Escolar Documentos

Profissional Documentos

Cultura Documentos

The Mechanical Properties of Steel Fibre Reinforced Concrete With Quarry Dust As A Partial Replacement of Fine Aggregate

Enviado por

IJRASETPublicationsTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

The Mechanical Properties of Steel Fibre Reinforced Concrete With Quarry Dust As A Partial Replacement of Fine Aggregate

Enviado por

IJRASETPublicationsDireitos autorais:

Formatos disponíveis

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue V, May 2018- Available at www.ijraset.com

The Mechanical Properties of Steel Fibre

Reinforced Concrete with Quarry Dust as a Partial

Replacement of Fine Aggregate

Hanumesh B. M1, Vinay V Benakanakonda2, Veeresh N Shirabadagi3, Vedashri U Chakravarti4, Banu S

Gangayikoppa5. Dr. shivakumara B6

Department of Civil Engineering, S. T. J Institute of Technology, Ranebennur. Karnataka. India

1

Assistant professor, Department of Civil Engineering

2, 3, 4 5

Bachelor of Engineering, Students [STJIT], Department of Civil Engineering.

6

The Principal STJ Institute of Technology, Ranebennur

Abstract: This present work is an attempt to use Quarry Dust as partial replacement for Sand in concrete along with the steel

fibres. Attempts have been made to study the properties of concrete and to investigate some properties of Quarry Dust reinforced

with steel fibres; this article presents the compressive and split tensile strengths of Crimped steel fibre reinforced concrete with

Quarry dust. In the experimental work natural Sand was replaced by Quarry dust in the proportion of 50% and 100%. The

Crimped steel fibres (CSF) were used in the concrete by 1 and 1.5% volume fraction. After conduction of experiments on the

cube and cylinder specimens, the results showed that, the incorporation of Crimped steel fibre reinforced concrete with 50%

Quarry dust for M20 grade of concrete increases the mechanical properties of concrete.

Keywords: Crimped steel fibre, quarry dust, compressive strength, split tensile strength, slump and compaction factor test.

I. INTRODUCTION

Concrete is the most widely used man-made construction material in the world. In the last fifty years, there has been significant

progress in concrete technology, the concrete without any fibre will develop the cracks due to plastic shrinkage, drying shrinkage

and other reasons of changes in volume of concrete. the development of these micro-cracks causes elastic deformation of concrete.

Plain concrete is a brittle material and having the values of modulus of rapture and strain capacity is low. The addition of fibres in

the plain concrete will control the cracking due to shrinkage and also reduce the bleeding of water. Fibres help to improve the post

peak ductility performance, pre crack tensile strength, fatigue strength, impact strength and eliminate temperature. Now a day’s river

erosion and other environmental issues have led to the scarcity of river sand So that excess river erosion is prevented and high

strength concrete is obtained at lower cost. One such material is Quarry stone dust, Quarry dust is a sand replacing material by-

product obtained during quarrying process. In concrete production quarry dust could be used as a partial or full replacement of

natural sand. Besides, the utilization of quarry waste, which itself is a waste material, will reduce the cost of concrete production

II. LITERATURE REVIEW

A. Several Experimental work has to be Conducted on Steel Fibre reinforced conCrete some of Them are Given beLow

1) Hanumesh B.M et. al. (2016),: in his experimental shows that the compressive and split tensile strength of concrete

increases and workability decreases with increase in the percentage of steel fibres

2) Nitin Kumar et al (2015),: in his study the addition of 1% 2% and 3% crimped steel fibres to the concrete with w/c ratio 0.35

and M40 grade of concrete shows increase strength toughness ductility and flexural strength of concret

3) Elson John et. al. (2014),: in his experimental study the addition of 0.5% and 1.0% crimped steel fibres to the concrete shows

more compressive and split tensile strength than plain concrete

4) Vikrant Vairagade et. al. (2012), : “experimental investigation on mechanical properties of steel fibre reinforced concrete” with

addition of 0% and 0.5% steel fibres it observed that for addition of 0.5% fibres shows slightly more compressive and tensile

strength than normal concrete

Several experimental work has to be conducted on replacement of natural sand with quarry dust some of them given below

5) P. Jagadeesh et. al. (2016), : in his study he was partial replace the quarry dust with 20%,30%,40% and 50%, finally he was

concluded that 50% replacement of sand with quarry dust shows an improvement in the compressive strength of the concrete.

©IJRASET: All Rights are Reserved 1521

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue V, May 2018- Available at www.ijraset.com

6) Ms. P. Sri Lakshmi Sai Teja et. al. (2013), - partial Replacement of Sand with Quarry Dust in Concrete” shows an improved in

the compressive strength of the concrete by replacing the sand with 50% of quarry dust

7) Closure: From the literature review it is observed that no work has been carried out on crimped steel fibre reinforced concrete

with quarry dust as a partial replacement of fine aggregate. We are conducted the experiment on steel fibre reinforced concrete

with quarry dust as a partial replacement of fine aggregate

III. OBJECTIVES OF THE STUDY

A. The Following are The Main Objectives of the Study

1) To find the effect of the addition of crimped steel fibre to the concrete with quarry dust as partial replacement of fine aggregate

2) To evaluate fresh properties of conventional concrete of M20 grade and concrete made with 1% and 1.5% addition of crimped

steel fibre by volume of mould and quarry dust as a partially replacement of fine aggregate. For fresh properties, slump cone

test and compaction factor tests are conducted.

3) To find out the compressive strength and split tensile strength of concrete made with 1% and 1.5% addition of crimped steel

fibre by volume of mould with and without quarry dust at 28 days of curing.

4) To evaluate the optimum dosage of crimped steel fibre and quarry dust for M20 grade of concrete to increase the mechanical

properties of concrete.

5) Comparison between reference/control concrete and concrete with crimped Steel fibre and quarry dust.

IV. MATERIALS

A. Cement

In this experimental work, Ordinary Portland Cement (OPC) 43 grade conform to IS: 8112-1989 was used for casting cubes and

cylinders for all concrete mixes. The specific gravity of cement was noticed as 3.1. The initial and final setting time was 30min and

510min respectively. The compressive strength of cement was found 46.28MPa at 28days.

B. Natural Sand

Locally available river sand confirming to zone II of IS 383-1970 was used for the project work. The specific gravity of sand was

observed as 2.64. The sieve analysis results are as shown in Fig 1.

C. Quarry Dust

In concrete production quarry dust could be used as a partial or full replacement of natural sand obtained during quarrying process.

The specific gravity of quarry dust was observed as 2.86. the typical properties and particle size distribution of quarry dust and

natural sand as shown in Table 1 and Fig 1 respectively.

Table 1

The typical chemical properties of quarry dust and natural sand (Ref: P.Jagadeesh et.al)

Constituents Quarry Dust (%) Natural Sand (%) Test method

SiO2 62.48 80.78

Al2O3 18.72 10.52

Fe2O3 6.54 1.75

CaO 4.83 3.21

IS

MgO 2.56 0.77 4032-

1968

Na2O Nil 1.37

K2O 3.18 1.23

TiO2 1.21 Nil

Loss of ignition 0.48 0.37

©IJRASET: All Rights are Reserved 1522

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue V, May 2018- Available at www.ijraset.com

Fig 1 The particle size distribution of natural sand and quarry dust

D. Coarse aggregate

Crushed natural granite aggregate from local crusher has been used and which has maximum size of 20 mm. The specific gravity of

coarse aggregate was observed as 2.78.

E. Crimped steel fibre

It is a one of the most commonly used fibre. In this project round crimped steel fibres are used. The diameter is 1mm. and length

will be 50mm. crimped steel fibres are likely to get rusted and lose some of its strengths. But investigations have shown that the

rusting of the fibres take place only at the surface. The physical properties of crimped steel fibre as shown in Table 2, and Fig 2

shows the types of steel fibres.

Table 2

Physical properties of crimped steel fibres (Ref: Elson john et al)

S.NO Property Description

1 Equivalent dia (mm) 1.0

3

2 Specific gravity (kg/m ) 7850

3 Tensile strength (Mpa) 1100

4 Young’s Modulus (Gpa) 200

5 Ultimate elongation (%) 4-10

6 Thermal conductivity (1%) 2.74

7 Aspect ratio 50

Fig. 2 Types of steel fibres

F. Water

Locally available portable water is used for making concrete and curing specimens.

©IJRASET: All Rights are Reserved 1523

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue V, May 2018- Available at www.ijraset.com

V. MIX-DESIGN AND CASTING

The cubes of inner dimensions 150x150x150 mm were cast to find out the compression strength of mixes. To evaluate the split

tensile strength, cylinders of 150 mm diameter with 300 mm height were cast. The various trial mixes are done to observe 100 mm

slump by changing w/c ratio, the 100mm slump was observed at 0.53 w/c ratio, the mixes are designed for M20 grade concrete.

Here in the IS code procedure was adopted with target strength as 26.6 N/mm2 . the obtained mix proportion as shown in Table 3,

and mix-description as shown in Table 4

All materials were weighed as per mix design separately. The cement, natural sand, coarse aggregate, quarry dust and crimped steel

fibre were dry mixed in pan mixer thoroughly till uniform mix is achieved. Required quantity of water is added to the dry mix. The

fresh concrete was placed in the mould and the compaction was adopted by mechanical vibrator. The specimens were removed from

moulds after 24 h and placed in water tank for 28 days curing. After a period of 28 days the specimens were taken out and allowed

to dry under shade, later the specimens are allowed for testing.

Table 3

Mix proportion

W/C Ratio Water (kg/m3) Cement (kg/m3) FA (kg/m3) CA (kg/m3) Mix Ratio (C:FA:CA)

0.53 234.08 372 678.43 1154.13 1:1.82:3.10

Table 4

Mix descriptions

Mix

Descriptions

designation

M0 Conventional concrete of grade M20

M1 1% of Crimped steel fibre

M2 1.5% Crimped steel fibre

M3 50% quarry dust

M4 50% quarry dust and 1% of Crimped steel fibre

M5 50% quarry dust and 1.5% of Crimped steel fibre

M6 100% quarry dust

M7 100% quarry dust and 1% of Crimped steel fibre

M8 100% quarry dust and 1.5% of Crimped steel fibre

VI. EXPERRIMENTAL RESULTS

A. Study on fresh Properties of Crimped steel Fibre Reinforced Concrete With Quarry Dust.

The concrete mixes were prepared based on the mix proportions of Table 4, workability of all mixes were observed in terms of

slump and compaction factor. These results are reported in Table 5. And variation in slump for different mixes as shown in Fig 3

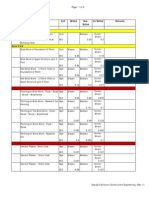

Table 5

Workability Properties of Concrete

Mix Slump in Compaction

Designation mm factor

M0 110 0.9

M1 103 0.88

M2 95 0.86

M3 96 0.92

M4 90 0.90

M5 86 0.89

M6 89 0.88

M7 83 0.87

M8 78 0.84

©IJRASET: All Rights are Reserved 1524

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue V, May 2018- Available at www.ijraset.com

Fig 3 variation in slump for different mixes

B. Study on Strength Properties of Crimped Steel Fibre Reinforced Concrete with Quarry dust (Compressive Strength Test)

The cubes and cylinders were tested as per IS 516-1959 and IS 5816-1999 to obtain compressive and split tensile strengths

respectively. The specimen was tested with manual operated compression testing machine of capacity 1000kN. The tested

specimens can be viewed in figure 4, The compressive strength test results are shown in Table 6 and in Fig 5.

Fig 4 Testing of cube and cylinder specimens in CTM

Table 6

Compressive Strength and Split tensile Strength at 28 Days

Compressive Split tensile

Mix

strength strength

Designation

(N/mm2) (N/mm2)

M0 21.94 9.43

M1 23.22 11.47

M2 25.28 12.38

M3 23.10 11.28

M4 25.86 12.10

M5 27.64 13.31

M6 19.62 8.88

M7 20.05 10.35

M8 20.78 11.09

©IJRASET: All Rights are Reserved 1525

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue V, May 2018- Available at www.ijraset.com

Fig 5 Compressive strength result for 28days curing period

C. Split Tensile Strength Test

For each concrete mix, the split tensile strength is determined on three150mm diameter and 300mm height cylinders at 28 days of

curing. Following Table 6 and Fig 6 give the split tensile strength test results of conventional concrete and steel fibre reinforced

concrete with quarry dust.

Fig 6 Split Tensile strength result for 28days curing period

VII. OBSERVATIONS AND DISCUSSIONS

A. From the experimental results and graphs the following observations are made

1) The slump of reference mix M0 is 110mm. As the percentage of fibre is increased in the mix the slump value still decreased.

Further when the natural sand is replaced with quarry dust decrease in the value of slump can be observed.

2) The compaction factor of reference mix M0 is 0.9. As the percentage of fibre is increased in the mix the compaction factor

values decreased. Further when the natural sand is replaced with quarry dust, compaction factor values got increased.

3) The compressive strength of concrete mix with only natural sand as fine aggregate without addition of crimped steel fibres is

21.94 N/mm2. The compressive strength of the concrete mix with addition of 1% and 1.5% crimped steel fibres with only

natural sand is increased by 5.83% and 15.22% respectively.

4) The compressive strength of concrete mix with 50% natural sand and 50% quarry dust without addition of crimped steel fibres

is 23.10 N/mm2. The compressive strength of concrete mix with 50% natural sand and 50% quarry dust addition with 1% and

1.5% of crimped steel fibres is increased by 11.94% and 19.65% respectively.

©IJRASET: All Rights are Reserved 1526

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue V, May 2018- Available at www.ijraset.com

5) The compressive strength of concrete mix with only quarry dust as fine aggregate without addition of crimped steel fibres is

19.62 N/mm2. The compressive strength of the concrete mix with addition of 1% and 1.5% crimped steel fibres with only

quarry dust is decrease by 2.91% and 5.91% respectively.

6) The Split tensile strength of concrete mix with only natural sand as fine aggregate without addition of crimped steel fibres is

9.43 N/mm2. The Split tensile strength of the concrete mix with addition of 1% and 1.5% crimped steel fibres with only natural

sand is increased by 21.63% and 31.28% respectively.

7) The Split tensile strength of concrete mix with 50% natural sand and 50% quarry dust without addition of crimped steel fibres is

11.28 N/mm2. The Split tensile strength of concrete mix with 50% natural sand and 50% quarry dust addition with 1% and

1.5% of crimped steel fibres is increased by 28.31% and 41.14% respectively.

8) The Split tensile strength of concrete mix with only quarry dust as fine aggregate without addition of crimped steel fibres is

8.88 N/mm2. The Split tensile strength of the concrete mix with addition of 1% and 1.5% crimped steel fibres with only quarry

dust is decrease by 9.65% and 17.6% respectively.

VIII. CONCLUSIONS

A. Use of quarry dust partial replacement of sand decreases the slump value. Hence decreasing the workability of the concrete.

Also as the fibre volume in the concrete increases, the workability in the concrete decreases.

B. As the quarry dust content in the concrete increased up to 50% increase in the compressive strength is observed. Further

increasing in the quarry dust content beyond 50% as replacement for natural sand compressive strength of concrete decreases.

C. As the percentage of the steel fibre in the concrete is increased compressive strength is also increased.

D. As the quarry dust content in the concrete increased up to 50% increase in the split tensile strength is observed. Further

increasing in the quarry dust content beyond 50% as replacement for natural sand split tensile strength of concrete decreases.

E. As the percentage of the steel fibre in the concrete is increased split tensile is also increased.

F. From the studies it is observed that, as the natural sand is replaced with quarry dust, increase in the values of compressive

strength and split tensile strength can be observed only up to 50% replacement. 50% is the optimum dosage of quarry dust for

natural sand.

REFERENCES

[1] Hanumesh B.M-“Experimental Study on the M20 Grade Cement Concrete Containing Crimped Steel Fibres” Sep-2016-IJST

[2] Elson John et al -“ the physical properties of the concrete after adding the different volume fractions of fibres are used in the concrete.” 2014-IJLRS

[3] Nitin Kumar et al-“ the use of steel fibers as reinforcement material with concrete” 2015-IJIRSE

[4] Jagadeesh-“ Influence of Quarry Dust on Compressive Strength of Concrete” 2016-IJSTE

[5] Ms. P. Sri Lakshmi Sai Teja-“ partial Replacement of Sand with Quarry Dust in Concrete” 2013-IJS

[6] Nataraja et al-“ a study on steel fiber reinforced concrete under compression” 1998-IJRE

[7] Sabapathi and Achyutha-“ stress-strain characteristics of steel fiber reinforced concrete under compression” 1989-IJSE

[8] Ganesan and Ramana Murthy-“ the stress – strain behavior of short, confined, reinforced concrete column with and without steel fibres” 1990-IJTR

[9] Anzar Hamid Mir-“ Improved Concrete Properties Using Quarry Dust as Replacement for Natural Sand” Mar-2015-IJEAR

[10] Chandana Sukesh-“ Partial Replacement of Sand with Quarry Dust in Concrete” May-2013-IJRRCM

[11] International Journal of Innovative Technology and Exploring Engineering (IJITEE)-vol 21 Nov 5- Mar 2015

[12] International Journal of Emerging Engineering Research and Technology Volume 2, Issue 4, July 2014, PP 85-95-Dr. Y. M. Ghuga

[13] Milind V. Mohod, Performance of Steel Fiber Reinforced Concrete IJCS ISSN: 2278-4721, Vol. 1, Issue 12 (December 2012)

[14] International Journal of Engineering Research and Development – IJSTE, volume 2 ,issue 4, PP 85-95, July 2014

[15] IS Codes ( IS 10262-2009, IS 383-1970, IS 516-1959, IS 5816-1999, IS 2386 (Part-3)-1963.)

©IJRASET: All Rights are Reserved 1527

Você também pode gostar

- Advances in Cement Technology: Critical Reviews and Case Studies on Manufacturing, Quality Control, Optimization and UseNo EverandAdvances in Cement Technology: Critical Reviews and Case Studies on Manufacturing, Quality Control, Optimization and UseNota: 4.5 de 5 estrelas4.5/5 (12)

- Designers' Guide To EN 1992-2 Concrete Bridges (2007)Documento381 páginasDesigners' Guide To EN 1992-2 Concrete Bridges (2007)Ialomiteanu Dan100% (7)

- Labour Productivity NormsDocumento3 páginasLabour Productivity NormsSharad Kumar67% (6)

- Study On Partial Replacement of Cement by Saw Dust Ash in ConcreteDocumento6 páginasStudy On Partial Replacement of Cement by Saw Dust Ash in ConcreteYonas D. Ebren100% (1)

- Brochure HYSTER H2.5 TX-25T PDFDocumento8 páginasBrochure HYSTER H2.5 TX-25T PDFFrancisco MoncayoAinda não há avaliações

- International Journal of Technical Innovation in Modern Engineering & Science (IJTIMES)Documento7 páginasInternational Journal of Technical Innovation in Modern Engineering & Science (IJTIMES)faumijkAinda não há avaliações

- Experimental Study of Partial Replacement of Cement by Pozzolanic MaterialsDocumento9 páginasExperimental Study of Partial Replacement of Cement by Pozzolanic MaterialsIJRASETPublicationsAinda não há avaliações

- A Comparative Study On Hardened Properties of Concrete by Partial Replacement of Cement With MetakaolinDocumento5 páginasA Comparative Study On Hardened Properties of Concrete by Partial Replacement of Cement With MetakaolinIJRASETPublicationsAinda não há avaliações

- Pk14ijciet 2014 PDFDocumento8 páginasPk14ijciet 2014 PDFAng Jun KangAinda não há avaliações

- An Experimental Study On Properties of Concrete by Partial Replacement of Sugarcane Bagasse Ash and Glass PowderDocumento12 páginasAn Experimental Study On Properties of Concrete by Partial Replacement of Sugarcane Bagasse Ash and Glass PowderIJRASETPublicationsAinda não há avaliações

- A Study of Mechanical Properties of Structural Concrete Incorporating Partial Replacement of Cement by GGBS and Natural Sand by Slag SandDocumento8 páginasA Study of Mechanical Properties of Structural Concrete Incorporating Partial Replacement of Cement by GGBS and Natural Sand by Slag SandIJRASETPublicationsAinda não há avaliações

- Partial Replacement of Cement With Marble Dust Powder in Cement ConcreteDocumento6 páginasPartial Replacement of Cement With Marble Dust Powder in Cement ConcreteMidhun JosephAinda não há avaliações

- Effect of Waste Foundry Sand As PartialDocumento4 páginasEffect of Waste Foundry Sand As Partialshivanand hippargaAinda não há avaliações

- Study On The Effect of Partial Replacement of Fly Ash and Rice Husk On Concrete PavementDocumento11 páginasStudy On The Effect of Partial Replacement of Fly Ash and Rice Husk On Concrete PavementIJRASETPublicationsAinda não há avaliações

- Self Compacting ConcreteDocumento15 páginasSelf Compacting ConcreteRadna kurniasariAinda não há avaliações

- GLASSDocumento6 páginasGLASSMR. ESHAN GHARPUREAinda não há avaliações

- 1 s2.0 S0950061820316329 MainDocumento11 páginas1 s2.0 S0950061820316329 MainKuah LaksanAinda não há avaliações

- Steel Fiber Reinforced Self-Compacting Concrete Incorporating Class F Fly AshDocumento8 páginasSteel Fiber Reinforced Self-Compacting Concrete Incorporating Class F Fly Asharshiya sultanaAinda não há avaliações

- Performance On Fly Ash Based Geopolymer Concrete With 8, 10 & 12 Molar Naoh Activator Using M40 Grade of ConcreteDocumento5 páginasPerformance On Fly Ash Based Geopolymer Concrete With 8, 10 & 12 Molar Naoh Activator Using M40 Grade of ConcreteIJRASETPublicationsAinda não há avaliações

- Assessment of Behaviour of High Performance Concrete On Incorporation of Waste MaterialsDocumento6 páginasAssessment of Behaviour of High Performance Concrete On Incorporation of Waste MaterialsIJRASETPublicationsAinda não há avaliações

- JETIRC006007Documento5 páginasJETIRC006007vyshnavkumarAinda não há avaliações

- To Investigate The Properties of Concrete Having Partial Replacement of Fine Aggregate With Copper Slag and Coarse Aggregate With Ceramic Tile WasteDocumento11 páginasTo Investigate The Properties of Concrete Having Partial Replacement of Fine Aggregate With Copper Slag and Coarse Aggregate With Ceramic Tile WasteIJRASETPublicationsAinda não há avaliações

- Effect of Fly Ash and Nano Titanium Dioxide On Compressive Strength of ConcreteDocumento5 páginasEffect of Fly Ash and Nano Titanium Dioxide On Compressive Strength of Concretesruthi jayadeepAinda não há avaliações

- 2.6. - Effects of Titanium Dioxide Nanopowder On Rheological Properties of Self Compacting ConcreteDocumento4 páginas2.6. - Effects of Titanium Dioxide Nanopowder On Rheological Properties of Self Compacting ConcreteCARLOS ALEJANDRO CABALLA OLIVARESAinda não há avaliações

- Experimental Study On Rubberized Concrete Using Zeolite and GeopolymerDocumento9 páginasExperimental Study On Rubberized Concrete Using Zeolite and GeopolymerIJRASETPublicationsAinda não há avaliações

- Development of High Strength High Performance Concrete Using Indian MetakaolinDocumento10 páginasDevelopment of High Strength High Performance Concrete Using Indian Metakaolindigvijay singhAinda não há avaliações

- Study of Effective Utilization of Waste P.E.T (Plastic) and Steel Slag To Enhance The Performance of Bitumen Based PavementDocumento8 páginasStudy of Effective Utilization of Waste P.E.T (Plastic) and Steel Slag To Enhance The Performance of Bitumen Based PavementIJRASETPublicationsAinda não há avaliações

- Partial Replacement of Sand With Sawdust in ConcreteDocumento4 páginasPartial Replacement of Sand With Sawdust in Concrete18TPCV008 DONA RENJITHAinda não há avaliações

- Replacement of Fine Aggregate With Sawdust: April 2017Documento6 páginasReplacement of Fine Aggregate With Sawdust: April 2017BAVIRISHETTY JAYKUMARAinda não há avaliações

- Comparative Study of Solid and Hollow Laterite Soil Cement Press Brick For Different ProportionDocumento14 páginasComparative Study of Solid and Hollow Laterite Soil Cement Press Brick For Different ProportionIJRASETPublicationsAinda não há avaliações

- Experimental Study On The Steel Fiber Reinforcement ConcreteDocumento6 páginasExperimental Study On The Steel Fiber Reinforcement ConcreteIJRASETPublicationsAinda não há avaliações

- Mortar Strength Using Stone Dust PDFDocumento11 páginasMortar Strength Using Stone Dust PDFbob gunnerAinda não há avaliações

- 2018-IJET (UAE) - Shrinkage PaperDocumento4 páginas2018-IJET (UAE) - Shrinkage Papersanthoshkumar thainanaAinda não há avaliações

- Study of Magnetically Driven ConcreteDocumento7 páginasStudy of Magnetically Driven ConcreteCeleste PerezAinda não há avaliações

- Investigation Into The Possibility of Partial Replacement of Cement With Bone Powder in Concrete ProductionDocumento6 páginasInvestigation Into The Possibility of Partial Replacement of Cement With Bone Powder in Concrete ProductionManuAinda não há avaliações

- Comparative Study of Concrete Using Recycled Coarse AggregateDocumento7 páginasComparative Study of Concrete Using Recycled Coarse AggregateIJRASETPublicationsAinda não há avaliações

- ScopusDocumento7 páginasScopusGODDEY ABAHAinda não há avaliações

- Investigation On Geopolymer Concrete by Using Different Mineral AdmixturesDocumento6 páginasInvestigation On Geopolymer Concrete by Using Different Mineral AdmixturesIJRASETPublicationsAinda não há avaliações

- Development of M20 and M30 Grade of Recycled Aggregate Concrete by Replacing 100% Virgin Aggregates With Recycled AggregatesDocumento7 páginasDevelopment of M20 and M30 Grade of Recycled Aggregate Concrete by Replacing 100% Virgin Aggregates With Recycled AggregatesmynameisgunaAinda não há avaliações

- An Experimental Study On High Performance Concrete Using Mineral Fly Ash and GGBS With M-60 Grade ConcreteDocumento6 páginasAn Experimental Study On High Performance Concrete Using Mineral Fly Ash and GGBS With M-60 Grade ConcreteIJRASETPublicationsAinda não há avaliações

- In Uence of Bottom Ash and Limestone Powder On The Properties of Ternary Cement and MortarDocumento13 páginasIn Uence of Bottom Ash and Limestone Powder On The Properties of Ternary Cement and Mortardummy dumdumAinda não há avaliações

- Influence of Recycling Waste Glass As Fine Aggregate On The Concrete PropertiesDocumento16 páginasInfluence of Recycling Waste Glass As Fine Aggregate On The Concrete PropertiesShaker QaidiAinda não há avaliações

- Study of Gold Mine Tailings Utilization As Fine Aggregate Material For Producing Shotcrete Based On Concept of Green TechnologyDocumento11 páginasStudy of Gold Mine Tailings Utilization As Fine Aggregate Material For Producing Shotcrete Based On Concept of Green TechnologyWisam BadarAinda não há avaliações

- Effect of Pozzolanic Materials On Fiber Reinforced ConcreteDocumento8 páginasEffect of Pozzolanic Materials On Fiber Reinforced ConcreteIJRASETPublicationsAinda não há avaliações

- Strength and Duriabilty Properties of Concrete With Partial Replacement of Cement With Metakaolin and Marble Dust IJERTV4IS070881Documento4 páginasStrength and Duriabilty Properties of Concrete With Partial Replacement of Cement With Metakaolin and Marble Dust IJERTV4IS070881اسد راجAinda não há avaliações

- Foamed Cocncrete With Carbon FiberDocumento14 páginasFoamed Cocncrete With Carbon FiberVirga PriyoAinda não há avaliações

- Analysis of Self Compacting Concrete by Partial Replacement of Cement With Industrial Waste Under Variable TemperatureDocumento33 páginasAnalysis of Self Compacting Concrete by Partial Replacement of Cement With Industrial Waste Under Variable TemperatureThe CiVil Engineering ESEAinda não há avaliações

- Jurnal Beton Busa PDFDocumento8 páginasJurnal Beton Busa PDFIqbalArifkyAinda não há avaliações

- Study On The Strength of Glass Fiber Reinforcement Concrete With Fragmentary ReplacementDocumento6 páginasStudy On The Strength of Glass Fiber Reinforcement Concrete With Fragmentary ReplacementIJRASETPublicationsAinda não há avaliações

- Ground Granulated Blast Furnace Slag (GGBS) : Effect of Particle Size and Dosage On Compressive Strength With Microstructural Analysis of ConcreteDocumento8 páginasGround Granulated Blast Furnace Slag (GGBS) : Effect of Particle Size and Dosage On Compressive Strength With Microstructural Analysis of ConcreteIJRASETPublicationsAinda não há avaliações

- Experimental Study On Properties of Concrete Using Industrial Waste Ceramic and Stone Dust With Partial Replacement of Cement and SandDocumento4 páginasExperimental Study On Properties of Concrete Using Industrial Waste Ceramic and Stone Dust With Partial Replacement of Cement and SandEditor IJTSRDAinda não há avaliações

- Benefits of Fe2O3 Nanoparticles in Concrete MixingDocumento6 páginasBenefits of Fe2O3 Nanoparticles in Concrete MixingyousifAinda não há avaliações

- Study of Partial Replacement of Cement Using Cow Dung Ash and Marble Dust Combination and Sand Using Glass PowderDocumento7 páginasStudy of Partial Replacement of Cement Using Cow Dung Ash and Marble Dust Combination and Sand Using Glass PowderIJRASETPublicationsAinda não há avaliações

- Author Version ManuscriptDocumento24 páginasAuthor Version Manuscriptlahcen essAinda não há avaliações

- Research Paper On Optimum Addition of Glass Powder in For Replacement of CementDocumento5 páginasResearch Paper On Optimum Addition of Glass Powder in For Replacement of CementJain SourabhAinda não há avaliações

- JETIR2302051Documento8 páginasJETIR2302051pramod Kumar sahaniAinda não há avaliações

- Foundry Sand Utilisation As A Partial Re PDFDocumento4 páginasFoundry Sand Utilisation As A Partial Re PDFHarshit KumarAinda não há avaliações

- To Investigate The Behavior of Concrete by Partial Replacement of Stone Dust With Fine Aggregates and Tobacco Waste Ash With CementDocumento10 páginasTo Investigate The Behavior of Concrete by Partial Replacement of Stone Dust With Fine Aggregates and Tobacco Waste Ash With CementIJRASETPublicationsAinda não há avaliações

- Comparative Study On The Effects of Steel Slag Aggregate Over Blended Cement ConcreteDocumento12 páginasComparative Study On The Effects of Steel Slag Aggregate Over Blended Cement ConcreteIJRASETPublicationsAinda não há avaliações

- Analysis of Mix Design of Concrete Using Ceramic WasteDocumento6 páginasAnalysis of Mix Design of Concrete Using Ceramic WasteEditor IJAERDAinda não há avaliações

- Mini Project Final ReviewDocumento19 páginasMini Project Final Reviewjagandas chouhanAinda não há avaliações

- Effect of Palm Oil Fuel Ash Fineness On Packing Effect and Pozzolanic Reaction of Blended Cement PasteDocumento9 páginasEffect of Palm Oil Fuel Ash Fineness On Packing Effect and Pozzolanic Reaction of Blended Cement PasteRameshNayakaAinda não há avaliações

- Design and Analysis of Components in Off-Road VehicleDocumento23 páginasDesign and Analysis of Components in Off-Road VehicleIJRASETPublicationsAinda não há avaliações

- Design and Analysis of Fixed-Segment Carrier at Carbon Thrust BearingDocumento10 páginasDesign and Analysis of Fixed-Segment Carrier at Carbon Thrust BearingIJRASETPublicationsAinda não há avaliações

- Advanced Wireless Multipurpose Mine Detection RobotDocumento7 páginasAdvanced Wireless Multipurpose Mine Detection RobotIJRASETPublicationsAinda não há avaliações

- IoT-Based Smart Medicine DispenserDocumento8 páginasIoT-Based Smart Medicine DispenserIJRASETPublications100% (1)

- 11 V May 2023Documento34 páginas11 V May 2023IJRASETPublicationsAinda não há avaliações

- Air Conditioning Heat Load Analysis of A CabinDocumento9 páginasAir Conditioning Heat Load Analysis of A CabinIJRASETPublicationsAinda não há avaliações

- BIM Data Analysis and Visualization WorkflowDocumento7 páginasBIM Data Analysis and Visualization WorkflowIJRASETPublicationsAinda não há avaliações

- TNP Portal Using Web Development and Machine LearningDocumento9 páginasTNP Portal Using Web Development and Machine LearningIJRASETPublicationsAinda não há avaliações

- Controlled Hand Gestures Using Python and OpenCVDocumento7 páginasControlled Hand Gestures Using Python and OpenCVIJRASETPublicationsAinda não há avaliações

- Real Time Human Body Posture Analysis Using Deep LearningDocumento7 páginasReal Time Human Body Posture Analysis Using Deep LearningIJRASETPublications100% (1)

- A Review On Speech Emotion Classification Using Linear Predictive Coding and Neural NetworksDocumento5 páginasA Review On Speech Emotion Classification Using Linear Predictive Coding and Neural NetworksIJRASETPublicationsAinda não há avaliações

- Design and Development of Cost-Effective 3D-PrinterDocumento7 páginasDesign and Development of Cost-Effective 3D-PrinterIJRASETPublicationsAinda não há avaliações

- Skill Verification System Using Blockchain SkillVioDocumento6 páginasSkill Verification System Using Blockchain SkillVioIJRASETPublicationsAinda não há avaliações

- Design and Analysis of Fixed Brake Caliper Using Additive ManufacturingDocumento9 páginasDesign and Analysis of Fixed Brake Caliper Using Additive ManufacturingIJRASETPublicationsAinda não há avaliações

- Skin Lesions Detection Using Deep Learning TechniquesDocumento5 páginasSkin Lesions Detection Using Deep Learning TechniquesIJRASETPublicationsAinda não há avaliações

- Comparative in Vivo Study On Quality Analysis On Bisacodyl of Different BrandsDocumento17 páginasComparative in Vivo Study On Quality Analysis On Bisacodyl of Different BrandsIJRASETPublicationsAinda não há avaliações

- Credit Card Fraud Detection Using Machine Learning and BlockchainDocumento9 páginasCredit Card Fraud Detection Using Machine Learning and BlockchainIJRASETPublications100% (1)

- A Blockchain and Edge-Computing-Based Secure Framework For Government Tender AllocationDocumento10 páginasA Blockchain and Edge-Computing-Based Secure Framework For Government Tender AllocationIJRASETPublicationsAinda não há avaliações

- Real-Time Video Violence Detection Using CNNDocumento7 páginasReal-Time Video Violence Detection Using CNNIJRASETPublicationsAinda não há avaliações

- Low Cost Scada System For Micro IndustryDocumento5 páginasLow Cost Scada System For Micro IndustryIJRASETPublicationsAinda não há avaliações

- An Automatic Driver's Drowsiness Alert SystemDocumento7 páginasAn Automatic Driver's Drowsiness Alert SystemIJRASETPublications100% (1)

- Smart Video Surveillance Using YOLO Algorithm and OpenCVDocumento8 páginasSmart Video Surveillance Using YOLO Algorithm and OpenCVIJRASETPublications100% (1)

- Literature Review For Study of Characteristics of Traffic FlowDocumento10 páginasLiterature Review For Study of Characteristics of Traffic FlowIJRASETPublicationsAinda não há avaliações

- CryptoDrive A Decentralized Car Sharing SystemDocumento9 páginasCryptoDrive A Decentralized Car Sharing SystemIJRASETPublications100% (1)

- Structural Design of Underwater Drone Using Brushless DC MotorDocumento9 páginasStructural Design of Underwater Drone Using Brushless DC MotorIJRASETPublicationsAinda não há avaliações

- Vehicles Exhaust Smoke Detection and Location TrackingDocumento8 páginasVehicles Exhaust Smoke Detection and Location TrackingIJRASETPublications100% (1)

- Application For Road Accident RescueDocumento18 páginasApplication For Road Accident RescueIJRASETPublications100% (1)

- Achieving Maximum Power Point Tracking With Partial ShadingDocumento10 páginasAchieving Maximum Power Point Tracking With Partial ShadingIJRASETPublicationsAinda não há avaliações

- Preparation of Herbal Hair DyeDocumento12 páginasPreparation of Herbal Hair DyeIJRASETPublications100% (1)

- Askelandphulenotes Ch01printableDocumento24 páginasAskelandphulenotes Ch01printableShivashankrappa BalawatAinda não há avaliações

- Dental Polymers Applied AspectsDocumento29 páginasDental Polymers Applied AspectsRajat DabholkarAinda não há avaliações

- Low Modulus 1 Part Polyurethane SealantDocumento2 páginasLow Modulus 1 Part Polyurethane SealantVietpapayaAinda não há avaliações

- Flexural Design of Beams To EC2 (2014 10 07)Documento48 páginasFlexural Design of Beams To EC2 (2014 10 07)L YO Pin100% (1)

- Automotive Engine Components DesignDocumento15 páginasAutomotive Engine Components DesignSathistrnpcAinda não há avaliações

- Reinforced C Vol IDocumento4 páginasReinforced C Vol IParth GajjarAinda não há avaliações

- Data Sheet Exxelor Maleic Anhydride Function Ali Zed EP VA 1803Documento2 páginasData Sheet Exxelor Maleic Anhydride Function Ali Zed EP VA 1803maheshgupte100% (1)

- Rocktrans Conveyor BeltDocumento11 páginasRocktrans Conveyor BeltDedi Sumaha WijayaAinda não há avaliações

- Plastic Identification ChartDocumento1 páginaPlastic Identification Chartmohammad100% (1)

- Continuously Transposed Conductors: Essex Italy SpaDocumento15 páginasContinuously Transposed Conductors: Essex Italy SpashasailappanAinda não há avaliações

- R.H. Bogue Has Identified Four Major CompoundsDocumento45 páginasR.H. Bogue Has Identified Four Major Compoundsbhkedar100% (1)

- Velloils High Temperature & Speciality Grease Velloplex GreaseDocumento6 páginasVelloils High Temperature & Speciality Grease Velloplex GreaseBhusarapu SrinivasAinda não há avaliações

- Constn Price List January 2011 FinalDocumento40 páginasConstn Price List January 2011 FinalBurak BaşAinda não há avaliações

- Etabs - Column Calculation ReportDocumento1 páginaEtabs - Column Calculation Reportkhlee.mitraAinda não há avaliações

- The Composition and Crystallography of An Anhydrous Calcium Aluminosulphate Occurring in Expanding Cement PDFDocumento5 páginasThe Composition and Crystallography of An Anhydrous Calcium Aluminosulphate Occurring in Expanding Cement PDFyinglvAinda não há avaliações

- Bis Standards & Specifications PDFDocumento9 páginasBis Standards & Specifications PDFPrabish KumarAinda não há avaliações

- Emm5706 - Lecture 04Documento41 páginasEmm5706 - Lecture 04JayAinda não há avaliações

- Somplan AS: Installation InstructionsDocumento3 páginasSomplan AS: Installation Instructionsaszklm105Ainda não há avaliações

- CASSAVA Manihot Esculenta PEELINGS AND UDocumento6 páginasCASSAVA Manihot Esculenta PEELINGS AND Ujhee SepriaAinda não há avaliações

- Fundamentals of ConcreteDocumento54 páginasFundamentals of ConcreteNolan PillayAinda não há avaliações

- Styro Lution Tds 400900240714Documento3 páginasStyro Lution Tds 400900240714vrjrAinda não há avaliações

- Method Statement All-Hbc PDFDocumento62 páginasMethod Statement All-Hbc PDFĐoàn Anh ĐứcAinda não há avaliações

- Cement, Gypsum Product, Quartz SandDocumento14 páginasCement, Gypsum Product, Quartz SandHuda FauziAinda não há avaliações

- Chemical and Physical Properties of PerliteDocumento11 páginasChemical and Physical Properties of PerlitekevinAinda não há avaliações

- Concrete Handbook - 1Documento198 páginasConcrete Handbook - 1Eko Santoso100% (1)

- Indian Institute of Welding - Anb Refresher Course - Module 01Documento65 páginasIndian Institute of Welding - Anb Refresher Course - Module 01aravindanAinda não há avaliações

- Kronos 2160 UsDocumento1 páginaKronos 2160 UsMi MonAinda não há avaliações