Escolar Documentos

Profissional Documentos

Cultura Documentos

Coordination With Other Department

Enviado por

danishsaifi2007Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Coordination With Other Department

Enviado por

danishsaifi2007Direitos autorais:

Formatos disponíveis

Your Employment Solution Professionals!

Smart Brains Institute of Engineering Design &

Research

2nd Floor, 12-A, Ahinsha Khand – II, Indirapuram, Ghaziabad

Chapter 2

COORDINATION WITH OTHER DISCIPLINES

At the earliest practical time in a project the engineers will need to identify areas of

engineering and design where interfaces are necessary. An efficient system of

communication and exchange of information should be established and

implemented at regular intervals. Meetings should be arranged to discuss problem

areas and short-falls in information. The following generally summarizes what is

needed, particularly during the feasibility and conceptual stage of a project.

In order to be able to engineer an economical and efficient power system it is

desirable for the electrical engineer to have:

A basic understanding of the hydrocarbon and chemical processes and

their supporting utilities e.g. compression, pumping, control and operation,

cooling arrangements.

A procedure for regular communication with engineers of other disciplines,

e.g. instrument, process, mechanical, safety, telecommunications, facilities,

operations and maintenance.

An appreciation of the technical and economical benefits and shortcomings

of the various electrical engineering options that may be available for a

particular project.

The technical flexibility to enable the final design to be kept simple, easy to

operate and easy to maintain.

Process Engineers

The process engineers should be able to inform the electrical engineers on

matters relating to the production processes and supporting utilities e.g.:

Oil, gas, condensate and product compositions and rates, and their method

of delivery to and from a plant.

Variation of production rates with time over the anticipated lifetime of the

plant.

Fuel availability, rates and calorific values, pollution components e.g.

sulphur, carbon dioxide, alkali contaminants, particle size and filtration.

Electrical heating and refrigeration loads, trace heating of vessels and

piping.

Make available process flow diagrams (PFD), process and instrumentation

diagrams (PID), utilities and instrumentation diagrams (UID).

Information about hazardous gases and liquids available at plant.

Mechanical Engineers

The mechanical engineers will normally need to advise on power consumption

data for rotating machines, e.g. pumps, compressors, fans, conveyors, and

cranes. They will also advise the power output options available for the different

types and models of prime movers for generators, e.g. gas turbines, diesel

engines, gas engines.

In all cases the electrical engineer needs to know the shaft power at the coupling

of the electrical machine. He is then able to calculate or check that the electrical

ELECTRICAL ENGINEERING DESIGN 1/3

Your Employment Solution Professionals!

Smart Brains Institute of Engineering Design &

Research

2nd Floor, 12-A, Ahinsha Khand – II, Indirapuram, Ghaziabad

power consumption is appropriate for the rating of the motor, or the power output

is adequate for the generator. The mechanical engineer will also advise on the

necessary duplication of machinery, e.g. continuous duty, maximum short-time

duty, standby duty and out-of-service spare machines. He will also give some

advice on the proposed method of operation and control of rotating machines, and

this may influence the choice of cooling media, construction materials, types of

bearings, ducting systems, sources of fresh air, hazardous area suitability, etc.The

electrical engineer should keep in close ‘contact’ with the progress of machinery

selection during the early stages of a project up to the procurement stage in

particular, so that he is sure the electrical machines and their associated

equipment are correctly specified. Likewise after the purchase orders are placed

he should ensure that he receives all the latest manufacturers’ data relating to the

electrical aspects, e.g. data sheets, drawings, changes, hazardous area

information.

Mechanical engineers are subdivided in to following two categories:-

1. Static Equipment Packages

Air Fan Coolers

HVAC

Electric Heaters

Fired heaters

2. Rotary Equipment Packages

Compressor

Turbines

Pump

EOT cranes

Machinery load list

Instrument Engineers

The process and instrument engineers will generally develop the operation and

control philosophies for individual equipments and overall schemes. The electrical

engineer should then interface to enable the following to be understood:

Interlocking and controls that affect motor control centres and

switchboards, generator controls, control panels, local and remote stations,

mimic panels, SCADA, computer networking, displays in the CCR and other

locations.

Cabling specifications and requirements, e.g. screening, numbers of cores,

materials, earthing, routing, segregation and racking of cables.

Power supplies for control systems, AC and DC, UPS requirements, battery

systems.

Symbolic notation, e.g. tag numbers, equipment names and labels, cable

and core numbering systems.

Special earthing Requirements for instruments and DCS/PLC.

Interface of electrical and communication system with DCS/PLC.

ELECTRICAL ENGINEERING DESIGN 2/3

Your Employment Solution Professionals!

Smart Brains Institute of Engineering Design &

Research

2nd Floor, 12-A, Ahinsha Khand – II, Indirapuram, Ghaziabad

Make available process and instrumentation diagrams (PID) and utilities and

instrumentation diagrams (UID).

Communication and Safety Engineers

The communication and safety engineers will be able to advise on power supply

requirements for:

• Radar, radio, telecommunications and public address.

• Aids to navigation, e.g. lamps, beacons, foghorns, sirens; also alarms, lifeboat

davits, etc.

• Emergency routing and exit lighting systems.

• Supplies for emergency shut-down systems.

Civil and Structure Engineers

The Civil and Structure engineers will be able to advise on following requirements

for:

Rolling Shutter and miscellaneous power used for construction.

Structural / Insert plate details

Foundation drawings

UG Composite drawings

Substation Engineering

Cable trench

Piping Engineers

The Piping engineers will be able to advice on following requirements for:

Plot Plan

Cathodic Protection

Electrical Heat Tracing

UG Composite drawings

Fire fighting

Facilities and Operations Engineers

These engineers do not normally contribute any power consumption data, but

their input to the work of the electrical engineer is to advise on subjects such as

equipment layout, access to equipment, maintainability, maintenance lay-down

space, emergency exit routing, operational philosophies of plant and systems,

hazardous area classification.

ELECTRICAL ENGINEERING DESIGN 3/3

Você também pode gostar

- Mitsubishi Electric Sales Canada Mca and Mop/Mocp ExplanationDocumento4 páginasMitsubishi Electric Sales Canada Mca and Mop/Mocp ExplanationHVAC SimplifiedAinda não há avaliações

- Part G.9 Appendix I - ADEC ICT GuidelinesDocumento245 páginasPart G.9 Appendix I - ADEC ICT GuidelineskRiSHNagiLLoAinda não há avaliações

- Logic Check Function Check ProcedureDocumento15 páginasLogic Check Function Check ProcedureArjun Shantaram Zope100% (1)

- Design Basis ReportDocumento9 páginasDesign Basis ReportRadhika KhandelwalAinda não há avaliações

- Manual Fujitsu General LimitedDocumento32 páginasManual Fujitsu General LimitedSergio100% (3)

- Cec 400 2009 008 BR Rev1Documento15 páginasCec 400 2009 008 BR Rev1Philip ScofieldAinda não há avaliações

- Mechanical CommentsDocumento6 páginasMechanical Commentspsn_kylmAinda não há avaliações

- Elements of Competence and Performance CriteriaDocumento25 páginasElements of Competence and Performance CriteriaAnonymous VHWPQErC3Ainda não há avaliações

- Mep SyllabusDocumento20 páginasMep SyllabusMunavir KAinda não há avaliações

- Final Load SheetDocumento25 páginasFinal Load SheetSatheesh Kumar NatarajanAinda não há avaliações

- Feeder List For CHP & Ahp MCC Quantity: Incomer: Outgoing: Type of ConstructionDocumento4 páginasFeeder List For CHP & Ahp MCC Quantity: Incomer: Outgoing: Type of ConstructionChandu GowdaAinda não há avaliações

- 1a Domestic Water Meter Installation in Villas and Sheds DrawingPEWSTDAMI001Documento1 página1a Domestic Water Meter Installation in Villas and Sheds DrawingPEWSTDAMI001Designer ForeverAinda não há avaliações

- Metric Handbook Planning AND Design Data: Edited by David AdlerDocumento12 páginasMetric Handbook Planning AND Design Data: Edited by David AdlerBachir lejlifaAinda não há avaliações

- Trfo Voltage DropDocumento16 páginasTrfo Voltage Dropshivvaram100% (1)

- HSD-1 Commissioning Test Protocol VerDDocumento57 páginasHSD-1 Commissioning Test Protocol VerDsonuchakdeAinda não há avaliações

- FINALDocumento21 páginasFINALRajesh ShingreAinda não há avaliações

- Solar LED Street Light - Ver - 2.0Documento24 páginasSolar LED Street Light - Ver - 2.0Mukul JainAinda não há avaliações

- Circuit Breaker RatingsDocumento75 páginasCircuit Breaker Ratingsyibelta abebeAinda não há avaliações

- Demand FactorDiversity FactorUtilization FactorLoad FactorDocumento15 páginasDemand FactorDiversity FactorUtilization FactorLoad FactorscribistAinda não há avaliações

- Busbar RatingsDocumento1 páginaBusbar RatingsRa ArAinda não há avaliações

- Review of Dimming Techniques For Solid-State LED LightsDocumento7 páginasReview of Dimming Techniques For Solid-State LED LightsijaertAinda não há avaliações

- Tender Iitjmusp 0532018Documento78 páginasTender Iitjmusp 0532018Srini VaSAinda não há avaliações

- 02 Design Based Report - 20140130Documento133 páginas02 Design Based Report - 20140130vinaygvm0% (1)

- Shop Drawing Check List (ELV)Documento8 páginasShop Drawing Check List (ELV)Satya N.GAinda não há avaliações

- 500 Kva OFTC L-1 - 220920 - 124238Documento3 páginas500 Kva OFTC L-1 - 220920 - 124238rameshAinda não há avaliações

- DM Auto Irrigation Systems SpecificationsDocumento71 páginasDM Auto Irrigation Systems SpecificationsbargothiAinda não há avaliações

- Hazards ZoneDocumento4 páginasHazards Zonedarsh2001patelAinda não há avaliações

- Major ProjectDocumento30 páginasMajor ProjectRakesh YadavAinda não há avaliações

- Blackall Aerodrome Lighting QuotationDocumento53 páginasBlackall Aerodrome Lighting Quotationgraceenggint8799Ainda não há avaliações

- CV - MEP Architects GharibDocumento5 páginasCV - MEP Architects GharibSHEIKH100% (1)

- Spec VSDDocumento8 páginasSpec VSDNicodemus Ervino MandalaAinda não há avaliações

- Electrical Design Manual For HospitalsDocumento14 páginasElectrical Design Manual For HospitalsfisplAinda não há avaliações

- RVT ElectricalDocumento42 páginasRVT ElectricalAbdelmoneimAinda não há avaliações

- Load SheetDocumento12 páginasLoad SheetSatheesh Kumar NatarajanAinda não há avaliações

- Pervez Ahmad Khan: Job Objective Areas of ExpertiseDocumento6 páginasPervez Ahmad Khan: Job Objective Areas of ExpertisePERVEZ AHMAD KHANAinda não há avaliações

- To: MR.: Masaaki KusunokiDocumento33 páginasTo: MR.: Masaaki KusunokiWnava Cris100% (1)

- Electrical Software Tools OverviewDocumento20 páginasElectrical Software Tools OverviewPanom ParinyaAinda não há avaliações

- Cop101 V7 1Documento95 páginasCop101 V7 1Kei WongAinda não há avaliações

- Ra-11 RNSDocumento64 páginasRa-11 RNSArif AnsariAinda não há avaliações

- Emergency D.G. Sizing 16.11.07Documento3 páginasEmergency D.G. Sizing 16.11.07mahesh_sali2003Ainda não há avaliações

- Handbook On Earthing System For Power Supply InstallationsDocumento82 páginasHandbook On Earthing System For Power Supply InstallationsKemfeyAinda não há avaliações

- Sizing of Busbar Trunking Systems (Busways) - Electrical Installation GuideDocumento2 páginasSizing of Busbar Trunking Systems (Busways) - Electrical Installation GuideENGMAinda não há avaliações

- Fan Selection GuideDocumento4 páginasFan Selection GuideamitbslpawarAinda não há avaliações

- HVAC, PHE & FF Eqpt - Elect LoadDocumento13 páginasHVAC, PHE & FF Eqpt - Elect LoadSaurabh DwivediAinda não há avaliações

- Engineering 2Documento4 páginasEngineering 2Tori SmallAinda não há avaliações

- 000 EE 153 CAD For EEE PDFDocumento35 páginas000 EE 153 CAD For EEE PDFStampinusStephanoAinda não há avaliações

- Project Remaining Works and Punclist Status ChecklistDocumento28 páginasProject Remaining Works and Punclist Status ChecklistEngr Benalito A Catap IIIAinda não há avaliações

- HVAC Control Solution PDFDocumento16 páginasHVAC Control Solution PDFlinus77Ainda não há avaliações

- 2021.01.015 - Submission Report No. 06Documento17 páginas2021.01.015 - Submission Report No. 06Julius Ceasar SanorjoAinda não há avaliações

- Ashrae - 2009 I-P - F09 - AddDocumento2 páginasAshrae - 2009 I-P - F09 - AddSergio SemmAinda não há avaliações

- WORK SCHEDULE at Unit-3 Area: Paiton III Expansion Project Construction Contractor: Mitsui Co., LTD and TOA CorporationDocumento10 páginasWORK SCHEDULE at Unit-3 Area: Paiton III Expansion Project Construction Contractor: Mitsui Co., LTD and TOA CorporationJosua Ferry ManurungAinda não há avaliações

- Final ReportDocumento94 páginasFinal ReportAJITH KUMARAinda não há avaliações

- Load ScheduleDocumento18 páginasLoad SchedulevijayAinda não há avaliações

- Selection of Water Cooled Chiller - 221 TRDocumento2 páginasSelection of Water Cooled Chiller - 221 TRcalvin.bloodaxe4478Ainda não há avaliações

- 3000kva Transformer DimensionDocumento20 páginas3000kva Transformer DimensionPopoola O. AdedotunAinda não há avaliações

- Eee Electrical Reference Standards Electrical Codes and StandardsDocumento4 páginasEee Electrical Reference Standards Electrical Codes and StandardsXozanAinda não há avaliações

- DBRDocumento13 páginasDBRpsjjoshiAinda não há avaliações

- Knowledge is "Real Power": Introduction to Power QualityNo EverandKnowledge is "Real Power": Introduction to Power QualityAinda não há avaliações

- Electrical Engineering JDsDocumento3 páginasElectrical Engineering JDsMr. Amit Kumar SinghAinda não há avaliações

- PLC Interview QuestionsDocumento8 páginasPLC Interview QuestionsShiva Prakasam Perneti100% (1)

- Connecting The Dots of Electrical Hardware DesignDocumento21 páginasConnecting The Dots of Electrical Hardware DesignjackAinda não há avaliações

- (New) 20elec. 20eng. 20resume 20Omar-2020-01-16T04 39 52ZDocumento3 páginas(New) 20elec. 20eng. 20resume 20Omar-2020-01-16T04 39 52ZhrAinda não há avaliações

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsNo EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsAinda não há avaliações

- Signed Inventory of Electrical Wok at Admin. BuildingDocumento6 páginasSigned Inventory of Electrical Wok at Admin. Buildingdanishsaifi2007Ainda não há avaliações

- Noi-Dc1-2f-L3-Br 1-Csu-2Documento14 páginasNoi-Dc1-2f-L3-Br 1-Csu-2danishsaifi2007Ainda não há avaliações

- Noi-Dc1-2f-L3-Br 1-Csu-2Documento14 páginasNoi-Dc1-2f-L3-Br 1-Csu-2danishsaifi2007Ainda não há avaliações

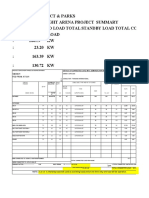

- Summary 3Documento1 páginaSummary 3danishsaifi2007Ainda não há avaliações

- Vol-Abc-El-607 Schematic Diagram For Power Panel Distribution - Phe and Elevator Tower-Abc-Abc-El-607Documento1 páginaVol-Abc-El-607 Schematic Diagram For Power Panel Distribution - Phe and Elevator Tower-Abc-Abc-El-607danishsaifi2007Ainda não há avaliações

- Read MeDocumento49 páginasRead MePriyawan SukisnoAinda não há avaliações

- Pending Work at Minto PressDocumento1 páginaPending Work at Minto Pressdanishsaifi2007Ainda não há avaliações

- ME2J 87007 (3) (AutoRecovered)Documento232 páginasME2J 87007 (3) (AutoRecovered)danishsaifi2007Ainda não há avaliações

- Resignation LatterDocumento1 páginaResignation Latterdanishsaifi2007Ainda não há avaliações

- Electrical Rising MainDocumento5 páginasElectrical Rising Maindanishsaifi2007Ainda não há avaliações

- Challan SPC - 110 - CableDocumento1 páginaChallan SPC - 110 - Cabledanishsaifi2007Ainda não há avaliações

- Read MeDocumento49 páginasRead MePriyawan SukisnoAinda não há avaliações

- Challan SPC - 110 - CableDocumento1 páginaChallan SPC - 110 - Cabledanishsaifi2007Ainda não há avaliações

- Arna Engineering Bill Final BillDocumento2 páginasArna Engineering Bill Final Billdanishsaifi2007Ainda não há avaliações

- Smart Brains Institute of Engineering Design & Research: Cabling SystemDocumento11 páginasSmart Brains Institute of Engineering Design & Research: Cabling SystemAshwin SevariaAinda não há avaliações

- Command On ExcelDocumento3 páginasCommand On Exceldanishsaifi2007Ainda não há avaliações

- TRIL SwitchDocumento2 páginasTRIL Switchdanishsaifi2007Ainda não há avaliações

- PipingDocumento3 páginasPipingdanishsaifi2007Ainda não há avaliações

- Earthing Control Room Ams Cal 29 SeptDocumento6 páginasEarthing Control Room Ams Cal 29 Septdanishsaifi2007Ainda não há avaliações

- PdlicelllDocumento1 páginaPdlicellljhonmatinxAinda não há avaliações

- Basics of Structural Engineering Analysis & Design of Structures Steel Frame ConnectionDocumento1 páginaBasics of Structural Engineering Analysis & Design of Structures Steel Frame Connectiondanishsaifi2007Ainda não há avaliações

- Etap Course ConteinDocumento1 páginaEtap Course Conteindanishsaifi2007Ainda não há avaliações

- Equipment ListDocumento14 páginasEquipment Listdanishsaifi2007Ainda não há avaliações

- Resignation LatterDocumento1 páginaResignation Latterdanishsaifi2007Ainda não há avaliações

- New Text DocumentDocumento1 páginaNew Text Documentdanishsaifi2007Ainda não há avaliações

- Interrio DesignerDocumento2 páginasInterrio Designerdanishsaifi2007Ainda não há avaliações

- Calculate Cable Trunking SizeDocumento2 páginasCalculate Cable Trunking Sizedanishsaifi2007100% (1)

- Hazardous Area ClassficationDocumento22 páginasHazardous Area Classficationdanishsaifi2007Ainda não há avaliações

- AnsysDocumento7 páginasAnsysdvarsastryAinda não há avaliações

- Sizing Steam Pipes I (KG H...Documento3 páginasSizing Steam Pipes I (KG H...Naveen KumarAinda não há avaliações

- AA Bard 5.0 TonRDocumento12 páginasAA Bard 5.0 TonRCarlos GudiñoAinda não há avaliações

- Design Criteria - Senior High - Mechanical (ACMV)Documento9 páginasDesign Criteria - Senior High - Mechanical (ACMV)Jethro AbanadorAinda não há avaliações

- Heat Pumps: Compact Reliable EfficientDocumento4 páginasHeat Pumps: Compact Reliable EfficientarminsarajevoAinda não há avaliações

- Hvac Sys Verification Checklist v2 5 PDFDocumento4 páginasHvac Sys Verification Checklist v2 5 PDFtsraj10100% (1)

- Rita MachineryDocumento203 páginasRita MachineryGheorghe CristianAinda não há avaliações

- Hometown - Kaslo & AreaDocumento8 páginasHometown - Kaslo & AreaPennywise PublishingAinda não há avaliações

- Hvac SystemDocumento17 páginasHvac SystemAhamed Manazir Hazzaan100% (1)

- 62 0238Documento6 páginas62 0238Denzo RyugaAinda não há avaliações

- Applied Research TechnologiesDocumento18 páginasApplied Research TechnologiessandunAinda não há avaliações

- I.t.t.presentation Feb.11Documento79 páginasI.t.t.presentation Feb.11densands100% (1)

- Fusing MachineDocumento74 páginasFusing MachineAkshita Sabharwal100% (2)

- DHCS Technical SpecsDocumento12 páginasDHCS Technical Specsameeri143Ainda não há avaliações

- Donalson GDX BrochureDocumento4 páginasDonalson GDX Brochuretoon_naAinda não há avaliações

- EPS GW GL 700 Rev 1 Chapter 1 Section 1 1Documento6 páginasEPS GW GL 700 Rev 1 Chapter 1 Section 1 1hafizgAinda não há avaliações

- HVAC Package-3 - SITC of AHU - Section - 3Documento18 páginasHVAC Package-3 - SITC of AHU - Section - 3FarzanaShaik100% (1)

- FlaresDocumento44 páginasFlaresAgus Sugiharto91% (11)

- Pump SpecificationDocumento8 páginasPump SpecificationsumitanuragAinda não há avaliações

- Envirable: Induction Heater CatalogDocumento23 páginasEnvirable: Induction Heater CatalogAamirMalikAinda não há avaliações

- Akua Klavuz enDocumento13 páginasAkua Klavuz enwwillieAinda não há avaliações

- Uh Svx01a en - 09032008 (Trane Unit Heaters)Documento60 páginasUh Svx01a en - 09032008 (Trane Unit Heaters)kayeleAinda não há avaliações

- Ch5.0 Operation of BoilersDocumento80 páginasCh5.0 Operation of BoilersRey100% (1)

- A 330 Level 1Documento299 páginasA 330 Level 1Ал-Mutairi Абдула100% (3)

- Continuous Emission Monitoring System PDFDocumento47 páginasContinuous Emission Monitoring System PDFnicoandayAinda não há avaliações

- Ett-6 PD enDocumento2 páginasEtt-6 PD enyounesAinda não há avaliações

- Coerse Dust Fine Dust Gas Adsorbtion EPA Hepa Ulpa: Filters For HVAC Systems and CleanroomsDocumento54 páginasCoerse Dust Fine Dust Gas Adsorbtion EPA Hepa Ulpa: Filters For HVAC Systems and CleanroomsAmyt SrivastavAinda não há avaliações

- Winter Reheat Calculations VimpoDocumento7 páginasWinter Reheat Calculations Vimpopsn_kylm100% (2)