Escolar Documentos

Profissional Documentos

Cultura Documentos

Oil Analysis Charge and Cleaning: Item Unit Test Method Limit

Enviado por

Jose Yebra DeaunaDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Oil Analysis Charge and Cleaning: Item Unit Test Method Limit

Enviado por

Jose Yebra DeaunaDireitos autorais:

Formatos disponíveis

Oil analysis charge and cleaning

After about 500 operating hours the oil must be changed for the first time. Drain the oil

soon after stopping the gear unit while the oil is still warm.

The lubrication oil should be replaced periodically in accordance with " Lubricating Oil

and Grease List “

I t i s also required to take oil sample from lube oil tank, and to investigate the oil quality,

ferrous sediment analysis if any, by a lubricant oil manufacturer. Oil sample analysis

should be required every 3 months. When the oil quality is degraded and contaminated ,

and beyond oil manufacturer’s guideline, it is time to replace the oil. Complete oil

replacement is necessary. At the time, lube oil tank inside and piping should be cleaned

by using flushing oil. Though an oil manufacture accepts to keep using present oil based

on sample analysis, oil must be replaced one per maximum 2 years. Oil analysis results by

oil manufacture should be kept by customer, so that oil quality change can be clearly

confirmed. A guideline of lubrication oil quality monitoring is given bellow for reference.

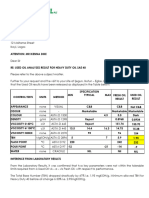

Guideline of oil monitoring (For reference)

Item Unit Test Limit

method

Kinematic viscosity mm^2/s ASTM D445 ISO VG220 : 187- 253

ISO VG320 : 272 - 368

Water content % ASTM D6304 Max. 1

Acid number MgKOH/g ASTM D664 Max.1.4

Pentane insolbles % ASTM D893 Max.0.1

Element Fe ppm ICP Max.250

Cu ppm ICP Max.75

Pb ppm ICP Max.75

AI ppm ICP Max.50

Si ppm ICP Max.100

When changing the oil, the gear unit should be refilled with the previously used grade of

o i l . D i f f e r e n t g r a d e s o f o i l o r oils obtained from different manufacturer should not be

mixed.

Você também pode gostar

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityNo EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityNota: 3 de 5 estrelas3/5 (4)

- Jordan Petroleum Refinery Co. Ltd. Gasoline 90 Specification QS-PL 103 Laboratories & Quality Control DepartmentDocumento2 páginasJordan Petroleum Refinery Co. Ltd. Gasoline 90 Specification QS-PL 103 Laboratories & Quality Control DepartmentMohammed NuseirAinda não há avaliações

- 4240 Motor Oil SN 20w 50Documento1 página4240 Motor Oil SN 20w 50Fer YanezAinda não há avaliações

- Rpo SpecificationDocumento2 páginasRpo SpecificationMayuresh Sudhir MokalAinda não há avaliações

- PH 474A-K - Synthetic Gear Oil - Extreme Pressure (EP)Documento4 páginasPH 474A-K - Synthetic Gear Oil - Extreme Pressure (EP)dfbdfbfdbfbAinda não há avaliações

- Turbine Oil PresentationDocumento30 páginasTurbine Oil PresentationVahidAinda não há avaliações

- Wartsila Data SheetDocumento1 páginaWartsila Data SheetMohamed MusaAinda não há avaliações

- Mitsubishi Diesel Engine Technical Information: Mitsubishi Heavy Industries, LTDDocumento4 páginasMitsubishi Diesel Engine Technical Information: Mitsubishi Heavy Industries, LTDMoniru islamAinda não há avaliações

- Repsol DXR 8 - 1 v1 15w40Documento1 páginaRepsol DXR 8 - 1 v1 15w40thrharsrgAinda não há avaliações

- Shell V Power Product Information 2013Documento1 páginaShell V Power Product Information 2013AKMAL RASYID PRIYONOAinda não há avaliações

- Elite Cosmos High Performance 5W-40: LubricantsDocumento1 páginaElite Cosmos High Performance 5W-40: Lubricantstehnicar1Ainda não há avaliações

- Divyol Naphthenic OilDocumento1 páginaDivyol Naphthenic OilJonas lumbuAinda não há avaliações

- Biodiesel Standards & PropertiesDocumento6 páginasBiodiesel Standards & PropertiesMarta Lopez BerralAinda não há avaliações

- RP Elite Super 20w50 en tcm14-189601Documento1 páginaRP Elite Super 20w50 en tcm14-189601ChemilomAinda não há avaliações

- Product Specifications & Usage, Quality Checks & QC Indexing ForDocumento69 páginasProduct Specifications & Usage, Quality Checks & QC Indexing ForAshwani Singh BaghelAinda não há avaliações

- Bio Diesel b20, En590 b5 SpecificationsDocumento1 páginaBio Diesel b20, En590 b5 Specificationsmohammed wajidAinda não há avaliações

- Repsol Diesel Turbo THPD MLX 15W40Documento1 páginaRepsol Diesel Turbo THPD MLX 15W40randiAinda não há avaliações

- Enersyn MP-S RangeDocumento2 páginasEnersyn MP-S RangecarmaAinda não há avaliações

- IP2028 DowpolDocumento1 páginaIP2028 DowpolRhea TalibAinda não há avaliações

- Indian Standard Specification For Petroleum Products-2019Documento15 páginasIndian Standard Specification For Petroleum Products-2019Ganesh BhandaryAinda não há avaliações

- REPSOL GXR PlatinumDocumento1 páginaREPSOL GXR PlatinumAankz AnggoroAinda não há avaliações

- Rop 10 Ton Per Day Internal Tanpa LahanDocumento26 páginasRop 10 Ton Per Day Internal Tanpa Lahanhadi prasetio100% (1)

- Engine Oil Test Results and Recommendations To Interkels - 07082019Documento2 páginasEngine Oil Test Results and Recommendations To Interkels - 07082019Georgina SuleAinda não há avaliações

- L-TSE Turbine OilDocumento3 páginasL-TSE Turbine OilYoong TanAinda não há avaliações

- Proven: Solid Partners SolutionsDocumento4 páginasProven: Solid Partners SolutionskevinAinda não há avaliações

- HO PLUS 32-PLUS 46 - Hydraulic Oil (HEES)Documento2 páginasHO PLUS 32-PLUS 46 - Hydraulic Oil (HEES)azimchemAinda não há avaliações

- REPSOL GXR EURO 5W40 v1 1Documento1 páginaREPSOL GXR EURO 5W40 v1 1Yousra MenotyAinda não há avaliações

- Aqualub 3040 Sae 30 TBN 40Documento1 páginaAqualub 3040 Sae 30 TBN 40selett0Ainda não há avaliações

- Racing 2t enDocumento1 páginaRacing 2t enCojocaru CatalinAinda não há avaliações

- Elite Cosmos High Performance 0w40 tcm14-190638Documento1 páginaElite Cosmos High Performance 0w40 tcm14-190638tehnicar1Ainda não há avaliações

- Repsol MXR Matic Platinum: LubricantsDocumento1 páginaRepsol MXR Matic Platinum: Lubricantskata annezAinda não há avaliações

- Requirements and Oil Quality: Installation ManualDocumento10 páginasRequirements and Oil Quality: Installation ManualABDUL REHMAN PIPRANIAinda não há avaliações

- Onyx 53000 - Api SN SMDocumento2 páginasOnyx 53000 - Api SN SMThaer HamedeAinda não há avaliações

- Spakester 9260 - and - Spakester 1192 1Documento1 páginaSpakester 9260 - and - Spakester 1192 1Menoddin shaikhAinda não há avaliações

- Repsol Diesel Serie 3 10wDocumento1 páginaRepsol Diesel Serie 3 10wthrharsrgAinda não há avaliações

- Product TDS-1475Documento1 páginaProduct TDS-1475Company EcoplastAinda não há avaliações

- Diesel Turbo THPD 15w40 tcm14-190015Documento2 páginasDiesel Turbo THPD 15w40 tcm14-190015Zeta QrsAinda não há avaliações

- RP MOTO TOWN 4T 20W50 EN tcm14-56018Documento1 páginaRP MOTO TOWN 4T 20W50 EN tcm14-56018TakAinda não há avaliações

- Bouri Crude Oil1Documento24 páginasBouri Crude Oil1زينب فرجAinda não há avaliações

- Eiffel Presti Silver 4at 10W40 SLDocumento1 páginaEiffel Presti Silver 4at 10W40 SLShuvo MahmudAinda não há avaliações

- HTS and HPC Specification DifferencesDocumento11 páginasHTS and HPC Specification Differencesmohammed kareemAinda não há avaliações

- Biodeisel Using FuelProDocumento4 páginasBiodeisel Using FuelProSylab InstrumentsAinda não há avaliações

- Lubrizonic Lz-1643 Gear Oil AdditiveDocumento1 páginaLubrizonic Lz-1643 Gear Oil AdditiveMuhammad WaqasAinda não há avaliações

- Elite Cosmos A3 b4 0w-40 enDocumento2 páginasElite Cosmos A3 b4 0w-40 enFaisal RidhoAinda não há avaliações

- Transmissions To4 10w 30 and 50 en tcm14-189615Documento1 páginaTransmissions To4 10w 30 and 50 en tcm14-189615agung fals dwi cahyonoAinda não há avaliações

- ISO 8217 2017 Residual Marine FuelsDocumento2 páginasISO 8217 2017 Residual Marine Fuelsasad razaAinda não há avaliações

- Turbine Oil Specifications TGO2-0171-E00000/B 02.03.16Documento7 páginasTurbine Oil Specifications TGO2-0171-E00000/B 02.03.16balaji3110Ainda não há avaliações

- Aeroshell Fluid 3Documento2 páginasAeroshell Fluid 3mertaktayAinda não há avaliações

- Leader Neo 10W-30 enDocumento2 páginasLeader Neo 10W-30 ennitty shiggersAinda não há avaliações

- Hi-Perf 4T Sport+: Semi SyntheticDocumento1 páginaHi-Perf 4T Sport+: Semi SyntheticahmadAinda não há avaliações

- Elite Cosmos VCC 0w-30 enDocumento1 páginaElite Cosmos VCC 0w-30 enAnderson MatioliAinda não há avaliações

- Icr-1454 - United Gold Sae 5w40 SN (Ua5161)Documento2 páginasIcr-1454 - United Gold Sae 5w40 SN (Ua5161)dnoaisapsAinda não há avaliações

- QALCO Syntholube GX 220Documento1 páginaQALCO Syntholube GX 220Deepak JoyAinda não há avaliações

- Repsol Transmission Ep 90 PDFDocumento1 páginaRepsol Transmission Ep 90 PDFrandiAinda não há avaliações

- Hi Perf 4t Sport10w40 Pds PDFDocumento1 páginaHi Perf 4t Sport10w40 Pds PDFhoussem houssemAinda não há avaliações

- Motor Oil SM 5W-40: Product Data SheetDocumento1 páginaMotor Oil SM 5W-40: Product Data SheetbarbastylAinda não há avaliações

- Toyota Premium Fuel Economy c2 5w30Documento2 páginasToyota Premium Fuel Economy c2 5w30regxhangoAinda não há avaliações

- BRO LubricantsAnalyisDocumento8 páginasBRO LubricantsAnalyisHenta DwyAinda não há avaliações

- AFRI 1-5 Specifications CombinedDocumento1 páginaAFRI 1-5 Specifications CombinedGuillaume Montarnal100% (1)

- 5 - Equipment Cost EstimateDocumento8 páginas5 - Equipment Cost EstimateJose Yebra DeaunaAinda não há avaliações

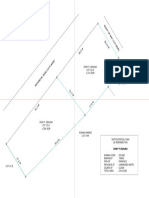

- Lot Plan - JPGDocumento1 páginaLot Plan - JPGJose Yebra DeaunaAinda não há avaliações

- Mrs. Konouz Dabjan Mrs. Konouz Dabjan Mrs. Konouz DabjanDocumento1 páginaMrs. Konouz Dabjan Mrs. Konouz Dabjan Mrs. Konouz DabjanJose Yebra DeaunaAinda não há avaliações

- Valve CV Sizing Liquids GasesDocumento22 páginasValve CV Sizing Liquids GasesJose Yebra DeaunaAinda não há avaliações