Escolar Documentos

Profissional Documentos

Cultura Documentos

Bypass Vav Terminal Unit

Enviado por

farshan296015Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Bypass Vav Terminal Unit

Enviado por

farshan296015Direitos autorais:

Formatos disponíveis

Bypass Terminal Units

Page: 1 of 3

BYPASS

TERMINAL UNITS

_______________________________

Dan Int-Hout

Chief Engineer

Krueger Corporate Headquarters

1401 N. Plano Rd. • Richardson, TX 75081

Phone: (972) 680-9136 | Fax: (972) 497-0450 | E-Mail: kruegerinfo@krueger-hvac.com

www.krueger-hvac.com

Bypass Terminal Units

Page: 2 of 3

INSTALLATION GUIDELINES

When designing small (4-6000 CFM) jobs, an engineer will often specify a constant volume air handler,

and then include in the design one or more VAV zone controls. To keep the air handler satisfied, he will

specify pressure dependent bypass terminals. These units, when properly designed, installed, and

maintained can work fine. All too often, however, they are miss-applied, miss-installed, and therefore do

not work. A bypass unit requires a balancing damper upstream of the unit, (optional on the Krueger KLB)

which is often left out when all parties do not understand the proper design of this system. Systems can be

noisy or inoperative if not installed properly. Bypass systems must be carefully balanced, and cannot be

designed to be self-balancing.

PRINCIPLE OF OPERATION

The By-Pass VAV terminal is a device that receives a constant volume into the unit and provides variable

volume to the space. It diverts a portion of the supply airflow to the plenum, either through a duct to the

return ductwork, or directly into a return air plenum. In order for the unit to operate properly, it must

accomplish several tasks:

• It must be invisible to the air handler – that is, regardless of the position of the bypass damper, the

airflow into the unit should remain relatively constant.

• It should always be located downstream of a balancing damper, as if it was a diffuser, as it cannot

regulate the total quantity of air delivered to that branch.

• It should be balanced such that the pressure drop into the plenum or return duct is the same as to the

diffuser(s) located downstream of the unit.

For these to take place, the balancer must carefully adjust the bypass relief damper, and the upstream

damper. As the unit does not regulate total flow, it cannot be provided with standard pressure independent

controls. It may be fitted with a pressure dependent control, such as a VVT controller, or with a pneumatic

or electric thermostat controlled actuator.

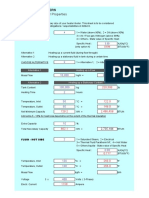

BALANCING GUIDELINES

• The balancer should adjust the upstream balancing damper (optional, or provided by the installing

contractor) with 100% of the unit supply air going into the room, using standard balancing methods. A

note should be made of the duct pressure at the inlet of the bypass unit in this condition.

• The balancer should then set the unit to 100% bypass. Then the discharge bypass damper should be

set so that the duct pressure at the inlet of the unit is the same as when the unit is supplying all the air

to the zone. This will ensure that the unit delivers relatively constant airflow over the full range of

bypass damper positions.

Failure to perform this balancing operation will result is air quantities varying as the thermostat calls for

more or less cooling, and will likely adversely affect other constant volume zones on the system.

CAUTIONS

Should a balancing damper not be provided, or adjusted, at the inlet of the unit, high pressure/ high flows

can result in excessive noise, and possible damage to the damper in the unit. It is designed to operate with

no more than 0.6in pressure, and typically sees only 0.2in. or less.

AN ALTERNATE TO BYPASS TERMINAL UNITS

Bypass units cannot be set to guarantee ventilation airflows, and may be noisy, even when properly

configured, if not balanced carefully. There are alternatives to the bypass terminal.

Krueger Corporate Headquarters

1401 N. Plano Rd. • Richardson, TX 75081

Phone: (972) 680-9136 | Fax: (972) 497-0450 | E-Mail: kruegerinfo@krueger-hvac.com

www.krueger-hvac.com

Bypass Terminal Units

Page: 3 of 3

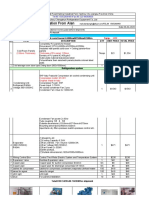

An effective alternate to the bypass terminal is a pressure-relieved loop. This system is a standard

pressure independent VAV terminal design; with an additional VAV terminal at the end of the run

"dumping" excess air (and pressure) to the return plenum. This terminal is configured as a constant

pressure unit, sensing pressure at a point typically 2/3 of the way down the run. The constant pressure

option is available for both Pneumatic and electronic control units. This unit is shown with a 90ø lined duct

"attenuator" (by others, simply a section of lined duct with an elbow) attached. This will reduce the potential

for any noise possibilities associated with the unit.

The VAV terminals, as well as the pressure relief damper, can all be factory set, requiring a minimum of

field balancing and accurate flows to the space.

The "Dump" box should be sized for about 60% of the air handler capacity, depending on the expected

system diversity. Note, however, that a typical pressure setting will be less than 0.5 in. W.g. so the noise

levels will be low, even for large units. In many cases, a slip-in damper will be a low cost solution for this

application.

When possible, the bypass loop should be utilized in place of a bypass zone. The overall cost will not be

significantly different, control will be much improved (Pressure independent controls with reheat, or even

Fan Terminals can be mounted), and the potential for problems will be significantly reduced.

Bypass terminals are an effective solution to small constant volume air handlers, but when designed or

installed improperly, can not be expected to operate as desired.

Krueger Corporate Headquarters

1401 N. Plano Rd. • Richardson, TX 75081

Phone: (972) 680-9136 | Fax: (972) 497-0450 | E-Mail: kruegerinfo@krueger-hvac.com

www.krueger-hvac.com

Você também pode gostar

- Im Trox Compact Controller EasyDocumento8 páginasIm Trox Compact Controller EasymichelesmiderleAinda não há avaliações

- Silencer Selection InstructionsDocumento9 páginasSilencer Selection InstructionsRyo TevezAinda não há avaliações

- Calmo: Sound Attenuator With Recessed Connection For Rectangular DuctsDocumento11 páginasCalmo: Sound Attenuator With Recessed Connection For Rectangular DuctsYazan AkAinda não há avaliações

- ACH580 Drives For HVAC Catalog 3AUA0000186691 RevEDocumento36 páginasACH580 Drives For HVAC Catalog 3AUA0000186691 RevESalaar AnsarAinda não há avaliações

- Chilled Beams in Heating: Design Criteria and Case StudyDocumento8 páginasChilled Beams in Heating: Design Criteria and Case StudyarjantinAinda não há avaliações

- Silver Hammer Construction & Supplies: Warranty ConditionsDocumento2 páginasSilver Hammer Construction & Supplies: Warranty ConditionsLimelily PensionAinda não há avaliações

- Sound Attenuators LeafletDocumento7 páginasSound Attenuators LeafletBalanSelvamAinda não há avaliações

- High Velocity Duct Design Tips by TraneDocumento50 páginasHigh Velocity Duct Design Tips by TraneInventor SolidworksAinda não há avaliações

- Continuous-Flow Rice Husk Gasifier-Belonio-2010 0Documento18 páginasContinuous-Flow Rice Husk Gasifier-Belonio-2010 0Erick Marzan AlvarezAinda não há avaliações

- Quick Selection Guide 2017 Linked VersionDocumento82 páginasQuick Selection Guide 2017 Linked VersionjdanastasAinda não há avaliações

- Jet Nozzles DUKDocumento14 páginasJet Nozzles DUKKerx EndranoAinda não há avaliações

- Selection and Application Manual: Fifth Edition April 2003Documento20 páginasSelection and Application Manual: Fifth Edition April 2003Anonymous ixIhrPM2Ainda não há avaliações

- CIBSE ASHRAE Oct 12 2016 - 5 - Frank Mills PDFDocumento42 páginasCIBSE ASHRAE Oct 12 2016 - 5 - Frank Mills PDFSHARATH GOWDA JAinda não há avaliações

- Kruger Air ManualDocumento17 páginasKruger Air ManualmoffatdabAinda não há avaliações

- EGAT Head OfficeDocumento33 páginasEGAT Head OfficeJasper_HVACAinda não há avaliações

- Application of Sound Power LevelDocumento8 páginasApplication of Sound Power LevelmanchuricoAinda não há avaliações

- Holyoake Engineering DataDocumento24 páginasHolyoake Engineering DataSantiago J. ramos jr100% (1)

- Basic Fs Training PresentationDocumento53 páginasBasic Fs Training PresentationDick HarryAinda não há avaliações

- AC V For Fast Food RestaurantsDocumento4 páginasAC V For Fast Food Restaurantselijah namomoAinda não há avaliações

- hp39gs Manual PDFDocumento314 páginashp39gs Manual PDFMatheus Paes PeçanhaAinda não há avaliações

- Parking Structures Guidelines enDocumento8 páginasParking Structures Guidelines enbudi budihardjoAinda não há avaliações

- 3rd QTR - Seminar Invitation (Lto - Mimaropa)Documento1 página3rd QTR - Seminar Invitation (Lto - Mimaropa)Maria GinalynAinda não há avaliações

- Dehumidification Equipment Advance ASHRAE Journal PDFDocumento6 páginasDehumidification Equipment Advance ASHRAE Journal PDFThomás ArévaloAinda não há avaliações

- Hpac Pools Article2Documento6 páginasHpac Pools Article2Moriyasu NguyenAinda não há avaliações

- Chapter 7 - Mechanical Ventillation and Smoke Control SystemsDocumento23 páginasChapter 7 - Mechanical Ventillation and Smoke Control SystemsBalgo BalgobinAinda não há avaliações

- Ventilation Lecture 4 PH Alleen LezenDocumento25 páginasVentilation Lecture 4 PH Alleen LezenNazimAhmedAinda não há avaliações

- Grease Duct ManualDocumento4 páginasGrease Duct Manualsaifi2004Ainda não há avaliações

- Simpson, RobertDocumento101 páginasSimpson, RobertKai JieAinda não há avaliações

- Determining Airtightness of Buildings Using An Orifice Blower DoorDocumento13 páginasDetermining Airtightness of Buildings Using An Orifice Blower DoorEric GozzerAinda não há avaliações

- Product Application Guide: Multiple F An Systems - F Ans in Series and ParallelDocumento4 páginasProduct Application Guide: Multiple F An Systems - F Ans in Series and ParallelgonvicAinda não há avaliações

- Application of Hydronic Radiant & Beam SystemsDocumento86 páginasApplication of Hydronic Radiant & Beam SystemsDhirendra Singh RathoreAinda não há avaliações

- Ruskin Fire DamperDocumento4 páginasRuskin Fire DamperRAGANAinda não há avaliações

- Proposal To AEPCDocumento10 páginasProposal To AEPCBimal BhattaraiAinda não há avaliações

- AHRI 880 Performance Rating of Air TerminalsDocumento16 páginasAHRI 880 Performance Rating of Air TerminalsDumitru Cristina100% (1)

- Damper Guide - Rev 4 Nov 2013 (Ireland & UK) 1. Why Are Dampers Required?Documento5 páginasDamper Guide - Rev 4 Nov 2013 (Ireland & UK) 1. Why Are Dampers Required?Mykael_pAinda não há avaliações

- Balancing Air Flow W FireSmoke DampersDocumento3 páginasBalancing Air Flow W FireSmoke DampersNg KhanhAinda não há avaliações

- State of The Art Atrium Smoke ControlDocumento12 páginasState of The Art Atrium Smoke ControlBasil OguakaAinda não há avaliações

- AS1668 Seminar NotesDocumento19 páginasAS1668 Seminar NotesOwen PerrinAinda não há avaliações

- Garage Ventilation System DesignDocumento8 páginasGarage Ventilation System DesignDiego PovedaAinda não há avaliações

- Ashrae D62Documento27 páginasAshrae D62Amro Metwally El HendawyAinda não há avaliações

- TITUS Diffusers 2017Documento216 páginasTITUS Diffusers 2017Anonymous 7z6OzoAinda não há avaliações

- Fire & Smoke ControlDocumento7 páginasFire & Smoke ControlAnkit JainAinda não há avaliações

- PREFCO Fire and Smoke Damper Product Catalog 2007Documento16 páginasPREFCO Fire and Smoke Damper Product Catalog 2007iask52750% (1)

- Belimo Vav ControllerDocumento9 páginasBelimo Vav ControllerckyprianouAinda não há avaliações

- Duct SweatingDocumento6 páginasDuct SweatingNeal JohnsonAinda não há avaliações

- HVAC Trane - Engineered Smoke Control System For Tracer Summit - Applications Guide PDFDocumento97 páginasHVAC Trane - Engineered Smoke Control System For Tracer Summit - Applications Guide PDFgarciajoyaAinda não há avaliações

- Specifications For Fire Rated Gi Duct WorksDocumento2 páginasSpecifications For Fire Rated Gi Duct Workspsn_kylmAinda não há avaliações

- Ahri 430 Ahu OmDocumento18 páginasAhri 430 Ahu OmvitaliskcAinda não há avaliações

- Fire Pump Compliance MatrixDocumento5 páginasFire Pump Compliance Matrixshakil612Ainda não há avaliações

- Ashrae Standard For GymDocumento2 páginasAshrae Standard For GymignatiadiskAinda não há avaliações

- Prefunctional Test Checklist-12 - VavDocumento6 páginasPrefunctional Test Checklist-12 - Vavlong minn2Ainda não há avaliações

- Kiểm Tra Bởi: Checked by:: PH AÀN ĐỒDocumento1 páginaKiểm Tra Bởi: Checked by:: PH AÀN ĐỒtran viet hungAinda não há avaliações

- Ashrae Acgih Covid 19 White PaperDocumento23 páginasAshrae Acgih Covid 19 White PaperBerk KÖTEŞLİAinda não há avaliações

- Moving Air For Comfort - ASHRAE JournalDocumento12 páginasMoving Air For Comfort - ASHRAE JournalJoel TorresAinda não há avaliações

- Allied Consultants LTD.: XXXX XXXX 1. Input DataDocumento4 páginasAllied Consultants LTD.: XXXX XXXX 1. Input DataNelson VargasAinda não há avaliações

- Vibration Isolator - Kinetic Noise ControlDocumento24 páginasVibration Isolator - Kinetic Noise ControlTengku Azaha Tengku IsmailAinda não há avaliações

- Copeland ZP SeriesDocumento4 páginasCopeland ZP Seriesakram rasheed shaikAinda não há avaliações

- Terminal Unit Airflow MeasurementsDocumento6 páginasTerminal Unit Airflow MeasurementsAliAinda não há avaliações

- Autoflow System Design PDFDocumento2 páginasAutoflow System Design PDFAnonymous WNWk1h2Ainda não há avaliações

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationAinda não há avaliações

- 15-3-1 - Fire ProtectionDocumento10 páginas15-3-1 - Fire Protectionfarshan296015Ainda não há avaliações

- Janitor SinkDocumento2 páginasJanitor Sinkfarshan296015Ainda não há avaliações

- Polo KalDocumento1 páginaPolo Kalfarshan296015Ainda não há avaliações

- 15-1-2 - Hvac DuctworkDocumento15 páginas15-1-2 - Hvac Ductworkfarshan296015Ainda não há avaliações

- 15-1-1 - Air Conditioning SystemDocumento12 páginas15-1-1 - Air Conditioning Systemfarshan296015Ainda não há avaliações

- 15-1-6 - Chilled Water Piping SystemDocumento10 páginas15-1-6 - Chilled Water Piping Systemfarshan296015Ainda não há avaliações

- Pumps: SECTION 15/1/5Documento10 páginasPumps: SECTION 15/1/5farshan296015Ainda não há avaliações

- Compliance With Ashrae (HAP)Documento7 páginasCompliance With Ashrae (HAP)farshan296015Ainda não há avaliações

- 15 1 3 Mechanical InsulationDocumento7 páginas15 1 3 Mechanical Insulationfarshan296015Ainda não há avaliações

- Transfer Pumps CalculationsDocumento4 páginasTransfer Pumps Calculationsfarshan296015Ainda não há avaliações

- HAP - Hourly Analysis Program TutorialDocumento58 páginasHAP - Hourly Analysis Program Tutorialfarshan296015Ainda não há avaliações

- Turf Catalog 2016Documento188 páginasTurf Catalog 2016farshan296015Ainda não há avaliações

- 01 1419-Use of SiteDocumento2 páginas01 1419-Use of Sitefarshan296015Ainda não há avaliações

- Ventilation Calculations Knowledge Base - Design Master SoftwareDocumento3 páginasVentilation Calculations Knowledge Base - Design Master Softwarefarshan296015Ainda não há avaliações

- Robocal Air VentDocumento2 páginasRobocal Air Ventfarshan296015Ainda não há avaliações

- Fire Hydrant InstallationDocumento8 páginasFire Hydrant Installationfarshan296015100% (1)

- GI Sheet Kg-m2Documento1 páginaGI Sheet Kg-m2farshan296015Ainda não há avaliações

- 15 5 4 Plumbing FixturesDocumento1 página15 5 4 Plumbing Fixturesfarshan296015Ainda não há avaliações

- DSP LowDocumento31 páginasDSP Lowfarshan296015100% (1)

- Radiation Heat TransferDocumento11 páginasRadiation Heat Transferfarshan296015Ainda não há avaliações

- Rtac Rapid RestartDocumento2 páginasRtac Rapid Restartfarshan296015Ainda não há avaliações

- Handicap TOILET StandardDocumento5 páginasHandicap TOILET Standardfarshan296015Ainda não há avaliações

- Trane RTACDocumento54 páginasTrane RTACfarshan296015100% (1)

- Pit Installations - Restricted Airflow SituationsDocumento16 páginasPit Installations - Restricted Airflow Situationsfarshan296015Ainda não há avaliações

- Experimental Study On The Thermal Performance of R600a PDFDocumento9 páginasExperimental Study On The Thermal Performance of R600a PDFEdy MesinAinda não há avaliações

- Primary-Secondary Pumping Rules of Thumb PDFDocumento2 páginasPrimary-Secondary Pumping Rules of Thumb PDFScott FreemanAinda não há avaliações

- Daikin Magnitude Magnetic Bearing ChillersDocumento27 páginasDaikin Magnitude Magnetic Bearing ChillersIbnu HanafiAinda não há avaliações

- Ecclp360a46 Manual Chiller 30 T.R PDFDocumento5 páginasEcclp360a46 Manual Chiller 30 T.R PDFgabriel quinteroAinda não há avaliações

- Refrigeration Systems Fme19Documento9 páginasRefrigeration Systems Fme19richmond alcalaAinda não há avaliações

- Manual Termostato EspañolDocumento24 páginasManual Termostato EspañoljuancgranadoAinda não há avaliações

- Capilary Tube For Ac and RefrigeratorDocumento4 páginasCapilary Tube For Ac and RefrigeratorJoko SubagyoAinda não há avaliações

- RZQSG 125 Ly 1Documento33 páginasRZQSG 125 Ly 1Thanasis TsellosAinda não há avaliações

- American Aldes Light Commercial HRV Erv - BrochureDocumento8 páginasAmerican Aldes Light Commercial HRV Erv - Brochuredugarias9927Ainda não há avaliações

- Indoor Air Quality:: A Guide For Building Owners, Managers, and OccupantsDocumento50 páginasIndoor Air Quality:: A Guide For Building Owners, Managers, and OccupantsMurray PeartAinda não há avaliações

- ASHRAE Journal - LEED and Standard 62.1-TaylorDocumento4 páginasASHRAE Journal - LEED and Standard 62.1-TaylorNg Khanh100% (1)

- Aab Acv Cooling SystDocumento35 páginasAab Acv Cooling SystAgusto C'estimo100% (1)

- Location: Split A/C No.: Monthly PM Check List For SPLIT A/C'sDocumento1 páginaLocation: Split A/C No.: Monthly PM Check List For SPLIT A/C'ssiruslara6491Ainda não há avaliações

- Calculation of Boiler Properties: Ab&Co TT BoilersDocumento2 páginasCalculation of Boiler Properties: Ab&Co TT BoilersMarco Ordoñez0% (1)

- Operation and Service: 69NT40 - 551 - 001 TO 199Documento104 páginasOperation and Service: 69NT40 - 551 - 001 TO 199SerhiiAinda não há avaliações

- WP-2 - Locker Rooms and Humidity ProblemsDocumento2 páginasWP-2 - Locker Rooms and Humidity ProblemskprasannanAinda não há avaliações

- Manual de Reparación de Refrigeradores PDFDocumento19 páginasManual de Reparación de Refrigeradores PDFmiguel angel pavonAinda não há avaliações

- 3.bojleri Ekspanzione Posude I Cisterne PDFDocumento9 páginas3.bojleri Ekspanzione Posude I Cisterne PDFmagic888Ainda não há avaliações

- Paquete 3 A 5 TON PDFDocumento19 páginasPaquete 3 A 5 TON PDFISMAEL ENRIQUE VALENCIA JURADOAinda não há avaliações

- Natural Ventilation and Collaborative DesignDocumento5 páginasNatural Ventilation and Collaborative DesignSaran KumarAinda não há avaliações

- BS1710:1984 Pipe Identification Tape: For Marine UseDocumento1 páginaBS1710:1984 Pipe Identification Tape: For Marine UseSaswita Sakti100% (1)

- Manual Del Usuario - Termostato Programmable Commercial T7350Documento12 páginasManual Del Usuario - Termostato Programmable Commercial T7350Misa Amane MisaAinda não há avaliações

- Fire & SmokeDocumento158 páginasFire & SmokeAnonymous 7CnrWpzZf1Ainda não há avaliações

- Catalogo Perylsa CompletoDocumento221 páginasCatalogo Perylsa CompletoAlvaro Diaz0% (1)

- Company PresentatoinDocumento40 páginasCompany PresentatoinNicholas CraigAinda não há avaliações

- Priklju Ni Elementi Za Pe) I Na Kruta Goriva: Fittings For Solid Fuel StovesDocumento11 páginasPriklju Ni Elementi Za Pe) I Na Kruta Goriva: Fittings For Solid Fuel StovesAnonymous Cpe6vcAinda não há avaliações

- 5HP Quotation For Blast FreezerDocumento3 páginas5HP Quotation For Blast Freezeradriannicolau10Ainda não há avaliações

- Ashrae Isbd ReportDocumento35 páginasAshrae Isbd ReportLuciano EbangAinda não há avaliações

- 2015 Volvo XC70 2.0L Eng VIN 40 T5Documento108 páginas2015 Volvo XC70 2.0L Eng VIN 40 T5Data TécnicaAinda não há avaliações

- Train-1 Process Flow DiagramDocumento1 páginaTrain-1 Process Flow DiagramHtoo Htoo KyawAinda não há avaliações