Escolar Documentos

Profissional Documentos

Cultura Documentos

Lifting Lugs Design Per ASME BTH-1-2005 PDF

Enviado por

HernâniCruzDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Lifting Lugs Design Per ASME BTH-1-2005 PDF

Enviado por

HernâniCruzDireitos autorais:

Formatos disponíveis

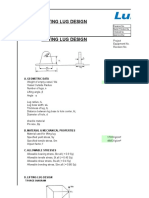

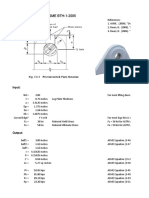

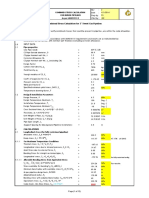

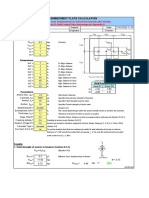

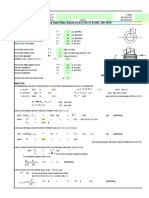

Lifting Lug Design Per ASME BTH-1-2005

Input:

Nd = 2,00

t= 0,472441 inches Lug Plate Thickness

a= 2,066929 inches

Dp = 1,259843 inches

be = 2,066929 inches

Dh = 1,377953 inches

Curved Edge? N Y or N

Fy = 34,08 ksi Material Yield Stress

Fu = 52,21 ksi Material Ultimate Stress

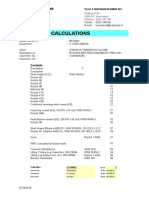

Output:

beff1 = 1,89 inches ASME Equation (3-46).

beff2 = 1,55 inches ASME Equation (3-47).

beff = 1,55 inches

r = 2,755906 inches

R = 2,755906 inches

Z' = 0,00 inches ASME Equation (C3-2).

Av = 2,14 sq. inches ASME Equation (3-50) modified per Commentary.

Pt = 31,89 kips ASME Equation (3-45).

Pb = 31,82 kips ASME Equation (3-48).

Pv = 32,64 kips ASME Equation (3-49).

Pp = 12,68 kips ASME Equation (3-51)*Dp*t.

3

2

1

0 08/07/2018 Projeto H.T.C. MC.

Revisão Data Designação Elaborou Verificou Aprovou

Pin Diameter Effect:

Dh/Dp = 1,09

Check All? Y Y or N. Check even when Dh/Dp <= 1.1? (Input)

Cr = 0,889 Reduction Factor Ref. 2 Equation (6)

phi = 50,286 Degrees Ref.2 Equation (9)

Z= 2,294 Inches Ref. 2 Equation (20)

Z' = 0,000 Inches Ref. 2 Equation (21)

Av = 2,17 sq. inches

Pt = 28,33 kips

Pb = 28,28 kips

Pv = 33,01 kips

Pp = 12,68 kips

Max. P = 12,68 kips

Você também pode gostar

- Lifting Lug Design Per ASME BTH-1Documento8 páginasLifting Lug Design Per ASME BTH-1luis nunezAinda não há avaliações

- 25 Lifting Lug Design Per ASME BTH-1-2005Documento6 páginas25 Lifting Lug Design Per ASME BTH-1-2005luis nunezAinda não há avaliações

- Design Data 610 3450 9.5 1650 2 3300 2 1650 120Documento3 páginasDesign Data 610 3450 9.5 1650 2 3300 2 1650 120miteshpatel191100% (1)

- Lug Design R4, ASME BTH-1Documento4 páginasLug Design R4, ASME BTH-1chuckhsu1248Ainda não há avaliações

- ASME BTH-1 Lifting Lug DesignDocumento4 páginasASME BTH-1 Lifting Lug DesignTim McCorkle50% (2)

- Spreader Beam (Planning)Documento28 páginasSpreader Beam (Planning)AKSHAY BHATKARAinda não há avaliações

- Spreader BarDocumento5 páginasSpreader Barmramico100% (1)

- Lifting Lug STD Design 5tDocumento3 páginasLifting Lug STD Design 5trustamriyadi50% (2)

- Lifting Lug Design (3064)Documento37 páginasLifting Lug Design (3064)Ganesh Bhardwaj50% (2)

- Design of Lifting LugDocumento7 páginasDesign of Lifting Luga_toups100% (1)

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionDocumento3 páginas"Lifting - Lug" - Lifting Lug Analysis: Program DescriptionNicoleta cristianAinda não há avaliações

- Lifting Lug SampleDocumento1 páginaLifting Lug Sampleabdul marpaung0% (1)

- Spreader Bar CalculationDocumento2 páginasSpreader Bar Calculationmahhor82_63564383870% (10)

- Spreader Bar Plus Free BodyDocumento17 páginasSpreader Bar Plus Free BodyMichael HaiseAinda não há avaliações

- Spreader Beam: ASME BTH-1: InputsDocumento17 páginasSpreader Beam: ASME BTH-1: InputsGokul AmarnathAinda não há avaliações

- Vitec Equipments PVT LTD Filename: Spreader Beam CalculationDocumento48 páginasVitec Equipments PVT LTD Filename: Spreader Beam CalculationDarshan PanchalAinda não há avaliações

- Lifting Lug Analysis (Asd) : ASME Notation AISC Preferred Geometry AISC Alternate GeometryDocumento2 páginasLifting Lug Analysis (Asd) : ASME Notation AISC Preferred Geometry AISC Alternate GeometryJohn PacelloAinda não há avaliações

- Pad Eye Design CalculationDocumento7 páginasPad Eye Design CalculationLưu Xuân0% (1)

- Padeye CheckDocumento12 páginasPadeye CheckBen100% (1)

- Din 28086Documento9 páginasDin 28086Fer VF100% (1)

- Appendix B Design Example Lifting LugDocumento6 páginasAppendix B Design Example Lifting LugfernandoAinda não há avaliações

- Spreader Bar Calc REF.Documento34 páginasSpreader Bar Calc REF.Gokul AmarnathAinda não há avaliações

- Most Applications, F.S. 5.0) : Calculation ReferenceDocumento5 páginasMost Applications, F.S. 5.0) : Calculation ReferenceParthibanAinda não há avaliações

- Design of Pad Eye Using Check PlatesDocumento3 páginasDesign of Pad Eye Using Check Plateshyoung65Ainda não há avaliações

- Lifting LugDocumento5 páginasLifting LugFarid Tata100% (1)

- Lifting Lug DesignDocumento4 páginasLifting Lug DesignRohith V VAinda não há avaliações

- Saddle Stresses On Shell During Transportation: Equipment NoDocumento5 páginasSaddle Stresses On Shell During Transportation: Equipment NoshazanAinda não há avaliações

- 6a Padeye Aisc 360 2005Documento6 páginas6a Padeye Aisc 360 2005mjlazoAinda não há avaliações

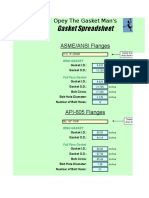

- Gasket Dimension (ASME B16.5 & B16.47)Documento4 páginasGasket Dimension (ASME B16.5 & B16.47)ama100% (1)

- Lifting Lug DesignDocumento27 páginasLifting Lug Designmramico100% (1)

- Lifting Lug DesignDocumento17 páginasLifting Lug Designguravdr100% (2)

- Lifting Beam CalculationDocumento2 páginasLifting Beam Calculationsalman1566Ainda não há avaliações

- Sparta Spreader Bar CalculatorDocumento1 páginaSparta Spreader Bar CalculatorNalini MathuraAinda não há avaliações

- Calculation Lifting LugDocumento4 páginasCalculation Lifting Lugelang purbayaAinda não há avaliações

- Lifting Beam CalculationDocumento2 páginasLifting Beam CalculationAnonymous BzGb2fnfE50% (2)

- Lifting Lug Design-MrDocumento5 páginasLifting Lug Design-MrMiguelRagasAinda não há avaliações

- Pad Eye New ReleaseDocumento10 páginasPad Eye New ReleaseEnrique BarajasAinda não há avaliações

- Lifting Lug DesignDocumento18 páginasLifting Lug DesignRui Salvador0% (1)

- Lifting Lug CalculationDocumento7 páginasLifting Lug CalculationErin JohnsonAinda não há avaliações

- Mathcad - Spreader Bar FinalDocumento4 páginasMathcad - Spreader Bar FinalOkondu Chiedu100% (3)

- Lifting Lug CalculationDocumento5 páginasLifting Lug CalculationEm Mar100% (2)

- Perhitungan Untuk Mencari Alat Bantu AngkatDocumento6 páginasPerhitungan Untuk Mencari Alat Bantu AngkatGame Just forAinda não há avaliações

- Combined Stress Calc Rev. 2Documento12 páginasCombined Stress Calc Rev. 2babu75% (4)

- Reference:: Design of Axially Loaded Tied ColumnsDocumento4 páginasReference:: Design of Axially Loaded Tied ColumnsjezAinda não há avaliações

- Ejma 8TDocumento3 páginasEjma 8TpiziyuAinda não há avaliações

- Mẫu Thiết Kế Tính ToánDocumento2 páginasMẫu Thiết Kế Tính ToánNhật NguyễnAinda não há avaliações

- H.E WordDocumento62 páginasH.E WordPatricia MirandaAinda não há avaliações

- 15-Cold Formed 2021Documento35 páginas15-Cold Formed 2021karim hassanAinda não há avaliações

- Embedded Plates Calculation - Part 2Documento8 páginasEmbedded Plates Calculation - Part 2Mai CAinda não há avaliações

- Splice Connection CHSDocumento180 páginasSplice Connection CHSRaveendra Babu Cherukuri100% (2)

- Steel BaleDocumento15 páginasSteel BaleRisman YusufAinda não há avaliações

- Project Name DOC. No.: Tank Name Rev No.: Item No.Documento4 páginasProject Name DOC. No.: Tank Name Rev No.: Item No.AnggaAinda não há avaliações

- API Calcs Rev1 Version 2Documento107 páginasAPI Calcs Rev1 Version 2JithuJohnAinda não há avaliações

- API 570 Exam CalculationsDocumento2 páginasAPI 570 Exam Calculationssnehal.deshmukhAinda não há avaliações

- Exce-Anclaje Al Concreto - Rosales Mendoza WaldoDocumento5 páginasExce-Anclaje Al Concreto - Rosales Mendoza WaldoGabbo pnukAinda não há avaliações

- Gas Pipeline Blowdown TimeDocumento7 páginasGas Pipeline Blowdown TimeBui Khoi NguyenAinda não há avaliações

- Gas Pipeline Blowdown TimeDocumento7 páginasGas Pipeline Blowdown TimeKarun DasAinda não há avaliações

- Shell Long Residu: Lampiran A PerhitunganDocumento12 páginasShell Long Residu: Lampiran A PerhitunganJulia Dwi LestariAinda não há avaliações

- Under Re - Attachment (Elastic Bend)Documento4 páginasUnder Re - Attachment (Elastic Bend)ISRAEL PORTILLOAinda não há avaliações

- Solution Manual for an Introduction to Equilibrium ThermodynamicsNo EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsAinda não há avaliações

- Accidental Damage Protection Services Agreement Important NoticeDocumento4 páginasAccidental Damage Protection Services Agreement Important NoticeHernâniCruzAinda não há avaliações

- FRAME MetricDocumento7 páginasFRAME MetricHernâniCruzAinda não há avaliações

- Vessel VolumesDocumento61 páginasVessel VolumesHernâniCruzAinda não há avaliações

- 06 Matrix BeamDocumento148 páginas06 Matrix BeamArif WaitsAinda não há avaliações

- VV Manual v1.1 PDFDocumento111 páginasVV Manual v1.1 PDFHernâniCruzAinda não há avaliações

- Lug Design R4Documento4 páginasLug Design R4Esapermana RiyanAinda não há avaliações

- Restaurantes A ExperimentarDocumento1 páginaRestaurantes A ExperimentarHernâniCruzAinda não há avaliações

- Restaurantes A ExperimentarDocumento1 páginaRestaurantes A ExperimentarHernâniCruzAinda não há avaliações

- Val Vent EmergDocumento4 páginasVal Vent EmergHernâniCruzAinda não há avaliações

- Restaurantes A ExperimentarDocumento1 páginaRestaurantes A ExperimentarHernâniCruzAinda não há avaliações

- Restaurantes A Experimentar Pedra Bela - Santa Maria Da FeiraDocumento1 páginaRestaurantes A Experimentar Pedra Bela - Santa Maria Da FeiraHernâniCruzAinda não há avaliações