Escolar Documentos

Profissional Documentos

Cultura Documentos

Calculation For Gauge Pole Supports

Enviado por

richardchiamTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Calculation For Gauge Pole Supports

Enviado por

richardchiamDireitos autorais:

Formatos disponíveis

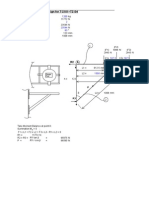

Gauge Pole Support Design for T-2101~T2104

Gauge Pole Weight = 1200 kg

11772 N

Impact factor = 2

Design weight = 23544 N

Used weight, W = 23544 N

Angle of support, b = 83 °

h = L2/ tan b = 123 mm

L4 = L2 / sin b = 1008 mm

1 (F2)

(F1) 5886 N (F3)

2943 N 2943 N

X1= 187.5 X2= 187.5

R2 A

L1 = 812.5 mm

R1

Gauge L2 = 1000 mm

Pole

h= 123 L3 = 1187.5 mm

b L4 = 1008 mm

R3

2

Take Moment Balance at point A:

Summation MA = 0 :

F1 x L1 + F2 x L2 + F3 x L3 - R1 x L2 = 0

R1 = 11772 N

R2 = R3 = R1 tan b = 95875 N

P = R1 / cos b = 96595 N

1 Check on support size

1.1 Use member: C-Channel 150 x 75 x 18.6 kg/m

A = 2371 mm2

Tensile stress: St = R1 / A = 5 N/mm2

Z chosen = 1.15E+05 mm 3

Bending Moment, BM = X2 x F3 + X1 x F1

= 1103625 Nmm

Bending Stress: Sb = BM / Z = 10 N/mm2

Yield Strength for struc. A36/EQ = 248 N/mm2

Allowable, Sy = 0.67 Yield = 166 N/mm2

Combined Stresses = St/Sy + Sb/Sy = 0.09 < 1.00

*** Satisfactory !!!! ***

2 Check on support size

2.1 Use member: C-Channel 150 x 75 x 18.6 kg/m

Least Radius of Gyration, ry = 22.7 mm and C.S.Area, A = 2371 mm2

Slenderness Ratio, l = 1.0 x L / ry = 44.384

Thus Allowable compressive stress, Fb = 18.86 ksi = 130.06 N/mm2

Compressive stress = P/A= 40.74 N/mm2 < Fb

*** Satisfactory !!!! ***

Reboiler

Reboiler (Size DIA 800 x 2400) Support Design for vessel T-2601

Reboiler Weight = 6500 kg

63739 N

Impact factor = 1.2

Design weight = 76487 N

Used weight, W = 80000 N

Angle of support, = 38 ° 1 (F2)

h = L2 tan delta = 976.607 mm (F1) 20000 N (F3)

L4 = L2/cos delta = 1586.273 mm 10000 N ### N

R1 X1= 577 X2=577

A

F

L1 = 673 mm

L2 = 1250 mm

h= 976.61 L3 = 1827 mm

1586 mm

R2

2

Take Moment Balance at point A: B

Summation MA = 0: F

F x h - F1 x L1 + F2 x L2 + F3 x L3 = 0

F= 51198 N

R2 = F tan (delta) = 40000 N

R1 = F1 + F2 + F3 - R2 = 0 N

T = F / cos delta = 64970.77 N

Check on size of support 1

Use member: Channel 152 x 76 x 17.88 kg/m

A = 2277 mm2

Tensile stress: St = R2 / A = 17.567 N/mm2

Z chosen = 111800 mm3

Bending Moment, BM = X2xF3 = 6E+06 Nmm

Bending Stress: Sb = BM / Z = 51.61 N/mm2

Yield Strength for A36 material = 248 N/mm2

Combined Stresses = St + Sb 69.17699 N/mm2 < 166.16 ( 0.67 Yield Strength )

*** Satisfactory !!!! ***

Check on size of support 1

Use member: Equal Anglel 150 x 150 x 10t x 23 kg/m

Least Radius of Gyration, ry = 29.7 mm and C.S.Area, A = 2930 mm2

Slenderness Ratio, lamda = 1.2 x L / ry = 64.092

Thus Allowable compressive stress, Fb = 15.79 ksi = 108.89 N/mm2

Compressive stress = T / A = 22.17432 N/mm 2

< Fb

*** Satisfactory !!!! ***

R2

Reboiler (Size DIA 800 x 2400) Support Design for vessel T-2601 Page

Reboiler Weight = 6500 kg

63765 N

Impact factor = 1.5

Design weight = 95648 N

Used weight, W = 100000 N

Angle of support, a = 60 °

h = L2 tan a = 1645 mm

L4 = L2 / cos a = 1900 mm

Note that the distance between top

and bottom clips will have slight different 1 (F2)

compared to detail in drawing since (F1) 25000 N (F3)

the curvature of vessel is not considered 12500 N ### N

but the angle of knee support.

R1 X1= 400 X2=400

A

F a

L1 = 550 mm R2

L2 = 950 mm

Reboile

r

h= 1645 L3 = 1350 mm

1900 mm

R2

2

B F

Take Moment Balance at point A:

Summation MA = 0:

F x h - F1 x L1 + F2 x L2 + F3 x L3 = 0

F= 28868 N

R2 = F tan a = 50000 N

R1 = F1 + F2 + F3 - R2 = 0 N

T = F / cos a = 57735 N

### Check on size and bolt size of support 1

### Use member: Channel 127 x 64 x 14.9 kg/m

A = 1898 mm2

Tensile stress: St = R2 / A = 26.34 N/mm2

Z chosen = 75990 mm3

Bending Moment, BM = X2 x F3 5E+06 Nmm

Bending Stress: Sb = BM / Z = 65.80 N/mm2

Page 1

Yield Strength for strucA36/EQ= 248 N/mm2

Combined Stresses = St + Sb 92.14 N/mm2 < 166.16 ( 0.67 Yield Strength )

*** Satisfactory !!!! ***

### Use bolt: M 20

A = 314 mm2

Shear stress: Sh = R2 / A = 159 N/mm2

Yield Strength for bolt = 723 N/mm2

Required Shear Stress = Sh = 159.15 N/mm2 < 484.41 ( 0.67 Yield Strength )

*** Satisfactory !!!! ***

### Check on size and bolt size of support 2

2 Use member: Equal Angle 100 x 100 x 10t x 14.9 kg/m

Least Radius of Gyration, ry = 19.5 mm and C.S.Area, A = 1900 mm2

Slenderness Ratio, l = 1.2 x L / ry = 116.92

Thus Allowable compressive stress, Fb = 10.85 ksi = 74.82 N/mm2

Compressive stress = T / A = 30.39 N/mm 2

< Fb

*** Satisfactory !!!! ***

### Use bolt: M 20

A = 314 mm2

Shear stress: Sh = T/A= 184 N/mm2

Yield Strength for bolt = 723 N/mm2

Required Shear Stress = Sh = 183.78 N/mm2 < 484.41 ( 0.67 Yield Strength )

*** Satisfactory !!!! ***

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- SOIL ASSESSMENT AND PLANT PROPAGATION OF BELL PEPPERS (Capsicum Annuum)Documento35 páginasSOIL ASSESSMENT AND PLANT PROPAGATION OF BELL PEPPERS (Capsicum Annuum)Audrey Desiderio100% (1)

- Aortic Stenosis, Mitral Regurgitation, Pulmonary Stenosis, and Tricuspid Regurgitation: Causes, Symptoms, Signs, and TreatmentDocumento7 páginasAortic Stenosis, Mitral Regurgitation, Pulmonary Stenosis, and Tricuspid Regurgitation: Causes, Symptoms, Signs, and TreatmentChuu Suen TayAinda não há avaliações

- DK Children Nature S Deadliest Creatures Visual Encyclopedia PDFDocumento210 páginasDK Children Nature S Deadliest Creatures Visual Encyclopedia PDFThu Hà100% (6)

- KNM Process Systems Sdn. BHD.: Project Name: Ammonia & Urea Plant Revamp ProjectDocumento32 páginasKNM Process Systems Sdn. BHD.: Project Name: Ammonia & Urea Plant Revamp ProjectrichardchiamAinda não há avaliações

- LiftingLug TrunnionDocumento22 páginasLiftingLug Trunnionrichardchiam100% (2)

- Sibuyan Island ResiliencyDocumento12 páginasSibuyan Island ResiliencyEndangeredSpeciesAinda não há avaliações

- Antonovsky (1979)Documento280 páginasAntonovsky (1979)M.Fakhrul Kurnia100% (1)

- Saddle Support CalculationDocumento7 páginasSaddle Support CalculationrichardchiamAinda não há avaliações

- (Razavi) Design of Analog Cmos Integrated CircuitsDocumento21 páginas(Razavi) Design of Analog Cmos Integrated CircuitsNiveditha Nivi100% (1)

- Gas and Oil Pipeline Project SkidsDocumento18 páginasGas and Oil Pipeline Project SkidsrichardchiamAinda não há avaliações

- Calculation For Gauge Pole SupportsDocumento7 páginasCalculation For Gauge Pole SupportsrichardchiamAinda não há avaliações

- Calculation For Gauge Pole SupportsDocumento7 páginasCalculation For Gauge Pole SupportsrichardchiamAinda não há avaliações

- Calculation For Gauge Pole SupportsDocumento7 páginasCalculation For Gauge Pole SupportsrichardchiamAinda não há avaliações

- Rotary Twin Scew Brochure UK HRDocumento20 páginasRotary Twin Scew Brochure UK HRNguyễn Hữu DũngAinda não há avaliações

- LiftingDocumento13 páginasLiftingrichardchiamAinda não há avaliações

- Wind OpeartingDocumento3 páginasWind OpeartingrichardchiamAinda não há avaliações

- List To Be Follow For TenderDocumento2 páginasList To Be Follow For TenderrichardchiamAinda não há avaliações

- Center Vent & Peripheral Vent CalDocumento1 páginaCenter Vent & Peripheral Vent CalrichardchiamAinda não há avaliações

- Base Plate DesignDocumento4 páginasBase Plate DesignrichardchiamAinda não há avaliações

- Pipe Specification Api5lDocumento1 páginaPipe Specification Api5lmrzodAinda não há avaliações

- Gen Conversion TableDocumento3 páginasGen Conversion TablerichardchiamAinda não há avaliações

- Forging SDocumento93 páginasForging SrichardchiamAinda não há avaliações

- Center Vent & Peripheral Vent CalDocumento1 páginaCenter Vent & Peripheral Vent CalrichardchiamAinda não há avaliações

- Qty of PlatsDocumento2 páginasQty of PlatsRichard Chiam Heng KuangAinda não há avaliações

- Seismic Hazard Map of Western IndonesiaDocumento1 páginaSeismic Hazard Map of Western IndonesiarichardchiamAinda não há avaliações

- Floater Weight CalculationDocumento10 páginasFloater Weight CalculationrichardchiamAinda não há avaliações

- Ring Cutting PlanDocumento1 páginaRing Cutting PlanrichardchiamAinda não há avaliações

- Angle Clip Stress Calculation For Inlet Nozzle Part 1001Documento2 páginasAngle Clip Stress Calculation For Inlet Nozzle Part 1001richardchiamAinda não há avaliações

- Fund for World Indices Futures/CFD Risk and Return AnalysisDocumento19 páginasFund for World Indices Futures/CFD Risk and Return AnalysisrichardchiamAinda não há avaliações

- NozloadDocumento1 páginaNozloadrichardchiamAinda não há avaliações

- Angle Clip Stress Calculation For Inlet Nozzle Part 1001Documento2 páginasAngle Clip Stress Calculation For Inlet Nozzle Part 1001richardchiamAinda não há avaliações

- Qty of Plats LATESTDocumento6 páginasQty of Plats LATESTrichardchiamAinda não há avaliações

- Slope Shell Course CalculationDocumento2 páginasSlope Shell Course CalculationrichardchiamAinda não há avaliações

- Shell Cutting PlanDocumento2 páginasShell Cutting PlanrichardchiamAinda não há avaliações

- Figure - Ci Vs HDDocumento3 páginasFigure - Ci Vs HDrichardchiamAinda não há avaliações

- Floater Weight CalculationDocumento10 páginasFloater Weight CalculationrichardchiamAinda não há avaliações

- Material and Energy Balance: PN Husna Binti ZulkiflyDocumento108 páginasMaterial and Energy Balance: PN Husna Binti ZulkiflyFiras 01Ainda não há avaliações

- Acuity Assessment in Obstetrical TriageDocumento9 páginasAcuity Assessment in Obstetrical TriageFikriAinda não há avaliações

- KoyoDocumento4 páginasKoyovichitAinda não há avaliações

- Reinforced Concrete Beam DesignDocumento13 páginasReinforced Concrete Beam Designmike smithAinda não há avaliações

- Answer Key p2 p1Documento95 páginasAnswer Key p2 p1Nafisa AliAinda não há avaliações

- Caterpillar Ep15krtDocumento37 páginasCaterpillar Ep15krtIvan MajikAinda não há avaliações

- Lesson Plan: Lesson: Projectiles Without Air ResistanceDocumento4 páginasLesson Plan: Lesson: Projectiles Without Air ResistanceeltytanAinda não há avaliações

- A Fossil Hunting Guide To The Tertiary Formations of Qatar, Middle-EastDocumento82 páginasA Fossil Hunting Guide To The Tertiary Formations of Qatar, Middle-EastJacques LeBlanc100% (18)

- Magnetic Pick UpsDocumento4 páginasMagnetic Pick UpslunikmirAinda não há avaliações

- What Is DSP BuilderDocumento3 páginasWhat Is DSP BuilderĐỗ ToànAinda não há avaliações

- Problem SolutionsDocumento5 páginasProblem SolutionskkappaAinda não há avaliações

- India - Wikipedia, The Free EncyclopediaDocumento40 páginasIndia - Wikipedia, The Free EncyclopediaPrashanth KrishAinda não há avaliações

- Daftar Spesifikasi Teknis Pembangunan Gedung Kantor BPN BojonegoroDocumento6 páginasDaftar Spesifikasi Teknis Pembangunan Gedung Kantor BPN BojonegoroIrwin DarmansyahAinda não há avaliações

- Introduction To Finite Element Methods (2001) (En) (489s)Documento489 páginasIntroduction To Finite Element Methods (2001) (En) (489s)green77parkAinda não há avaliações

- VA TearDownDocumento5 páginasVA TearDownfaj_larcfave5149Ainda não há avaliações

- Lightwave Maya 3D TutorialsDocumento8 páginasLightwave Maya 3D TutorialsrandfranAinda não há avaliações

- Chain Surveying InstrumentsDocumento5 páginasChain Surveying InstrumentsSachin RanaAinda não há avaliações

- Sri Radhakrishna SwamijiDocumento43 páginasSri Radhakrishna SwamijiNarayana IyengarAinda não há avaliações

- Helmitin R 14030Documento3 páginasHelmitin R 14030katie.snapeAinda não há avaliações

- IEQ CompleteDocumento19 páginasIEQ Completeharshal patilAinda não há avaliações

- Who will buy electric vehicles Segmenting the young Indian buyers using cluster analysisDocumento12 páginasWho will buy electric vehicles Segmenting the young Indian buyers using cluster analysisbhasker sharmaAinda não há avaliações

- The Art of Now: Six Steps To Living in The MomentDocumento5 páginasThe Art of Now: Six Steps To Living in The MomentGiovanni AlloccaAinda não há avaliações

- Hypophosphatemic Rickets: Etiology, Clinical Features and TreatmentDocumento6 páginasHypophosphatemic Rickets: Etiology, Clinical Features and TreatmentDeysi Blanco CohuoAinda não há avaliações