Escolar Documentos

Profissional Documentos

Cultura Documentos

Safety relief valve bulletin for refrigerants

Enviado por

miguel cuevasDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Safety relief valve bulletin for refrigerants

Enviado por

miguel cuevasDireitos autorais:

Formatos disponíveis

SAFETY RELIEF VALVE BULLETIN 71-00

TYPE SR

Type SR1, SR2, SR3 & SR4

Size 13mm & 20mm (1/2” & 3/4”)

FOR R22, R134A, R404A, R717 AND

OTHER COMMON REFRIGERANTS

FEATURES

ANSI/ASHRAE 15 compliant

Excellent repeatability

All Stainless Steel Internal Parts

Unaffected by vibration January 2002

Installation and Service Information

PTFE Seat stainless steel, and a PTFE disc prevent sticking due to

corrosion or cold welding and assure valve opening at

Pressure settings 150 to 400 psi the set pressure long after installation. They are not

Description suitable for corrosive ambient atmospheres such as

The Type SR Safety Relief Valves are designed and chlorine, etc. Connection sizes are 1/2” FPT inlet with 3/

constructed to meet the requirements of Section VIII 4” or 1” FPT outlet. A 3/4” inlet with 1” FPT outlet is also

ASME Boiler and Pressure Vessel Code and ANSI/ available.

ASHRAE 15 Code requirements and bear the ASME Code Purpose

Symbol (UV). Employing proven principles of design, Safety Relief Valves should be used to protect each

these Safety Relief Valves are highly reliable and refrigeration system pressure vessel that can be isolated

dependable. Precision machined moving parts of by valves. In many localities state or municipal codes

govern selection and installation of Relief Valves. Many

Type SR are patterned after the ASME Boiler and Pressure Vessel

Code and the ANSI/ASHRAE 15 Safety Code for

O-Ring Mechanical Refrigeration. Where no compulsory code

exists, installation of Relief Valves according to this ANSI/

Stem ASHRAE Code is highly recommended.

Application

The Type SR1 thru SR4 valves are for use with Ammonia

Spring and Halocarbon refrigerants in non-corrosive

environments. Pressure settings and capacities apply

only when the valve is discharging to atmospheric

pressure.

Pressure Settings

Codes require valve settings equal to or less than design

working pressure of the vessel protected. The Type SR

Safety Relief Valves are available in six standard settings,

from 150 psig to 400 psig in 50 lb. increments. Special

settings between 150 psig to 400 psig in 25 lb. increments

are also available. To retain the validity of the code

PTFE symbols, pressure settings and capacity, these valves

Seat must be set and sealed at the factory. When required,

Seat

Valve valves can be returned to the factory for verification of

setting, or readjustment to the original setting. No major

Fig. 1 repairs or reconditioning will be done. Contact factory for

details.

Refrigerating Specialties Division 1 I S O 9 0 0 1 C E R T I F I E D

310204

C apacities

Relief Relief P res s ure Lbs .

S CFM

V alv e V alv e V alv e S etting P er.M in

A ir

Ty pe Inlet Outlet ps ig A ir

150 10 130

200 13 170

S R1 1/2" 3/4" 250 16 210

FP T FP T 300 19 250

350 22 290

400 25 329

150 19 246

200 25 321

S R2 1/2" 1" 250 30 397

FP T FP T 300 36 472

350 42 547

400 48 622

150 29 377

200 38 493

S R3 3/4" 1-1/4" 250 46 608

FP T FP T 300 55 724

350 64 839

400 73 955

150 37 491

200 49 641

S R4 3/4" 1-1/2" 250 60 791

FP T FP T 300 72 945

F

350 83 1091

400 95 1241

Selection Data

The Type SR Safety Relief Valve is intended to prevent DIMENSIONS IN INCHES

the pressure of the vessel from rising more than 10% VALVE A B C D F

above the Design Working Pressure (DWP) of the vessel SR1 1.562 2.50 5.05 3/4" NPT 1/2" NPT

or the pressure setting of the relief device, whichever is SR2 1.562 2.50 5.05 1" NPT 1/2" NPT

the lower pressure. SR3 1.875 3.00 5.92 1-1/4" NPT 3/4" NPT

SR4 1.875 3.00 5.92 1-1/2" NPT 3/4" NPT

Whenever conditions permit, it is advisable to have the

relief valve pressure setting (which must not exceed the

Refrigerant F

design working pressure of the vessel) at least 25% higher

than the normal operating pressure for the refrigerant used. R-717 0.5

R-22, -134a, -500 1.6

Pressure limiting devices, such as high pressure cutouts

on positive displacement compressor systems, must stop R-13, -404A, -502, -507 2.5

the action of the pressure imposing element at no higher All others 1.0

than 90% of the pressure setting for the pressure relief Warranty

device. All Refrigerating Specialties Products are warranted against defect

in workmanship and materials for a period of one year from date of

For non-positive displacement compressors, the pressure shipment from the factory, This warranty is in force only when

limiting device, such as a high pressure cut-out, may be products are properly installed, maintained and operated in use and

set at the DWP of the high side; providing, the low side is service as specifically stated in Refrigerating Specialties Catalogs

protected by a properly sized pressure relief device set or Bulletins for normal refrigeration applications, unless otherwise

approved in writing by Refrigerating Specialties Division. Defective

to relieve pressure at low side DWP and there are no products, or parts thereof returned to the factory with transportation

stop valves in the system that isolate the high side from charges prepaid and found to be defective by factory inspection will

the low side. be replaced or repaired at Refrigerating Specialties’ option, free of

charge, F.O.B. factory. Warranty does not cover products which

Discharge piping from relief devices must not exceed have been altered or repaired in the field; damaged in transit, or

specified lengths indicated in ANSI/ASHRAE 15 with have suffered accidents, misuse, or abuse. Products disabled by

discharge to atmosphere. dirt, or other foreign substances will not be considered defective.

THE EXPRESS WARRANTY SET FORTH ABOVE CONSTITUTES

Per ANSI/ASHRAE 15 the minimum required discharge THE ONLY WARRANTY APPLICABLE TO REFRIGERATING

capacity of a relief device for each pressure vessel where SPECIALTIES PRODUCTS, AND IS IN LIEU OF ALL OTHER

vessel is valved off from refrigerating systems is WARRANTIES, EXPRESS OR IMPLIED, WRITTEN OR ORAL,

determined as follows: C = FDL. Where D = outside INCLUDING ANY WARRANTY OF MERCHANTABILITY, OR

FITNESS FOR A PARTICULAR PURPOSE. No employee, agent,

diameter of vessel, ft.; L = Length of vessel, ft.; dealer or other person is authorized to give any warranties on

C = Capacity, lb/min air and F = Factor determined as behalf of Refrigerating Specialties, nor to assume, for Refrigerating

follows: Specialties, any other liability in connection with any of its products.

Refrigerating Specialties Division 2

Você também pode gostar

- Business Startup Practical Plan PDFDocumento70 páginasBusiness Startup Practical Plan PDFShaji Viswanathan. Mcom, MBA (U.K)Ainda não há avaliações

- HierbasDocumento25 páginasHierbasrincón de la iohAinda não há avaliações

- Jamesbury Ball Valves PDFDocumento20 páginasJamesbury Ball Valves PDFGabriel Andrés Barcha Angulo100% (1)

- Bendix Valvula Qr1cDocumento4 páginasBendix Valvula Qr1cmiguel cuevasAinda não há avaliações

- Nursing Care PlansDocumento10 páginasNursing Care PlansGracie S. Vergara100% (1)

- Pocket Guide to Flanges, Fittings, and Piping DataNo EverandPocket Guide to Flanges, Fittings, and Piping DataNota: 3.5 de 5 estrelas3.5/5 (22)

- Quiz EmbryologyDocumento41 páginasQuiz EmbryologyMedShare90% (67)

- The National Building Code of The PhilippinesDocumento390 páginasThe National Building Code of The PhilippinesJohn Joseph EstebanAinda não há avaliações

- L&T Gate Globe Check Valves API 602Documento12 páginasL&T Gate Globe Check Valves API 602Nilesh MistryAinda não há avaliações

- PT6 Training ManualDocumento64 páginasPT6 Training ManualAnderson Guimarães100% (2)

- Sigma monitor relayDocumento32 páginasSigma monitor relayEdwin Oria EspinozaAinda não há avaliações

- HTM 2025 2 (New) Ventilation in HospitalsDocumento123 páginasHTM 2025 2 (New) Ventilation in HospitalsArvish RamseebaluckAinda não há avaliações

- Manual de Referencia PlanmecaDocumento288 páginasManual de Referencia PlanmecaJorge Escalona Hernandez100% (2)

- Bendix Valvula BPR1Documento12 páginasBendix Valvula BPR1miguel cuevasAinda não há avaliações

- Parker Válvula de Segurança Modelos Type HDocumento2 páginasParker Válvula de Segurança Modelos Type HFrancisco Javier Leal BrachoAinda não há avaliações

- BV502Documento3 páginasBV502plvillarrealAinda não há avaliações

- Ball Valves: For SteamDocumento8 páginasBall Valves: For SteamcontorrresjulianAinda não há avaliações

- AV2000_ThermostaticAirVentDocumento1 páginaAV2000_ThermostaticAirVentauxiliar.termicaAinda não há avaliações

- Spor LanDocumento30 páginasSpor LanKumar sssssAinda não há avaliações

- Confirmation Fan Discharge-DirectionDocumento2 páginasConfirmation Fan Discharge-DirectionCuong TruongAinda não há avaliações

- Orbit Parts List and Ordering InstructionsDocumento24 páginasOrbit Parts List and Ordering Instructionskeertiraj09Ainda não há avaliações

- 200rb Solenoid-Valves-Catalog-En-Us-4763170Documento4 páginas200rb Solenoid-Valves-Catalog-En-Us-4763170desenvolvimentoAinda não há avaliações

- Asco 8344 PDFDocumento2 páginasAsco 8344 PDFOsman Lopez SalasAinda não há avaliações

- Descarga 1er Paso Mercer 91-52j11t84u1Documento16 páginasDescarga 1er Paso Mercer 91-52j11t84u1Alberto Esau Reyes CruzAinda não há avaliações

- E300 Globe ValvesDocumento24 páginasE300 Globe ValvesBOUZAIDAAinda não há avaliações

- Burmad 400 Series-Globe Type Deluge ValveDocumento8 páginasBurmad 400 Series-Globe Type Deluge Valvenastyn-1Ainda não há avaliações

- Pilot Operated Air and Water Solenoid ValvesDocumento4 páginasPilot Operated Air and Water Solenoid ValvesDevinAinda não há avaliações

- Safety Relief Valves for Refrigeration SystemsDocumento2 páginasSafety Relief Valves for Refrigeration SystemsAlejandro VazAinda não há avaliações

- Appendix 2-7.ep11482 - g-16Documento17 páginasAppendix 2-7.ep11482 - g-16bsnegi111Ainda não há avaliações

- SSBall ValvesDocumento5 páginasSSBall ValvesEmilly ChavesAinda não há avaliações

- E30C - Globe Valves NewDocumento20 páginasE30C - Globe Valves NewTaha FaAinda não há avaliações

- Parker Ball - Valves - Series - 502SSDocumento2 páginasParker Ball - Valves - Series - 502SScobalAinda não há avaliações

- Alarm Valve DetailsDocumento5 páginasAlarm Valve DetailsRoshan JaiswalAinda não há avaliações

- Válvulas Jamesbury SERIES 860Documento8 páginasVálvulas Jamesbury SERIES 860Felipe Ribeiro da CostaAinda não há avaliações

- Danfoss SFVLDocumento8 páginasDanfoss SFVLTorres Ivan100% (1)

- 400E EngineeringDocumento8 páginas400E EngineeringDenis Oliveira CostaAinda não há avaliações

- FMAV61Documento4 páginasFMAV61Amr ATTIAAinda não há avaliações

- Dossier Suministro de Valvulas de Seccionamiento CONTRATO No. 6000004219Documento212 páginasDossier Suministro de Valvulas de Seccionamiento CONTRATO No. 6000004219Bureau VeritasAinda não há avaliações

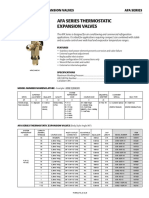

- Afa Series Thermostatic Expansion Valves Catalog en Us 1569678Documento3 páginasAfa Series Thermostatic Expansion Valves Catalog en Us 1569678Muhammad SyafiqAinda não há avaliações

- Industrial Valve CatalogDocumento126 páginasIndustrial Valve CatalogHung Nguyen VietAinda não há avaliações

- Series MR Flowmeters: FeaturesDocumento2 páginasSeries MR Flowmeters: FeaturesccnbtAinda não há avaliações

- Fisher ET and EZ Easy e Control Valves With Trim Cartridge: Scope of ManualDocumento12 páginasFisher ET and EZ Easy e Control Valves With Trim Cartridge: Scope of ManualGieAinda não há avaliações

- CROSS REFERENCE DE VALVULAS SOLENOIDES - Danfoss - Alco - Sporlan-ParkerDocumento4 páginasCROSS REFERENCE DE VALVULAS SOLENOIDES - Danfoss - Alco - Sporlan-ParkerJoss CastellAinda não há avaliações

- PDP Series Positive Displacement Plunger Dosing Pump Technical SpecsDocumento12 páginasPDP Series Positive Displacement Plunger Dosing Pump Technical SpecsTrungGVAinda não há avaliações

- Asco Series 316 Air Water CatalogDocumento4 páginasAsco Series 316 Air Water CatalogekoAinda não há avaliações

- Safety Relief Valve: Type SRH1, SRH2, SRH3, SRH4 & Srh5Documento2 páginasSafety Relief Valve: Type SRH1, SRH2, SRH3, SRH4 & Srh5Subbarayan SaravanakumarAinda não há avaliações

- Firesafe Ball Valve: InlineDocumento4 páginasFiresafe Ball Valve: InlineMASOUDAinda não há avaliações

- Vc d v Kea Kfa Kla Spira Trol Ti d413 03Documento8 páginasVc d v Kea Kfa Kla Spira Trol Ti d413 03Rinto SilalahiAinda não há avaliações

- Catalog Series 223 Asco en 3674094Documento2 páginasCatalog Series 223 Asco en 3674094LouisAinda não há avaliações

- Dust Collector Main Pulse Valves: FeaturesDocumento4 páginasDust Collector Main Pulse Valves: FeaturesQuân TrịnhAinda não há avaliações

- Amco CR4000 PDFDocumento4 páginasAmco CR4000 PDFDANIEL CASTAÑEDAAinda não há avaliações

- Lead Free: Cast Carbon & Alloy Steel Flanged & Butt Weld End Y StrainersDocumento2 páginasLead Free: Cast Carbon & Alloy Steel Flanged & Butt Weld End Y StrainersRockny2011Ainda não há avaliações

- Manuals 1190 Low Pressure Gas Blanketing Regulator Instruction Manual Fisher en en 5985974Documento24 páginasManuals 1190 Low Pressure Gas Blanketing Regulator Instruction Manual Fisher en en 5985974marinjerman6Ainda não há avaliações

- Válvula DurcoDocumento12 páginasVálvula DurcoJames Henrry López EspejoAinda não há avaliações

- Mercer Valve 9100 Relief Valve Flanged AEDocumento16 páginasMercer Valve 9100 Relief Valve Flanged AEChristopher Kenneth ChoaAinda não há avaliações

- High-Performance Butterfly Valve CatalogDocumento2 páginasHigh-Performance Butterfly Valve CatalogAndrea Tapia FuentesAinda não há avaliações

- HIGH FLOW PULSE VALVESDocumento4 páginasHIGH FLOW PULSE VALVESFelipe SalvatierraAinda não há avaliações

- Perar WCWB Trunnion Welded BodyDocumento19 páginasPerar WCWB Trunnion Welded BodyAlexandra HarperAinda não há avaliações

- Nutron TM Trunnion Mounted Ball Valve FlyerDocumento2 páginasNutron TM Trunnion Mounted Ball Valve FlyerAlbert RubianoAinda não há avaliações

- Top Entry Trunnion 600 - 2500Documento20 páginasTop Entry Trunnion 600 - 2500Danny PuchaAinda não há avaliações

- Safety Relief Valves and Double Stop Valves,: Type SFVL and DSVLDocumento8 páginasSafety Relief Valves and Double Stop Valves,: Type SFVL and DSVLJason CampbellAinda não há avaliações

- ValvesDocumento7 páginasValvesAnonymous NR3qZ30Ainda não há avaliações

- Mercer Valve 8100Documento12 páginasMercer Valve 8100yanethAinda não há avaliações

- Hydraulic Hose Catalogue & Price List 2017Documento20 páginasHydraulic Hose Catalogue & Price List 2017Anonymous VRspXsmAinda não há avaliações

- Bulletin 71.1:1301: Types 1301F and 1301G High-Pressure RegulatorsDocumento8 páginasBulletin 71.1:1301: Types 1301F and 1301G High-Pressure RegulatorsinvidiuoAinda não há avaliações

- Aot Om2700aDocumento9 páginasAot Om2700aModestyAinda não há avaliações

- Butterfly TrainingDocumento24 páginasButterfly TrainingOlawale John AdeotiAinda não há avaliações

- CVC Steel FullDocumento28 páginasCVC Steel FullSergio Bacca SantiagoAinda não há avaliações

- Drum Roller and ComponentsDocumento1 páginaDrum Roller and Componentsmiguel cuevasAinda não há avaliações

- Bendix Valve Sr5Documento3 páginasBendix Valve Sr5miguel cuevasAinda não há avaliações

- Bendix Abs BloqueoDocumento75 páginasBendix Abs Bloqueomiguel cuevasAinda não há avaliações

- 8-26-16 Police ReportDocumento14 páginas8-26-16 Police ReportNoah StubbsAinda não há avaliações

- Indonesia Organic Farming 2011 - IndonesiaDOCDocumento18 páginasIndonesia Organic Farming 2011 - IndonesiaDOCJamal BakarAinda não há avaliações

- Natural Resources in PakistanDocumento5 páginasNatural Resources in PakistanSohaib EAinda não há avaliações

- Forest Fire Detection and Guiding Animals To A Safe Area by Using Sensor Networks and SoundDocumento4 páginasForest Fire Detection and Guiding Animals To A Safe Area by Using Sensor Networks and SoundAnonymous 6iFFjEpzYjAinda não há avaliações

- ME JBP 70A Pen Dissolved Oxygen Meter PDFDocumento1 páginaME JBP 70A Pen Dissolved Oxygen Meter PDFpiknikmonsterAinda não há avaliações

- Board Review Endocrinology A. ApiradeeDocumento47 páginasBoard Review Endocrinology A. ApiradeePiyasak NaumnaAinda não há avaliações

- Fuck Your LawnDocumento86 páginasFuck Your Lawnhuneebee100% (1)

- Design and Built-A4Documento2 páginasDesign and Built-A4farahazuraAinda não há avaliações

- Philippines implements external quality assessment for clinical labsDocumento2 páginasPhilippines implements external quality assessment for clinical labsKimberly PeranteAinda não há avaliações

- Immune System Quiz ResultsDocumento6 páginasImmune System Quiz ResultsShafeeq ZamanAinda não há avaliações

- Genetics ProblemsDocumento50 páginasGenetics ProblemsTasneem SweedanAinda não há avaliações

- PERSONS Finals Reviewer Chi 0809Documento153 páginasPERSONS Finals Reviewer Chi 0809Erika Angela GalceranAinda não há avaliações

- Consumer Behaviour: Group ProjectDocumento5 páginasConsumer Behaviour: Group ProjectAanchal MahajanAinda não há avaliações

- The Impact of StressDocumento3 páginasThe Impact of StressACabalIronedKryptonAinda não há avaliações

- BOF, LF & CasterDocumento14 páginasBOF, LF & CastermaklesurrahmanAinda não há avaliações

- Exercise 4 Summary - KEY PDFDocumento3 páginasExercise 4 Summary - KEY PDFFrida Olea100% (1)

- Reference For Biology AssignmentDocumento2 páginasReference For Biology Assignmentdhanieya ganeishAinda não há avaliações

- Roadblocks Overcome Cruise PurchaseTITLE Top 15 Cruise Hesitations Answered TITLE How to Convince People Cruises Worth CostDocumento4 páginasRoadblocks Overcome Cruise PurchaseTITLE Top 15 Cruise Hesitations Answered TITLE How to Convince People Cruises Worth CostJanel Castillo Balbiran33% (3)

- 57882d4608ae21394a0c7b00 PDFDocumento574 páginas57882d4608ae21394a0c7b00 PDFtualaAinda não há avaliações

- Apc 8x Install Config Guide - rn0 - LT - enDocumento162 páginasApc 8x Install Config Guide - rn0 - LT - enOney Enrique Mendez MercadoAinda não há avaliações

- Akshaya Trust NgoDocumento24 páginasAkshaya Trust NgodushyantAinda não há avaliações