Escolar Documentos

Profissional Documentos

Cultura Documentos

Datasheet Anchor Flange

Enviado por

Hafiz Ashadi100%(1)100% acharam este documento útil (1 voto)

314 visualizações1 páginadone

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentodone

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

100%(1)100% acharam este documento útil (1 voto)

314 visualizações1 páginaDatasheet Anchor Flange

Enviado por

Hafiz Ashadidone

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 1

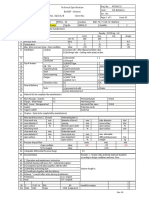

DATE : 16/07/2018 Datasheet Anchor Flange

REV : Doc. No. PGDD-KPE-1472-00-EMC-DS-012 PAGE :

Client : KSO PT. PERTAMINA GAS - PT.PGN

Location : DUMAI STATION Equipment Name : Anchor Flange

Engineer : Konsorsium PDC - ELNUSA

A GENERAL

A.1 FLUID SERVICE : HYDROCARBON GAS

A.2 DESIGN LIFE : 20 Years

A.3 DESIGN PRESSURE : 690 Psi

A.4 DESIGN TEMPERATURE : 150 °F

A.5 FLANGE TYPE : WELD NECK

A.6 DESIGN CODE : ASME B 16.5 or ASME Sec.VIII (Div.1 or 2)

A.7 PIPELINE MATERIAL : API 5L Gr X65

A.8 MATCHING PIPE WALL THICKNESS : 0.562 Inch

A.9 PIPE NOMINAL DIAMETER : 24 Inch

A.10 FLANGE CLASS : #300

B FLANGE MATERIAL D INSPECTION AND TESTING

B.1 MATERIAL CODE ASTM A 105 D.1 VISUAL INSPECTION API 5L

B.2 CHEMICAL COMPOSITION ASTM A 105. Table 1 D.2 ULTRASONIC INSPECTION MSS-SP 75

B.3 COATING as per Manufacture Standard D.3 MAGNETIC PARTICLE EXAMINATION MSS-SP 75

B.4 BORE TYPE Full Bore D.4 LIQUID PENETRANT INSPECTION MSS-SP 75

B.5 YIELD STRENGTH, Min (Psi) 36000 D.5 RADIOGRAPH EXAMINATION MSS-SP 75

B.6 TENSILE STRENGTH, Min (Psi) 70000 D.6 HYDROSTATIC TESTING API 5L

B.7 HARDNESS, HB (Max) 180 D.7 TENSILE TEST ASTM A 370

D.8 IMPACT TEST ASTM A 370

D.9 HARDNESS TEST ASTM A 370

C DIMENSION AND SCHEMATIC NOTES / MISCELLANEOUS REQUIREMENT

MATERIAL SUBSTITUTION ARE SUBJECT TO CONTRACTOR

1

C.1 DIMENSION WRITTER APPROVAL

2 ALL FLANGES SHALL BE NEW AND NOT BEING USED BEFORE

All Dimension is Refer to Manufacture Standard

FLANGE ASSSEMBLY SHALL BE HYDROSTATICALLY TESTED WITH

C.2 SCHEMATIC

3 1.25 TIMES OF THE SPECIFIED DESIGN PRESSURE AND DURATION

OF TEST SHALL BE AT LEAST THAN 10 SECOND

WELDS SHALL E EXAMINED EITHER ULTRASONICALLY OR

4

RADIOGRAPHY AT FULL LENGTH AFTER HYDROSTATIC TESTING

NOTES

Você também pode gostar

- Piping Stress Critical Lines - Basis For Piping Critical Line List PDFDocumento3 páginasPiping Stress Critical Lines - Basis For Piping Critical Line List PDFanup15balagarhAinda não há avaliações

- Cementing Operation - Part IDocumento26 páginasCementing Operation - Part IDoni KurniawanAinda não há avaliações

- VMS 1Documento121 páginasVMS 1Subash ChandraboseAinda não há avaliações

- 7 090 L03 00001 C 2, Piping Material Specification - 170531Documento85 páginas7 090 L03 00001 C 2, Piping Material Specification - 170531ddddAinda não há avaliações

- Stress Analysis Specification: CONT. NO.: 1032/GC-GN/CON-EP09-00 DOC. NO.: 3607/34-78-ED-PI-SPDocumento23 páginasStress Analysis Specification: CONT. NO.: 1032/GC-GN/CON-EP09-00 DOC. NO.: 3607/34-78-ED-PI-SPhamedpdms100% (1)

- QUERCETANUSDocumento64 páginasQUERCETANUSganyesod100% (2)

- Thermal Design Considerations For Centrifugal Compressor Piping SystemsDocumento5 páginasThermal Design Considerations For Centrifugal Compressor Piping SystemsSerge Rinaudo100% (1)

- Data Sheet For Ball ValveDocumento6 páginasData Sheet For Ball ValveTauqueerAhmadAinda não há avaliações

- Pipl Stress AnalysisDocumento62 páginasPipl Stress AnalysisShanthaAinda não há avaliações

- CHEMISTRY LAB VIVA QuestionsDocumento3 páginasCHEMISTRY LAB VIVA QuestionsUjjWal MahAjan55% (20)

- TN10 Critical Line List SampleDocumento2 páginasTN10 Critical Line List Sampleyulianus_srAinda não há avaliações

- SIF Calculation For Piping ConnectionsDocumento6 páginasSIF Calculation For Piping ConnectionsManuelAinda não há avaliações

- Water Quality WSO Student Workbook Water Supply OperationsDocumento69 páginasWater Quality WSO Student Workbook Water Supply OperationsdikeAinda não há avaliações

- Evaluation of Flanged Connections Due To Piping L.oaoDocumento9 páginasEvaluation of Flanged Connections Due To Piping L.oaoSJAinda não há avaliações

- Oil & Gas Pipeline Design, Maintenance & Repairs CourseDocumento27 páginasOil & Gas Pipeline Design, Maintenance & Repairs CourseernmrajaAinda não há avaliações

- 5.00 A Conundrum The Difficulties of Pipe Stress Analysis For Cold PipesDocumento17 páginas5.00 A Conundrum The Difficulties of Pipe Stress Analysis For Cold Pipesprabu2001Ainda não há avaliações

- Gas supply pig launcher datasheetDocumento9 páginasGas supply pig launcher datasheetOlusayoAinda não há avaliações

- Adam Lechter: Resident Course in Confectionery TechnologyDocumento73 páginasAdam Lechter: Resident Course in Confectionery TechnologyJulio KinenAinda não há avaliações

- PIP PCECV001 Guidelines For Application of Control ValvesDocumento39 páginasPIP PCECV001 Guidelines For Application of Control ValvesAndresAinda não há avaliações

- Steam Turbine ConstructionDocumento14 páginasSteam Turbine ConstructionKamal Arab100% (4)

- 20 01 BRGA PIP CAL VDR 0101 001 - Piping Flexibility Calculation and Analysis - R1 AFC (APPROVED)Documento122 páginas20 01 BRGA PIP CAL VDR 0101 001 - Piping Flexibility Calculation and Analysis - R1 AFC (APPROVED)Dheska AgungwAinda não há avaliações

- Gate Globe Check Butterfly and Needle Valve Specification - 0000-TS-L007 Rev 2Documento32 páginasGate Globe Check Butterfly and Needle Valve Specification - 0000-TS-L007 Rev 2Susan Sue Berrospi Merino100% (1)

- Flange Leakage - NC 3658.3Documento4 páginasFlange Leakage - NC 3658.3gharsallah mounaAinda não há avaliações

- Piping Layout, Supports and Flexibility Design SpecificationDocumento12 páginasPiping Layout, Supports and Flexibility Design SpecificationRiyan EsapermanaAinda não há avaliações

- Pipeline Virtual AnchorDocumento15 páginasPipeline Virtual AnchormaninventorAinda não há avaliações

- Petroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputDocumento5 páginasPetroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputAbhijeetAinda não há avaliações

- Data Sheet - Pipeline Barred Tee: Category Sl. Attribute ValueDocumento2 páginasData Sheet - Pipeline Barred Tee: Category Sl. Attribute ValueYusri Fakhrizal100% (1)

- Petroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputDocumento5 páginasPetroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputAbhijeetAinda não há avaliações

- API 570-Final Model Exam-Open Book Without AnswersDocumento6 páginasAPI 570-Final Model Exam-Open Book Without Answersbanana100% (1)

- Insulation Joint PDFDocumento7 páginasInsulation Joint PDFBabatunde OlalekanAinda não há avaliações

- Wall Theo PDFDocumento23 páginasWall Theo PDFFranklin UkaohaAinda não há avaliações

- Ac 036630 001Documento1 páginaAc 036630 001navaronefraAinda não há avaliações

- QuillsDocumento4 páginasQuillsajostosAinda não há avaliações

- Apache Alpine Piping Analysis ReportDocumento80 páginasApache Alpine Piping Analysis ReportEdward JulianAinda não há avaliações

- Design and Analysis of Piping System With Supports Using CAESAR-IIDocumento5 páginasDesign and Analysis of Piping System With Supports Using CAESAR-IIincaurcoAinda não há avaliações

- Virtual Anchors For Dummies - M Blackman Jan 09: Modelling in CAESAR IIDocumento4 páginasVirtual Anchors For Dummies - M Blackman Jan 09: Modelling in CAESAR IImartin_blackmanAinda não há avaliações

- SPE 76-002 (2006) Flange MaterialsDocumento6 páginasSPE 76-002 (2006) Flange Materials김창배Ainda não há avaliações

- PLD-108 Anchor FlangeDocumento7 páginasPLD-108 Anchor FlangeBiginch100% (1)

- SPC-0804.02-50.08 Rev D2 Pipe Stress AnalysisDocumento11 páginasSPC-0804.02-50.08 Rev D2 Pipe Stress Analysisrajabi_m100% (1)

- Data Sheet For Gate, Globe and Check ValvesDocumento7 páginasData Sheet For Gate, Globe and Check Valvesvenka07Ainda não há avaliações

- Barred Tee DatasheetDocumento3 páginasBarred Tee DatasheetBiginch67% (3)

- Wall thickness calculation for 36-inch gas pipelineDocumento1 páginaWall thickness calculation for 36-inch gas pipelinetitir bagchiAinda não há avaliações

- PDIL-Stress Analysis Design Basis PDFDocumento13 páginasPDIL-Stress Analysis Design Basis PDFDarshan Panchal100% (1)

- Hydrostatic Test Pressure Calculation: Pipe DataDocumento2 páginasHydrostatic Test Pressure Calculation: Pipe DataAkram AlhaddadAinda não há avaliações

- Dimensions Reducing - Mss Sp97: Weldolet®Documento2 páginasDimensions Reducing - Mss Sp97: Weldolet®Emer Roy Castillo OlivosAinda não há avaliações

- SLR Strainer Data Sheet PDFDocumento7 páginasSLR Strainer Data Sheet PDFKailas NimbalkarAinda não há avaliações

- Anchor FlangeDocumento2 páginasAnchor Flangeannu300100% (1)

- 9273E-300-CN-3531-613 - Attachment 3: About Upheaval and Lateral Buckling of Embedded PipelinesDocumento12 páginas9273E-300-CN-3531-613 - Attachment 3: About Upheaval and Lateral Buckling of Embedded PipelinesAnjani Prabhakar100% (1)

- Final-Mr For Scaper Traps, Pig Sinallers, Quick Opeing End Closures - 20100209 - 113815Documento80 páginasFinal-Mr For Scaper Traps, Pig Sinallers, Quick Opeing End Closures - 20100209 - 113815KalaiYarasanAinda não há avaliações

- Valve Company's Floating & Trunnion Ball ValvesDocumento15 páginasValve Company's Floating & Trunnion Ball ValvesAlienshowAinda não há avaliações

- A545-736-11-42-DS-0034 - A - Flow TeeDocumento2 páginasA545-736-11-42-DS-0034 - A - Flow TeeMurli ramchandranAinda não há avaliações

- Vol 2 Technical 20180703 181711 PDFDocumento116 páginasVol 2 Technical 20180703 181711 PDFMEHDIAinda não há avaliações

- Standard Specification FOR High Frequency Welded (HFW) Line Pipe (Onshore)Documento31 páginasStandard Specification FOR High Frequency Welded (HFW) Line Pipe (Onshore)Agniva DuttaAinda não há avaliações

- Data Sheet For Barred Tee 010719 PDFDocumento1 páginaData Sheet For Barred Tee 010719 PDFkandraAinda não há avaliações

- Cross Country Piping Stress AnalysisDocumento8 páginasCross Country Piping Stress Analysisprabu2001Ainda não há avaliações

- Bolt Tightening Procedure GuideDocumento6 páginasBolt Tightening Procedure Guideal arabiAinda não há avaliações

- Velan Forged Steel Gate Globe Checks PDFDocumento25 páginasVelan Forged Steel Gate Globe Checks PDFsunil kumarAinda não há avaliações

- EPM-GL-PI-CLC-0004 - Rev 0 - Slug Flow Force CalculationDocumento4 páginasEPM-GL-PI-CLC-0004 - Rev 0 - Slug Flow Force CalculationHernán DazaAinda não há avaliações

- Hot TapDocumento1 páginaHot TapDavid Rios CruzAinda não há avaliações

- Flow TeeDocumento1 páginaFlow TeeMahesh BhansaliAinda não há avaliações

- Pipeline Stress Analysis with Caesar IIDocumento16 páginasPipeline Stress Analysis with Caesar IISharbel WgAinda não há avaliações

- Pig Launcher Data Sheet 91303 - 8 InchDocumento4 páginasPig Launcher Data Sheet 91303 - 8 InchSinaAinda não há avaliações

- Flange Leakage 6Documento2 páginasFlange Leakage 6hamid sobirinAinda não há avaliações

- YS2-03-C10017-TL-BOD-L-001 Rev A0 - Piping Design BasisDocumento26 páginasYS2-03-C10017-TL-BOD-L-001 Rev A0 - Piping Design BasisameerAinda não há avaliações

- DataSheet 2 More 300# BV - FB - BW - NT-77 PDFDocumento1 páginaDataSheet 2 More 300# BV - FB - BW - NT-77 PDFSachin KumarAinda não há avaliações

- Saudi Pipe System Co. Mold Final Inspection ReportDocumento8 páginasSaudi Pipe System Co. Mold Final Inspection ReportNADEEM AHMEDAinda não há avaliações

- New Australian Curriculum Senior Secondary ChemistryDocumento44 páginasNew Australian Curriculum Senior Secondary Chemistryapi-252350138Ainda não há avaliações

- Analytical Techniques for Evaluating Quality of Herbal DrugsDocumento7 páginasAnalytical Techniques for Evaluating Quality of Herbal DrugsZaidAinda não há avaliações

- Binary and TernaryDocumento13 páginasBinary and TernaryRosemarie Degala LateAinda não há avaliações

- Yeom 2012Documento10 páginasYeom 2012Deysi Suarez GomezAinda não há avaliações

- Gnaser H., Huber B., Ziegler C. - Nanocrystalline TiO2 For Photocatalysis (2004) PDFDocumento32 páginasGnaser H., Huber B., Ziegler C. - Nanocrystalline TiO2 For Photocatalysis (2004) PDFoscuraAinda não há avaliações

- The Effect of Size Thickness and Type of The Bonding Interlayer On Bullet Proof Glass As Per EN 1063Documento4 páginasThe Effect of Size Thickness and Type of The Bonding Interlayer On Bullet Proof Glass As Per EN 1063Anonymous hk1fhAkwyAinda não há avaliações

- 02-04800 Painting SafetyDocumento29 páginas02-04800 Painting SafetykumarAinda não há avaliações

- Is 10204 PDFDocumento4 páginasIs 10204 PDFDimple EntertainmentAinda não há avaliações

- Index TO XV: ArsphenamineDocumento7 páginasIndex TO XV: ArsphenamineAlex12Ainda não há avaliações

- 2014 Ifa Phosphate Method PDFDocumento21 páginas2014 Ifa Phosphate Method PDFsanford siegelAinda não há avaliações

- Solution Manual Chemical Reaction Engineering, 3rd EditionDocumento137 páginasSolution Manual Chemical Reaction Engineering, 3rd Editionboni_briantoni75% (8)

- Kimo Kigaz 200 Combustion Gas Analyzer DatasheetDocumento4 páginasKimo Kigaz 200 Combustion Gas Analyzer DatasheetayannathompsoneqsAinda não há avaliações

- 309-King Agar-110991 PDFDocumento1 página309-King Agar-110991 PDFSneyder MurciaAinda não há avaliações

- Method Statement FOR Waste Polymer Slurry Disposal: PT Bauer Pratama IndonesiaDocumento4 páginasMethod Statement FOR Waste Polymer Slurry Disposal: PT Bauer Pratama IndonesiaFendi Rang TigorAinda não há avaliações

- HP-PN4291A-5 - Dielectric Constant Measurement of Rough-Surfaced MaterialsDocumento4 páginasHP-PN4291A-5 - Dielectric Constant Measurement of Rough-Surfaced Materialssirjole7584Ainda não há avaliações

- WHMIS Handbook PDFDocumento22 páginasWHMIS Handbook PDFNAinda não há avaliações

- BioreactorsDocumento32 páginasBioreactorskhadeeja vjfndnAinda não há avaliações

- Rigaku Nex QCDocumento12 páginasRigaku Nex QCLuis ReyesAinda não há avaliações

- Removal of Hardness 1Documento35 páginasRemoval of Hardness 1KISHAN PATELAinda não há avaliações

- Agoo Montessori Learning Center and High School Inc.: Fruit Waste As Biodegradable PlasticDocumento6 páginasAgoo Montessori Learning Center and High School Inc.: Fruit Waste As Biodegradable PlasticAlejandro De la GarzaAinda não há avaliações

- Fosroc Solvent 102 resin cleaning solventDocumento2 páginasFosroc Solvent 102 resin cleaning solventShaikhRizwanAinda não há avaliações

- Preslia 68 - MSDSDocumento12 páginasPreslia 68 - MSDSFraAinda não há avaliações

- Calculation Dilute Phase Pressure Drop Rhodes MethodDocumento3 páginasCalculation Dilute Phase Pressure Drop Rhodes MethodBTEAinda não há avaliações