construction of MSE Walls and Reinforced Soil Slopes - Volume IKathleen Noonan100% (3)

- HMA Lay Down and CompactionDocumento50 páginasHMA Lay Down and Compactionaji100% (1)

- Specifications For Prefabricated BuildingDocumento3 páginasSpecifications For Prefabricated Buildingm8877223Ainda não há avaliações

- TableDocumento24 páginasTableAhmed MandorAinda não há avaliações

- Marshall Method of Asphalt-Concrete Mix DesignDocumento16 páginasMarshall Method of Asphalt-Concrete Mix DesignfitrianiAinda não há avaliações

- DocumentDocumento2 páginasDocumentm8877223Ainda não há avaliações

- Engineer's Monthly ReportDocumento4 páginasEngineer's Monthly Reportm8877223Ainda não há avaliações

- Pile Cap Reinforcement - BCA Singapore PDFDocumento11 páginasPile Cap Reinforcement - BCA Singapore PDFkarthicksipAinda não há avaliações

- Standards DWG. - Guard RailDocumento2 páginasStandards DWG. - Guard Railm8877223Ainda não há avaliações

- 2Documento2 páginas2m8877223Ainda não há avaliações

- Lecture 1 - Joining Processes-1Documento9 páginasLecture 1 - Joining Processes-1Shaheer FarrukhAinda não há avaliações

- Pert - CPM For Proposed Cons. of One Storey State of The Art Multi Purpose BLDG at Salay) Revised 1Documento87 páginasPert - CPM For Proposed Cons. of One Storey State of The Art Multi Purpose BLDG at Salay) Revised 1Rodelio AbodaAinda não há avaliações

- Metal Seated Ball ValveDocumento12 páginasMetal Seated Ball ValvezazamoteurAinda não há avaliações

- Tutorial Vapor and Combined Power CyclesDocumento3 páginasTutorial Vapor and Combined Power CyclesShariff Mohamad Fairuz0% (1)

- JNTUK-DAP-Course Structure and Syllabus-B.tech (Mechanical Engineering) - II YEAR.R10 StudentsDocumento25 páginasJNTUK-DAP-Course Structure and Syllabus-B.tech (Mechanical Engineering) - II YEAR.R10 StudentsAnusha MylavarapuAinda não há avaliações

- Structures Module 3 Notes FullDocumento273 páginasStructures Module 3 Notes Fulljohnmunjuga50Ainda não há avaliações

- Paper Id (Me302) : Nav'.O (Documento2 páginasPaper Id (Me302) : Nav'.O (RaJan GargAinda não há avaliações

- Inplant Training Presentation Aniket Shinde 151Documento17 páginasInplant Training Presentation Aniket Shinde 151ajayAinda não há avaliações

- R320LC 7Documento673 páginasR320LC 7Ricardo VilcaAinda não há avaliações

- Anti-Seismic Gas Installation Systems For Households: ContactDocumento2 páginasAnti-Seismic Gas Installation Systems For Households: ContactCak NhassAinda não há avaliações

- Jig Boring, Jig Grinding and BroachingDocumento14 páginasJig Boring, Jig Grinding and Broachingjineesha p jAinda não há avaliações

- Almas-Tower Structural DesignDocumento12 páginasAlmas-Tower Structural DesignBalaji PalaniAinda não há avaliações

- Range Rover11 MainDocumento19 páginasRange Rover11 Main15101980Ainda não há avaliações

- Ce353 CH7 PDFDocumento19 páginasCe353 CH7 PDFDarlene Mae ZaraAinda não há avaliações

- RigsPresentation PDFDocumento16 páginasRigsPresentation PDFAndrei ClaudYuAinda não há avaliações

- Chilled Water System OptimizationDocumento36 páginasChilled Water System OptimizationPramod EkAinda não há avaliações

- Flexible Design - Geo Synthetic LCR MethodDocumento14 páginasFlexible Design - Geo Synthetic LCR MethodartiAinda não há avaliações

- Replacement Parts BUSHDocumento33 páginasReplacement Parts BUSHIsaac Rodríguez BetancourtAinda não há avaliações

- Testing and Adjusting: Troubleshooting Problem ListDocumento101 páginasTesting and Adjusting: Troubleshooting Problem ListJose DarioAinda não há avaliações

- Cornell Pump Company Refrigerant Pump 1.5CBHDocumento2 páginasCornell Pump Company Refrigerant Pump 1.5CBHJavier AffifAinda não há avaliações

- SID97-2B: Service Information DirectiveDocumento26 páginasSID97-2B: Service Information Directivefranco lopezAinda não há avaliações

- Orientation Syllabus Thermo 2Documento16 páginasOrientation Syllabus Thermo 2Kenneth Rodriguez HerminadoAinda não há avaliações

- AISC Night School 9 Session 2Documento49 páginasAISC Night School 9 Session 2LCS100% (1)

- Performance Task in General Physics 1Documento3 páginasPerformance Task in General Physics 1Erica JoyAinda não há avaliações

- Odorizatin UnitDocumento4 páginasOdorizatin UnitSachin VermaAinda não há avaliações

- Duct Design For "Super" SupermarketDocumento47 páginasDuct Design For "Super" Supermarketkevin_thian_1100% (4)

- Refresher No.4 (Pipe)Documento5 páginasRefresher No.4 (Pipe)chyno.kang08Ainda não há avaliações

- Fuel System Non Cert Montacargas 30L-7 ListaDocumento1 páginaFuel System Non Cert Montacargas 30L-7 ListaJose A PerezAinda não há avaliações

- Wind Loads Calculations by ASCE7 05 For Any BuildingDocumento12 páginasWind Loads Calculations by ASCE7 05 For Any BuildingshubhamdereAinda não há avaliações

- Materials and Design: Jun Li, Chengqing Wu, Hong Hao, Yu SuDocumento15 páginasMaterials and Design: Jun Li, Chengqing Wu, Hong Hao, Yu SuAbdulkhaliq AbdulyimahAinda não há avaliações