Escolar Documentos

Profissional Documentos

Cultura Documentos

ERIKS - O-Ring Datasheet - FKM 75-Compound 514322 Black

Enviado por

seeralan_1986Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

ERIKS - O-Ring Datasheet - FKM 75-Compound 514322 Black

Enviado por

seeralan_1986Direitos autorais:

Formatos disponíveis

Sealing elements

F K M 7 5 - c o m p o u n d 5 1 4 3 2 2 b l a c k - Te c h n i c a l D a t a S h e e t

1. Introduction

FKM fluoroelastomer designed for high demanding sealing applications in agressive

chemicals at low temperature.

2. Product Description

Chemical Composition : Low temperature fluoroelastomer, 65% fluorine, peroxide cured

Physical form : O-Rings, cord

Colour : Black

Odour : None

Storage stability * : Excellent

* : Following ISO 2230 conditions

3. Physical Properties

Test Method Norm Test Values

Hardness ISO 868 75 ± 5 Shore A

Density ISO 2781 1,8 g/cm3

Modulus at 100% ISO 37 2,4 MPa

Tensile Strength ISO 37 15,0 MPa

Elongation ISO 37 min.180%

Compression Set 70h/200°C ISO 815 <22,5%

Low Temperature Resistance

TR10 ASTM D 1329 -40°C

Heat Ageing in air 168h/200°C

Hardness Change ISO 188 +3 Shore A

Tensile Strength Change ISO 188 +10%

Ultimate Elongation Change ISO 188 -15%

Aging in Fuel C 70h/23°C

Hardness Change ASTM D 471 -8 Shore A

Tensile Strength Change ASTM D 471 -25%

Ultimate Elongation Change ASTM D 471 -15%

Volume Swell ASTM D 471 +6,0%

4. Temperature Resistance 5. Chemical Resistance

• -45 to +200°C Concentrated acids : excellent

Acetone : bad

80 Hydroxides : excellent

Benzene : excellent

60 Crude oil : excellent

Toluene : excellent

Retraction (%)

40 Fuel C : excellent

Gasoline : very good

20 BTM oil 3 : excellent

Methylene chloride : very good

0 MEK : bad

-45 -40 -35 -30 -25 -20 MTBE : bad

Temperature (°C) Water <100°C : good

This information is, to the best of our knowledge, accurate and reliable to the date indicated. The above mentioned data

have been obtained by tests we consider as reliable. We don’t assure that the same results can be obtained in other 12.01.2010

laboratories, using different conditions by the preparation and evaluation of the samples. 86

Você também pode gostar

- O Rings HandbookDocumento292 páginasO Rings HandbookleocastarlenasAinda não há avaliações

- Learn-Kannada in 30 DaysDocumento16 páginasLearn-Kannada in 30 DaysSatish Reddy Kunduru92% (12)

- Non-Intrusive Magnetic Pig SignallerDocumento2 páginasNon-Intrusive Magnetic Pig SignallerAndresAinda não há avaliações

- John Deere 4044M, 4044R, 4049M, 4049R, 4052M, 4052R, 4066M, 4066R Tractor Manual TM131019 PDFDocumento31 páginasJohn Deere 4044M, 4044R, 4049M, 4049R, 4052M, 4052R, 4066M, 4066R Tractor Manual TM131019 PDFEquipment Manuals0% (3)

- Overview of Pipeline Coatings) PDFDocumento7 páginasOverview of Pipeline Coatings) PDFTamer Hesham AhmedAinda não há avaliações

- C - Evaluation Selection of Directional Drill Pipe Coatings - 2023 - P9Documento51 páginasC - Evaluation Selection of Directional Drill Pipe Coatings - 2023 - P9Pammy JainAinda não há avaliações

- 03 - Traffic and Equivalent Axle Loads (Updated)Documento88 páginas03 - Traffic and Equivalent Axle Loads (Updated)Besim QelajAinda não há avaliações

- Book Abstract ICDEMOS 2014Documento70 páginasBook Abstract ICDEMOS 201423045566Ainda não há avaliações

- A High Performance, Damage Tolerant Fusion Bonded Epoxy CoatingDocumento15 páginasA High Performance, Damage Tolerant Fusion Bonded Epoxy CoatingpaimpillyAinda não há avaliações

- Pig SignallerDocumento4 páginasPig SignallerHạo Nam-Born To WinAinda não há avaliações

- Law of AttractionDocumento61 páginasLaw of Attractionrajiv ranjanAinda não há avaliações

- Abu Dhabi Parking Standards PDFDocumento40 páginasAbu Dhabi Parking Standards PDFyvette100% (3)

- KSB AmriDocumento40 páginasKSB Amriseeralan_1986Ainda não há avaliações

- Tender9 Vol II o II PDFDocumento31 páginasTender9 Vol II o II PDFmusaveerAinda não há avaliações

- A860 WPHY52-WPHY70: DescriptionDocumento2 páginasA860 WPHY52-WPHY70: DescriptionJuan SimbaAinda não há avaliações

- Engine Room VentillationDocumento36 páginasEngine Room VentillationAnwarul Shafiq AwalludinAinda não há avaliações

- Air ConditioningDocumento25 páginasAir ConditioningJohanAinda não há avaliações

- Datasheet Pigging Control Systems 0212 Rev1Documento5 páginasDatasheet Pigging Control Systems 0212 Rev1Murli ramchandranAinda não há avaliações

- Combisafe Net BarrierDocumento10 páginasCombisafe Net BarrierjoebriffaAinda não há avaliações

- ASTM E436 Drop-Weight Tear Tests of Ferritic SteelsDocumento5 páginasASTM E436 Drop-Weight Tear Tests of Ferritic SteelsledaswanAinda não há avaliações

- Offshore Applications of SRTPDocumento5 páginasOffshore Applications of SRTPArif AshrafAinda não há avaliações

- Corrosion Coupon Installation Procedure PDFDocumento31 páginasCorrosion Coupon Installation Procedure PDFtrichysayeeAinda não há avaliações

- Technical Requirements For Pipes & FittingsDocumento7 páginasTechnical Requirements For Pipes & FittingsKyaw Kyaw AungAinda não há avaliações

- Seat Material PDFDocumento2 páginasSeat Material PDFkrisAinda não há avaliações

- 24-84-83-1648 - 0 Attachment-III PDFDocumento5 páginas24-84-83-1648 - 0 Attachment-III PDFSabu Abdul NoorAinda não há avaliações

- Canusa Pipeline Repair Products Installation GuideDocumento2 páginasCanusa Pipeline Repair Products Installation GuideLewoski100% (1)

- Squares and Square RootsDocumento8 páginasSquares and Square RootsJessica RamerAinda não há avaliações

- Testing and Analysis of Pipeline Ball Valves Part 1 PDFDocumento3 páginasTesting and Analysis of Pipeline Ball Valves Part 1 PDFNovianto Rachmad100% (1)

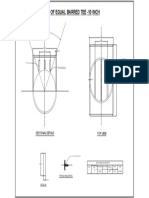

- Fabrication GAD of Equal Barred Tee - 10 Inch PDFDocumento1 páginaFabrication GAD of Equal Barred Tee - 10 Inch PDFThamaraikani Mani100% (1)

- Datasheet - Pig Signallers: Product Description and FunctionsDocumento2 páginasDatasheet - Pig Signallers: Product Description and FunctionsMurli ramchandranAinda não há avaliações

- Difference Between Izod and Charpy MethodsDocumento2 páginasDifference Between Izod and Charpy Methodsvasudeva yasasAinda não há avaliações

- Seat Material Selection in Ball ValvesDocumento2 páginasSeat Material Selection in Ball Valvescoolguy12345Ainda não há avaliações

- Double Block Bleed Twin Plug Ball Valve Single Body ANSI ASMEDocumento4 páginasDouble Block Bleed Twin Plug Ball Valve Single Body ANSI ASMEBharuk MechAinda não há avaliações

- BrederoShaw PDS FBE PDFDocumento2 páginasBrederoShaw PDS FBE PDFJR RZAinda não há avaliações

- Corrosion Coupon Rack: Installation & Operation ManualDocumento7 páginasCorrosion Coupon Rack: Installation & Operation ManualVania Nicol Arapa YugarAinda não há avaliações

- CRA Pipes: Corrosion TestDocumento2 páginasCRA Pipes: Corrosion TestNavafAinda não há avaliações

- MISC Materials ListDocumento10 páginasMISC Materials ListWaqas WaqasAinda não há avaliações

- Pigging System PDFDocumento4 páginasPigging System PDFeka resmanaAinda não há avaliações

- The Meaning of Angel Number 1111 Is A Question That Many People Ask Every DayDocumento2 páginasThe Meaning of Angel Number 1111 Is A Question That Many People Ask Every DayAsim Bashir100% (1)

- Global Valve & Controls: Depend On Us, We Can Handle The PressureDocumento4 páginasGlobal Valve & Controls: Depend On Us, We Can Handle The PressurealeeimeranAinda não há avaliações

- tb2 Articulo 1 PDFDocumento9 páginastb2 Articulo 1 PDFKaty Milagros Pacheco CalderonAinda não há avaliações

- Railway Cased CrossingDocumento1 páginaRailway Cased Crossingbinay kumarAinda não há avaliações

- Ball ValvesDocumento4 páginasBall ValvesJorge Arana YiAinda não há avaliações

- Thermoplastic Seals & Components For The Oil & Gas IndustryDocumento20 páginasThermoplastic Seals & Components For The Oil & Gas Industrya100acom100% (1)

- Nozzles and DiffusersDocumento3 páginasNozzles and DiffusersOwais SialAinda não há avaliações

- Product Data Booklet Fibertec Ultimate HDD Coating SystemDocumento8 páginasProduct Data Booklet Fibertec Ultimate HDD Coating Systemmkash028Ainda não há avaliações

- Lecture Note 4 (Metallic & Non-Metallic Pipes) PDFDocumento20 páginasLecture Note 4 (Metallic & Non-Metallic Pipes) PDFhkaqlqAinda não há avaliações

- Charpy Impact Test - WikipediaDocumento18 páginasCharpy Impact Test - WikipediaAshik Speed YuvanAinda não há avaliações

- Hydrostatic Test Procedure (Rev.1)Documento8 páginasHydrostatic Test Procedure (Rev.1)lukman100% (1)

- Fracture Toughness and FatigueDocumento10 páginasFracture Toughness and FatigueiamjemahAinda não há avaliações

- Valve Materials DetailsDocumento15 páginasValve Materials DetailsKasthuri Rangan KAinda não há avaliações

- API 5L 45-th Edition: Item No SawlDocumento6 páginasAPI 5L 45-th Edition: Item No SawlRob WillestoneAinda não há avaliações

- Surveying 2Documento81 páginasSurveying 2زبیر شاہAinda não há avaliações

- DBB ValveDocumento6 páginasDBB ValveshyamAinda não há avaliações

- Criteria For The Selection of Metallic Pipelines CoatingsDocumento10 páginasCriteria For The Selection of Metallic Pipelines CoatingsVinicius CarvalhoAinda não há avaliações

- PMSS Ball ValveDocumento1 páginaPMSS Ball ValveGourav SharmaAinda não há avaliações

- Crack Opening DisplacementDocumento2 páginasCrack Opening Displacementsqaiba_gAinda não há avaliações

- Vibration Assessment of Barred TeeDocumento1 páginaVibration Assessment of Barred Teeข้าวเม่า ทอดAinda não há avaliações

- Fracture Toughness TestingDocumento2 páginasFracture Toughness TestingArghadeep RoyAinda não há avaliações

- New Gen Trunnion Soft Seat Ball ValveDocumento7 páginasNew Gen Trunnion Soft Seat Ball ValvedirtylsuAinda não há avaliações

- Cs - Ad Crude Oil VFDocumento1 páginaCs - Ad Crude Oil VFKommu RohithAinda não há avaliações

- MicrotunellingDocumento10 páginasMicrotunellingleo.caguimbal6433Ainda não há avaliações

- PPI Handbook of PE Pipe - Chapter 10Documento37 páginasPPI Handbook of PE Pipe - Chapter 10Nicko Adrianto100% (1)

- ERIKS - Datasheet - FKM 70-Compound 514308Documento1 páginaERIKS - Datasheet - FKM 70-Compound 514308DarkedgeAinda não há avaliações

- ERIKS - Datasheet - FKM 75-Compound 514010 WhiteDocumento1 páginaERIKS - Datasheet - FKM 75-Compound 514010 WhiteDarkedgeAinda não há avaliações

- ERIKS - Datasheet - FKM 75-Compound 514206 Copolymer For Vulc-O-RingDocumento1 páginaERIKS - Datasheet - FKM 75-Compound 514206 Copolymer For Vulc-O-RingDarkedgeAinda não há avaliações

- Eriks - Datasheet - NBR 70-Compound 366005Documento1 páginaEriks - Datasheet - NBR 70-Compound 366005Guillaume JaAinda não há avaliações

- NBR 70-Compound 36626 - Technical Data SheetDocumento1 páginaNBR 70-Compound 36626 - Technical Data SheetGuillaume JaAinda não há avaliações

- Madhavi, Alli, SakunthalaDocumento3 páginasMadhavi, Alli, Sakunthalaseeralan_1986Ainda não há avaliações

- Ride Details Bill Details: Thanks For Travelling With Us, VinodDocumento3 páginasRide Details Bill Details: Thanks For Travelling With Us, Vinodseeralan_1986Ainda não há avaliações

- Covid-19 Q&ADocumento10 páginasCovid-19 Q&AAjay_mane22Ainda não há avaliações

- PCTFEDocumento20 páginasPCTFEKresno BriAinda não há avaliações

- Arlon 3000 XT:: Superior Insulative Performance For High Power ConductorsDocumento2 páginasArlon 3000 XT:: Superior Insulative Performance For High Power Conductorsseeralan_1986Ainda não há avaliações

- Is.6157.1981 Gate Valve TestDocumento6 páginasIs.6157.1981 Gate Valve TestUjwolAinda não há avaliações

- Tax Invoice: Sgst/UtgstDocumento1 páginaTax Invoice: Sgst/Utgstseeralan_1986Ainda não há avaliações

- Tax Invoice: Sgst/UtgstDocumento1 páginaTax Invoice: Sgst/Utgstseeralan_1986Ainda não há avaliações

- Loaned IT Assets: Employee Name 1Documento2 páginasLoaned IT Assets: Employee Name 1seeralan_1986Ainda não há avaliações

- Avk Butterfly Valves, Centric With Loose Liner: Series 820Documento6 páginasAvk Butterfly Valves, Centric With Loose Liner: Series 820utzu_yooAinda não há avaliações

- Untitled Document LALA KAKADocumento2 páginasUntitled Document LALA KAKAAnkit YadavAinda não há avaliações

- October 25, 1999 13:58:08 Information Handling Services, 1999Documento4 páginasOctober 25, 1999 13:58:08 Information Handling Services, 1999seeralan_1986Ainda não há avaliações

- Butterfly Valves Double Offset Kennedy Series 614 To EN/ISO StandardsDocumento2 páginasButterfly Valves Double Offset Kennedy Series 614 To EN/ISO Standardsseeralan_1986Ainda não há avaliações

- Is.6157.1981 Gate Valve TestDocumento6 páginasIs.6157.1981 Gate Valve TestUjwolAinda não há avaliações

- Kannada Language GuideDocumento5 páginasKannada Language GuideSankar SasmalAinda não há avaliações

- Sylax Gas B: Technical ManualDocumento15 páginasSylax Gas B: Technical Manualseeralan_1986Ainda não há avaliações

- Professional Plastics, Inc.: USA Phone (888) 995-7767 Asia Phone +65-6266-6193Documento1 páginaProfessional Plastics, Inc.: USA Phone (888) 995-7767 Asia Phone +65-6266-6193seeralan_1986Ainda não há avaliações

- Water Supplies Department: M-02-01 June 2016Documento11 páginasWater Supplies Department: M-02-01 June 2016seeralan_1986Ainda não há avaliações

- Butterfly Valves Double Offset Kennedy Series 614 To EN/ISO StandardsDocumento2 páginasButterfly Valves Double Offset Kennedy Series 614 To EN/ISO Standardsseeralan_1986Ainda não há avaliações

- Armature NDocumento2 páginasArmature Nseeralan_1986Ainda não há avaliações

- How AVK Complies To The en 1074 Standard - AVK InternationalDocumento5 páginasHow AVK Complies To The en 1074 Standard - AVK Internationalseeralan_1986Ainda não há avaliações

- Sylax Gas B: Technical ManualDocumento15 páginasSylax Gas B: Technical Manualseeralan_1986Ainda não há avaliações

- Temple TownDocumento28 páginasTemple Townseeralan_1986Ainda não há avaliações

- China - Bundle Plan New PDFDocumento1 páginaChina - Bundle Plan New PDFseeralan_1986Ainda não há avaliações

- Important Spoken Tamil SituationsDocumento3 páginasImportant Spoken Tamil Situationsseeralan_1986Ainda não há avaliações

- Madurai Bangalore Train SCHDocumento2 páginasMadurai Bangalore Train SCHseeralan_1986Ainda não há avaliações

- S. No. Station Code Station Name Route No. Arrival Time Departure Time Halt Time (In Minutes) Distance DDocumento1 páginaS. No. Station Code Station Name Route No. Arrival Time Departure Time Halt Time (In Minutes) Distance Dseeralan_1986Ainda não há avaliações

- DCDC Selection Guide-EDocumento36 páginasDCDC Selection Guide-EJose CabusAinda não há avaliações

- Conduit Steel: Barton Engineering CatalogueDocumento37 páginasConduit Steel: Barton Engineering CatalogueBilal HussainAinda não há avaliações

- Evaluation of Iron and Steel in Historic BridgesDocumento8 páginasEvaluation of Iron and Steel in Historic BridgesjayaramanrathnamAinda não há avaliações

- Pettit Paints Pettit ThinnersDocumento1 páginaPettit Paints Pettit ThinnersRoddy GonzalezAinda não há avaliações

- Indian Standard: Specification For Indented Wire For Prestressed ConcreteDocumento17 páginasIndian Standard: Specification For Indented Wire For Prestressed ConcreteAjit P. SinghAinda não há avaliações

- SMS OMAV Announcement 19102011rev1Documento1 páginaSMS OMAV Announcement 19102011rev1Mohamed Sayed Abdel GaffarAinda não há avaliações

- General Characteristics: Power DefinitionDocumento6 páginasGeneral Characteristics: Power Definitionzekson1Ainda não há avaliações

- ABB JAC Control Drive 1804 20180913 FinalDocumento4 páginasABB JAC Control Drive 1804 20180913 FinalisctomaslopezAinda não há avaliações

- Service Bulletin IndexDocumento19 páginasService Bulletin IndexRafael SchelbauerAinda não há avaliações

- Feed Mixer 420-12 490-14: Assembly, Operation and Parts ManualDocumento63 páginasFeed Mixer 420-12 490-14: Assembly, Operation and Parts ManualErich illanes uribeAinda não há avaliações

- Construction Project ManagerDocumento2 páginasConstruction Project Managerapi-76791423Ainda não há avaliações

- DC Blue Digital User ManualDocumento5 páginasDC Blue Digital User ManualacinsaAinda não há avaliações

- Sproket Ratio CalculatorDocumento2 páginasSproket Ratio CalculatorH3liax100% (6)

- What Is MEMS TechnologyDocumento6 páginasWhat Is MEMS TechnologyMAHDILEE100% (2)

- Cycle Gas Compressor For Polyolefin, DH SeriesDocumento5 páginasCycle Gas Compressor For Polyolefin, DH SeriesridanormaAinda não há avaliações

- TowFLEXX® 600 RCDocumento12 páginasTowFLEXX® 600 RCAREZZO AVIAAinda não há avaliações

- 14.Cttc Bhuvaneshwar Admma QualfileDocumento24 páginas14.Cttc Bhuvaneshwar Admma QualfileGold SmithAinda não há avaliações

- PresentationDocumento22 páginasPresentationEstiakAinda não há avaliações

- Fukada TreeDocumento4 páginasFukada Treeiuridicaprima4Ainda não há avaliações

- Test Procedure For Determining of Aggregate Abrasion Value: Purpose of Testing: Table No: 1Documento2 páginasTest Procedure For Determining of Aggregate Abrasion Value: Purpose of Testing: Table No: 1Pankaj shahAinda não há avaliações

- Sista Foam SpecificationDocumento1 páginaSista Foam SpecificationFrancois-Ainda não há avaliações

- Total Volume of Column Footing: Concrete WorksDocumento4 páginasTotal Volume of Column Footing: Concrete Workssheralld salasAinda não há avaliações

- Valuejet 1604 ServiceManualDocumento422 páginasValuejet 1604 ServiceManualIonel VanguAinda não há avaliações

- NASA: Changes To Non-AST NSCS SchematicDocumento20 páginasNASA: Changes To Non-AST NSCS SchematicNASAdocumentsAinda não há avaliações