Escolar Documentos

Profissional Documentos

Cultura Documentos

In Depth: Providing Easy Access To A 3D Experience

Enviado por

Khairul FirdausDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

In Depth: Providing Easy Access To A 3D Experience

Enviado por

Khairul FirdausDireitos autorais:

Formatos disponíveis

�and

Casting is one of the most

widely applicable processing

technologies in the production

of metal products. From

the perspective of making

complex product shapes

and reducing costs, the

manufacture of sand molds

using 3D printers is attracting

attention.

Providing Easy Access to a 3D Experience

CUBE (Shibuya Ward, Tokyo), a 3D printer showroom opened

by iGUAZU Corporation, displays 3D printers and offers

a scanning service using a body scanner. In addition, K’s

The Latest Design Lab, which operates the showroom together with

iGUAZU, organizes workshops that provide the opportunity

Technology to actually use a 3D printer. Visitors are required to make

IN DEPTH

reservations in advance.

CLICK! ● 3D Printer showroom CUBE

B Creating “Things

ecause of their strong impact, applications, such as the production

3D printers have quickly of figurines, to manufacturing precision

gained widespread attention. industrial products. In Japan as well, that are Impossible

3D printing is based on 3D additive moves to keep up with this trend, to Make”

manufacturing technology, which by developing high-performance,

produces three-dimensional objects

by gradually adding layers of materials

industrial-use 3D printers are increasing.

A new public-private project has been

T he fact is, a large number of excellent

metals with a variety properties have

been developed; however, only a handful

such as resins or metals to solid layers launched, with a view to developing have been commercialized. Even though

printed below. 3D printing machines that can process the development of new materials may have

been successful in terms of research, it

What changes will the introduction metals into various objects.

has been difficult to establish a processing

of 3D printers bring? How will this From the automobile and medical technique that turns new materials into

technology evolve in the future? We equipment to the aerospace industries, commercial products because of their

diverse properties ― in some cases the

will explore this question in detail in the fields where 3D printers are used

materials are too hard, in others too brittle,

the following pages, but one thing to and where their further evolution is for example.

note for now is that this technology being promoted are steadily spreading. 3D additive manufacturing technology

could change the way things are We will take a look at both the wonders removes such constraints on processing.

The range of fields where metal materials can Professor Akihiko Chiba

manufactured around the world. of 3D printing ― next-generation be used is expected to broaden dramatically, Deformation Processing Laboratory

Looking at global trends, Western manufacturing technique that will and we also have high expectations for Institute for Materials Research, Tohoku University

countries have already established 3D act as a new driving force of Japan’s 3D printers as a development tool for

composite materials. Whereas conventional ● Institute

for Materials

additive manufacturing technology that manufacturing superiority ― and some CLICK!

Research, Tohoku University

manufacturing produces “things that are

uses metals. In these countries, 3D obstacles to its dissemination. possible to be made,” 3D printer-based

printing is transitioning from hobbyist manufacturing creates “things that are

impossible to make,” so to speak.

�esin

The processing of resins

Metal powder 3D printers

�etal

u s i n g s t e re o l i t h o g r a p h y i s

widely used for prototyping. are commonly used to make

It is best suited not only for custom-made products. Such

checking design accuracy printers can manufacture

but also for realizing “internal final products with superior

visualization” and conducting strength, tenacity and heat

“assembly testing.” resistance. Research is

underway to use metal powder

3D printers for medium volume

production in addition to low-

volume production.

01 METI Journal The Potential of 3D PRINTING

1

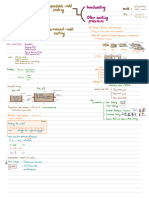

The Frontline Manufacturing Process using a 3D Printer

From left: Makoto Arai, Board Member

of Next- and General Manager of the Sales (using resin materials)

Generation Department; Toshihiro Yoshida,

Manufacturing Manager of Sales Department; Tsuneo

Murakami, President. Mr. Arai and

Mr. Yoshida are holding a prototype

1 The first step is

preparing 3D data.

automotive lamp manufactured through First, draft a 3D model based on

Application Areas

stereolithography. CAD design data and CT and MRI

measurement data. The quality of the

manufactured object depends on the

precision of the data.

Shifting from R&D to 2 Specifying layers to be built

one on top of the other.

Production

The next step is compiling cross-

section data by slicing the 3D model.

The thickness of the layers to be built is

specified. The thinner the layer, the more

precise the manufactured model.

CMET Inc. 3 Creating layers one by

one with a 3D printer

Now the manufacturing process begins.

When the laser is applied to the surface

of the photocuring resin based on cross-

sectional data, only the areas exposed to

Next-generation the laser are solidified.

stereolithography machine

RAPID MEISTER

NRM-6000 4 Post-manufacturing

treatment

When all the layers have been built, the

manufactured object is extracted and

post-manufacturing treatment applied,

thereby completing the 3D model. It

should be noted that the printer type and

printing process to be used differently

depending on the type of material the

object is composed of, for example,

metal powder or sand.

“T

hat was the largest crowd of visitors that we 3D printers, among other products, the visitors’enthusiasm precision and quality. However, the application is shifting to product manufacturing.

had ever seen. I was surprised at the high level indicated the great potential of 3D printers. CMET’s stereolithography machines manufacture 3D objects In other words, 3D printers are being used for the mass

of attention we received.” The 23rd Design As a pioneer of stereolithography, CMET has a quarter- by processing resins which are exposed to ultraviolet laser production of products. This could dramatically change

Engineering and Manufacturing Solutions Expo was held in century-history of developing stereolithography machines. beams. Thin-sliced layers of resins created on the basis of 3D manufacturing methodologies.” (President Murakami)

June (Tokyo Big Sight). To Makoto Arai, General Manager of As it has participated in the Design Engineering and CAD data are solidified by laser and are stacked one on top CMET started working on RM around one year ago. The

the Sales Department at CMET Inc., which displayed its own Manufacturing Solutions Expo as an exhibitor since this of the other. The thickness of each layer is 0.05 to 0.1 mm, company is beginning to provide new solutions to the

event was first held, the company has directly witnessed the assuring a high level of precision. Moreover, the resin’s high production process of precision mold products. Moreover,

changes occurring in the environment surrounding 3D additive degree of transparency “provides an easy look at fluid and CMET is actively conducting future-oriented activities. For

manufacturing technology. “Previously, few customers had gas flows inside the manufactured object. If this visualization example, the company is involved in the development of a

3D CAD equipment. In those days, we compiled CAD data model and computer simulation are used in combination, it new 3D printer that manufactures sand molds for a METI

based on blueprints borrowed from customers,” President will become possible to both increase the speed and reduce project to develop ultra-precision 3D manufacturing systems

Tsuneo Murakami of CMET recalled. CMET is proud of having the cost of development.” (General Manager Arai) technology.

developed technology and built the market together with its “Japanese companies have a culture that encourages high-

customers, which include core industries such as automakers Pursuing Original and Ingenious Solutions level cooperation and original and ingenuous solutions. Our

and electric and precision machinery makers. hope is not only to strengthen Japan’s manufacturing industry

CMET excels in the field of rapid prototyping (RP). Previously, the production of a prototype required a mold. with “Made in Japan” technology, but also to provide a source

Manufacturers conduct various tests on new products, However, if a 3D printer is used, it is possible to manufacture of pride for people involved in manufacturing.” (General

3D prototyping beginning with the design and development stages. a prototype without using a mold. The lead time is reduced Manager Arai).

of an engine Prototypes that are close to the “real products” but which from weeks to days. Some types of objects “are automatically 3D printers are beginning to give Japan a new edge in leading

block are transparent have been widely used, with significant manufactured overnight if the machine operation is set in the the world in manufacturing.

benefits. The ability to thoroughly inspect models, including evening.” (General Manager Arai)

their insides, rather than merely looking at the outer surface, In addition, the range of applications has broadened and ● CMET

CLICK! Inc.

Development of this enables the detection of defects that might be overlooked diversified in the past couple of years. The keyword is rapid

technology was prompted with the examination of blueprints alone, leading to the manufacturing (RM). “Until now, 3D printers have been used

by the needs of customers

development of products that have higher standards of mainly to manufacture prototypes at the development stage.

who wanted to evaluate

liquid flows inside an engine

block.

03 METI Journal The Potential of 3D PRINTING METI Journal 04

2

The Frontline

of Next-

Comparison of Workflows of Conventional Molding and

Generation

3D Additive Manufacturing

Manufacturing

By simplifying processes, Koiwai Co. has dramatically reduced lead times,

for example, from three weeks to three days. 3D additive manufacturing has

also eliminated the need for separating and assembling molds. By blending

Toward Expansion Across

skilled engineers’ “basic design capability” and young engineers’ “digital

literacy” (the capability to use computers and other digital equipment),

Koiwai is tackling the challenge of creating unique molds.

National Borders by Conventional

processing

3D additive

Integrating the power of

manufacturing

technology

youth and new molding

Basic design Basic design

Manufacturing of a

Technology

model

Insertion of a model and

manufacturing of a sand mold

Can be

Separation of the mold and replaced by a

Koiwai Co., Ltd. extraction of the model Additive manufacturing

3D printer of a sand mold and a

Manufacturing of a mold core

mold core

Additive manufacturing sand Assembly of

the mold core

casting machine

S-MAX President Toyomi Koiwai and

Morea Koiwai of the Planning

Assembly of

the sand mold

Office standing in front of an inkjet

machine. The inkjet machine is used Injection of Injection of molten

in combination with a laser additive molten metal metal

manufacturing machine.

Destruction of the sand Destruction of the sand

mold and mold core mold and mold core

T Second Chapter in Realizing the Dream

he table is similar in size to a tatami mat, sufficiently developing a similar technology. Our company’s ideal is to

large for a person to lie down on. “We can manufacture preserve and develop molding technology. To achieve this

a life-size sand model if you like,” says Morea Koiwai of A sand mold is a sand-made frame used to manufacture ideal, both veteran and young workers have been pursuing

Koiwai Co., Ltd., smiling. “A scanner which converts objects mold parts. Sand molds have been widely used since ancient that dream together.”

The colors of the inner and

into 3D data is available in the office.” Koiwai Co. is tackling times. The manufacture of sand molds itself requires a frame. Koiwai Co. is now starting to tackle the new challenge of outer areas are different

various challenges and bringing about various changes as However, an additive manufacturing sand casting machine establishing a metal powder 3D additive manufacturing because two different A sand mold for

a pioneer of additive manufacturing sand casting, a type of can directly manufacture a sand mold, thereby reducing the technology. This is an “ultimate” manufacturing technology manufacturing methods,

ink-jetting and laser

an automotive

manufacturing technology, and molds through methods using lead time and making it possible to manufacture a complex- that does not use sand molds. This technology manufactures

lasers and ink-jetting. shape integral mold product with high precision. “For metal parts by applying electron beams to metal powder.

sintering, were used. These part

two methods may be used

Seven years ago, Koiwai Co. took its first step forward in example, with regard to a motor casing used in an electric “With this technology, we can manufacture things that have in combination to meet user

Germany. The company mainly manufactures prototype vehicle, we must take countermeasures against excessive never been manufactured before. If this technology takes root needs.

molds on behalf of automakers. As the shapes of engines heating. For that purpose, creating coolant passageways among manufacturers, I am sure that new ideas premised on

and other components have become increasingly complex, around the motor with very precise positioning is one solution. 3D printing will arise. I also hope to see new people with such

the company’s officials came to the conclusion that “additive However, this is very difficult to achieve unless we use additive ideas.” (President Koiwai)

manufacturing is the only option” and visited a German manufacturing, which enables integral molding,” President Like CMET Inc., which was featured earlier, Koiwai Co. is

company with a world-class 3D printer technology. “For Koiwai explains. participating in the METI project to develop ultra-precision 3D

six months, we traveled between Japan and Germany The introduction of 3D printers has brought several benefits to manufacturing system technology. The company is presenting

and conducted a series of reviews. After introducing the Koiwai Co. “Regarding product design and development, the various proposals with end-users in mind and is cooperating

technology, we grew confident that we would be able to move range of fields in which customers need this technology has in review work to resolve problems. Last year, Koiwai Co.

forward. At that time, there were only a handful of Japanese widened.” In addition, by creating an advanced workplace began prototype development with overseas companies,

companies that had introduced sand casting machines. environment… “We are now able to recruit new graduates including a major automaker in India. Koiwai Co. is

There was general surprise at the fact that a small company every year, as we have succeeded in improving the image demonstrating a strong willingness to expand its business on

like Koiwai Co. had introduced a state-of-the art machine of molding companies, which were previously regarded as a global scale, with a view to becoming the No. 1 company in

that only major research institutions would usually possess.” ‘difficult-looking’ workplaces,” President Koiwai said. the field of additive manufacturing in the Asia-Pacific region.

(President Toyomi Koiwai) “We have been trying to realize our dream. I was amazed by a

magazine article about 3D additive manufacturing technology

CLICK! ● Koiwai Co., Ltd.

that I read some time ago, and we have come to dream of

05 METI Journal The Potential of 3D PRINTING METI Journal 06

of 3D Prin

view tin

Re g

Advantages of 3D Additive Manufacturing Technology

This is a Good Heat- and abrasion-resistant

ceramic material Research

stage

Chance to Establish

W

e hope that we have given you a glimpse into

the wonders of 3D printers, such as their ability

Technological to create what would be difficult or impossible

to manufacture with conventional technologies. However,

Copper alloys

with high

thermal

Superiority over the 3D printing is still in the development stage, so there are still conductivity

and low

subjects that must be resolved. Let us take another look at thermal

expansion

U.S. and Europe

its potential and the challenges we face. Toshimitsu Okane at

AIST, which plays a central role in the Development of Ultra-

precision 3D Manufacturing System Technology Project,

explains as follows.

1 2 3

Enabling Manufacturing Enabling Various Kinds Enabling

of Products of Any of Small Quantitiy Combinations of Different

Increasing Manufacturing Speed 10-Fold Shape Production Materials

With 3D additive manufacturing technology, it As the use of metal powders as starting As powder is processed into a stack of

Toshimitsu Okane Speed and price bottlenecks are impeding the dissemination is easy to manufacture parts that are difficult materials makes it possible to manufacture layers, it is possible to have different kinds

Leader, Metal Processing Group to process with cutting tools and to use hard products without metal or sand molds, 3D of metals harmoniously co-exist in a product.

of 3D printers. The market for industrial-use 3D printers is

Advanced Manufacturing Research materials that are normally difficult to process. additive manufacturing will contribute to This advantage may lead to the development

Institute currently dominated by foreign-made machines, and it is not A 3D printer makes it possible to manufacture significant cost reduction. Moreover, it is of new metal alloys with unconventional

National Institute of Advanced one integral object where two or more separate adaptable to the ultimate various kinds of small characteristics.

unusual for a 3D printer to be priced as high as 100 million parts would previously have been necessary. quantity production, such as manufacturing

Industrial Science and Technology

yen/unit. Despite the high price, there are many cases in one unit each of ten types of products.

After working for Nikon Corp. and the

University of Tokyo, Dr. Okane joined which it is difficult to recognize the clear benefits of 3D printing

the National Institute of Advanced

Industrial Science and Technology over conventional manufacturing technologies in terms of

(AIST) in 2002. He is engaged in the

development of molding technology

productivity and the quality of finished products. brought together. That thought led us to start this project. Bringing New Ideas to Manufacturing

and application technology for 3D “It occurred to us that it may be possible to develop a Under AIST’s leadership, 3D printer makers and automakers

additive manufacturing.

low-cost 3D printer with sufficient performance to satisfy are conducting a joint study. We are working to develop In recent years, rapid progress is being made in the

manufacturers if technological potaintialities in Japan are equipment that can manufacture high-precision sand development of technology to directly manufacture products

molds more efficiently. Our goal is to increase the speed of by melting and solidifying metal powder instead of using

manufacturing sand molds with a 3D printer 10-fold and to molds. “With this method, we can create mesh patterns

features by type

reduce costs over the next five years. The increased speed and hollow structures that would have been difficult to

Types of 3D printers and would be equivalent to monthly production of around 3,000 manufacture through machining. We aim to gradually advance

our research and develop technology to use combinations of

automotive parts. Future tasks include applying 3D printing to

Additive method Materials (current) Features various metal materials, such as heat-resistant titanium. If that various metals. Japan excels in the field of processing that

Industrial requires such meticulousness. There is a good chance that

use is achieved, it will become possible to manufacture aircraft

Currently, titanium alloys and nickel alloys Japanese technology will surpass Western equivalents.”

High-density energy beam Metal materials

are used to manufacture mold products. In parts.”

Laser/electron beam

the future, applications for new materials

However, improving performance alone is not enough. Dr. Finally, Dr. Okane gives the following message:

such as ceramics will enter the limelight.

Okane cites another key point - how to blend the skills of “I am sure that 3D printers will spur more lateral thinking.

Used to manufacture sand molds and nylon Japanese technicians and skilled workers with 3D printing. There have been countless cases in which wonderful ideas

Sand mold/nylon

resin products. The aim is to increase

“Even if a high-precision sand mold is manufactured with a 3D withered in the absence of the technology to put them into

Ink jet resins

manufacturing speeds and realize multi-

layering while improving the heat resistance printer, it is impossible to manufacture a high-quality product practice. I hope that this new method of manufacturing

of molds.

without adequate knowhow of, for example, from which angle unencumbered by conventional constraints will be widely

and at what speed molten metal should be poured. Japanese disseminated.”

Using a photocuring resin to build layers.

Photocuring The development of new resins combining molding technology is among the best in the world. If we

Stereolithography resins t r a n s p a r e n cy, h e a t r e s i s t a n c e a n d

toughness is underway. successfully integrate the expertise of skilled casters and 3D

printing technology into manufacturing processes, I am sure

that we will be able to make the most of Japanese strengths CLICK! ● National Institute of Advanced Industrial

The simplest 3D additive manufacturing

Thermoplastic Science and Technology

Hobbyist Fused deposition modeling resins

technology, using a thermoplastic resin, in manufacturing.”

use which softens when heat is applied.

07 METI Journal The Potential of 3D PRINTING METI Journal 08

Reference Data

In terms of production of metal powder additive manufacturing machines, Germany and other European companies have dominant market

shares. Meanwhile, the U.S. has the largest share in terms of the number of such machines introduced. Metal powder additive manufacturing

machines are widely used in high-end fields such as aircraft manufacturing. Japan has a 10% share in terms of machine introduction. In

Japan, metal powder additive manufacturing machines are mainly used for prototyping.

Share in terms of production of metal powder additive Share in terms of the number of metal powder additive

manufacturing machines manufacturing machines introduced

ReaLiser SLM Solutions(Germany)1%

Taiwan 2%

(Germany)

Renishaw(UK)1% South Korea 2%

7%

Phoenix Others

Systems 15%

(France)

12% EOS U.S.

MTT

(Germany)

38%

41%

Technologies

(Germany)

12% Spain 2%

Canada 2%

Arcam France 3%

(Sweden) China

Italy 4%

12% Concept Japan

Laser UK 4% 9%

Germany 10%

(Germany) 9%

17%

Source: Wohlers Report 2012

Production Process of Metal Products

3D additive manufacturing technology is expected to take root as an option. For example, existing manufacturing technologies will continue

to be applied to products that can be made using them, while 3D additive manufacturing will be used to manufacture what until now has been

impossible to manufacture.

Suited for mass production Suited for various kinds of small

(existing manufacturing methods) quantity production

Metal pressing New 3D additive manufacturing

Forging

Molding

Die casting

Powder metallurgy

09 METI Journal The Potential of 3D PRINTING METI Journal 10

Você também pode gostar

- MDP 39015047936219 110 1710616662Documento1 páginaMDP 39015047936219 110 1710616662حسام ساجت عويدAinda não há avaliações

- Machine - Learning-Based - Model - For - Single - Event - Upset - Current - Prediction - in - 14nm - FinFETs - ChosenDocumento6 páginasMachine - Learning-Based - Model - For - Single - Event - Upset - Current - Prediction - in - 14nm - FinFETs - ChosenShanthini SridharAinda não há avaliações

- Decorative ConcretesDocumento5 páginasDecorative Concretesnaveen kumar pathiAinda não há avaliações

- Final Project TitaneyeplusDocumento16 páginasFinal Project Titaneyepluspiyush rawatAinda não há avaliações

- Flexible Smoke Curtains: Mechanical Design For SupercoilDocumento22 páginasFlexible Smoke Curtains: Mechanical Design For SupercoilEmmanuel HilarioAinda não há avaliações

- Creo Manufacturing 4 0 PDFDocumento26 páginasCreo Manufacturing 4 0 PDFtwo-1Ainda não há avaliações

- Aggregates - The Difference Between Crushed Stone and GravelDocumento6 páginasAggregates - The Difference Between Crushed Stone and GravelKehinde Olaoluwa100% (1)

- Checklist of Candidates ExcelDocumento5 páginasChecklist of Candidates Excelmmrahman93Ainda não há avaliações

- Total Area of Plot/flat: ............... BetweenDocumento4 páginasTotal Area of Plot/flat: ............... BetweenVINEETA VINEETAAinda não há avaliações

- ISMR February 2015Documento1 páginaISMR February 2015Suresh GandikotaAinda não há avaliações

- The Design Act 2000Documento5 páginasThe Design Act 2000Nikita SharmaAinda não há avaliações

- Production 1 and 2Documento4 páginasProduction 1 and 2Emilio ZunigaAinda não há avaliações

- Web United in Diversity - Building Trust For Our Common FutureDocumento1 páginaWeb United in Diversity - Building Trust For Our Common Futurein UBBPAinda não há avaliações

- For Energy ConservationDocumento65 páginasFor Energy Conservationhoonie hoonieAinda não há avaliações

- AR COVER - PRINT PDF FINAL (Cov22-13582-1 - 460047 - Client)Documento100 páginasAR COVER - PRINT PDF FINAL (Cov22-13582-1 - 460047 - Client)arhontisAinda não há avaliações

- A Low-Power Resistive Tail Dynamic Comparator With Self-Shut MechanismDocumento6 páginasA Low-Power Resistive Tail Dynamic Comparator With Self-Shut Mechanism22pimt01Ainda não há avaliações

- ARD Brochure-BricsCAD - RO Site PDFDocumento2 páginasARD Brochure-BricsCAD - RO Site PDFcristina.serbanAinda não há avaliações

- 21MB0001 ModelDocumento1 página21MB0001 ModelPhreetzi ÜnseenAinda não há avaliações

- Carl Deckard - Father of The SLS Method and One of The Pioneers of 3D Printing Technologies, Died... - 3DPC We Speak 3D PrintiDocumento1 páginaCarl Deckard - Father of The SLS Method and One of The Pioneers of 3D Printing Technologies, Died... - 3DPC We Speak 3D PrintiA GHAILANE EL HASSANI RABII SOUMAYAAinda não há avaliações

- Past Paper QuestionDocumento2 páginasPast Paper Questionbiologyexpert158Ainda não há avaliações

- Materiology The Creative Industry S Guide To Mater... - (03 Processes)Documento80 páginasMateriology The Creative Industry S Guide To Mater... - (03 Processes)fatmagul aslanerAinda não há avaliações

- Eight Attributes of Contract Furniture CEUDocumento68 páginasEight Attributes of Contract Furniture CEUMoaz MunirAinda não há avaliações

- Sales Kit IFEX Agustus 2022 (New)Documento1 páginaSales Kit IFEX Agustus 2022 (New)Edi widodoAinda não há avaliações

- Business C4-C6 NotesDocumento2 páginasBusiness C4-C6 NotesNivriti RayAinda não há avaliações

- สรุป CastingDocumento1 páginaสรุป CastingTranrissAinda não há avaliações

- Nucleus ProfileDocumento63 páginasNucleus ProfileShahbaz SiddiquiAinda não há avaliações

- NPL Schools Poster - Measurement v5 HR NCDocumento1 páginaNPL Schools Poster - Measurement v5 HR NCRobert HookeAinda não há avaliações

- Mindmap Strategic Transport OptimizationDocumento1 páginaMindmap Strategic Transport OptimizationNgoc PhamAinda não há avaliações

- 3.1 Gestion de Proyectos - Ingles - EntregadoDocumento1 página3.1 Gestion de Proyectos - Ingles - EntregadoDavid SanchezAinda não há avaliações

- Basic Principles of Metal Forming 4Documento28 páginasBasic Principles of Metal Forming 4Luka Rabuzin0% (1)

- Intro To 3D Modeling Lesson 2Documento32 páginasIntro To 3D Modeling Lesson 2Lourisvan Costa100% (1)

- Artificial Intelligence:: A Rival For Humans, or A Partner?Documento1 páginaArtificial Intelligence:: A Rival For Humans, or A Partner?patmos666Ainda não há avaliações

- EDU TAHlookinside DraftingDocumento2 páginasEDU TAHlookinside DraftingwolfvorAinda não há avaliações

- Windengineering Persianwindmill Oct10printDocumento8 páginasWindengineering Persianwindmill Oct10printEmmanuel AklagbeAinda não há avaliações

- Materiology The Creative Industry's Guide To Mater... - (03 Processes) PDFDocumento80 páginasMateriology The Creative Industry's Guide To Mater... - (03 Processes) PDFfurkanAinda não há avaliações

- Stathatos FAIM2021Documento6 páginasStathatos FAIM2021George VosniakosAinda não há avaliações

- The Achieving Socety P 83-90Documento8 páginasThe Achieving Socety P 83-90Harry AlfathAinda não há avaliações

- Comfull 007 BrochureDocumento2 páginasComfull 007 BrochureDon RidzwanilAinda não há avaliações

- Computer Management ForeignDocumento2 páginasComputer Management ForeignKarabo moetiAinda não há avaliações

- 4 Ways Greener BrochureDocumento2 páginas4 Ways Greener BrochurevivesinjefeAinda não há avaliações

- 2022 Kawasaki Catalogue - V1Documento100 páginas2022 Kawasaki Catalogue - V1Elizabeth EstradaAinda não há avaliações

- Nucleus ProfileDocumento63 páginasNucleus ProfileShahbaz SiddiquiAinda não há avaliações

- CNC Workcentre To Process Marble, Granite and Other Stone MaterialsDocumento2 páginasCNC Workcentre To Process Marble, Granite and Other Stone MaterialsMadster RobertsAinda não há avaliações

- Success by NumbersDocumento2 páginasSuccess by NumberstinaeminiAinda não há avaliações

- Poem 1 - The City Planners - AtwoodDocumento1 páginaPoem 1 - The City Planners - AtwoodAlyssa Wong Yi ReiAinda não há avaliações

- Construction Equipment Management: Concrete Production Process - LifecycleDocumento3 páginasConstruction Equipment Management: Concrete Production Process - Lifecycleavant.07012024Ainda não há avaliações

- Atzec MP DITDocumento3 páginasAtzec MP DITClaudia SandovalAinda não há avaliações

- Lampara de Fotocurado Smartlite ProDocumento2 páginasLampara de Fotocurado Smartlite ProJadar ProyectosAinda não há avaliações

- Armstrong ArmatuffDocumento1 páginaArmstrong Armatuffaditarian .pAinda não há avaliações

- Dubai BIM RoadmapDocumento1 páginaDubai BIM RoadmapZÄkãrîãêÊlJêmLîAinda não há avaliações

- Preface: THE Rigid - ofDocumento1 páginaPreface: THE Rigid - ofjosAinda não há avaliações

- Production and Law of Variable Proportion EconomicsDocumento6 páginasProduction and Law of Variable Proportion EconomicsmayureshbachhavchessAinda não há avaliações

- Towards Agenda 2030Documento23 páginasTowards Agenda 2030Muhammad Syailendra Prima PutraAinda não há avaliações

- COVID-19: Mitigation Strategy For Indian Textile and Apparel SectorDocumento11 páginasCOVID-19: Mitigation Strategy For Indian Textile and Apparel SectorRavi BabuAinda não há avaliações

- Revit Central File Research by AiDocumento1 páginaRevit Central File Research by Aisittinun munsagateAinda não há avaliações

- Product: - Long Product Manufacturing Process - A Big Showing Machine - Large Production Costs - Complex ProductionDocumento1 páginaProduct: - Long Product Manufacturing Process - A Big Showing Machine - Large Production Costs - Complex ProductionAbdurAinda não há avaliações

- Intro To 3D Modeling Lesson 1Documento24 páginasIntro To 3D Modeling Lesson 1felixoidAinda não há avaliações

- Sample Format of Baseline Data Presentation of SBDPODocumento2 páginasSample Format of Baseline Data Presentation of SBDPORemigio EskandorAinda não há avaliações

- Identification of Business OppoturnityDocumento1 páginaIdentification of Business OppoturnityKhairul FirdausAinda não há avaliações

- Discussion 1Documento1 páginaDiscussion 1Khairul FirdausAinda não há avaliações

- Chap3 Magnetic CircuitsDocumento16 páginasChap3 Magnetic CircuitsKhairul FirdausAinda não há avaliações

- Magnetisation CurveDocumento1 páginaMagnetisation CurveKhairul FirdausAinda não há avaliações

- AI in Insurance Fraud DetectionDocumento37 páginasAI in Insurance Fraud Detectionpatrick wafulaAinda não há avaliações

- Wind Turbine Design ProcedureDocumento4 páginasWind Turbine Design ProcedureEkambaramMuniyandi100% (1)

- Post Baccalaureate Certificate in Integrated Product Development and ManufacturingDocumento2 páginasPost Baccalaureate Certificate in Integrated Product Development and Manufacturingpritish_09Ainda não há avaliações

- System Analysis and Design: Pangasinan State University San Carlos Campus San Carlos City, Pangasinan S.Y. 2017-2018Documento21 páginasSystem Analysis and Design: Pangasinan State University San Carlos Campus San Carlos City, Pangasinan S.Y. 2017-2018Jojo Alcantara Rosario Jr.Ainda não há avaliações

- IDEO EssayDocumento26 páginasIDEO Essaytowermeng100% (1)

- Example ProposalDocumento11 páginasExample ProposalMatzainiAinda não há avaliações

- A Software Requirements SpecificationDocumento12 páginasA Software Requirements SpecificationRahul RulzzAinda não há avaliações

- Efficient and Innovative Jeepney For Persons With Disabilities and Senior CitizensDocumento16 páginasEfficient and Innovative Jeepney For Persons With Disabilities and Senior CitizensMelissaAinda não há avaliações

- Experimental Technological Development of The ProductDocumento21 páginasExperimental Technological Development of The ProductAlvaro Ronaldo Elizalde CamachoAinda não há avaliações

- 11 - Desain, Prototipe Dan KonstruksiDocumento46 páginas11 - Desain, Prototipe Dan KonstruksiUtari Via VivianAinda não há avaliações

- Digital Manufacturing For Aerospace IndustryDocumento3 páginasDigital Manufacturing For Aerospace IndustryShashi ShekharAinda não há avaliações

- CW8503 Design ThinkingDocumento15 páginasCW8503 Design ThinkingUpendra NeravatiAinda não há avaliações

- UNIT 1 NotesDocumento45 páginasUNIT 1 NoteslaluAinda não há avaliações

- Software Process ModelDocumento49 páginasSoftware Process ModelHarsha VardhanAinda não há avaliações

- Project ChatAppDocumento28 páginasProject ChatAppSa'ad PramanikAinda não há avaliações

- The Computer Aided System For Planning Efficient Routes: Purdue E-PubsDocumento61 páginasThe Computer Aided System For Planning Efficient Routes: Purdue E-PubsMadhan ReddyAinda não há avaliações

- Software Engineering (Se-207) : 1) AnalysisDocumento30 páginasSoftware Engineering (Se-207) : 1) AnalysisWaqar GulAinda não há avaliações

- Bright Spark Design Thinking Full WorksheetDocumento15 páginasBright Spark Design Thinking Full Worksheetsujal patelAinda não há avaliações

- Slides of Software Engineering ConsortiumDocumento611 páginasSlides of Software Engineering ConsortiumAmudhan KandasameAinda não há avaliações

- PrototypeDocumento5 páginasPrototypeSyaa MalyqaAinda não há avaliações

- Software Engineering Unit 1& 2Documento22 páginasSoftware Engineering Unit 1& 2Anshika DubeyAinda não há avaliações

- CSBS DT Sem 5 Unit1 FinalDocumento62 páginasCSBS DT Sem 5 Unit1 FinalsunnybaggaAinda não há avaliações

- Luthbg Thit 03 XXXX SeDocumento85 páginasLuthbg Thit 03 XXXX SekcwbsgAinda não há avaliações

- Design and Analysis Artificial Intelligence (AI) Research For Power Supply - Power Electronics Expert System (PEES)Documento7 páginasDesign and Analysis Artificial Intelligence (AI) Research For Power Supply - Power Electronics Expert System (PEES)Jandfor Tansfg ErrottAinda não há avaliações

- Anti-Tremor Glove: Preparatory Centre For Science and Technology English SBOO34Documento16 páginasAnti-Tremor Glove: Preparatory Centre For Science and Technology English SBOO34Tura NochellAinda não há avaliações

- UX Design For MobileDocumento506 páginasUX Design For MobileTam Minh78% (9)

- Mini Project 2011Documento2 páginasMini Project 2011Faizal HakimAinda não há avaliações

- Prototyping Essentials With Axure Sample ChapterDocumento66 páginasPrototyping Essentials With Axure Sample ChapterPackt PublishingAinda não há avaliações

- Design Thinking at NetflixDocumento8 páginasDesign Thinking at NetflixJaya Naga Sanjay MamidiAinda não há avaliações

- Morin, G. Et. Al (2014) Case Study - The Real Life Benefits ofDocumento8 páginasMorin, G. Et. Al (2014) Case Study - The Real Life Benefits ofpatrickanjosAinda não há avaliações