Escolar Documentos

Profissional Documentos

Cultura Documentos

Pipeline Pressure Testing Calculations Client: Date: Project: Pipeline Details: From KP 0.012 To KP 22.3 (Insert (A) To (D) )

Enviado por

Rahul MoottolikandyTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Pipeline Pressure Testing Calculations Client: Date: Project: Pipeline Details: From KP 0.012 To KP 22.3 (Insert (A) To (D) )

Enviado por

Rahul MoottolikandyDireitos autorais:

Formatos disponíveis

PIPELINE PRESSURE TESTING CALCULATIONS

CLIENT: Qatar Petroleum DATE: 18.03.09

PROJECT: MPPL From QP to Doha Depot

PIPELINE DETAILS: FROM KP 0.012 TO KP 22.3

(Insert (a) to (d))

Outside Diameter: (a) 457 mm = 0.457 metres

Wall Thickness: (b) 7.9 mm = 0.0079 metres

Inside Diameter: 441.2 mm = 0.4412 metres

Length: (c) 19708.433 m = 19.708433 kilometres

VOLUMES:

Using the formula:- FV = ᴫ x ( id2 ) x L

4

Where: FV = Pipeline fill volume (m3)

Pi = 3.14159

id = Pipeline internal diameter (m)

L = Pipeline length (m)

V = 3.14159 x 0.19465744 x 1 / 4

VOLUME PER LINEAR METRE TOTAL VOLUME

= 0.152883467 m3 = 3013.093561 m3

or 152.8834667 litres or 3013093.561 litres

or 5.39831521 SCF or 106392.3336 SCF

or 33.63436268 imp gallons or 662880.5834 imp gallons

or 40.3780524 US gallons (liquid) or 795788.1404 US gallons (liquid)

or 1.292097677 US barrels (liquid) or 25465.22049 US barrels (liquid)

or 0.9613822 US barrels (oil) or 18947.33668 US barrels (oil)

HYDROTEST DETAILS: Insert (e) to (i)

Test Pressure: (e) 61.25 bar or 888.125 psig

or 6125 kpa

Test Temperature: (f) 26 deg C or 78.8 deg F

or 299.16 kelvin

Type of test medium (g) potable water

Compressibility of test medium (h) 44.168 x 10-6 = 0.0000442 Graphs

Coefficient of expansion of test medium (i) 27.559 x 10-5 = 0.0002756

PRESSURISATION VOLUME - ( RESTRAINED PIPELINES )

Using the formula:- PV = V + V x ( 1-y2 ) x

id

K

W x E

Where: PV = Volume to raise the pressure 1 bar (m3)

V = Pipeline total fill volume (m3)

K = 1 / C

C = Compressibility of water x 10-6 per barg per deg C

( taken from compressibility of water graph ).

y = Poissons ratio ( 0.3 )

id = Pipeline internal diameter (m)

W = Pipeline wall thickness (m)

E = Youngs modulus of elasticity ( 2070000 )

PV = 3013.093561 + 3013.0935609032 x 0.91 x 0.4412

22640.82594 0.0079 x 2070000

= 0.133082316 + 0.0739762099

= 0.207058526 m3 = 207.0585262649 litres per barg

= 12.68233473 m3 = 12682.334733726 litres to reach test pressure

PUMP SIZE BEST SUITED TO ACHIEVE 1 BARG RISE PER MINUTE

207 litres / min or 46 gallons / min

MAXIMUM ALLOWABLE AIR CONTENT VOLUME 0.2%

6026 litres or 1327 gallons

PRESSURE TEMPERATURE - ( RESTRAINED PIPELINES )

The pressure change per unit change in temperature may be calculated by the following formula

from J.C. Gray, " How temperature affects Pipeline Hydrostatic Testing ". (Taken from the Pipeline and Gas Journal,

December 1976.).

P = (B - 2A)

OD x (1 - y2) + C

W x E

Where: P = Change in pressure (barg) per 1 deg C change in temperature

y = Poissons ratio ( 0.3 )

C = Compressibility of test water x 10-6 per barg per deg C

( taken from compressibility of test water graph ).

A = Coefficient of expansion of pipeline material 1.116 x 10-5 per deg C

B = Coefficient of expansion of test water x 10-5 per barg per deg C

( taken from thermal expansion of test water graph ).

OD = Pipeline outside diameter (m)

W = Pipeline wall thickness (m)

E = Youngs modulus of elasticity ( 2070000 )

The properties of A, E and y are constant for any type of pipe material. Properties for B and C 'must be obtained from the

0.0002524

P = 0.457 x 0.91 + 0.0000442

0.0079 x 2070000

= 0.00025239

0.00002543 + 0.0000442

= 3.63 bar per 1 deg C temperature change

or 53 psig

or 363 kpa

Note: The allowable pressure change attributable to temperature affect must be calculated for each deg C of the

temperature change over the test period.

GULMAR PLL TPI QP

SINATURE $

NAME

DATE

Você também pode gostar

- All Calculations For Pump, HE, ContainersDocumento6 páginasAll Calculations For Pump, HE, Containersamrsadek1Ainda não há avaliações

- Hge Refresher Exam 9 SolutionDocumento12 páginasHge Refresher Exam 9 SolutionaceeeceeeAinda não há avaliações

- MATERIAL Mechanical DesignDocumento11 páginasMATERIAL Mechanical DesignanisAinda não há avaliações

- MixerDocumento10 páginasMixerKRYSTEL WENDY LAHOMAinda não há avaliações

- MECHANICAL DESIGN: Superheater Design for Ammonia HeatingDocumento13 páginasMECHANICAL DESIGN: Superheater Design for Ammonia HeatingSchaieraAinda não há avaliações

- Rotary Dryer DesignDocumento43 páginasRotary Dryer DesignsasitharAinda não há avaliações

- Cooling EquipmentDocumento15 páginasCooling EquipmentRomelyn Suyom PingkianAinda não há avaliações

- 5.3 Design of Waste Heat Boiler: (13) : DataDocumento7 páginas5.3 Design of Waste Heat Boiler: (13) : Datamoni beeAinda não há avaliações

- Tankless Water Heater Heat Transfer AnalysisDocumento3 páginasTankless Water Heater Heat Transfer AnalysisSercan BaşarAinda não há avaliações

- Fluid FrictionDocumento11 páginasFluid FrictionChandni SeelochanAinda não há avaliações

- Shallow Foundation DesignDocumento10 páginasShallow Foundation DesignHelen Joy AdvientoAinda não há avaliações

- Ec 2 Problem SetDocumento11 páginasEc 2 Problem SetNenia RosasAinda não há avaliações

- CH 05Documento117 páginasCH 05pablo naragAinda não há avaliações

- ilide.info-exercise-c2-and-c3-group-1-pr_460b39743ded9744b4e45c894f64bb0bDocumento20 páginasilide.info-exercise-c2-and-c3-group-1-pr_460b39743ded9744b4e45c894f64bb0bAdrija ChakrabortyAinda não há avaliações

- Exercise C2 and C3 - Group 1Documento20 páginasExercise C2 and C3 - Group 1Trung Kỹ PhạmAinda não há avaliações

- Upheaval Buckling Calculation 24Documento10 páginasUpheaval Buckling Calculation 24Moustafa Fares100% (1)

- C 4Documento52 páginasC 4saur1Ainda não há avaliações

- Dimaano, John Michael A. 10-40670 Chapter FiveDocumento27 páginasDimaano, John Michael A. 10-40670 Chapter FiveJohn Michael DimaanoAinda não há avaliações

- Example CoagulFloccu1Documento3 páginasExample CoagulFloccu1Adarsh Agrawal100% (3)

- Monteron Jaji C4 2Documento15 páginasMonteron Jaji C4 2John Lloyd TulopAinda não há avaliações

- Exp.6. V T ProfilesDocumento7 páginasExp.6. V T Profilesmohmmad othmanAinda não há avaliações

- Example (1) :: SolutionDocumento12 páginasExample (1) :: Solutionياسر فاضلAinda não há avaliações

- SEO Irrigation Efficiency CalculationsDocumento6 páginasSEO Irrigation Efficiency CalculationsBeza Getachew100% (3)

- Chap 8. CondenserDocumento9 páginasChap 8. CondenserAli Ahsan100% (1)

- HT Lecture 13 ConvectionSolvedProblemsDocumento17 páginasHT Lecture 13 ConvectionSolvedProblemsclaudette colladoAinda não há avaliações

- 4 - 4 DISEÑO DE ZAPATAS ClaseDocumento7 páginas4 - 4 DISEÑO DE ZAPATAS ClaseMarcelo NavaAinda não há avaliações

- 4 - 4 Diseño de Zapatas ClaseDocumento5 páginas4 - 4 Diseño de Zapatas ClaseNicolas NuñezAinda não há avaliações

- HT Lecture 13 ConvectionSolvedProblemsDocumento17 páginasHT Lecture 13 ConvectionSolvedProblemsJulio Cesar Castañeda MancipeAinda não há avaliações

- Energy Loss Due To Friction in A PipelineDocumento7 páginasEnergy Loss Due To Friction in A PipelineAbdullah al-amerAinda não há avaliações

- Problem Set For HydroDocumento9 páginasProblem Set For HydroogulAinda não há avaliações

- Chap 3 ProblemsDocumento10 páginasChap 3 ProblemsShara Jane DelmoAinda não há avaliações

- Alcorcon Engineering Review Center: Power & Industrial Plant EngineeringDocumento15 páginasAlcorcon Engineering Review Center: Power & Industrial Plant EngineeringNeil SequioAinda não há avaliações

- ReviewerDocumento84 páginasReviewerEdmil Jhon Ariquez100% (6)

- 11.0 Appendix: CalculationDocumento10 páginas11.0 Appendix: CalculationLim Xiu XianAinda não há avaliações

- ISA-2 - QP - HMT - 16 June 2021 - Solutions and SchemeDocumento4 páginasISA-2 - QP - HMT - 16 June 2021 - Solutions and SchemeWild BotAinda não há avaliações

- WellheadModalOil GGDocumento4 páginasWellheadModalOil GGKhanz KhanAinda não há avaliações

- Assignment - 1 - finaFPP L - Fluid - & - Particle - FinalDocumento24 páginasAssignment - 1 - finaFPP L - Fluid - & - Particle - FinalKharkhodaAinda não há avaliações

- New Raw Water Rising MainDocumento5 páginasNew Raw Water Rising MainLusubilo MalakalingaAinda não há avaliações

- Thermodynamics MC Graw HillDocumento26 páginasThermodynamics MC Graw HillLemuel PurisimaAinda não há avaliações

- CH 03Documento136 páginasCH 03Larissa Albunio SilvaAinda não há avaliações

- Fluid Mechanics D203 Sae Solutions Tutorial 2 - Applications of Bernoulli Self Assessment Exercise 3Documento5 páginasFluid Mechanics D203 Sae Solutions Tutorial 2 - Applications of Bernoulli Self Assessment Exercise 3nanduslns07Ainda não há avaliações

- Design: of Shell & Tube Heat ExchangerDocumento27 páginasDesign: of Shell & Tube Heat ExchangerBalamurugan SakthivelAinda não há avaliações

- CLTModule StudyQuestionsAnswerKEYDocumento7 páginasCLTModule StudyQuestionsAnswerKEYotlacasAinda não há avaliações

- Hasil Perhitungan Percobaan Nozel HorizontalDocumento18 páginasHasil Perhitungan Percobaan Nozel HorizontalLuiiz AziizAinda não há avaliações

- GENERAL SCIENCES (Key)Documento4 páginasGENERAL SCIENCES (Key)HectorCabzAinda não há avaliações

- Calculation of A 2-4 Oil CoolerDocumento45 páginasCalculation of A 2-4 Oil CoolerAndre HenriqueAinda não há avaliações

- Fundamental of Reservoir Engineering, Homework #3 Due: December 4, 2020Documento3 páginasFundamental of Reservoir Engineering, Homework #3 Due: December 4, 2020Baba DookAinda não há avaliações

- DQ-R-SET B With SolutionsDocumento6 páginasDQ-R-SET B With SolutionsBurner AccountAinda não há avaliações

- ReviewerDocumento8 páginasReviewermaylynXiXAinda não há avaliações

- GATE 2007 CHEMICAL ENGINEERING EXAM REVIEWDocumento23 páginasGATE 2007 CHEMICAL ENGINEERING EXAM REVIEWVammsy Manikanta SaiAinda não há avaliações

- 1.0 Sizing and Costing 1.1. Medium Pressure Decomposer: L V L VDocumento8 páginas1.0 Sizing and Costing 1.1. Medium Pressure Decomposer: L V L VShahmi AsnawiAinda não há avaliações

- Elevated Water Tank ComputationDocumento28 páginasElevated Water Tank ComputationAiron Kaye SameloAinda não há avaliações

- Filtration: Nur Istianah, ST, MT, M.Eng - KP2 - THP UBDocumento48 páginasFiltration: Nur Istianah, ST, MT, M.Eng - KP2 - THP UBNoer FaizinAinda não há avaliações

- Filtration: Nur Istianah, ST, MT, M.Eng - KP2 - THP UBDocumento48 páginasFiltration: Nur Istianah, ST, MT, M.Eng - KP2 - THP UBNoer FaizinAinda não há avaliações

- Design Stripper Column ProcessDocumento10 páginasDesign Stripper Column ProcessAhmed HassanAinda não há avaliações

- FM Epad QP Solution-2022Documento13 páginasFM Epad QP Solution-2022Om RanjalkarAinda não há avaliações

- Lampiran A Perhitungan: Hari KG 337918,601 Hari LT 160303,57 Hari KG 129060,40Documento7 páginasLampiran A Perhitungan: Hari KG 337918,601 Hari LT 160303,57 Hari KG 129060,40wahyuAinda não há avaliações

- Solved Problems in Heat TransferDocumento16 páginasSolved Problems in Heat TransferAngelica Joyce Benito100% (3)

- 5) Problems (Ch. 3)Documento26 páginas5) Problems (Ch. 3)Arham AmjadAinda não há avaliações

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportAinda não há avaliações

- OrganicDocumento11 páginasOrganicRahul MoottolikandyAinda não há avaliações

- What Is Surface Cleanliness?? How Do You Relate It With Surface Profile?? Where Do You Find Details About Surface Profile??Documento1 páginaWhat Is Surface Cleanliness?? How Do You Relate It With Surface Profile?? Where Do You Find Details About Surface Profile??Rahul MoottolikandyAinda não há avaliações

- Need of Surface TreatmentDocumento6 páginasNeed of Surface TreatmentRahul MoottolikandyAinda não há avaliações

- The Importance of Chemical Treatment for Welding Stainless Steel and AluminiumDocumento6 páginasThe Importance of Chemical Treatment for Welding Stainless Steel and AluminiumRahul MoottolikandyAinda não há avaliações

- Material Inspected This Visit Pipe Unloading Inspection at Sohar PortDocumento7 páginasMaterial Inspected This Visit Pipe Unloading Inspection at Sohar PortRahul MoottolikandyAinda não há avaliações

- 1Documento17 páginas1Rahul MoottolikandyAinda não há avaliações

- Paint GlossaryDocumento18 páginasPaint Glossaryramaraj_37Ainda não há avaliações

- Report #19aDocumento2 páginasReport #19aRahul MoottolikandyAinda não há avaliações

- Guide To Fillet WeldingDocumento7 páginasGuide To Fillet WeldingPeter KyawAinda não há avaliações

- Material Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocumento3 páginasMaterial Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyAinda não há avaliações

- Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocumento3 páginasItem Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyAinda não há avaliações

- Material Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocumento3 páginasMaterial Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyAinda não há avaliações

- Report #16ADocumento2 páginasReport #16ARahul MoottolikandyAinda não há avaliações

- Stainless 20Documento45 páginasStainless 20k_sivakumar16Ainda não há avaliações

- Inspection NotesDocumento1 páginaInspection NotesRahul MoottolikandyAinda não há avaliações

- Intresting To KnowDocumento1 páginaIntresting To KnowRahul MoottolikandyAinda não há avaliações

- Date Inspectors Mandays Rahul Sandip 7am To 7pm 7pm To 7am 4/7/2018 1.5 1.5 3 4/8/2018 1.5 7 Am To 10pm TotalDocumento1 páginaDate Inspectors Mandays Rahul Sandip 7am To 7pm 7pm To 7am 4/7/2018 1.5 1.5 3 4/8/2018 1.5 7 Am To 10pm TotalRahul MoottolikandyAinda não há avaliações

- Report #01Documento4 páginasReport #01Rahul MoottolikandyAinda não há avaliações

- Safety Relief ValveDocumento1 páginaSafety Relief ValveRahulAinda não há avaliações

- HYDocumento6 páginasHYRahul MoottolikandyAinda não há avaliações

- Gate Pass Request Form: Requested Date: Reference NoDocumento1 páginaGate Pass Request Form: Requested Date: Reference NoRahul MoottolikandyAinda não há avaliações

- Pipeline Pressure Testing Calculations Client: Date: Project: Pipeline Details: From KP 0.012 To KP 22.3 (Insert (A) To (D) )Documento3 páginasPipeline Pressure Testing Calculations Client: Date: Project: Pipeline Details: From KP 0.012 To KP 22.3 (Insert (A) To (D) )Rahul MoottolikandyAinda não há avaliações

- Air Density FactorsDocumento23 páginasAir Density FactorsRahul MoottolikandyAinda não há avaliações

- Safety Relief ValveDocumento1 páginaSafety Relief ValveRahulAinda não há avaliações

- Hydro Test Key PointsDocumento16 páginasHydro Test Key PointsRahulAinda não há avaliações

- 026 To 033test ReportsDocumento40 páginas026 To 033test ReportsRahul MoottolikandyAinda não há avaliações

- Material Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocumento3 páginasMaterial Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyAinda não há avaliações

- Material Inspected This Visit Pipe Unloading Inspection at Sohar PortDocumento7 páginasMaterial Inspected This Visit Pipe Unloading Inspection at Sohar PortRahul MoottolikandyAinda não há avaliações

- 026 To 033test ReportsDocumento40 páginas026 To 033test ReportsRahul MoottolikandyAinda não há avaliações

- Material Inspected This Visit: Marking On The Pipes Were Randomly Checked and Found To Be SatisfactoryDocumento5 páginasMaterial Inspected This Visit: Marking On The Pipes Were Randomly Checked and Found To Be SatisfactoryRahul MoottolikandyAinda não há avaliações

- Euler's Buckling Analysis of Aluminum TubeDocumento14 páginasEuler's Buckling Analysis of Aluminum TubeSyedAmmarSamiAinda não há avaliações

- SL Series Compact Loose Central Tube Fiberoptic CableDocumento5 páginasSL Series Compact Loose Central Tube Fiberoptic CableJhon SanabriaAinda não há avaliações

- Rheology of Melts and Solutions Part 1: Viscosity and Its MeasurementDocumento6 páginasRheology of Melts and Solutions Part 1: Viscosity and Its Measurementzeqs9Ainda não há avaliações

- Module 2 - Stoichiometry & Percent YieldDocumento5 páginasModule 2 - Stoichiometry & Percent YieldDirk Lucas0% (1)

- Effects of PVC Pipes on the EnvironmentDocumento9 páginasEffects of PVC Pipes on the EnvironmentNeeraj KumarAinda não há avaliações

- Chapter: 3 Materials: 22 February 2008 J.C. WalravenDocumento30 páginasChapter: 3 Materials: 22 February 2008 J.C. WalravenglmuralidharAinda não há avaliações

- Methane to Chloromethanes Process DescriptionDocumento15 páginasMethane to Chloromethanes Process DescriptionAlsello Diveni ManuputtyAinda não há avaliações

- Seeing NPR Material From The Mechanic Point of ViewDocumento14 páginasSeeing NPR Material From The Mechanic Point of View施元Ainda não há avaliações

- TeccDocumento8 páginasTeccChristian Galvez BarrantesAinda não há avaliações

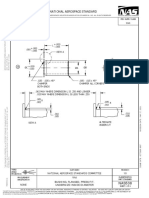

- National Aerospace Standard: Fed. Supply ClassDocumento4 páginasNational Aerospace Standard: Fed. Supply ClassGlenn CHOU100% (1)

- Heterogeneous Reaction Kinetics: Determining the Rate-Controlling StepDocumento35 páginasHeterogeneous Reaction Kinetics: Determining the Rate-Controlling StepDaniel OmolewaAinda não há avaliações

- Practical Plate - Pipe InspectionDocumento10 páginasPractical Plate - Pipe InspectionPratheep ShansAinda não há avaliações

- CRC Handbook KivonatDocumento12 páginasCRC Handbook KivonatPresslly Gebol LopezAinda não há avaliações

- Diffusion in Crystalline SolidsDocumento15 páginasDiffusion in Crystalline SolidsabhishekAinda não há avaliações

- Solid Dosage Forms: Tablets: Abhay ML Verma (Pharmaceutics)Documento5 páginasSolid Dosage Forms: Tablets: Abhay ML Verma (Pharmaceutics)meet2abhayAinda não há avaliações

- L3-Ch15 - Thermal Energy (Lesson 1)Documento35 páginasL3-Ch15 - Thermal Energy (Lesson 1)Jamal RamadanAinda não há avaliações

- ColaTeric CBSDocumento1 páginaColaTeric CBSmndmattAinda não há avaliações

- 20 Things You Can Do With Graphene: ApplicationsDocumento4 páginas20 Things You Can Do With Graphene: ApplicationsEmilio Lecaros BustamanteAinda não há avaliações

- Ucalgary 2020 Du StevenDocumento65 páginasUcalgary 2020 Du StevenmnasiroleslamiAinda não há avaliações

- Capítulo J - Diseño de Conexiones AISCDocumento36 páginasCapítulo J - Diseño de Conexiones AISCArgentina EspinozaAinda não há avaliações

- The Separation and Examination of Stickies: Standard Practice ForDocumento5 páginasThe Separation and Examination of Stickies: Standard Practice Forjamaljamal20Ainda não há avaliações

- MINERALOGY Notes 2022Documento60 páginasMINERALOGY Notes 2022Kisaakye GraceAinda não há avaliações

- The Environmental Geology of Mineral Dep PDFDocumento46 páginasThe Environmental Geology of Mineral Dep PDFbenwarrenallianceoliAinda não há avaliações

- 2022 ASRJC H2 Current of Electricity AQ SolnsDocumento7 páginas2022 ASRJC H2 Current of Electricity AQ SolnsBooAinda não há avaliações

- Propriedades Quânticas de Nanomateriais Utilizando A Teoria Do Funcional Densidade (DFT)Documento13 páginasPropriedades Quânticas de Nanomateriais Utilizando A Teoria Do Funcional Densidade (DFT)Leandro Costa Sobrinho MutucAinda não há avaliações

- Chemical Bonds: Modular SystemDocumento66 páginasChemical Bonds: Modular SystemKerimberdiAinda não há avaliações

- MECH466 Lecture 4 PDFDocumento28 páginasMECH466 Lecture 4 PDFSaran ArunAinda não há avaliações

- SSC-Tech Residential Building Cost EstimatesDocumento20 páginasSSC-Tech Residential Building Cost EstimatesBenmark JabayAinda não há avaliações

- Shell Cyprina 963 PDFDocumento2 páginasShell Cyprina 963 PDFAnonymous oAbjbl4HAinda não há avaliações

- Sizing (Slashing)Documento46 páginasSizing (Slashing)Nikhil Nani100% (1)